Spiral type dryer

A dryer and spiral technology, applied in the direction of progressive dryers, dryers, drying chambers/containers, etc., can solve the problems of short drying time and large waste of space for materials, and achieve long residence time and large waste of space , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

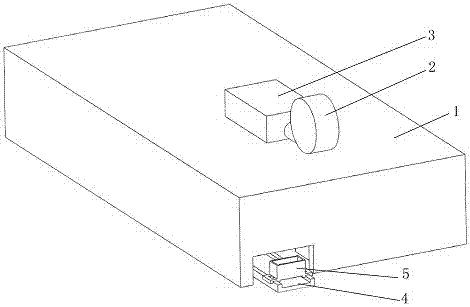

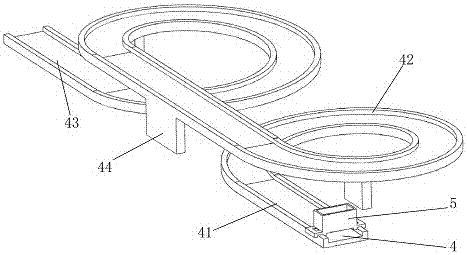

[0014] Such as Figure 1-2 As shown, the present invention mainly includes a drying chamber 1, a fan 2 for blowing air, an electric heating box 3 for generating heat, a trolley 5 for transporting materials, and a material track 4 for the movement of the trolley, and the fan 2 is connected to an electric heater. The box 3 is installed on the top of the drying chamber 1, and the trolley 5 is placed on the material rail 4. The material rail 4 is composed of an inlet rail 41, a spiral rail 42, an outlet rail 43, and a support 44. The inlet rail 41 is exposed from the entrance of the drying chamber 1. An exit rail 43 emerges from the exit of the drying chamber 1 .

[0015] When working, start the fan 2 and the electric heating box 3 to deliver dry hot air to the drying chamber 1, place the trolley on the inlet track 41 of the material track 4, load the material on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com