Medium-pressure and low-pressure industrial steam supply method and system through medium-pressure and low-pressure communication butterfly valve adjustment and hot press adoption

A hot press, industrial technology, applied in the direction of steam application, mechanical equipment, steam engine device, etc., can solve the problems of poor adaptability to unit load fluctuations, large throttling loss, and poor energy-saving benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

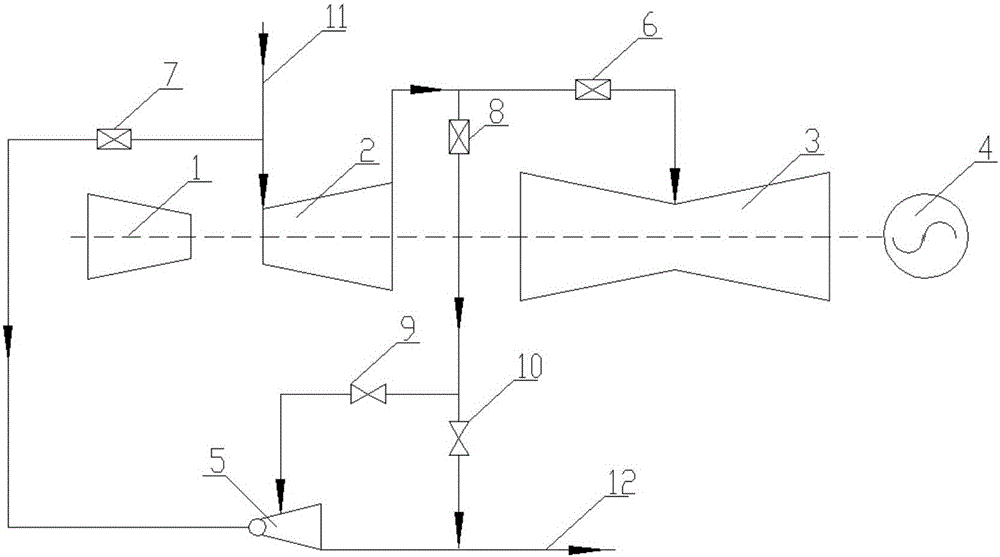

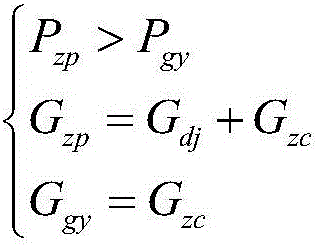

[0049]The invention provides a medium and low pressure industrial steam supply method for regulating the medium and low pressure connected butterfly valve combined with the hot press. The technical system mainly includes a steam turbine high pressure cylinder, a medium pressure cylinder, a low pressure cylinder, a generator, a heat press, and a butterfly valve connected to the medium and low pressure cylinders. , reheat steam intermediate pressure cylinder inlet pipe, industrial steam supply and outlet pipe, and valves and pipe fittings connected to related devices. The hot press can match the reheated steam and the exhaust steam of the medium-pressure cylinder into the target parameter steam between the two pressures. The demand for industrial steam supply pressure and temperature is basically stable. Generally, to ensure the safety of steam supply, the middle and low pressure connecting butterfly valve of the unit participates in pressure adjustment. If the load of the unit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com