Natural gas pressure difference generating system self-adaptive to back-end load change

A power generation system and load change technology, applied in engine components, machines/engines, and mechanisms that generate mechanical power, etc., can solve problems such as large fluctuations in natural gas flow, improve power generation efficiency, solve inconvenience in transportation and use, and increase system reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The natural gas differential pressure power generation system adaptive to back-end load changes provided by the present invention will be described in detail below with reference to the drawings and specific embodiments.

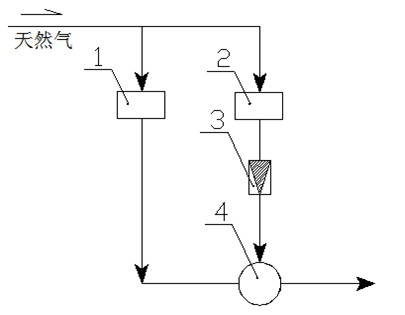

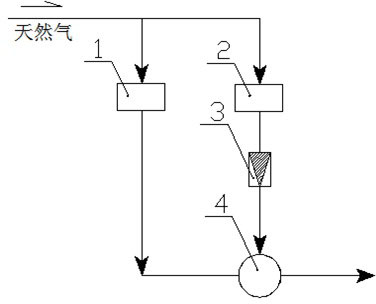

[0023] Such as figure 1 , figure 2 As shown, the natural gas differential pressure power generation system is composed of a natural gas load automatic bypass step-down voltage stabilization system 1, a natural gas differential pressure power generation system 2, a pressure stabilizing valve 3, and a pressure stabilizing tank 4.

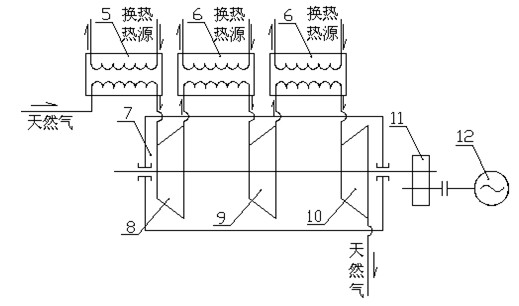

[0024] Such as figure 2 As shown, the natural gas differential pressure power generation system 2 mainly includes a front-end preheater 5 , an intermediate reheater 6 , a multistage centripetal turbo expander unit 7 , a speed reducer 11 and a generator set 12 . The inlet end of the preheater 5 is connected to natural gas, and the gas outlet end is connected to the inlet end of the single-stage or multi-stage centripetal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com