Thermal oxidation incineration treatment burner, device and process for HCN-containing waste gas

A treatment device and thermal oxidation technology, applied in the direction of combustion type, combustion method, incinerator, etc., can solve the problems of small burner operation flexibility and cannot meet the adjustment requirements, and achieve the effect of improving operation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

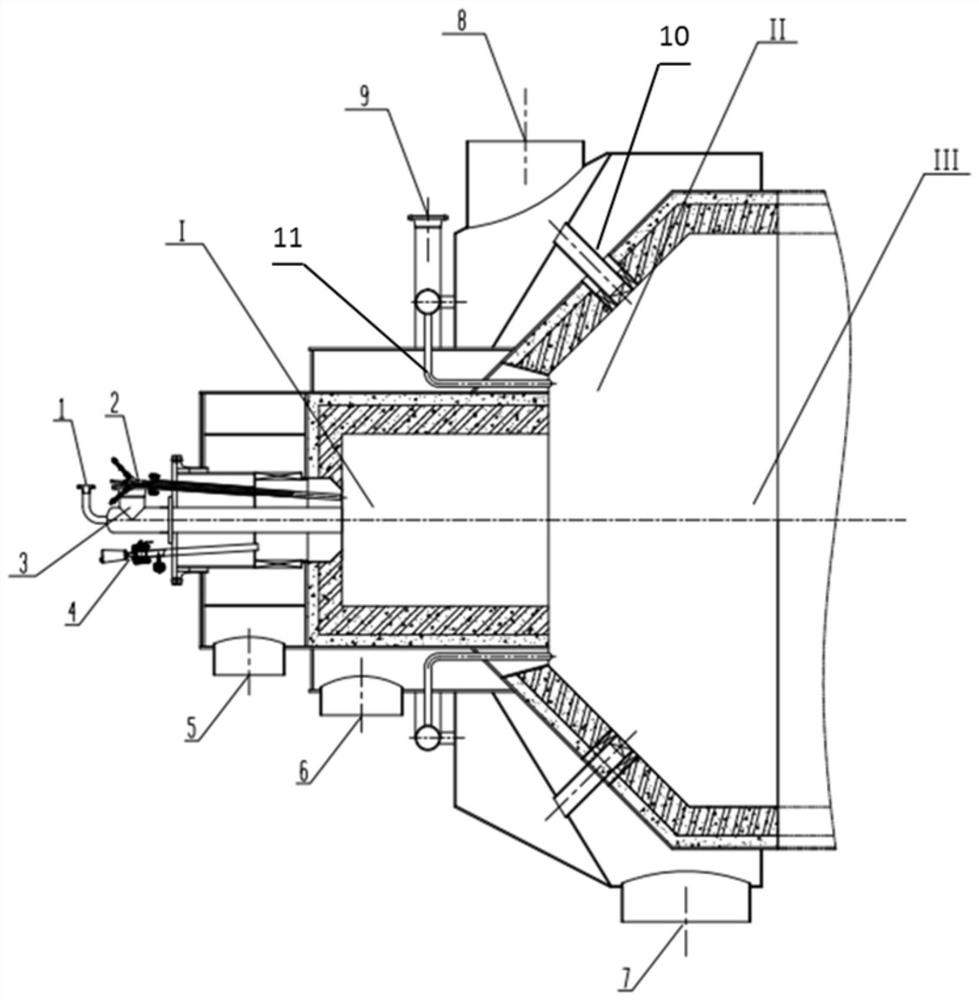

[0043] like Figure 1-2 As shown, the present invention provides a thermal oxidation incineration treatment burner containing HCN waste gas, the burner is a combined low-nitrogen burner, and is sequentially divided into I-level combustion zone and II-level combustion along the direction close to the exhaust gas incinerator 102. Zone, III-level combustion zone, the front end of the I-level combustion zone includes a primary air inlet 5, a central inner gun 1 and a plurality of central outer guns 2 with an inner and outer coaxial jacket structure, and the front end of the II-level combustion zone is annularly arranged with A secondary air inlet 6, an outer ring fuel gas inlet 9, a plurality of outer ring spray guns 11, the front end of the stage III combustion zone is annularly arranged with a tertiary air inlet 7, an exhaust gas inlet 8, and a plurality of exhaust gas spray guns 10. The outer ring spray guns 11. The exhaust gas spray gun 10 is of a jacketed annular gap structur...

Embodiment 2

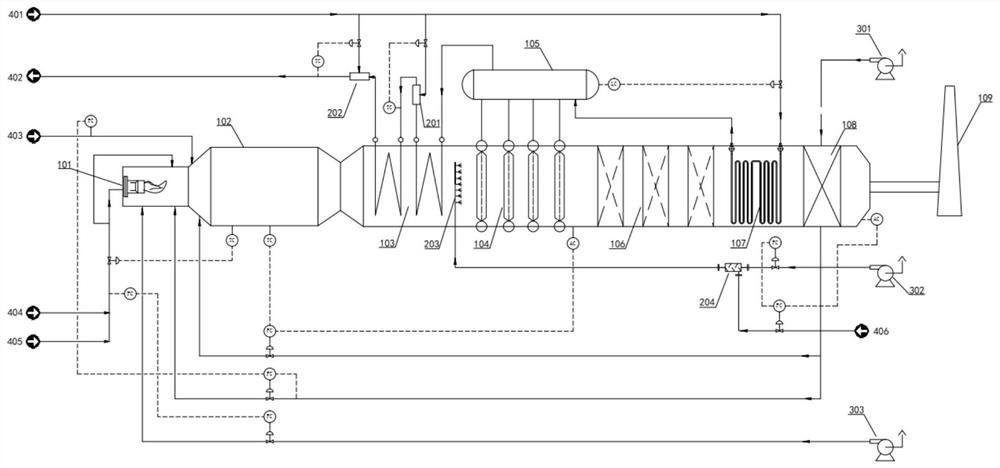

[0058] like figure 1 As shown, the present invention also provides a thermal oxidation incineration treatment device containing HCN waste gas, the incineration treatment device comprises an exhaust gas incinerator 102, a waste heat boiler, and a chimney 109 connected in sequence, the waste heat boiler includes a denitration module, the The exhaust gas incinerator 102 is a micro-positive pressure fully sealed structure, the design temperature of its furnace chamber is not lower than 1000 ° C, and an oxygen content analyzer is provided at its outlet. Burner for thermal oxidation incineration of waste gas.

[0059] Specifically, the waste gas incinerator 102 is equipped with the thermal oxidation incineration treatment burner containing HCN waste gas described in Example 1, which satisfies the requirements of the incineration treatment device for the upstream hydrocyanic acid preparation device with large displacement, high fluctuation, and complexity. Adjustment requirements un...

Embodiment 3

[0073] like figure 1 As shown, the present invention also proposes a thermal oxidation incineration treatment process containing HCN waste gas, using the thermal oxidation incineration treatment device containing HCN waste gas as described in this embodiment 2, and the process includes:

[0074] According to the load fluctuation of the upstream hydrocyanic acid preparation device, the air-fuel ratio adjustment loop of the burner's stage III combustion zone is adaptively adjusted for the tertiary air of any number of exhaust gas lances 10. At the same time, the air-fuel ratio adjustment loop of the II stage combustion zone is adjusted. Adaptive adjustment is performed for the secondary air and fuel gas of any number of outer ring lances 11 , and / or the air-fuel ratio adjustment loop of the I-stage combustion zone is adaptively adjusted for the primary air and fuel gas of any number of central outer lances 2 ;

[0075] Wherein, the self-adaptive adjustment method includes: 1) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com