Industrial furnace with liftable dust-collecting furnace cover

A technology for industrial furnaces and furnace covers, applied in the field of heat treatment, can solve the problems of inability to apply heat treatment production lines, unfavorable health of production personnel, and long circulation time of toxic gases, and achieves a technology that is beneficial to workers' health, good suction effect and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

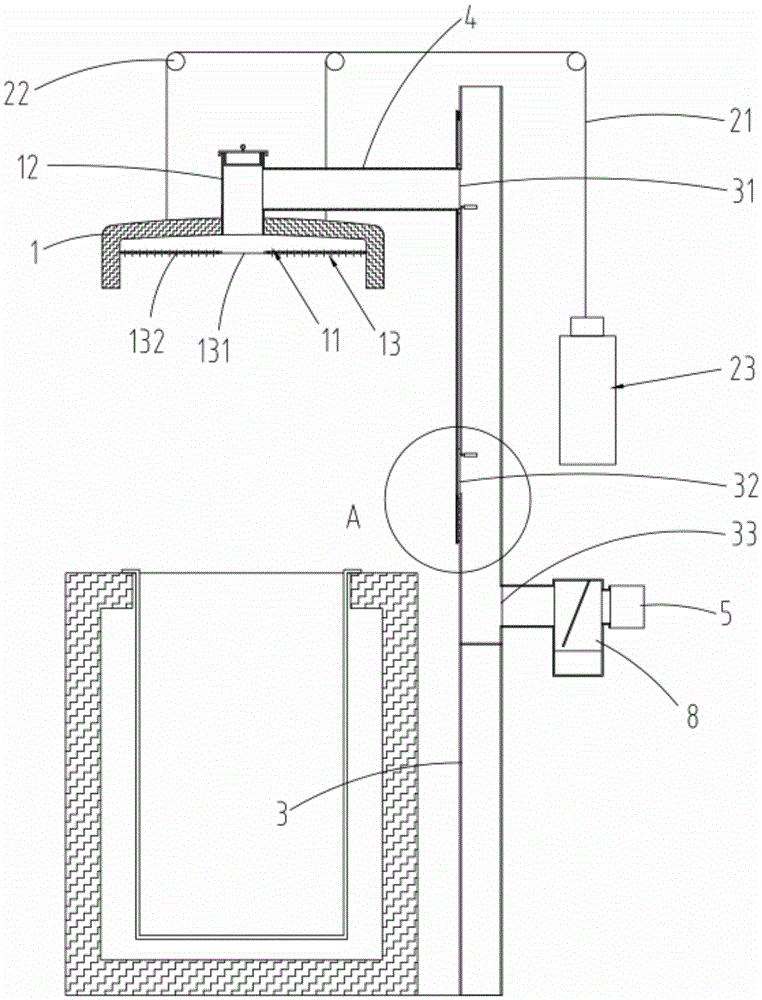

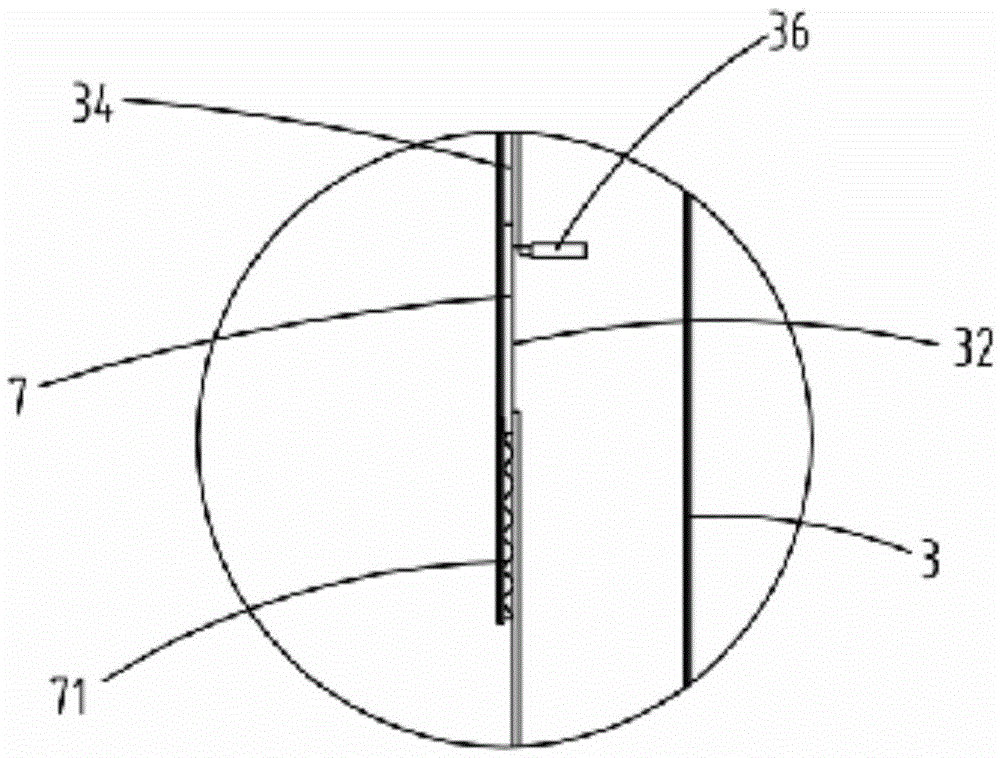

[0032] Such as figure 2 As shown, the present invention provides an industrial furnace with a liftable dust-absorbing furnace cover, including a furnace body 9, a furnace cover 1 arranged on the furnace mouth of the furnace body 9 that can be opened or closed, and a lifting device for lifting the furnace cover 1. Mechanism 2, the inner wall of the furnace cover 1 is formed with a semi-closed cavity 11, and the top of the furnace cover 1 is provided with a salt adding channel 12 communicating with the cavity 11. 9. The fixed flue gas pipe 3 next to it and the movable flue gas pipe 4 with one end connected to the salt adding channel 12 are provided with a first flue gas inlet 31 and a second flue gas inlet 32 communicating with the inside of the fixed flue gas pipe 3. and the flue gas outlet 33, the flue gas outlet 33 is connected with a smoking device 5; the end of the movable flue gas pipe 4 can move up and down along the outer wall of the fixed flue gas pipe 3, and the sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com