Heating equipment

A technology of heating equipment and heating chamber, which is applied in the direction of lighting and heating equipment, electric furnace heating, furnace control device, etc., which can solve the problems of environmental pollution, safety and hidden dangers, and achieve the effect of simple equipment structure, convenient operation and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

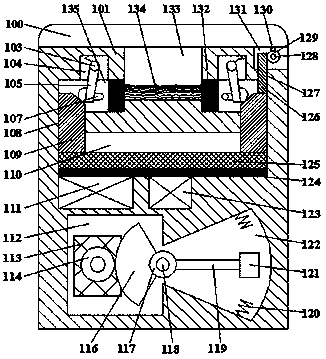

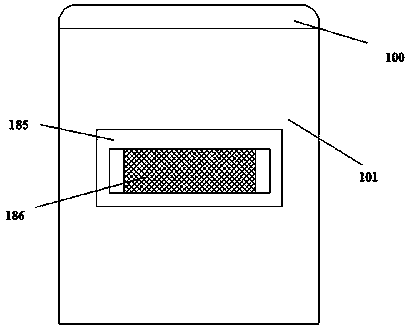

[0017] Such as Figure 1-Figure 3 As shown, a heating device of the present invention includes a box body 101 and a cover plate 100 arranged on the top of the box body 101, and the left and right sides of the box body 101 are provided with carrying slots 185 at the same time, and the carrying slots 185 is provided with a handle 186, and the top end surface of the box body 101 is provided with a concave groove 131 with a notch upward, and the right end of the concave groove 131 runs through the right end surface of the box body 101, and the concave groove 131 The rotation fit is connected with the first revolving pin shaft 128, the first revolving pin shaft 128 is provided with the first toothed wheel 129, the top of the first toothed wheel 129 is provided with a strut 130, and the top of the strut 130 is The end surface is fixedly connected with the bottom end surface of the cover plate 100, and a heating cavity 133 with a notch upward is provided in the box body 101, and a sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com