Closable type automatic material throwing copper furnace cover used for continuous casting of copper and aluminum composite materials

A copper-aluminum composite material and automatic feeding technology, which is applied in the field of metallurgical equipment, can solve the problems of poor sealing of the furnace cover, manual feeding, and poor safety, and achieve the effects of good airtightness, good heat preservation effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

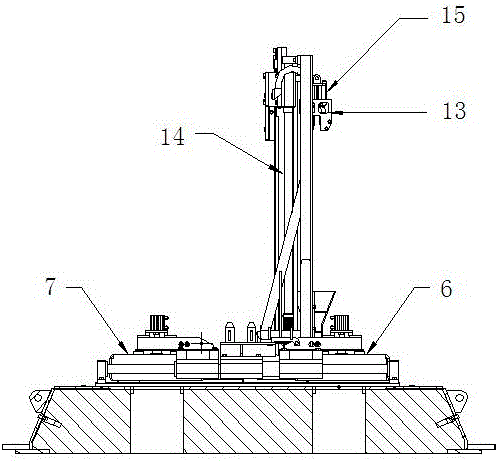

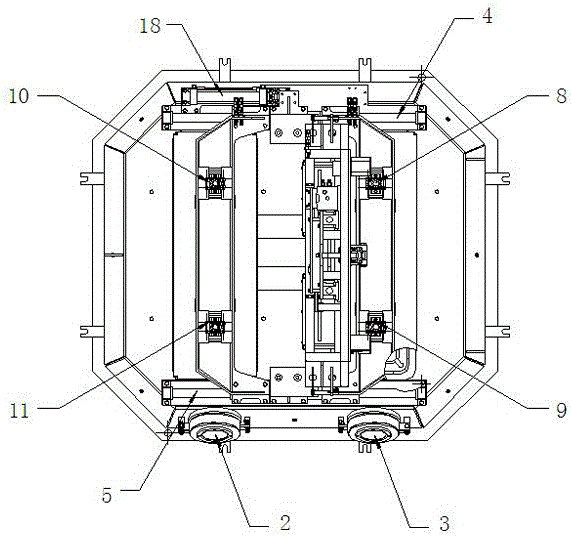

[0018] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: a sealable automatic feeding copper furnace cover for continuous casting of copper-aluminum composite materials, including a sealing device, a feeding device and an electrical control device.

[0019] The sealing device is composed of a sealing cover 1, an observation window A2 and an observation window B3 installed on the sealing cover 1, a guide rod A4 and a guide rod B5 installed on the sealing cover 1, and a connecting rod connected with the guide rod A4 and the guide rod B5. The melting furnace cover 6, the heat preservation furnace cover 7 connected with the guide rod A4 and the guide rod B5, the lifting cylinder A8 and the lifting cylinder B9 connected with the melting furnace cover 6, the lifting cylinder C10 and the lifting cylinder D11 connected with the heat preservation furnace cover 7 ;

[0020] The feeding device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com