Pit type furnace opening device

A technology for opening devices and well-type furnaces, which is applied to vertical furnaces, furnaces, furnace components, etc., which can solve the problems of complex processing procedures, inconvenient opening and closing of well-type furnaces, and large floor space of well-type furnaces, and achieve improved The effects of processing efficiency, improving the opening method, and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments are described in detail in conjunction with the accompanying drawings,

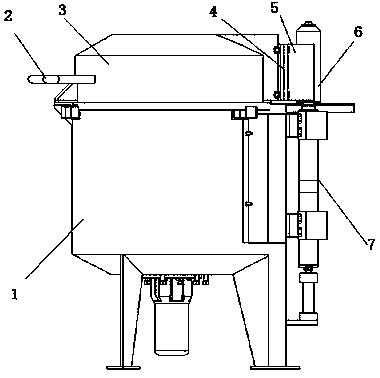

[0008] A well-type furnace opening device, which includes a furnace body 1, a hydraulic cylinder 7 is installed on one side of the furnace body, a hydraulic rod 6 is installed in the hydraulic cylinder, the end of the hydraulic rod is fixedly connected with the rotating seat 5, and the rotating seat is equipped with The rotating shaft 4 and the furnace cover 3 are fixedly connected with the bushing set on the rotating shaft, the furnace cover can rotate around the rotating shaft, and a handle 2 is arranged on the furnace cover; the furnace cover is made of alloy material.

[0009] When the present invention is in use, a hydraulic cylinder is used to control the furnace cover together with the rotating seat, and then the furnace cover is rotated by using the handle. This structure is more reasonable and the use is more efficient.

[0010] The above-mentioned embodiments are only examples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com