MOX batch sintering furnace synchronous lifting device

A technology of synchronous lifting and sintering furnace, applied in the direction of furnace control device, furnace, furnace components, etc., can solve the problems of unusable, complex furnace structure, dislocation collision between furnace bottom cover and furnace body, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

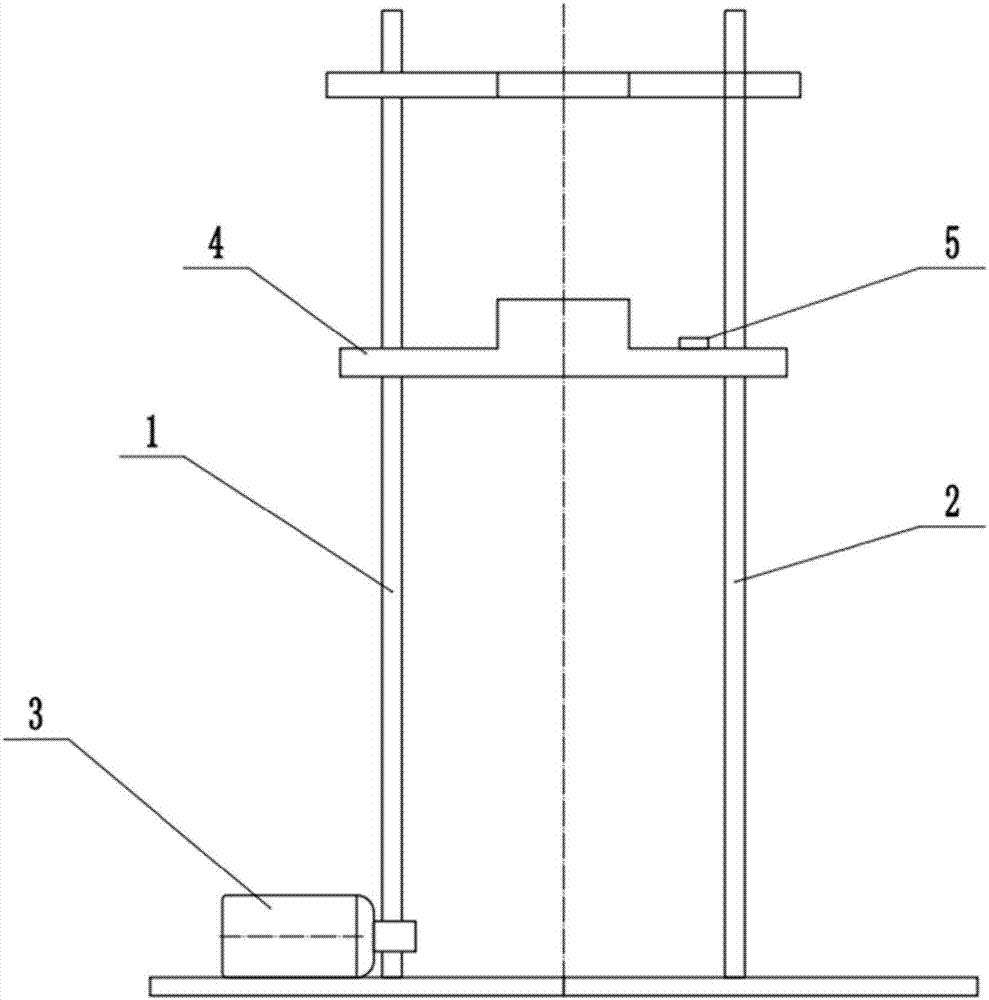

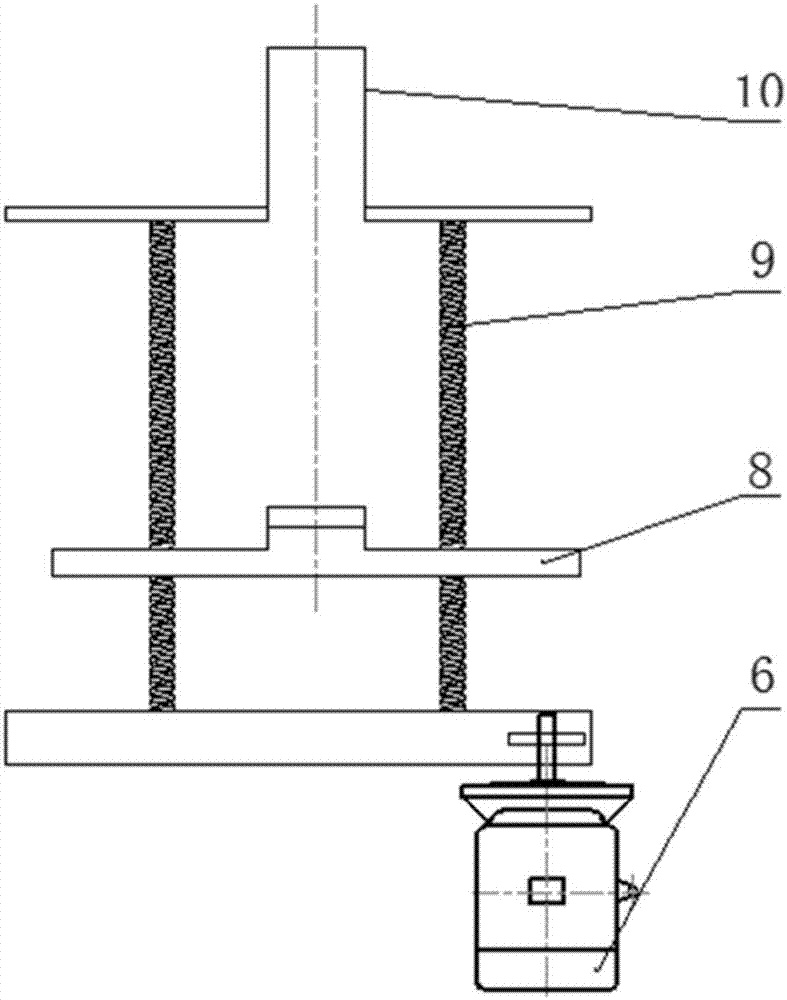

[0014] A synchronous lifting device for a MOX batch sintering furnace, including a synchronous lifting device, a synchronous circuit, and a furnace bottom lifting device. The furnace bottom lifting device includes a lifting motor 6, a furnace bottom cover 8, a lead screw 9, and a furnace body 10, wherein the lifting motor 6 The leading screw 9 is driven to rotate, and the leading screw 9 makes the furnace bottom cover 8 rise so as to approach the furnace body 10 . The synchronous lifting device includes a threaded screw 1, a guide rod 2, a synchronous motor 3, a simulated sintering furnace bottom 4, and a laser ranging sensor 5, wherein the synchronous motor 3 drives the threaded screw 1 to rotate, so that the threaded screw 1 and the guide rod The simulated sintering furnace bottom 4 on the 2 rises, and a laser ranging sensor 5 is installed on the simulated sintering furnace bottom 4.

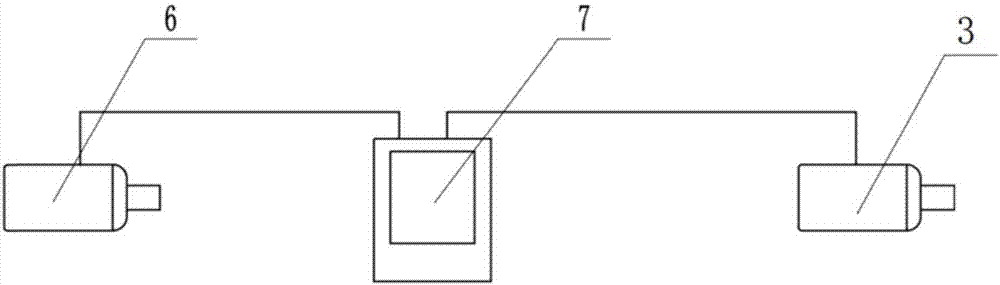

[0015] Such as figure 2 As shown, in the synchronous circuit, the lifting motor 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com