Furnace lid for rare earth alloy smelting furnace, smelting furnace and method

A rare earth alloy and smelting furnace technology, which is applied to the furnace cover of rare earth alloy smelting furnace and the field of smelting furnace, can solve the problems such as the inability to meet the melting point gap of alloy raw materials, and achieve the method of reducing the amount of slag, accelerating the dispersion and improving the yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

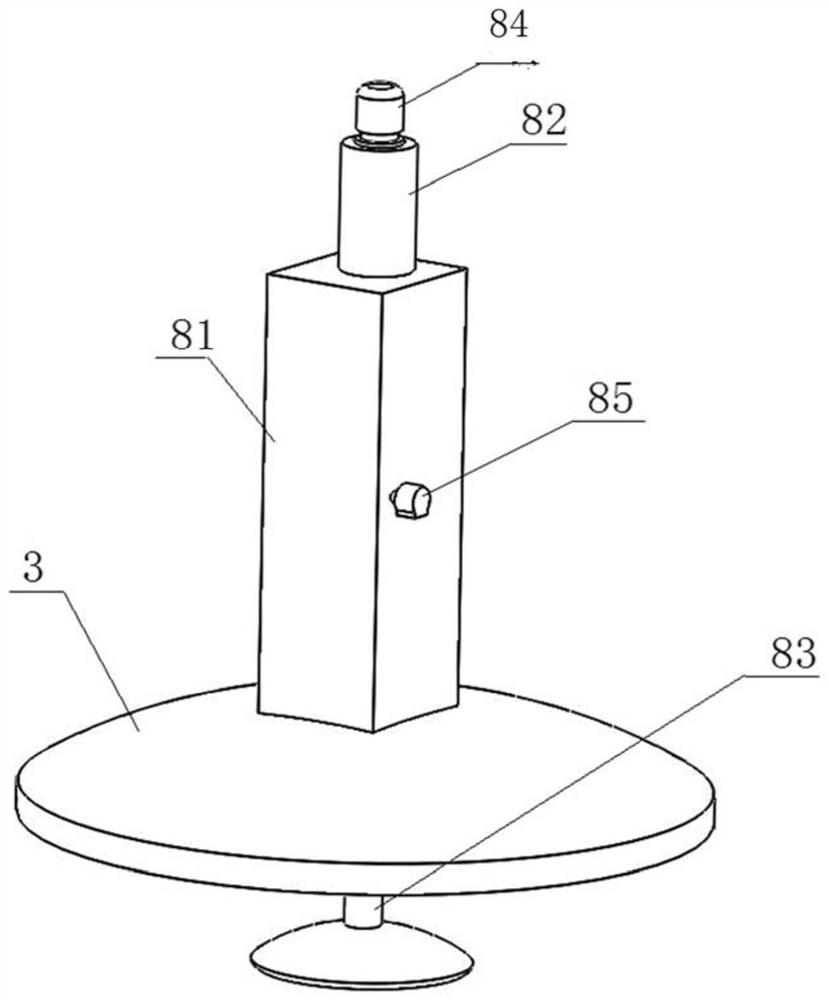

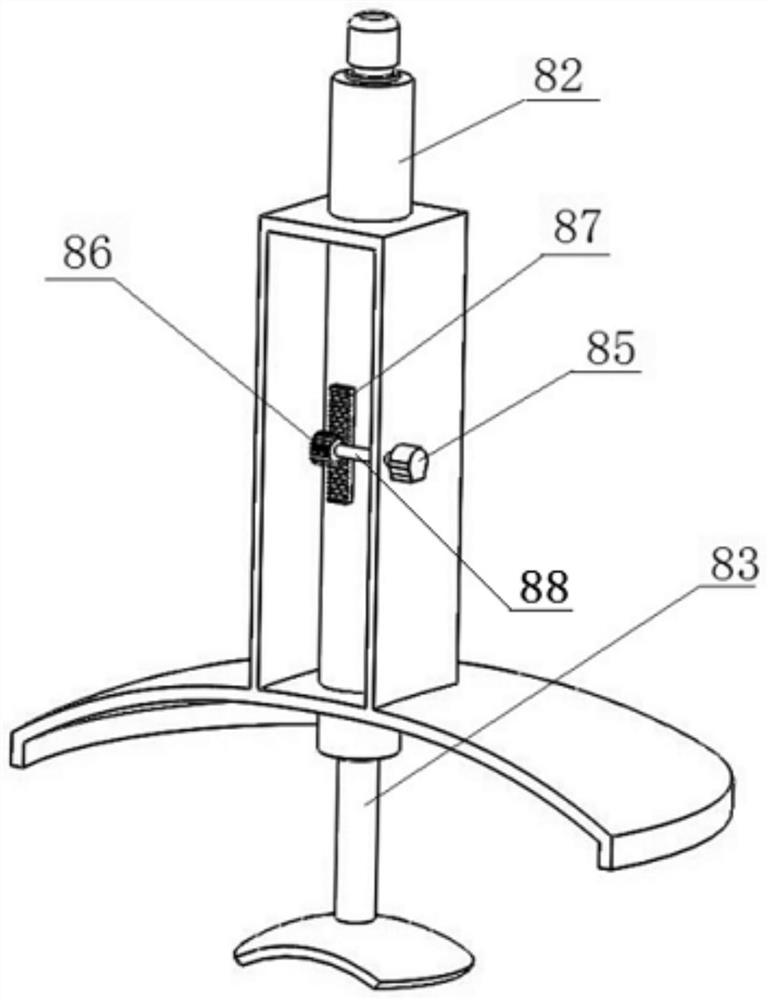

[0141] figure 1 It is a structural schematic diagram of a furnace cover for a rare earth alloy smelting furnace of the present invention, figure 2 for figure 1 A cross-sectional view of a furnace cover for a rare earth alloy smelting furnace is shown. The furnace cover for the rare earth alloy smelting furnace in this embodiment includes a cover body 3 and a raw material rotating and lifting device 8 . The rotary lifting device 8 includes a rotating rod 83, a rotating rod outer cylinder 82, a rotating motor 84, a fixed outer cylinder 81, a connecting rod 88, a lifting motor 85, a gear 86 and a rack 87, and also includes a metal raw material holding disc 7.

[0142] The surface of the cover body 3 has a circular structure and protrudes upwards at the center, and the protrusion smoothly transitions to the edge of the cover body 3 . The central position of the cover body 3 is provided with an opening, and the size of the opening is such that the rotating rod outer cylinder 82...

Embodiment 2

[0148] Except following structure, all the other are with embodiment 1:

[0149] The furnace cover of this embodiment also includes: an infrared temperature measuring device 14 , a pressure gauge 13 and a furnace cover locking device 11 .

[0150] The infrared detection device 14 is arranged on the cover body 3 to monitor the temperature of the smelting raw material.

[0151] The pressure gauge 13 is arranged on the cover body 3 to detect the pressure in the rare earth alloy smelting furnace.

[0152] There are multiple furnace cover locking devices 11, which are evenly distributed on the edge of the cover body 3, and lock the furnace cover 3 and the furnace body of the rare earth alloy smelting furnace.

Embodiment 3

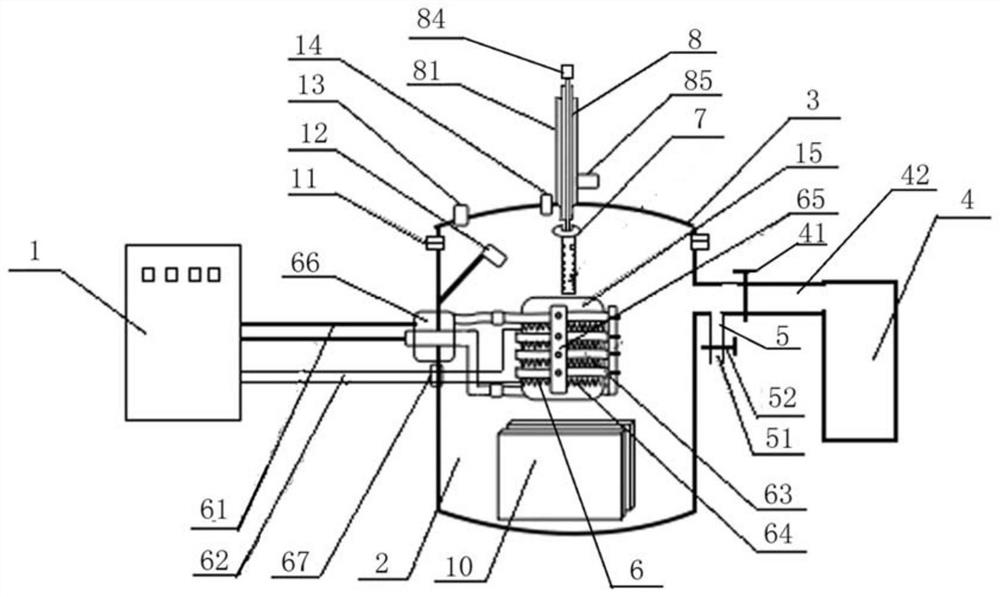

[0154] image 3 It is a structural schematic diagram of a rare earth alloy smelting furnace of the present invention. Figure 4 for image 3 A partial enlarged view of the rare earth alloy melting furnace shown. The rare earth alloy smelting furnace of this embodiment includes: a furnace cover 3, a furnace body 2, a raw material holding device 15, a heating device 6, a casting ingot mold 10, a pouring device 9, a vacuum-inflating device, a power control cabinet 1, a monitoring camera 12 and PLC controller. Furnace cover 3 is as shown in embodiment 2.

[0155] The power control cabinet 1 is arranged on one side of the furnace body 2 . The PLC controller is set in the power control cabinet 1 . The power control cabinet can control the power supply.

[0156] The output end of the infrared temperature measuring device 14 is connected with the input end of the PLC controller. The controlled end of the lifting motor 85 and the controlled end of the rotating motor 84 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com