Antimony concentrate vacuum smelting device

A vacuum smelting and concentrate technology, applied in the field of metal smelting, can solve the problems of low recovery rate of antimony metal and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

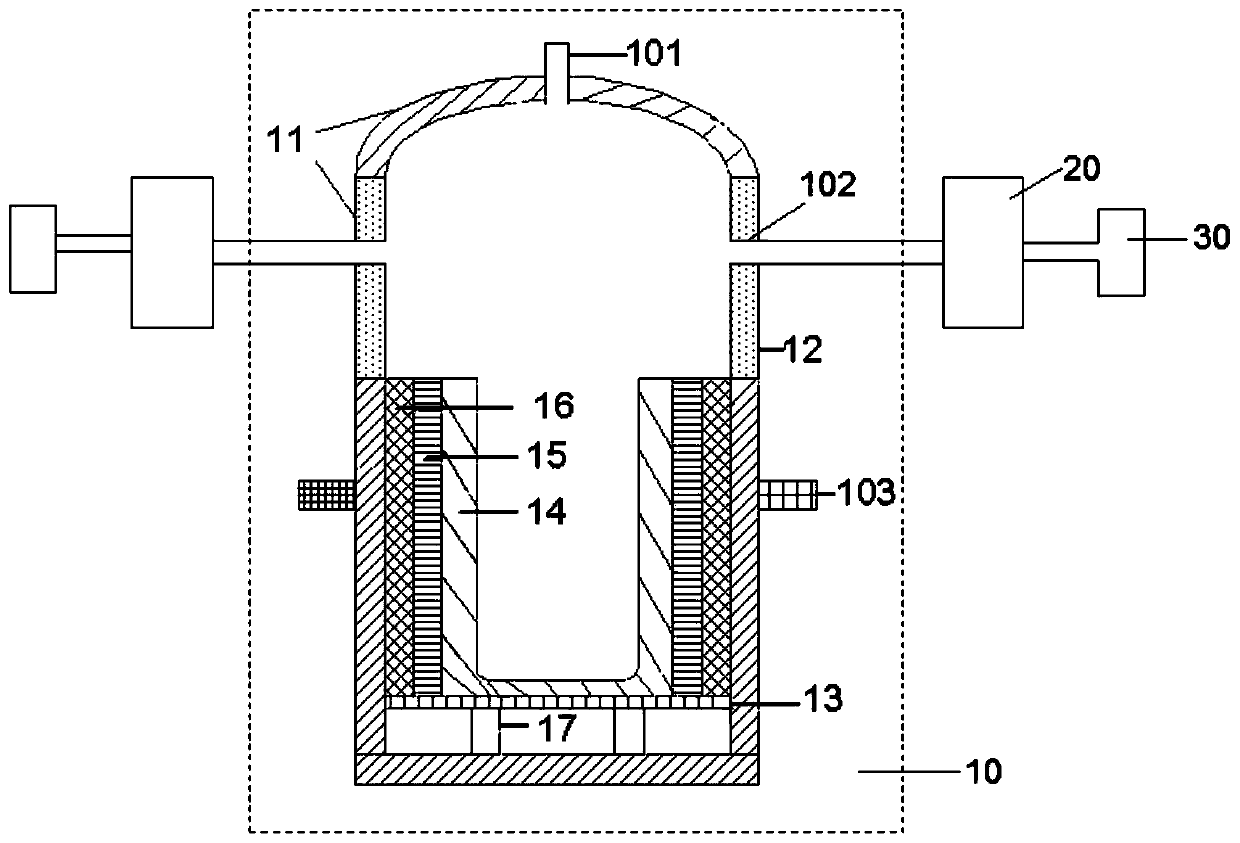

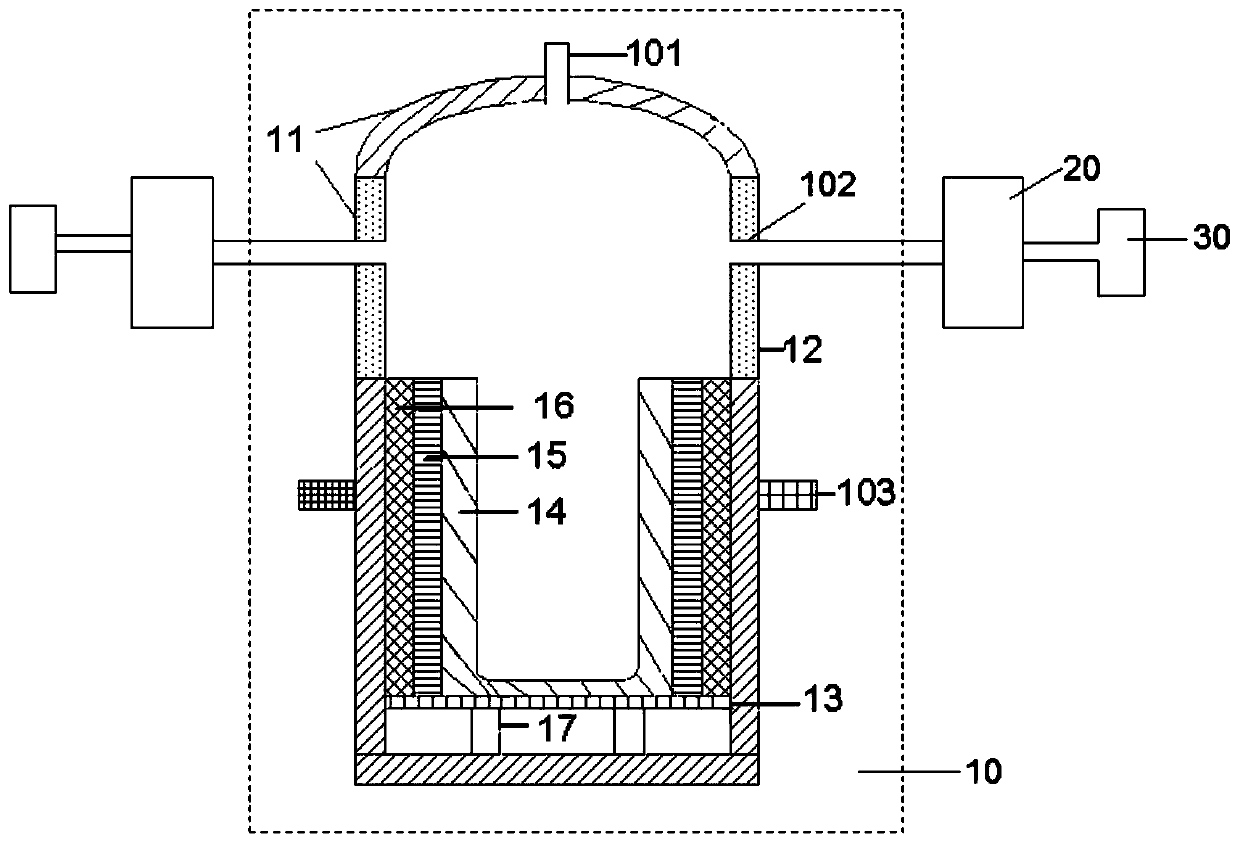

[0052] A method for smelting antimony metal, using vacuum melting equipment such as figure 1 As shown, the smelting method includes:

[0053] After mixing 1t antimony concentrate, soda ash (adding amount accounts for 70% of antimony concentrate), carbon powder (adding amount accounts for 6% of antimony concentrate), add binder (water, adding amount accounts for antimony concentrate, 5% of the total weight of soda ash and carbon powder) for briquetting or pelletizing; place the weighed crude antimony on the bottom plate 13 of the antimony concentrate vacuum smelting device, and then dry the briquette or pellet Above the rough antimony.

[0054] The pressure control device 20 (vacuum pump) is used to vacuum the melting chamber, so that the gas pressure in the furnace is 50 Pa, and then the electric heating device 16 (induction coil) is started for heating, and the materials in the furnace are heated to 700°C. The first smelting process is performed at the temperature, and the smelt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com