Aluminum alloy smelting furnace and smelting device

A technology for smelting furnaces and aluminum alloys, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems such as the greater influence of the suction device on the work, and achieve the effect of avoiding the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

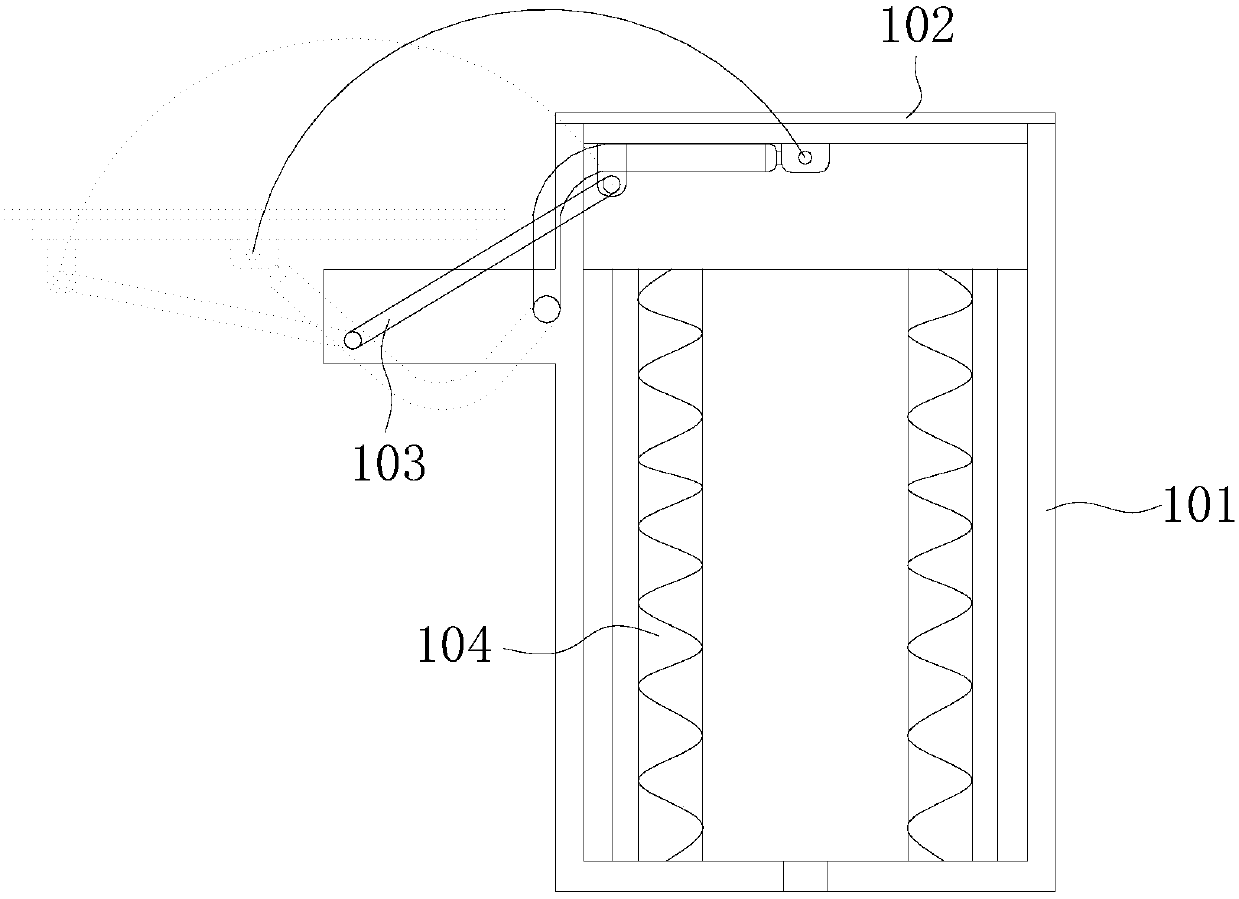

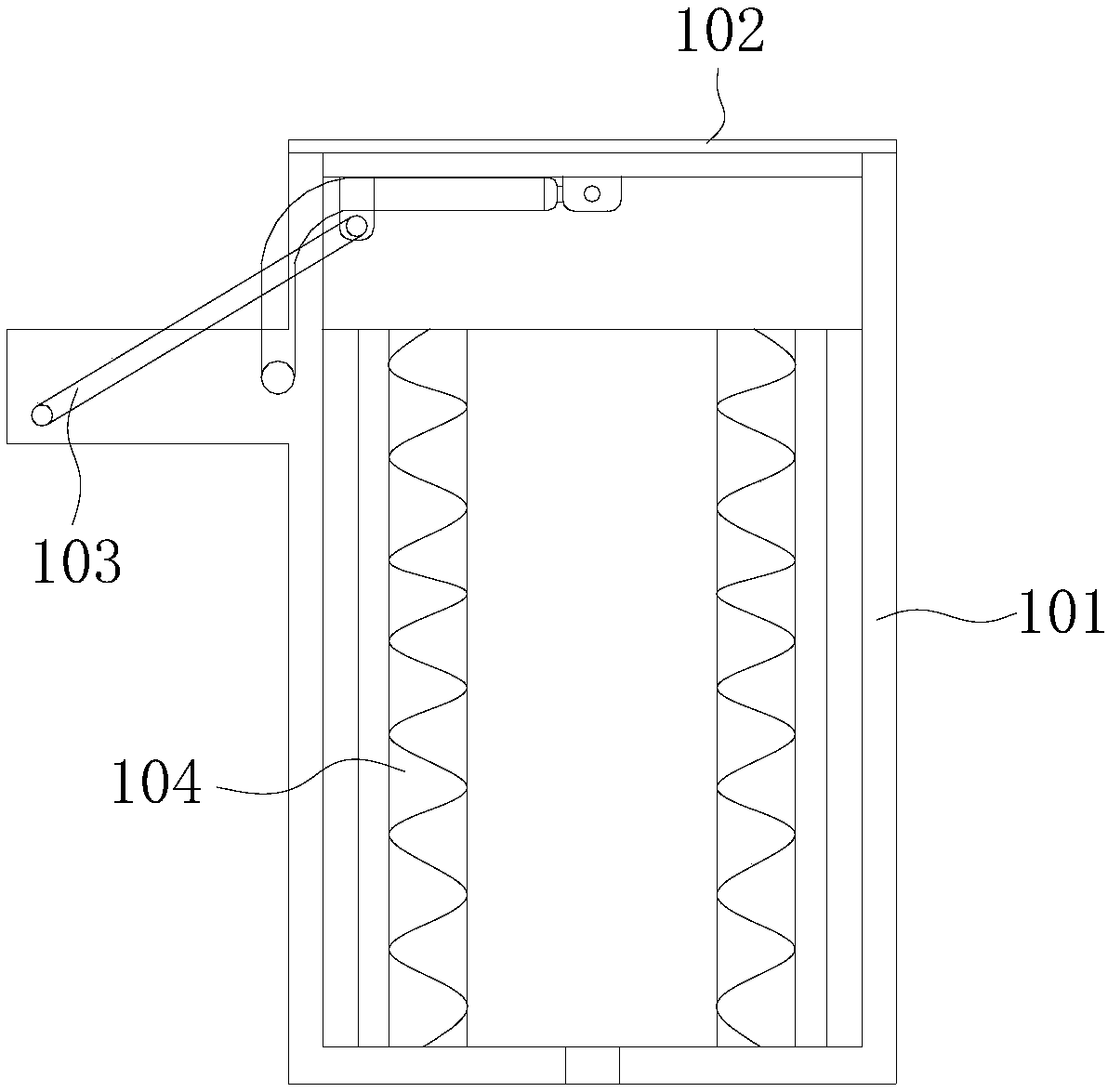

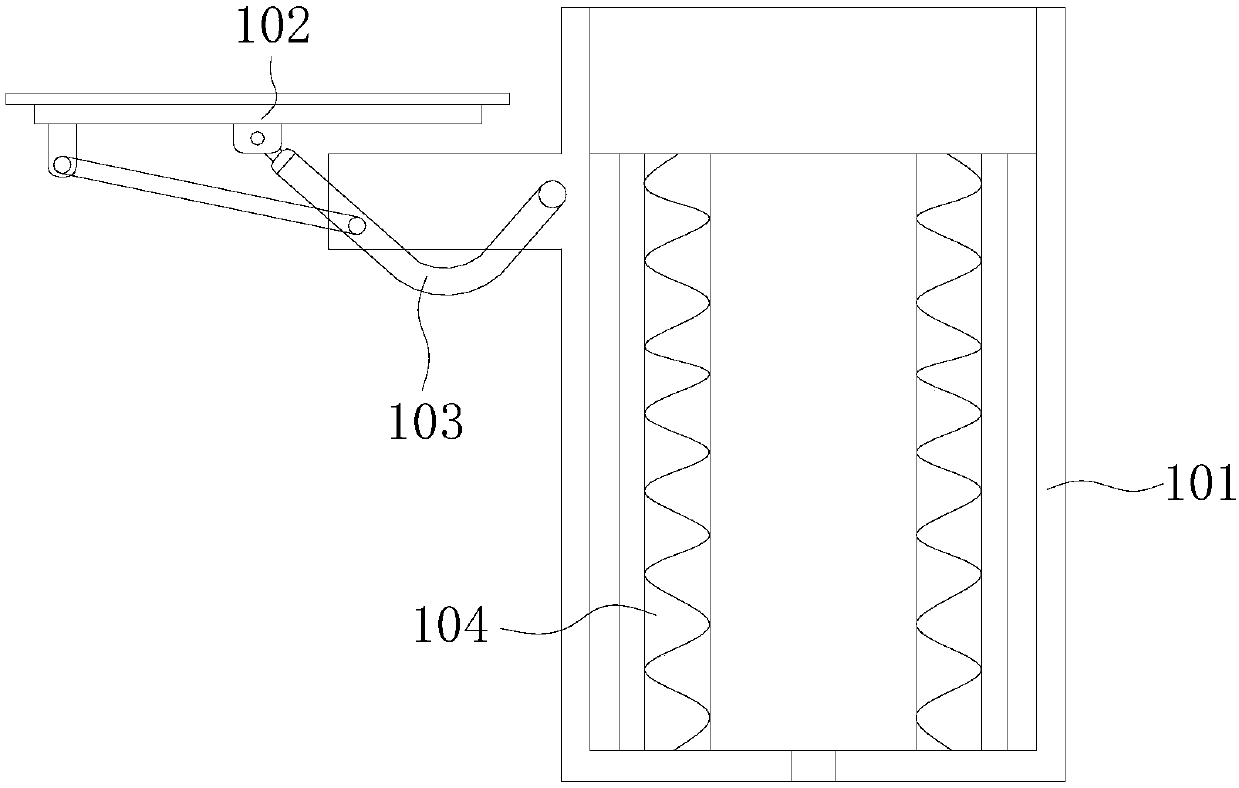

[0053] refer to Figure 1 to Figure 7 , the present embodiment provides an aluminum alloy melting furnace, including a furnace body 101, a cover body 102, a control device 103 and a melting device 104, the cover body 102 is connected with the furnace body 101 through the control device 103, and the control device 103 makes the cover body 102 Move relative to the furnace body 101 in a translational manner, the cover body 102 and the furnace body 101 form a furnace 105, the end of the furnace body 101 away from the cover body 102 is provided with an outlet 106, the outlet 106 communicates with the furnace chamber 105, and the melting device 104 is located in the furnace chamber 105 Inside, the smelting device 104 includes a high-frequency heating device 107, a heat collecting device 108, and a reflective layer 109 arranged in sequence. The reflective layer 109 is connected to the furnace body 101, and the reflective layer 109 is located between the high-frequency heating device 1...

Embodiment 2

[0064] This embodiment provides a smelting device 104, including the aluminum alloy smelting furnace as above.

[0065] The smelting device 104 provided in this embodiment includes the above-mentioned aluminum alloy smelting furnace, which will not affect the operation of the suction device during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com