Simplified straw-returning-to-field method applicable to clay paddy fields

A technology for paddy field and white soil, which is applied in the field of comprehensive utilization of crop straw returning to the field and soil improvement to achieve the effects of reducing the amount of incineration, promoting the release of nutrients, and promoting the formation of agglomerate structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

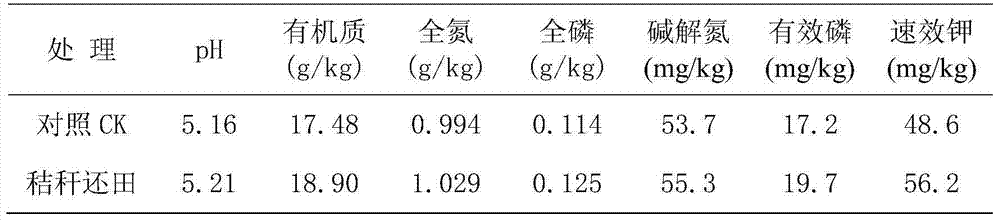

[0042] Straw light and simplified method of returning to the field and its effect of improving fertilization on low-yielding white soil paddy fields—a field comparative experiment in 2011 (Location: Yandian Township, Feixi County, Anhui Province).

[0043] The soil used for the test is a white soil type paddy soil developed from Xiashu loess, with low organic matter and available nutrient content, and the annual rice yield is 6500kg / hm 2 Left and right are paddy fields with medium and low yields.

[0044] A light and simplified straw returning method suitable for white soil paddy field includes the following 6 steps:

[0045] (1) Return the straw directly to the field. Before the wheat matures in May, a field with uniform fertility and convenient irrigation and drainage is selected in advance in Yandian Township, with an area of 2.3 mu. After the wheat matures in late May, grab the time to harvest in time. Use a combine harvester equipped with a cutting device to harvest w...

Embodiment 2

[0057] The light and simplified method of straw returning to the field and its effect of improving low-yield white soil

[0058] The method and implementation process of light and simplified straw returning to the field and its improvement and fertilization of low-yield white clay paddy fields are the same as in Example 1.

[0059] Taking Luotang Township, Changfeng County, Anhui Province as the test site, the soil is also a low-yield white clay paddy soil developed from Xiashu loess, and the rice variety Fengliangyou 6 was tested.

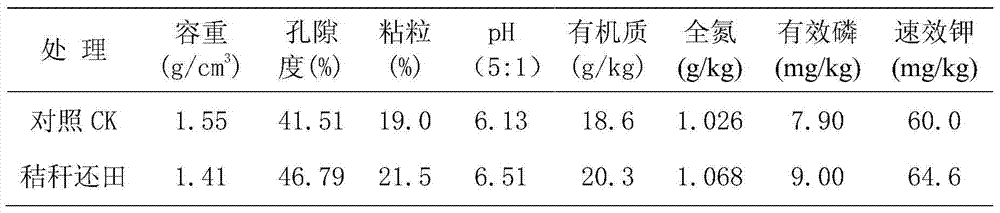

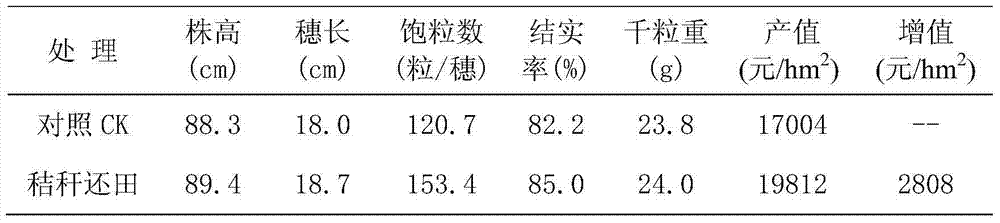

[0060] Table 2 shows that the application of the present invention—light and simplified straw returning to the field, the soil bulk density of the white soil tillage layer decreased by 9.0%, the total porosity increased by 5.28 percentage points, the absolute content of <0.001mm clay particles increased by 2.5 percentage points, and the sand-clay ratio decreased by 0.6 values . The pH of the white soil paddy field increased by 0.38 units from 6.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com