Garbage feeding, prewarming and drying arrangement

A technology of drying device and pushing device, which is applied in the direction of lighting and heating equipment, combustion method, combustion type, etc., can solve the problems of insufficient drying uniformity, extrusion, garbage reunion, etc., and achieve uniform drying of garbage and ensure controllability Sexuality, beneficial to incineration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

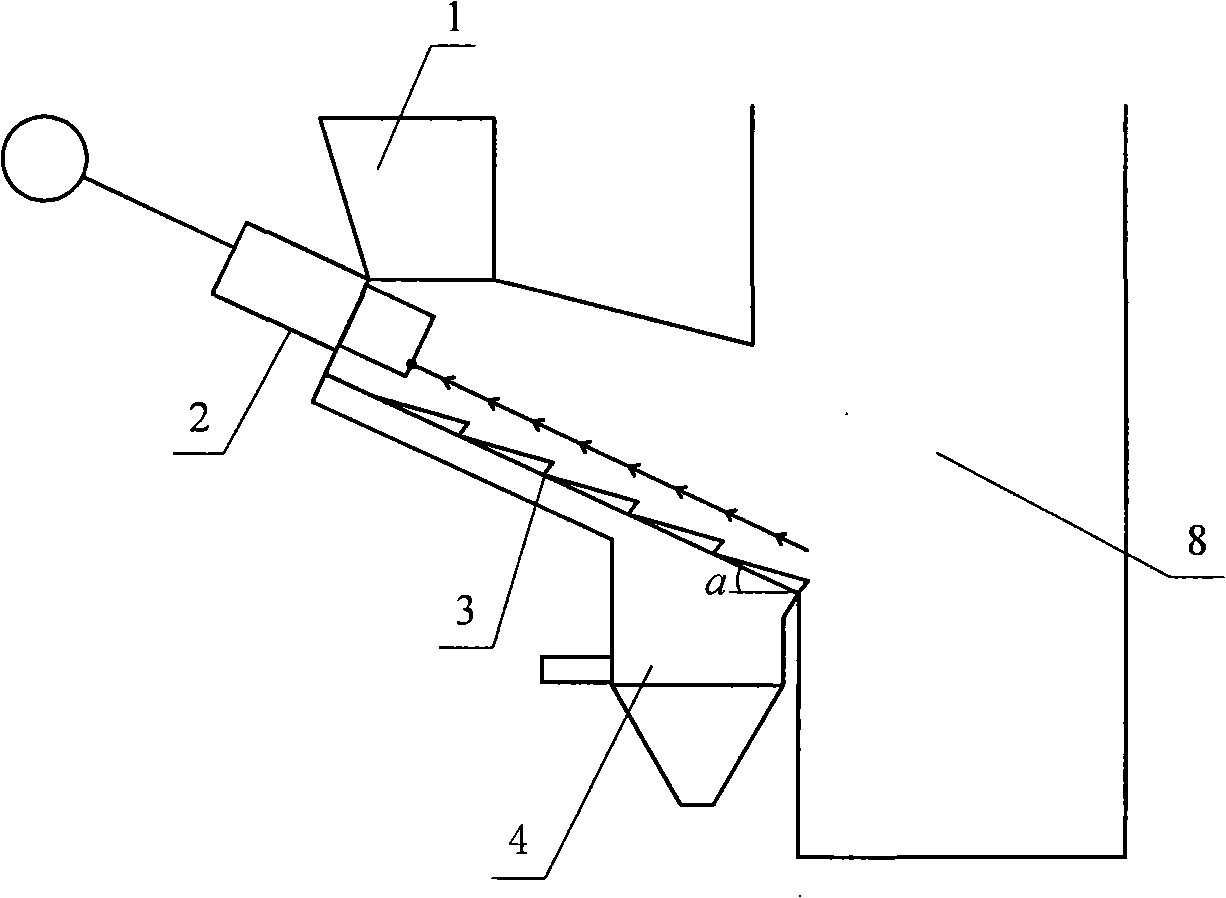

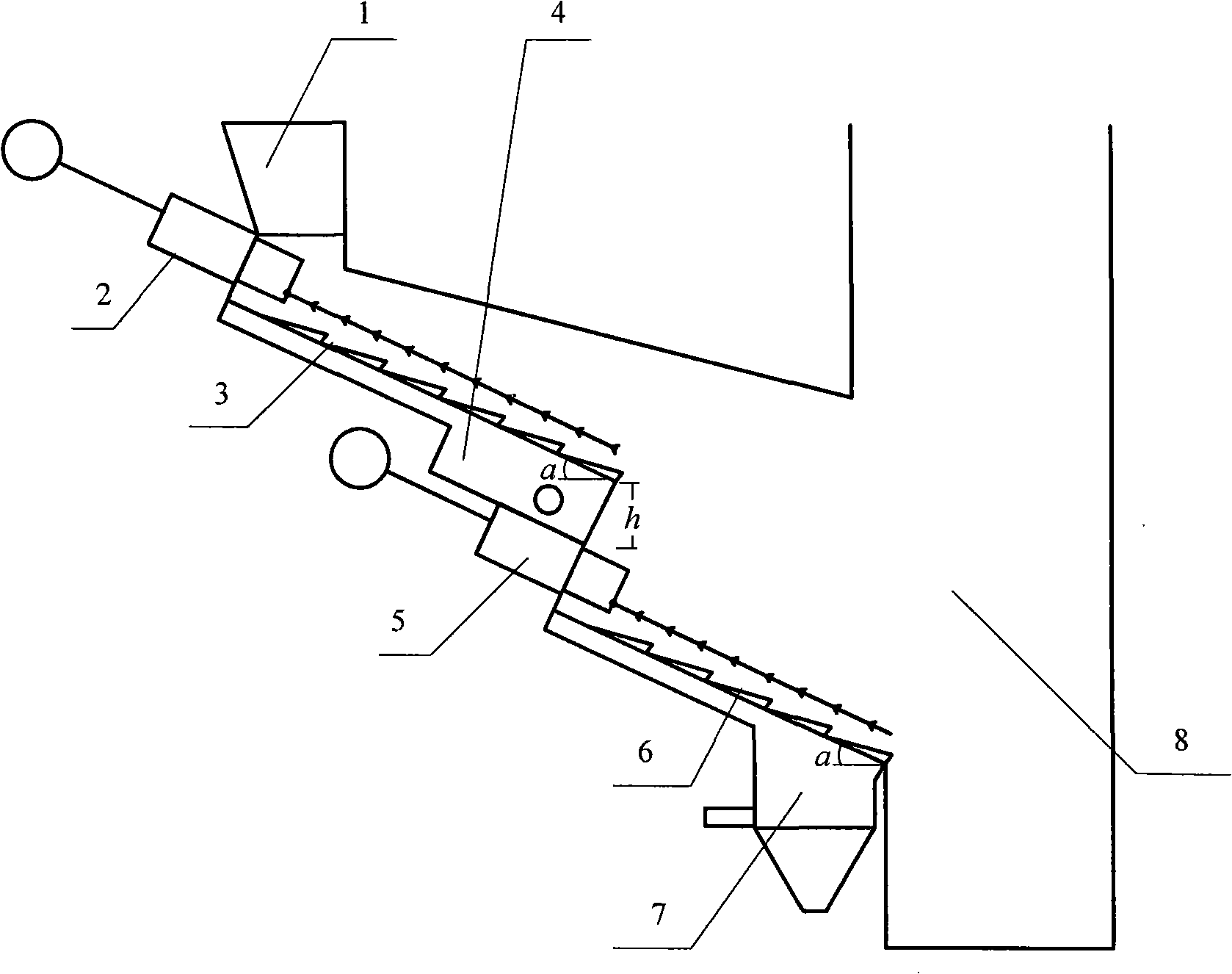

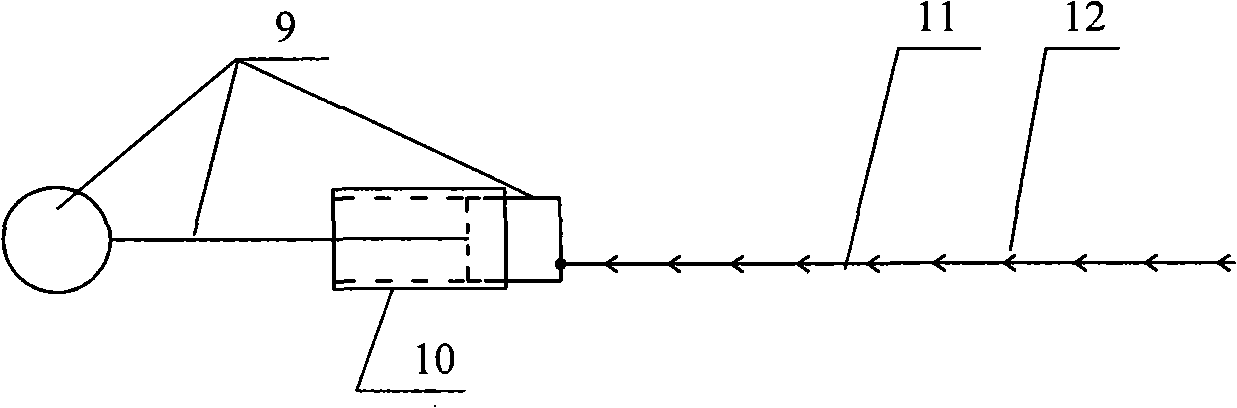

[0018] figure 1 It is a schematic diagram of a garbage feeding and preheating drying device arranged in one stage involved in the present invention. Such as figure 1 Shown, the present invention is made up of rubbish hopper 1, previous stage pushing device 2 and preceding stage drying bed 3. The previous-stage pushing device 2 is arranged above the previous-stage drying bed 3, which is fixed and inclined downward along the garbage feeding direction, with an inclination angle a of 3° to 30°. The former stage pusher device 2 is made up of slider guide rail reciprocating mechanism 9, connection box 10, pusher rod 11; Slider guide rail is arranged in the connection box, and connection box is fixed on the front end of drying bed; Pusher rod 11 is connected with slider The blocks are hinged, and inverted triangular fins 12 are arranged on the push rod.

[0019] By adjusting the moving speed of the slider guide rail reciprocating mechanism 9, the garbage falling from the garbage h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com