Efficient automatic control method for sludge deep dehydration

A deep dewatering, sludge concentration meter technology, applied in water/sludge/sewage treatment, sludge treatment, electrical program control, etc., can solve the problems of no stable parameters, high equipment requirements, large equipment damage, etc., to save The effect of manpower and material resources, improving safety and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

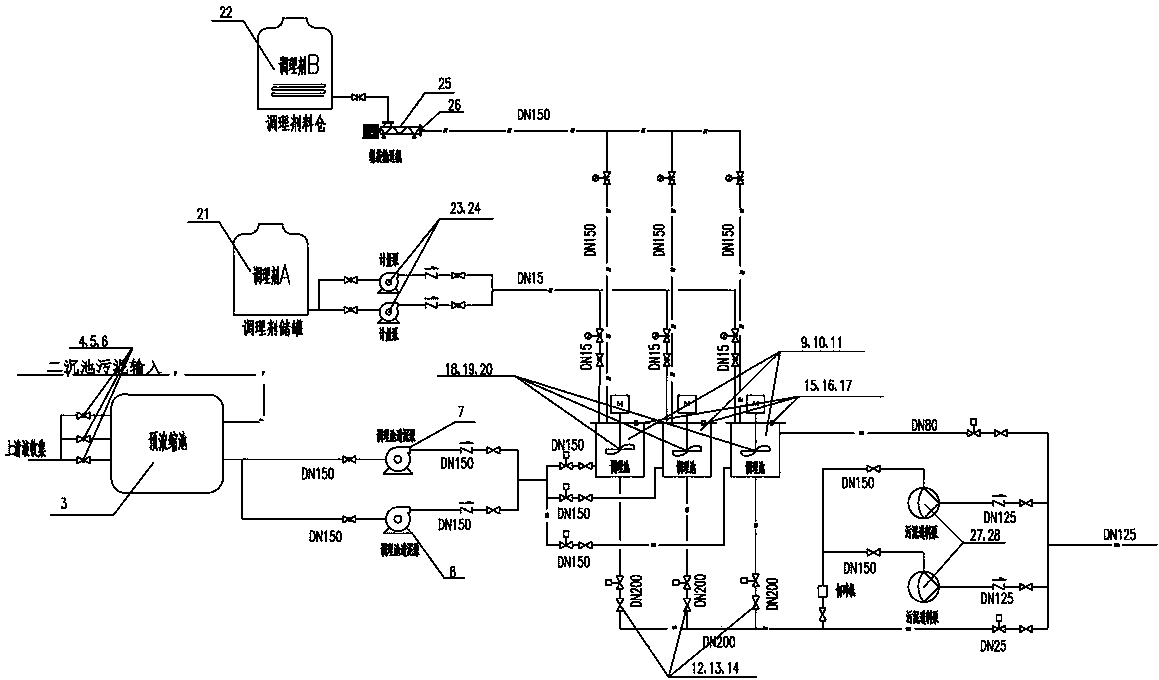

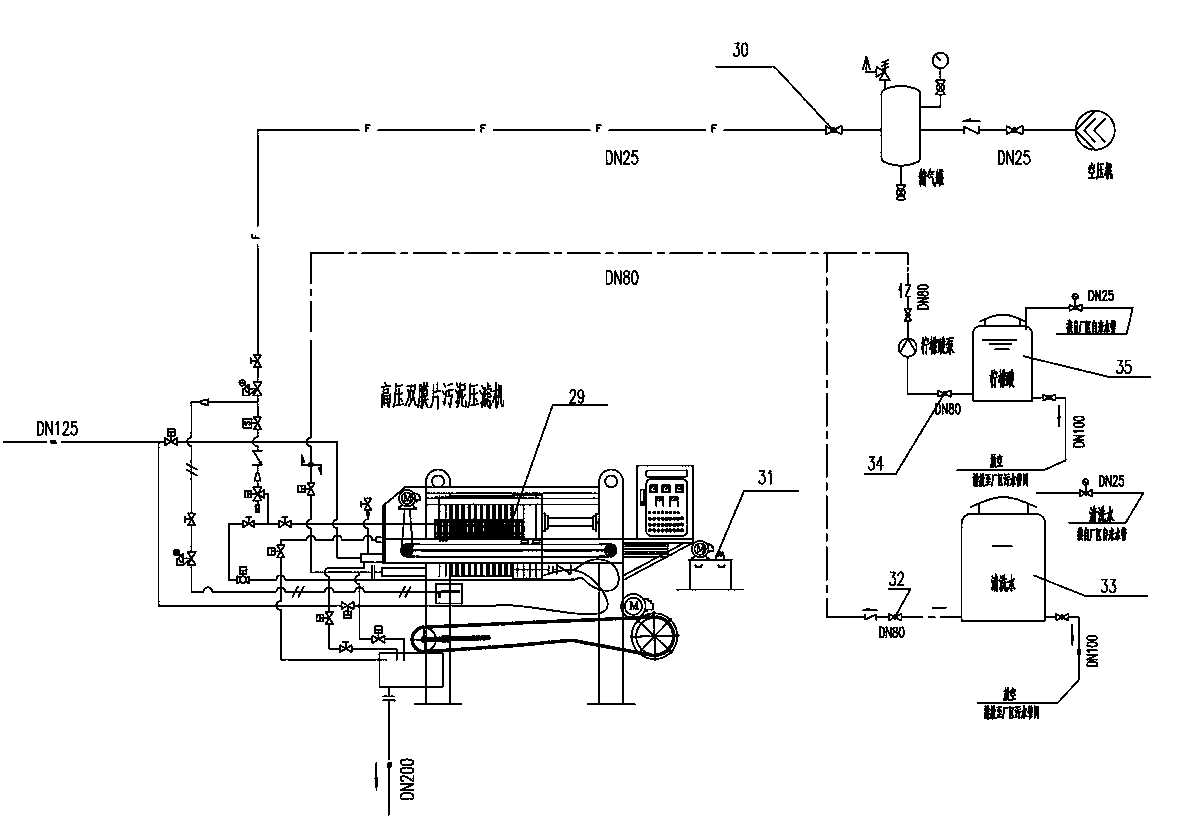

[0011] The technical solutions of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

[0012] like figure 1 , figure 2 as shown, figure 1 , figure 2 Based on the process flow chart of the automatic control system. The process route is as follows: the sludge from the secondary settling tank 1 enters the concentration tank 3 through the sludge pump 2, and pre-concentrates in the concentration tank for 8-24 hours to achieve a certain degree of mud-water separation; the actual liquid level detected by the liquid level gauge Compared with the preset value, control the opening and closing of the outlet electric valves 4, 5, 6; the concentrated sludge is transported into the sludge conditioning tanks 9, 10, 11 by the sludge pumps 7, 8, and controlled by the pneumatic valves 12, 13, 14 To adjust the transportation of concentrated sludge, install sludge level gauges 15, 16, and 17 above the conditionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com