Solid garbage crusher

A solid waste and pulverizer technology, which is applied in the removal of solid waste, presses, grain processing, etc., can solve the problems of hidden secondary pollution, cumbersome processing, and high manufacturing costs, to improve work efficiency, reduce labor intensity, Combining well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

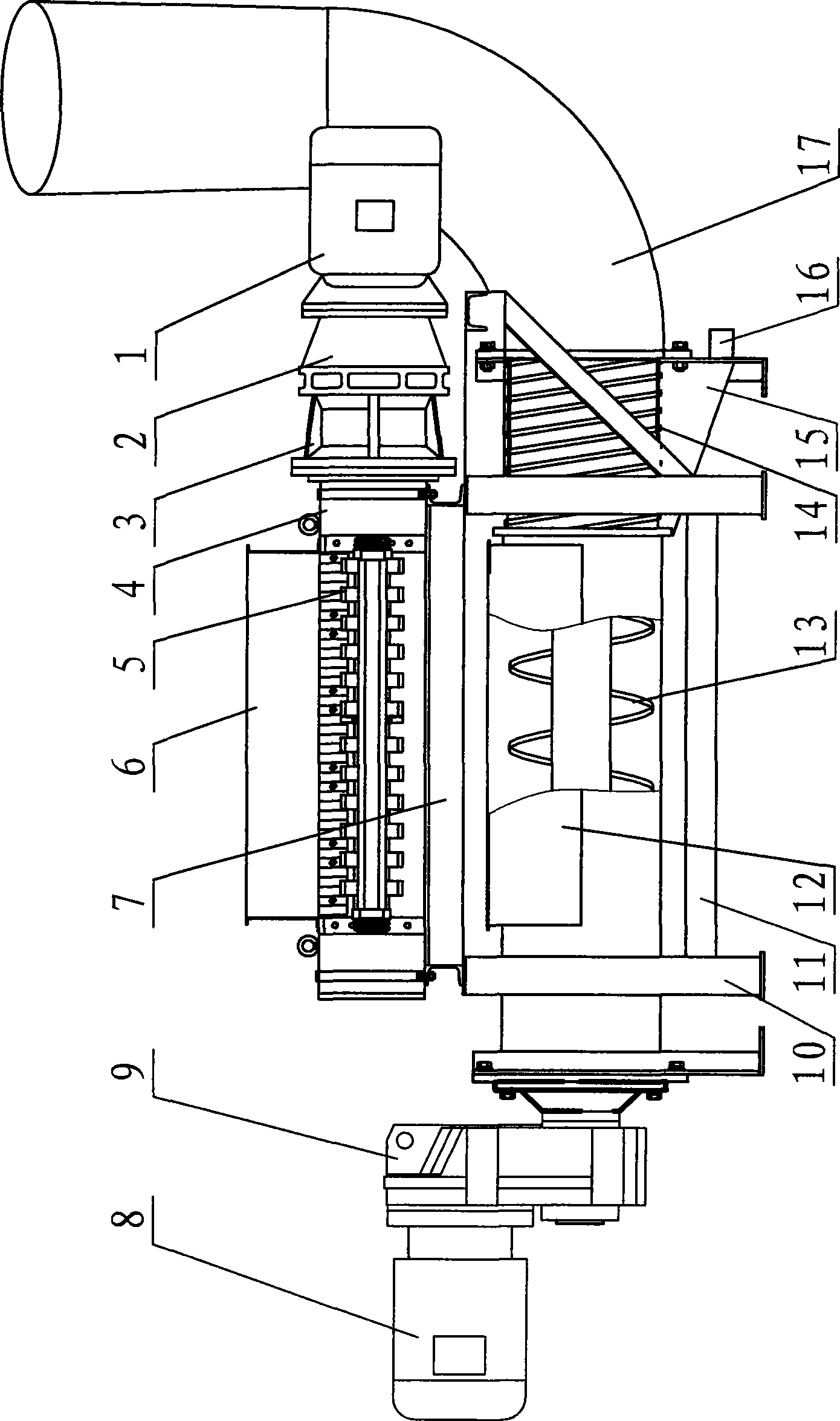

[0011] figure 1 A solid pulverizer is shown, including a pulverizer and a press machine. The pulverizer is mainly composed of a motor 1, a reducer 2, a gear transmission box 3, a box body 4, and a blade group 5. The motor is connected to the reducer transmission gear transmission box. The dual gears, the dual gear transmission blade group 5 tangentially move to achieve crushing, the box body 4 is provided with a feed port 6 and a discharge port 7; the press includes a motor 8, a reducer 9, a mounting bracket 10, a housing 11, Feed hopper 12, screw shaft 13, dehydration screen cylinder 14, squeeze pipe 17, the two ends of the housing 11 are connected to the mounting bracket 10, the top of the housing is provided with a feed hopper 12 corresponding to the pulverizer outlet 7, and the motor is connected to the reducer Drive the screw shaft 13 located in the inner cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com