A method for removing dioxins in waste incinerator flue gas

A waste incinerator and dioxin technology, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problem of dioxin emission that cannot be completely solved by waste incineration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for removing dioxins from waste incinerator flue gas, which combines an incineration process for removing dioxins from waste incinerator flue gas and a method of spraying inhibitors into the incinerator furnace, wherein , the incineration process used to remove dioxins in the flue gas of the garbage incinerator is as follows: the garbage is placed on the grate at the bottom of the furnace of the garbage incinerator and burned, and the incineration air with an excess air coefficient of 2.2 is supplied from the bottom of the grate. The secondary combustion area above the row is injected with secondary gas (generally referring to natural gas or coal gas) and secondary excess combustion air with an excess air coefficient of 1.05. By controlling the amount of secondary fuel and secondary combustion air, the nozzle area The temperature in the secondary combustion zone is at 1100°C; while implementing the aforementioned incineration process, inject inhibitor powder int...

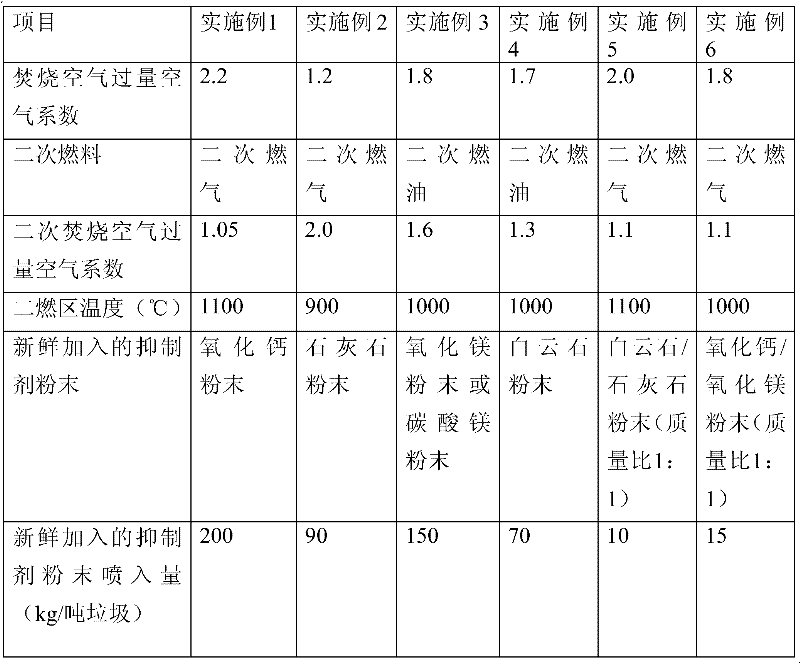

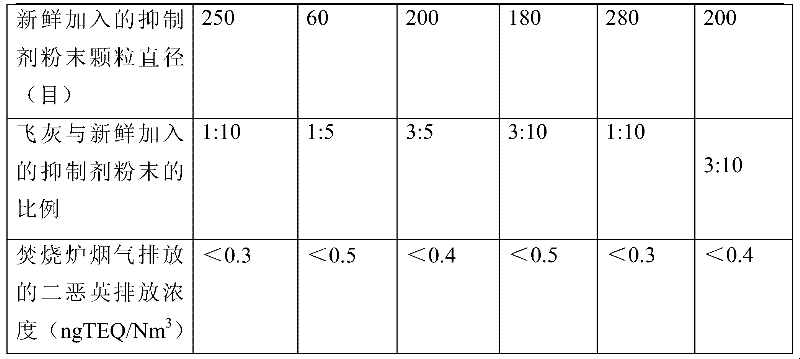

Embodiment 2~ Embodiment 6

[0023] Embodiment 2 to embodiment 6 take embodiment 1 as a reference, and the dioxin discharge concentration of its various process parameter changes and incinerator flue gas discharge is compared with embodiment 1 in tabular form and lists as follows:

[0024]

[0025]

[0026] The dioxin emission concentration of the incinerator flue gas discharge of embodiment 1~6 is all less than 0.5ngTEQ / Nm 3 , are in line with my country's latest dioxin emission standards. Therefore, it can be proved that the method for removing dioxins in the flue gas of garbage incinerators of the present invention is very effective in decomposing dioxins produced during garbage incineration and inhibiting the formation of dioxins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com