Wet mud burning treatment apparatus with compound dryer

A composite dryer and treatment device technology, which is applied in the direction of oxidation treatment of sludge, incinerators, combustion methods, etc., can solve the problems of high cost of harmless treatment, complex sludge incineration system, and high energy consumption of drying equipment. Achieve the effects of simplifying the dry incineration treatment process, enhancing heat transfer, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

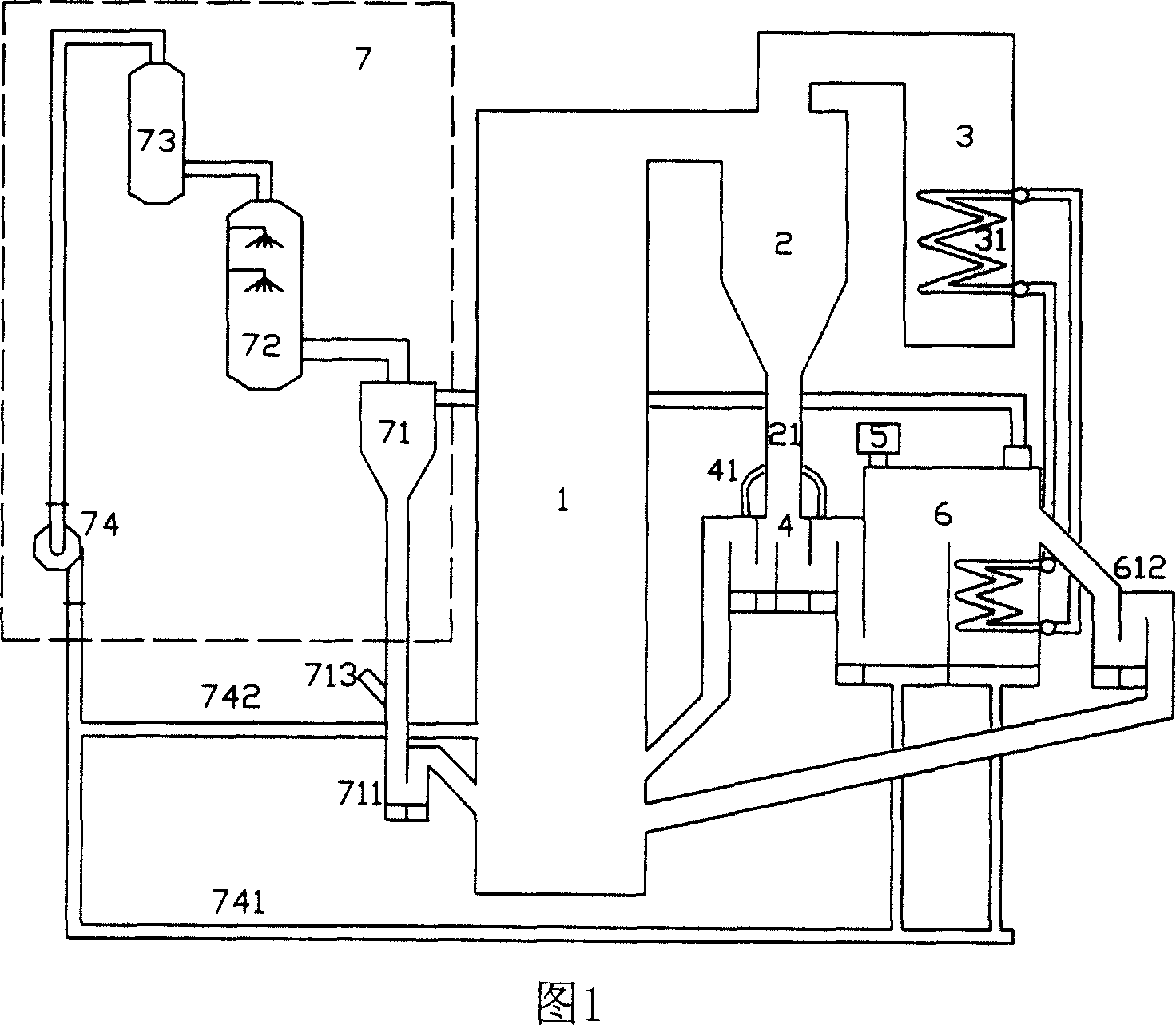

[0037] Fig. 1 and Fig. 2 are the schematic structural diagrams of this embodiment, as can be seen from the figure, the wet sludge incineration treatment device with composite drier of this embodiment is composed of circulating fluidized bed incinerator hearth 1, high temperature gas-solid separator 2 , tail flue 3, hot ash distribution valve 4, sludge breaking device 5, composite dryer 6, dryer exhaust treatment system 7 (including fine powder separator 71, cooler 72, steam-water separator 73 and fan 74 etc.) composition.

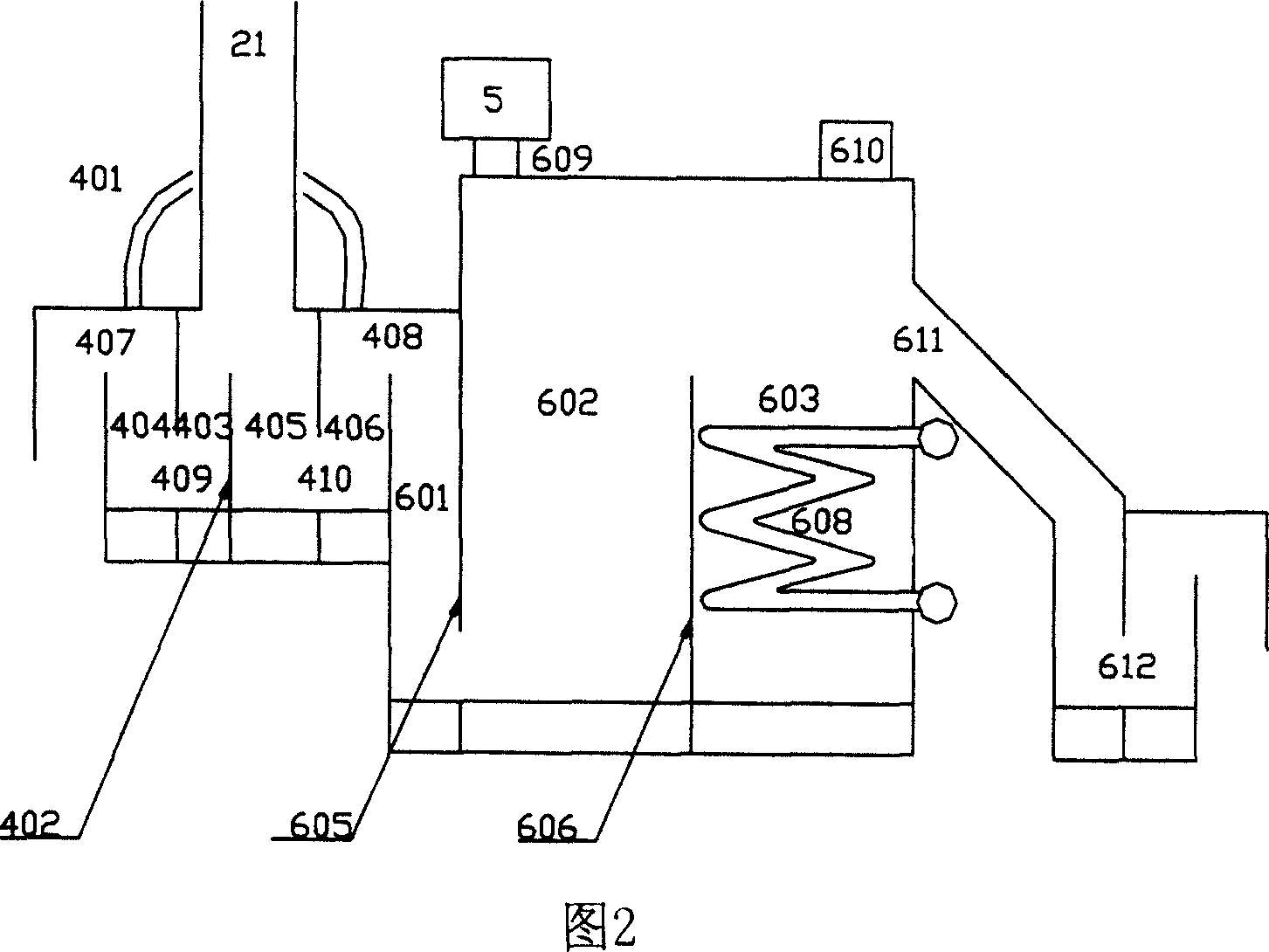

[0038] The hot ash distribution valve 4 is located below the separator 2, the inlet is connected to the material leg 21 of the separator, and the outlet is respectively connected to the incinerator hearth 1 and the composite dryer 6, and its specific structure is:

[0039] A vertical splitter plate 402 is arranged directly below the separator material leg 21, and the first feed chamber 403 and the second feed chamber 405 of hot ash distribution valves are r...

Embodiment 2

[0049] Fig. 1 and Fig. 2 are the schematic structural diagrams of this embodiment, as can be seen from the figure, the wet sludge incineration treatment device with composite drier of this embodiment is composed of circulating fluidized bed incinerator hearth 1, high temperature gas-solid separator 2 , tail flue 3, hot ash distribution valve 4, sludge breaking device 5, composite dryer 6, dryer exhaust treatment system 7 (including fine powder separator 71, cooler 72, steam-water separator 73 and fan 74 etc.) composition.

[0050] The hot ash distribution valve 4 is located below the separator 2, the inlet is connected to the material leg 21 of the separator, and the outlet is respectively connected to the incinerator hearth 1 and the composite dryer 6, and its specific structure is:

[0051] A vertical splitter plate 402 is arranged directly below the separator material leg 21, and the first feed chamber 403 and the second feed chamber 405 of hot ash distribution valves are r...

Embodiment 3

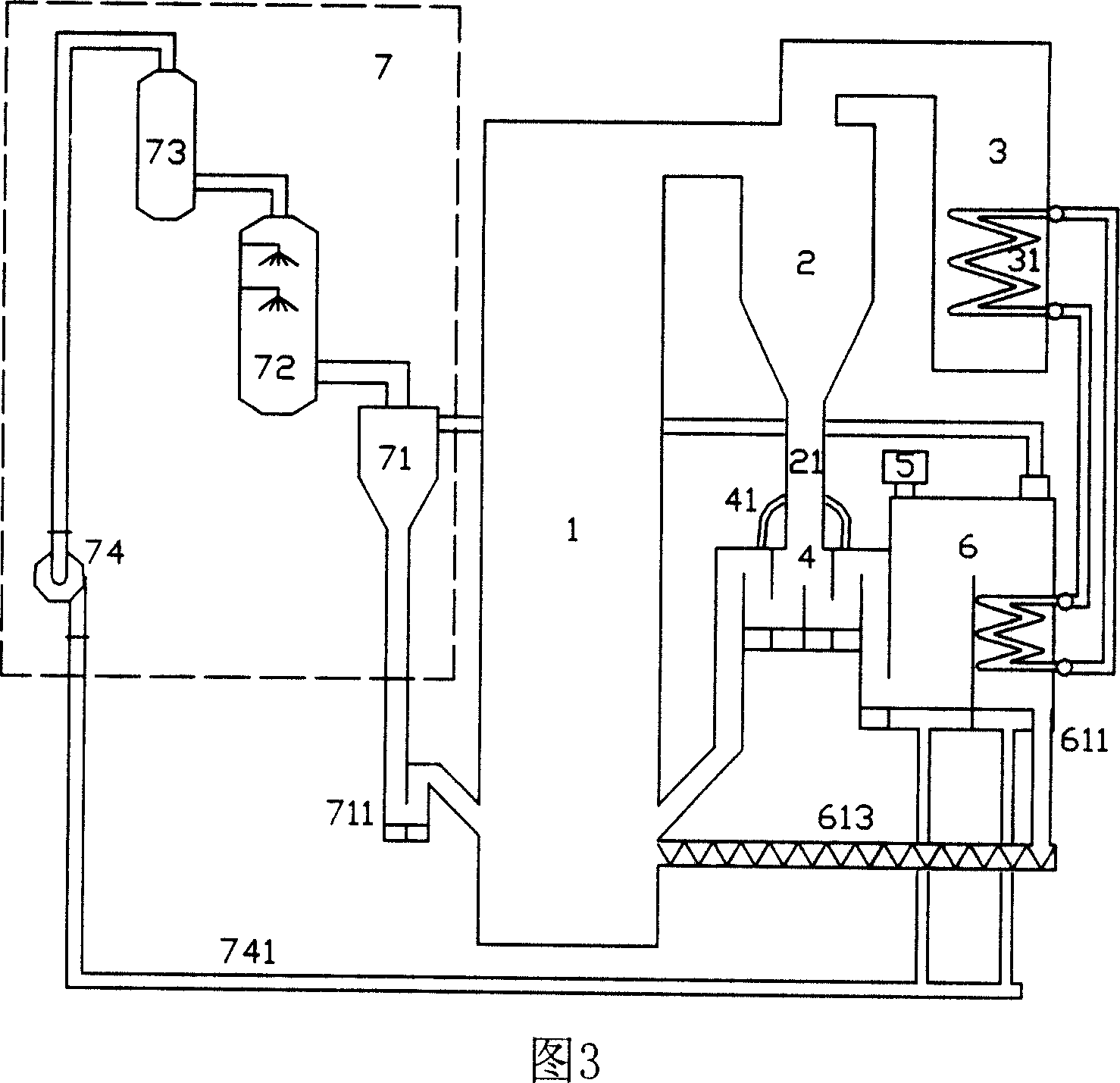

[0060] A wet sludge incineration treatment device with a composite dryer provided by the present invention is composed of a circulating fluidized bed incinerator hearth 1, a high-temperature gas-solid separator 2, a tail flue 3, a hot ash distribution valve 4, and a sludge blower. Dispersing device 5, composite dryer 6, dryer exhaust treatment system 7 (including fine powder separator 71, cooler 72, steam-water separator 73 and fan 74, etc.).

[0061] The hot ash distribution valve 4 is located below the separator 2, the inlet is connected to the material leg 21 of the separator, and the outlet is respectively connected to the incinerator hearth 1 and the composite dryer 6, and its specific structure is:

[0062] A vertical splitter plate 402 is arranged directly below the separator material leg 21, and its two sides are respectively the first feed chamber 403 and the second feed chamber 405 of the hot ash distribution valve. The projection of the separator dipleg 21 on the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com