Wet sludge drying and incinerating treatment method employing circulating fluidized bed with combined dryer

A composite dryer and circulating fluidized bed technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve the problems of high cost of harmless treatment, complex sludge incineration system, and high energy consumption of drying equipment. Achieve the effects of simplifying the dry incineration treatment process, enhancing heat transfer, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

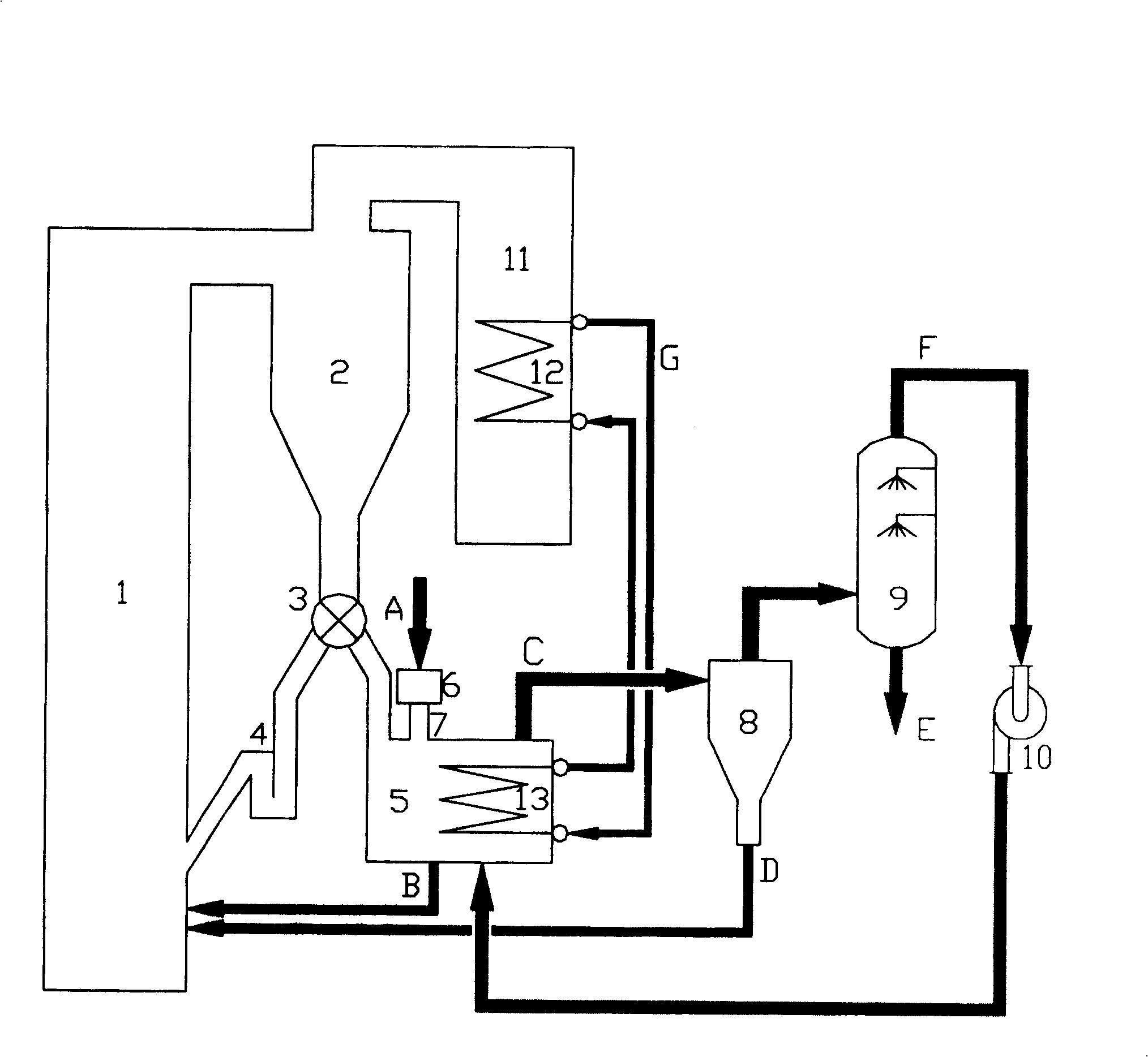

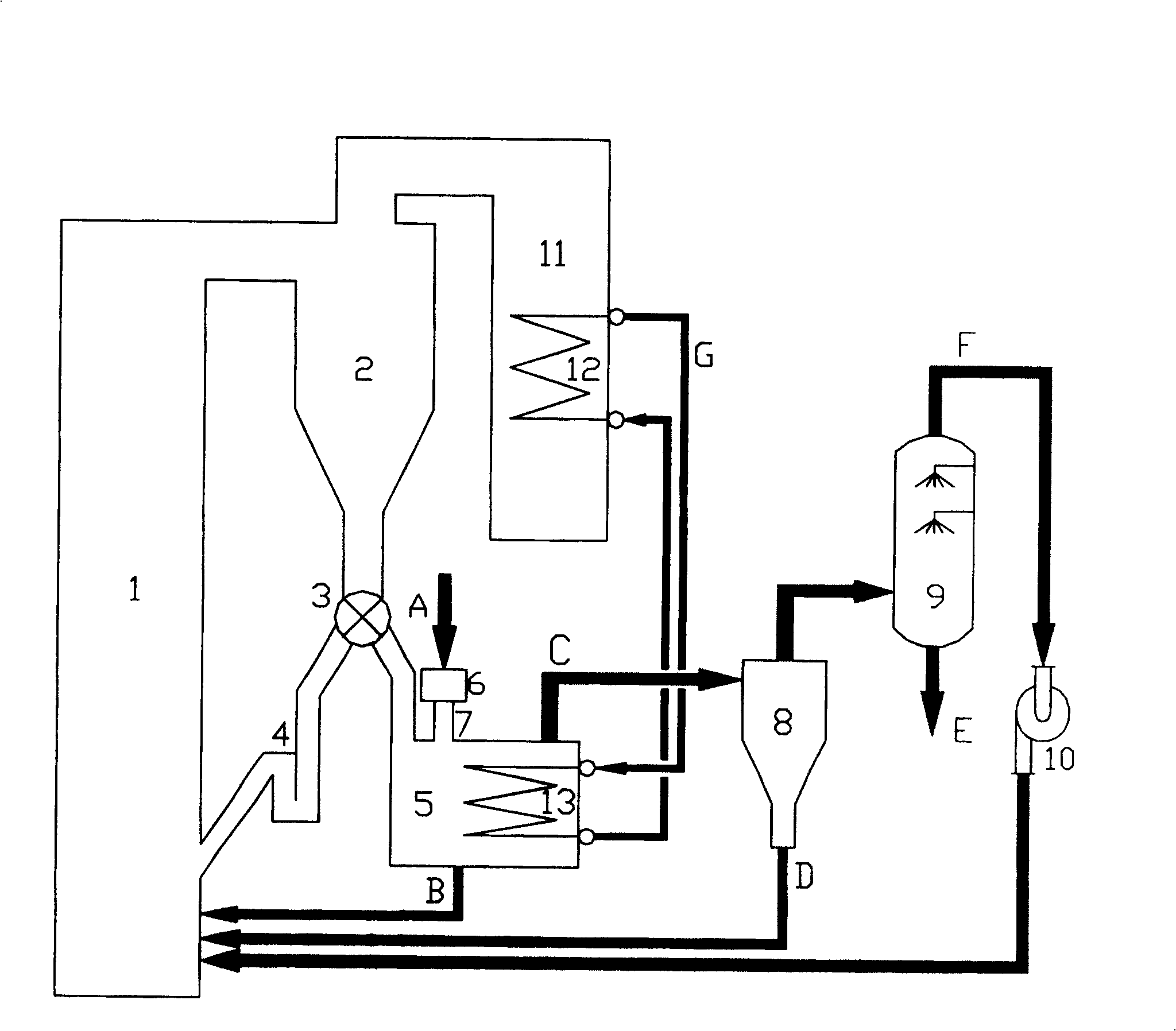

[0022] In the circulating fluidized bed incinerator, the wet sludge A with a moisture content of 60% is dried and incinerated separately, and the wet sludge A is added from the wet sludge inlet 7 provided on the composite dryer 5, and is installed in the The dispersing device 6 on the inlet 7 disperses; the composite dryer 5 is set in the circulating ash circulation circuit of the circulating fluidized bed incinerator, and the high-temperature circulating ash separated by the cyclone separator 2 passes through the mechanical hot ash distribution valve 3, and a part Enter the feeder 4 and return directly to the furnace 1, and the other part enters the composite dryer 5; the composite dryer 5 is a bubbling fluidized bed type, and the bottom is fed with fluidized gas, and a heat release coil 13 is arranged in it; It is connected with the tubular heat exchanger 12 in the flue 11 at the tail of the incinerator, and the heat exchange medium G (steam) absorbs the heat generated by com...

Embodiment 2

[0024]In the circulating fluidized bed incinerator, coal is added as an auxiliary fuel to dry and incinerate wet sludge A with a moisture content of 90%, and the wet sludge A is added from the wet sludge inlet 7 provided on the composite dryer 5, adding It is broken up by the dispersing device 6 installed on the inlet 7; the composite dryer 5 is set in the circulating ash circulation loop of the circulating fluidized bed incinerator, and the high-temperature circulating ash separated by the cyclone separator 2 is passed through the pneumatically controlled hot ash Part of the distribution valve 3 enters the feeder 4 and directly returns to the furnace 1, and the other part enters the composite dryer 5; the composite dryer 5 is a bubbling fluidized bed type, and the bottom is fed with fluidized gas, and a heat release coil 13 is arranged in it; The heat release coil 13 is connected to the tubular heat exchanger 12 in the flue 11 at the tail of the incinerator, and the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com