Gasification incinerator and waste gasification incineration method

An incinerator and waste technology, applied in the field of gasification combustion, can solve the problems of unsafe, inconvenient operation, and the need for manual slag removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

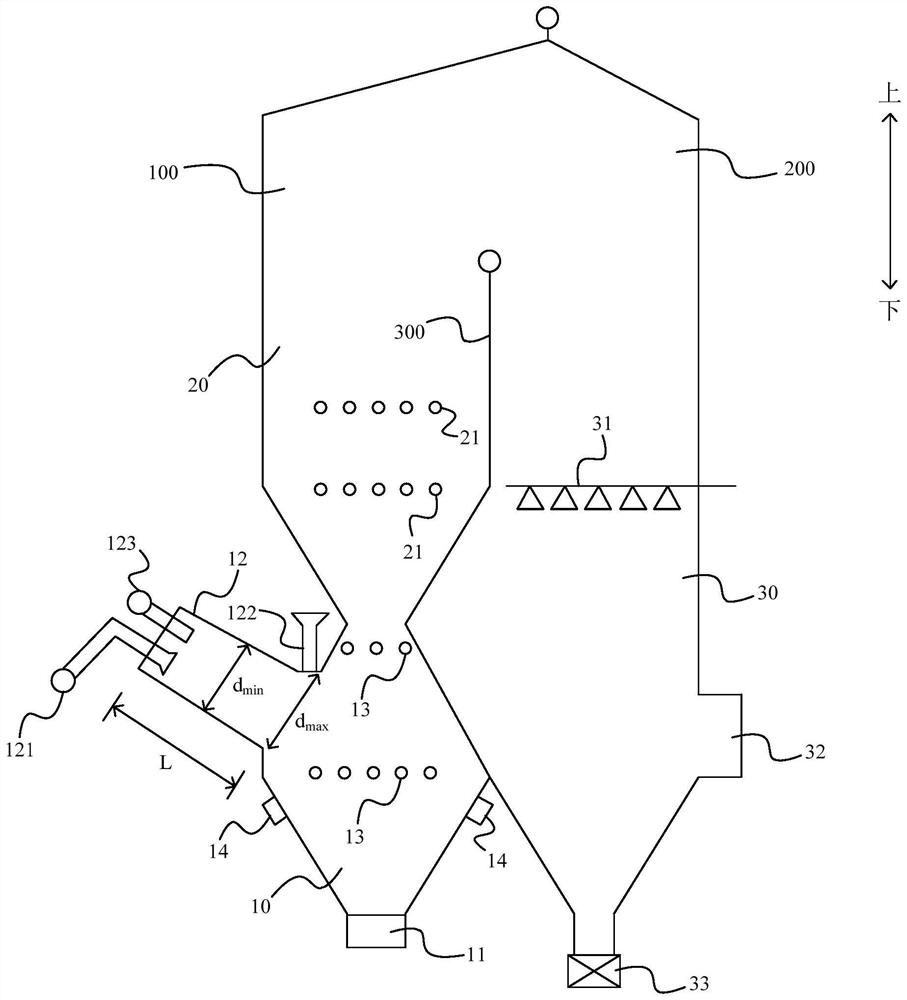

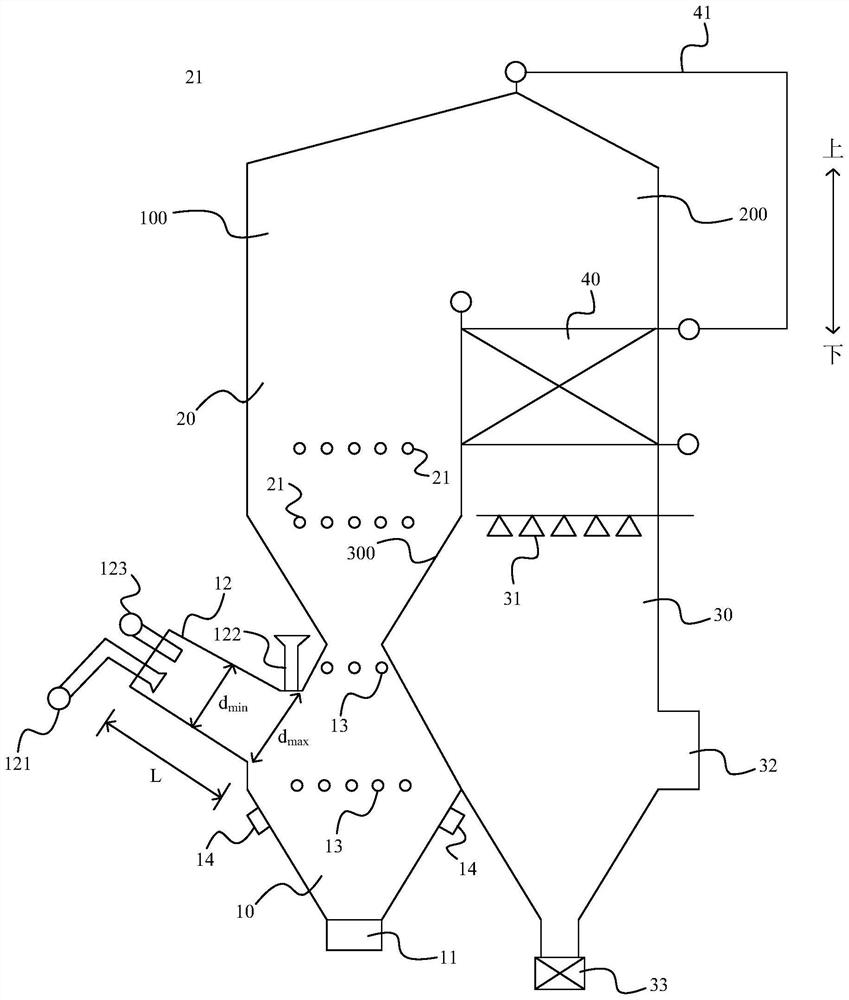

[0053] refer to figure 2 , the gasification incinerator includes a first furnace body 100 and a second furnace body 200 . The first furnace body 100 includes a gasification section 10 and a combustion section 20 , and the second furnace body 200 includes a quenching section 30 . The tops of the first furnace body 100 and the second furnace body 200 communicate with each other and have a common wall 300 therebetween. The bottom of the gasification section 10 is provided with a primary air distribution device 11, and the side of the gasification section 10 is provided with a pre-combustion section 12 and a secondary air distribution device 13. The pre-combustion section 12 includes a liquid or slurry waste feeding device 121, The solid feeding device 122 and the combustion device 133 , the outlet of the pre-combustion section 12 is connected to the upper section of the gasification section 10 , and the lower section of the gasification section 10 is provided with a steam inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com