Atomizing spray gun

A technology of atomizing spray gun and atomizing nozzle, which is applied in the field of leachate back-spraying treatment, can solve problems such as difficulty in meeting sewage discharge standards, inability to continue to decompose concentrated liquid, high operation and maintenance costs, and increase the amount of garbage incinerated and occupy an area Small, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

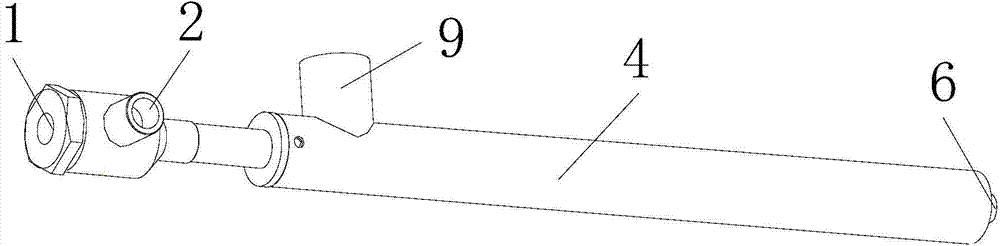

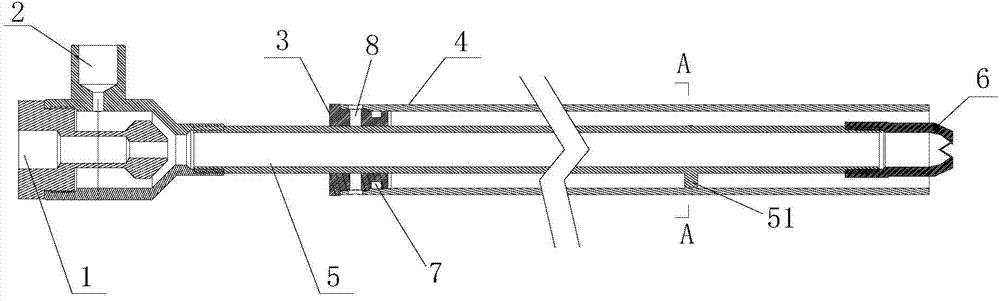

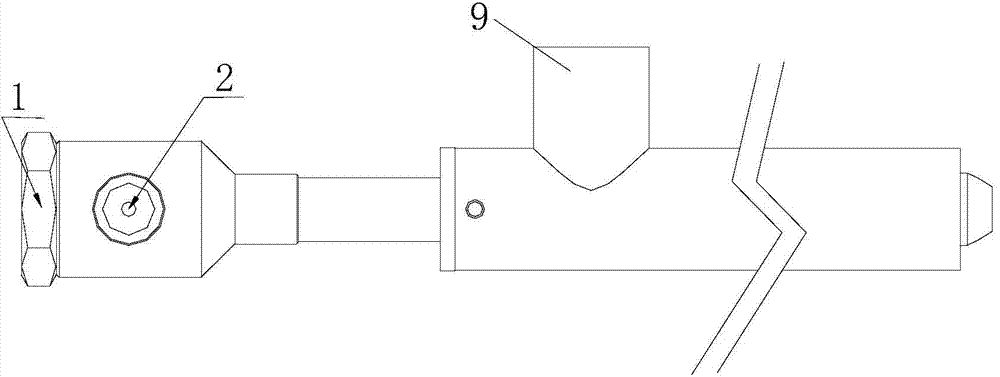

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 3 As shown, the present invention is made up of a compressed air nozzle 1, a leachate nozzle 2, a flange 3 plus a sealing ring 7, a protective sleeve 4, a gun shaft 5, and an atomizing nozzle 6; the compressed air nozzle 1 Screw the big end of the leachate nozzle 2 through the thread, and then screw the gun shaft 5 on the small end of the leachate nozzle 2 through the thread, the flange 3 is fixed on the fixed position of the gun shaft 5 by welding and then put on the sealing ring 7 to protect the sleeve 4 The end with the installation hole is set on the flange 3, fixed by the screw 8 to prevent slipping, the end of the atomizing nozzle 6 with internal thread is screwed on the external thread of the gun rod 5, and the atomizing nozzle 6 is slightly higher than the protective sleeve 4 . as attached Figure 4 As shown, the gun shaft 5 is provided with a positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com