Purified terephthalic acid residue recycling and incineration treatment method

A technology of purified terephthalic acid and its treatment method, which is applied in the field of recycling and incineration of purified terephthalic acid residues, and can solve the problem of increasing the amount and difficulty of processing flue gas in incinerators, increasing the workload of operators, and wasting residues. Resources and other issues, to achieve the effect of thorough harmless treatment, reduction of residues, and recycling of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

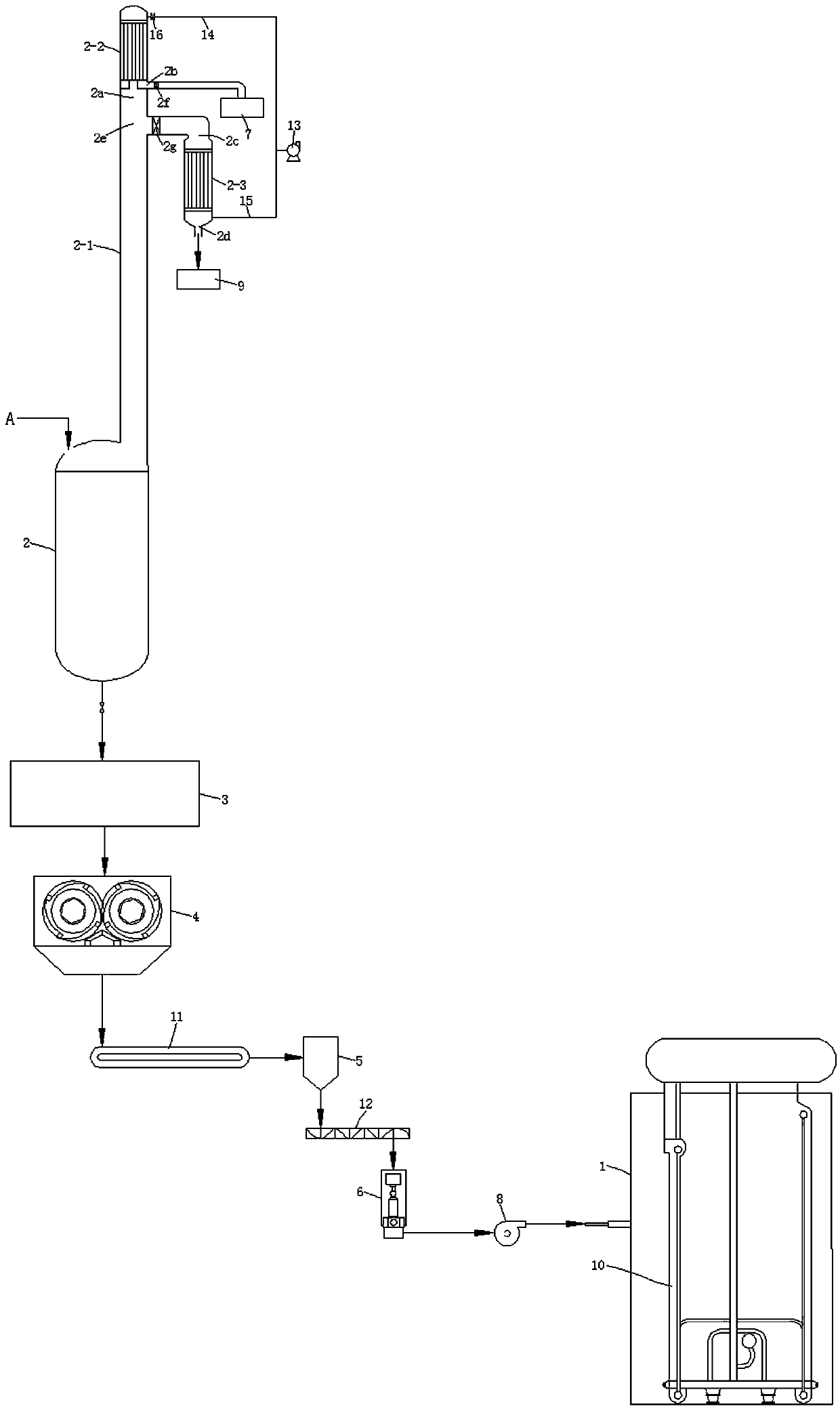

[0032] see figure 1 , the present invention provides a resource recovery and incineration treatment method for purified terephthalic acid residues. An incinerator 1 is used as the incineration treatment equipment, and a reaction kettle 2 is used as the resource recovery treatment equipment. The reaction kettle 2 has a rectification tower 2 -1. The first condenser 2-2 and the second condenser 2-3. The first condenser 2-2 and the second condenser 2-3 are preferably commercially available water-cooled condensers. The first The condenser 2-2 has a gas inlet 2a and a liquid outlet 2b, and a stop valve 2f is usually installed on the pipeline of the liquid outlet 2b of the first condenser 2-2, and the second condenser 2-3 has a gas inlet 2c and the liquid outlet 2d, a stop valve 2g is usually installed on the gas inlet 2c pipeline of the second condenser 2-3, the gas inlet 2a of the first condenser 2-2, the gas inlet 2a of the second condenser 2-3 The inlet 2c is respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com