Efficient garbage combustion furnace

A waste combustion and efficient technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of air pollution, affecting the atmospheric environment, low combustion efficiency, etc., and achieve the goal of reducing emissions, improving combustion efficiency, and realizing resource recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

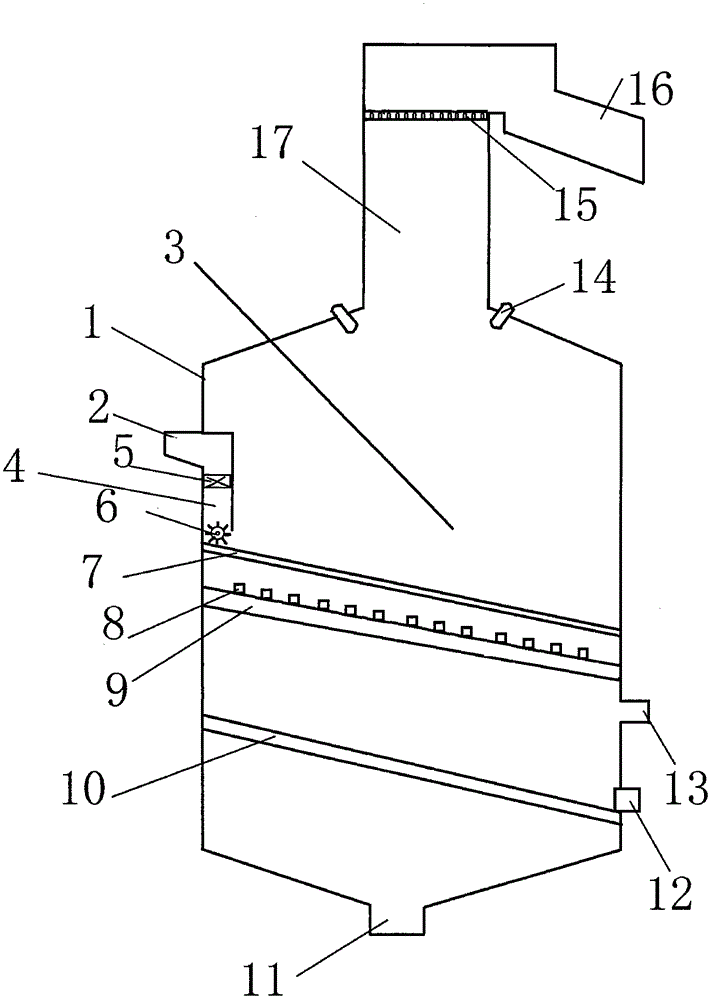

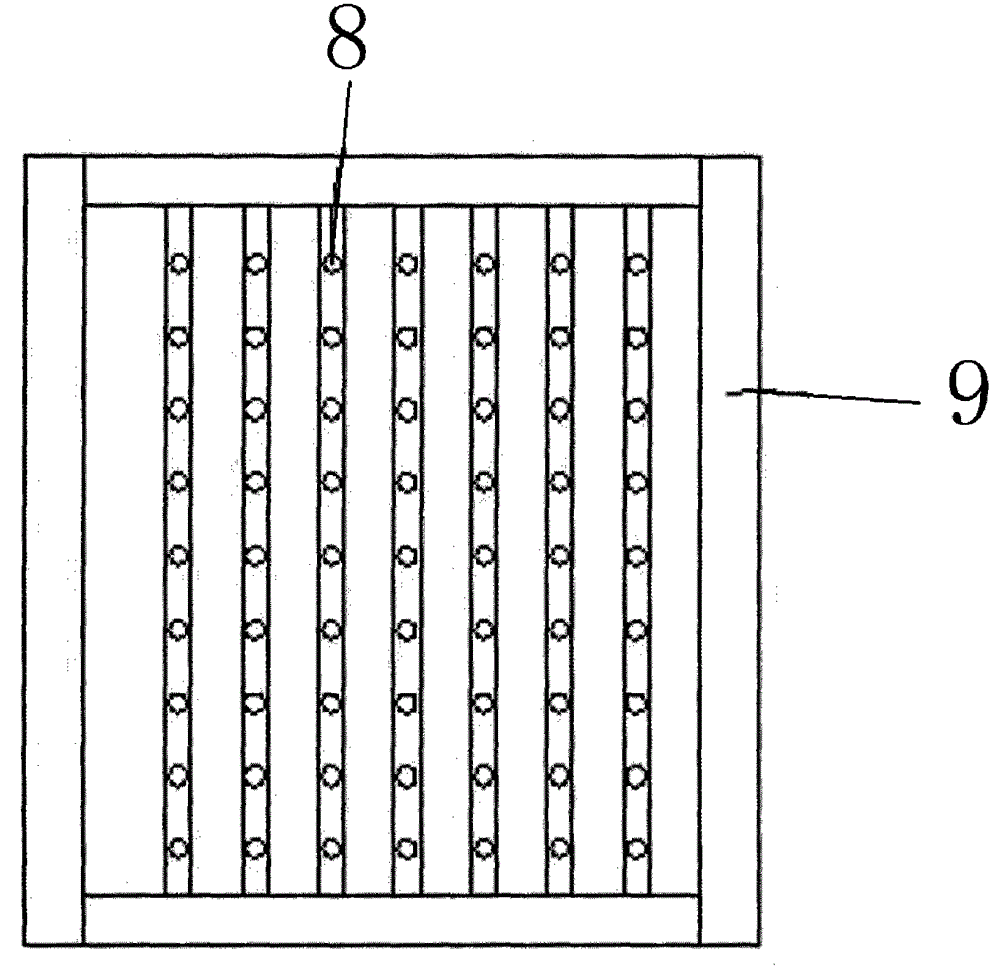

[0014] see Figure 1-2 , a high-efficiency garbage combustion furnace, comprising a furnace body 1, a garbage feeding port 2, a feeding pipe 4, a combustion net 7, a fire grate 9, a vibrating screen 10, an ash discharge port 11, a slag discharge port 12, a tuyere 13, Secondary air supply nozzle 14 and exhaust chimney 16, described furnace body 1 side is provided with garbage feeding port 2, and garbage feeding port 2 communicates with feeding pipe 4, is provided with pulverizer 5 in feeding pipe 4, pulverizes Machine 5 crushes the garbage into moderately sized fragments to ensure full garbage combustion, improve efficiency, and reduce harmful gases such as carbon monoxide and hydrides formed by insufficient combustion. The combustion net 7 is installed obliquely below, and the material spreading device 6 includes a rotating roller that is rotated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com