Anti-blocking feeding device

A feeding device and anti-clogging technology, applied in the field of feeding devices, can solve problems such as easy blockage and uncontrollable amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

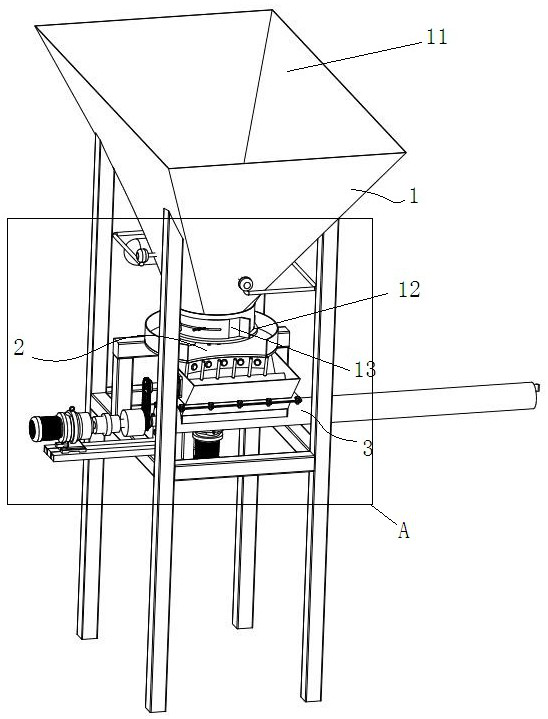

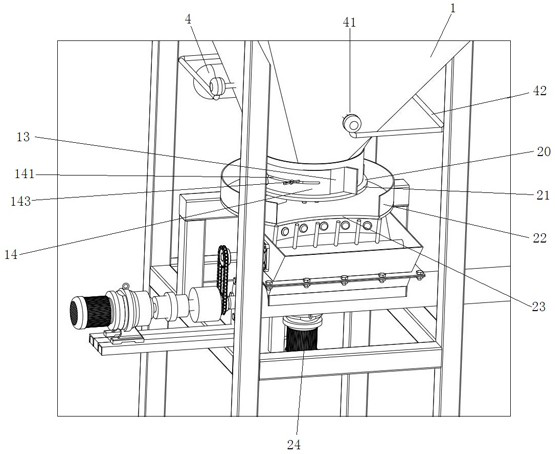

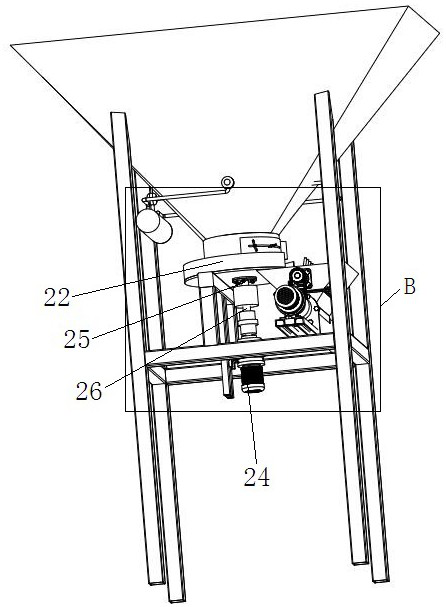

[0059] This embodiment provides a kind of anti-clogging feeding device, such as Figure 1-2 As shown, it includes: a hopper 1 for temporarily storing materials, with a material inlet 11, a bottom outlet 12 and a side outlet 13, the bottom outlet 12 opens downward, and the side outlet 13 It is arranged on the lower side wall of the hopper 1 and communicates with the bottom outlet 12; the discharge structure 2 is arranged below the bottom outlet 12 for controlling the flow from the hopper 1 through the The amount of material discharged from the bottom discharge port 12 and / or the side discharge port 13; the conveying device 3, arranged downstream of the discharge structure 2, is used to receive and convey the material from the discharge structure.

[0060] The anti-clogging feeding device of this embodiment is mainly used for conveying small pieces of material, or materials that are easy to stick but not particularly viscous (such as wet activated carbon). After the material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com