Environment-friendly and efficient waste incineration device

A waste incineration and high-efficiency technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of non-falling leakage holes, safety hazards, blockages, etc., to achieve good environmental protection, speed up incineration, efficient and fast processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

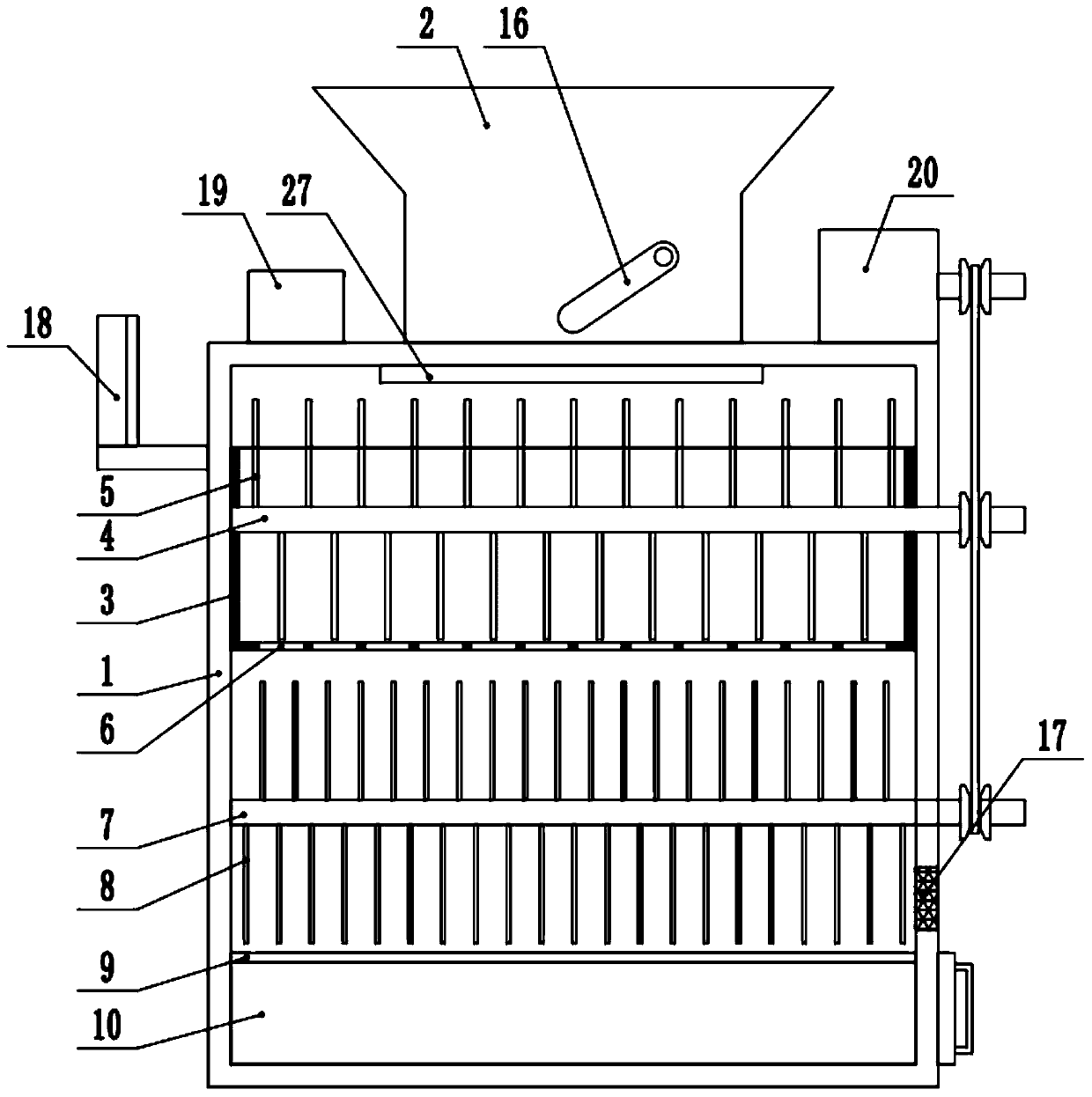

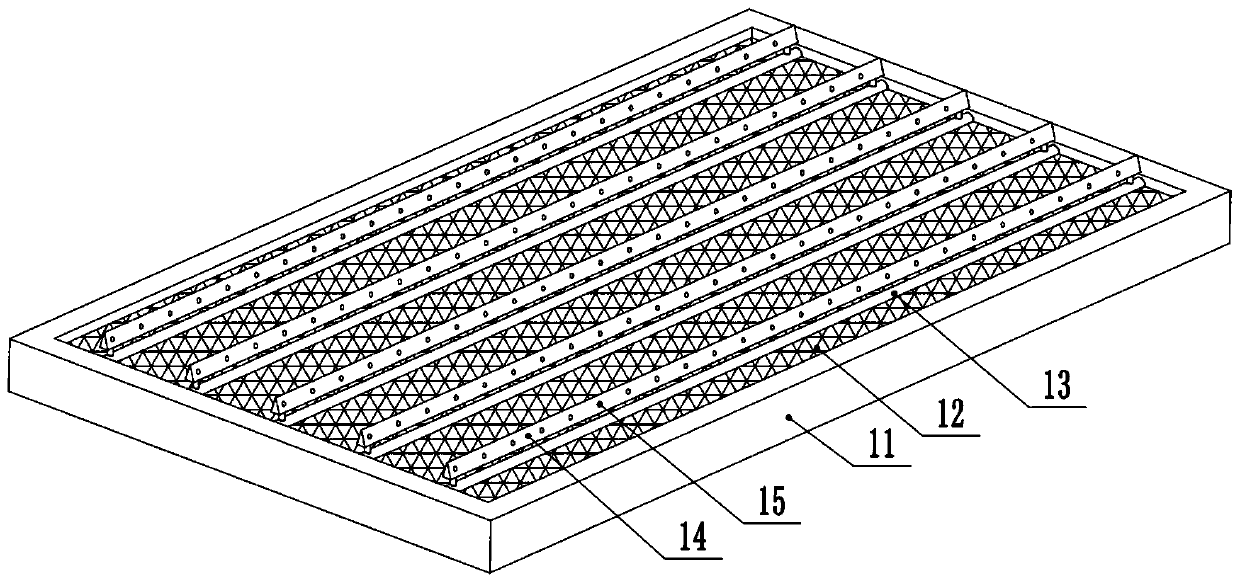

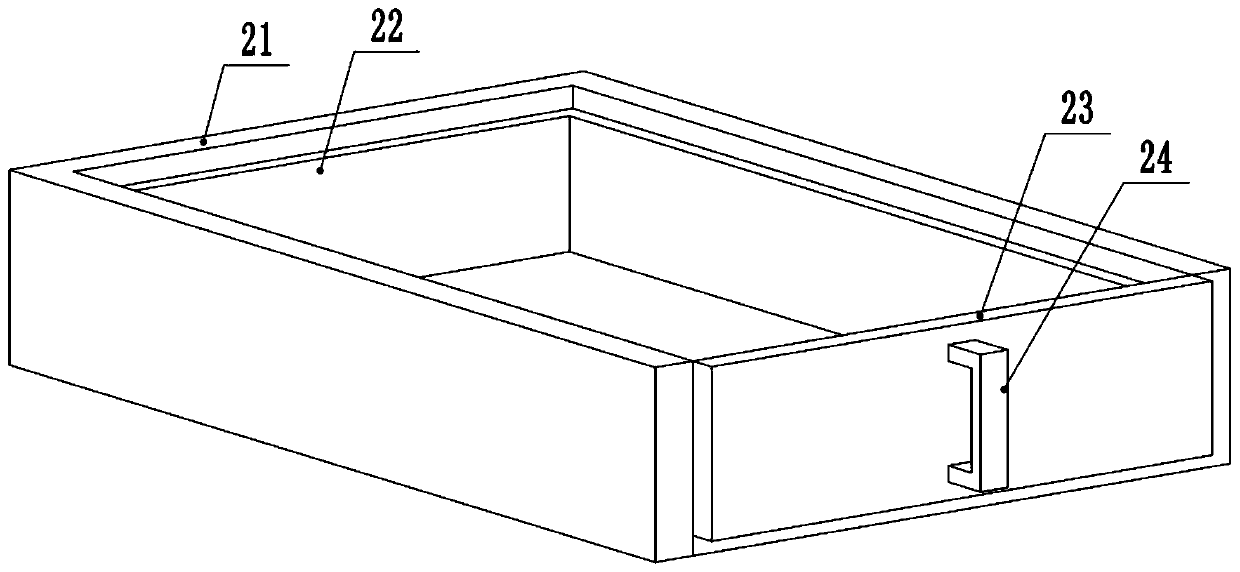

[0024] see Figure 1-4 , an environmentally friendly and efficient garbage incineration device, comprising an incineration box 1, the top of the incineration box 1 is fixedly connected to a hopper 2, and a first incineration mechanism and a second incineration mechanism are arranged in the incineration box 1, and the first incineration mechanism includes a screening cover 3. The bottom end of the screening cover 3 is provided with a feeding port 6, the inside of the screening cover 3 is rotatably connected to the first crushing shaft 4, and a plurality of first crushing blades 5 are fixedly connected to the first crushing shaft 4, and the top of the incineration box 1 is fixed Connect the flame-spraying ring 27, the second incineration mechanism includes a second crushing shaft 7, a plurality of second crushing blades 8 are fixedly connected on the second crushing shaft 7, a bottom separation device 9 is provided below the second incineration mechanism, and the bottom separatio...

Embodiment 2

[0027] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the feed hopper 2 is provided with a material distribution mechanism, and the material distribution mechanism includes a rotating shaft 25 that is rotatably connected with the feed hopper 2, and the rotation The shaft 25 is fixedly connected with a plurality of fixed plates 26 , and one end of the rotating shaft 25 passes through the feed hopper 2 and is fixedly connected with the crank handle 16 .

[0028] The present invention can crush and burn the garbage twice by setting the first incineration mechanism and the second incineration mechanism, so that the incineration speed of the garbage can be accelerated, and the products after the incineration of the garbage can be crushed, so that it is convenient for processing and transportation. The processing is efficient and fast, and the environmental protection is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com