Main body and grate running unit of life garbage incinerator

A technology of domestic waste incineration and operation device, applied in incinerators, grate, combustion method and other directions, can solve problems such as affecting the operation of the grate, easy cracking of the furnace, and lack of loosening devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] (Embodiment 1, grate operating device)

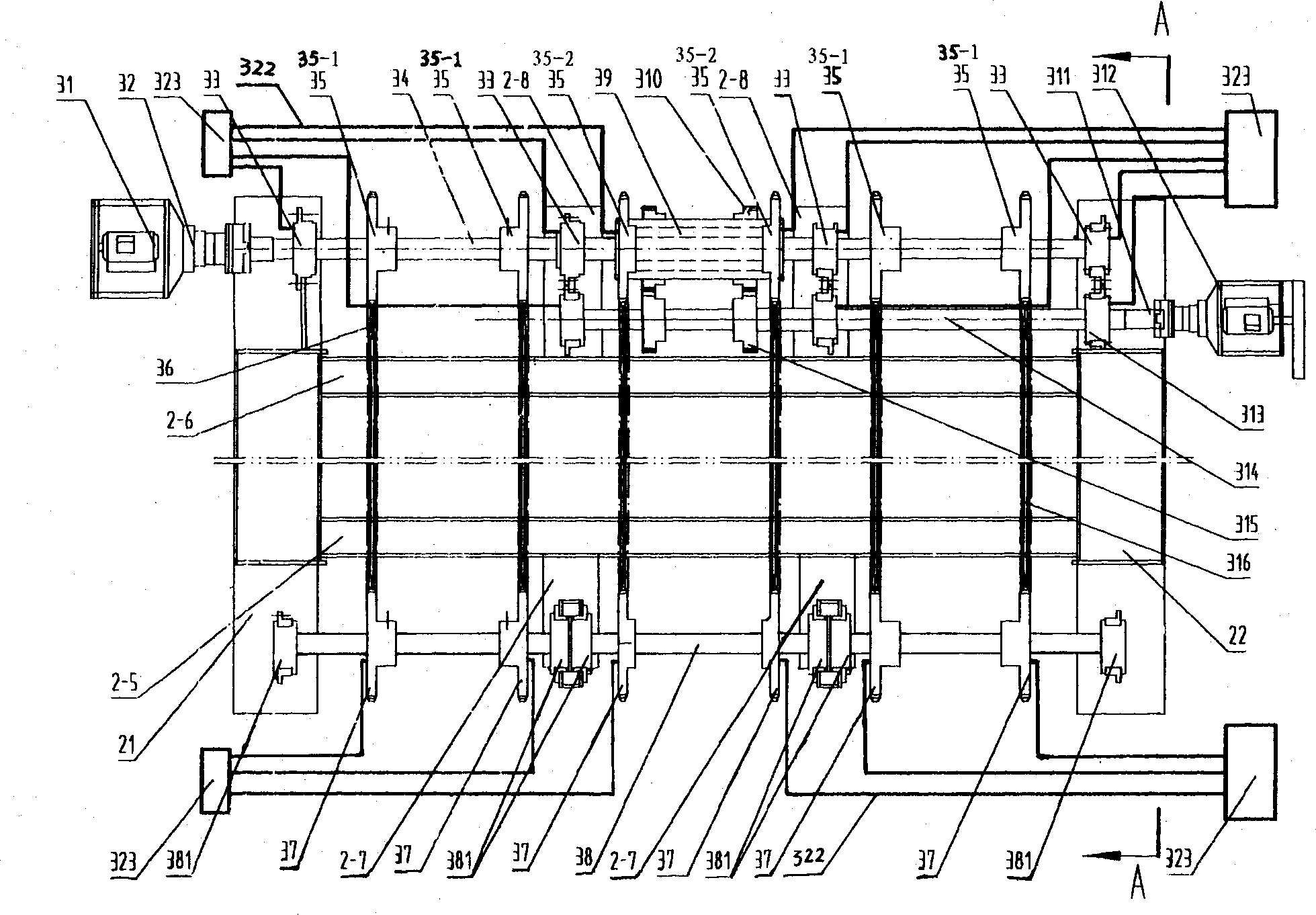

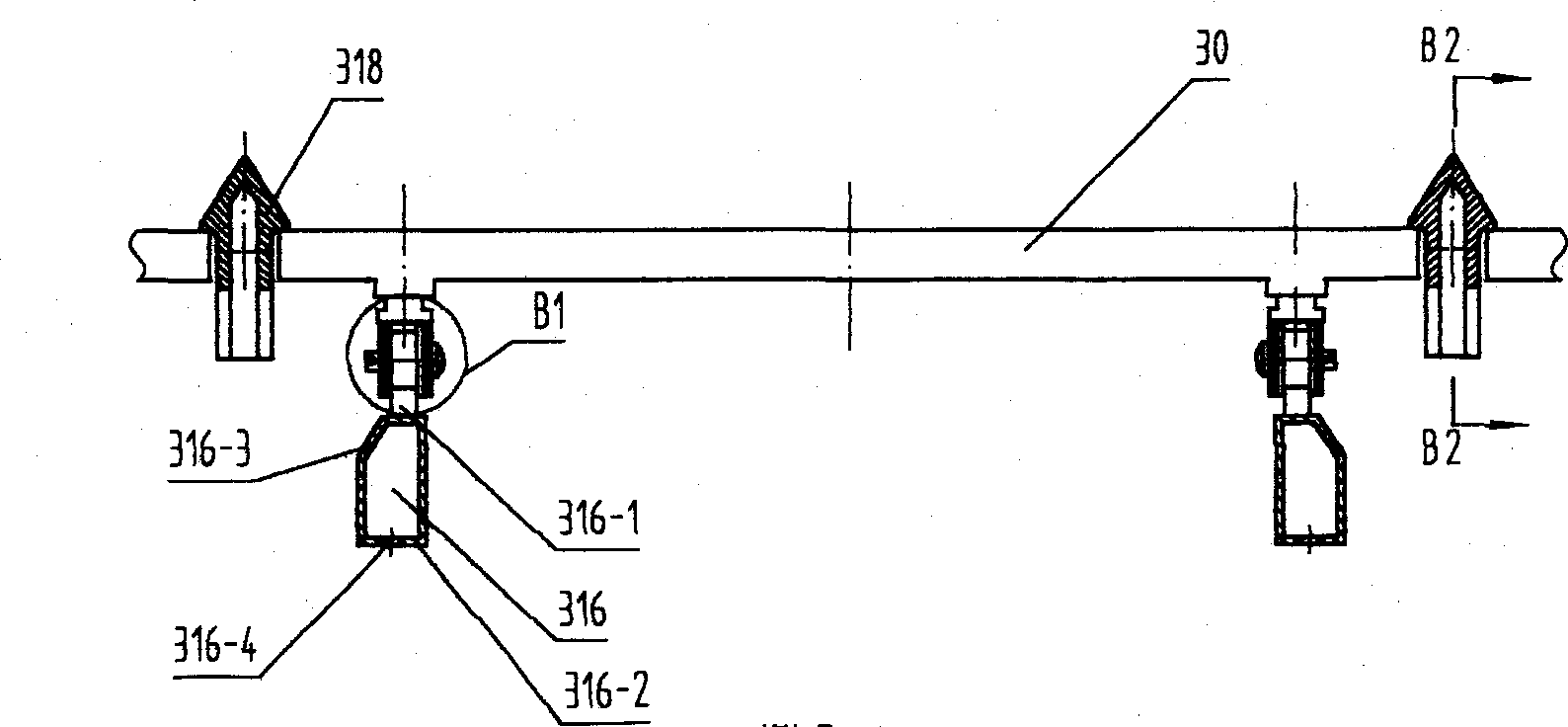

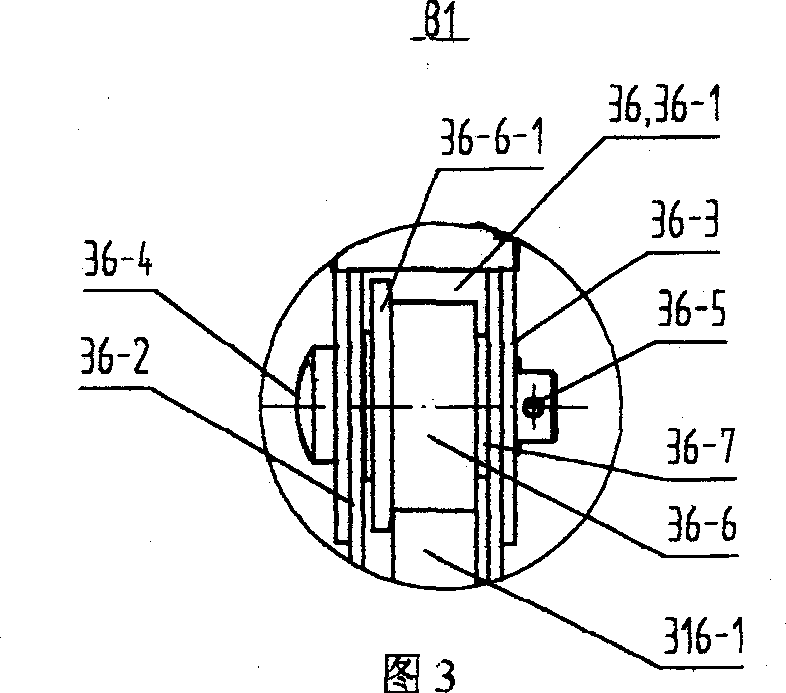

[0063] See figure 1, the grate operating device 3 of the present embodiment has a furnace base 2, six guide rails 316, a main reduction unit 31, a driving shaft 34, a driving shaft bearing, a driving shaft bearing seat 33, an auxiliary reduction unit 312, an auxiliary driving shaft 314, an auxiliary driving Shaft bearing, sub-drive shaft bearing seat 313, sleeve shaft 39, sleeve shaft bearing, driven shaft 38, driven shaft bearing, driven shaft bearing seat 381 and grate components. The driving shaft bearing block 33, the auxiliary driving shaft bearing block 313, the driven shaft bearing block and the guide rail 316 are all fixed on the furnace base 2. The driving shaft bearing is arranged on the driving shaft bearing seat 33, the driving shaft 34 is rotatably connected with the driving shaft bearing seat 33 through the driving shaft bearing, and the driving shaft 34 is connected with the main reduction unit 31. The middle par...

Embodiment 2

[0072] (Embodiment 2, grate operating device)

[0073] The rest are the same as in Embodiment 1, except that the connection between the secondary drive shaft 314 and the sleeve shaft 39 is a chain drive connection; the secondary drive shaft 314 is fixed with 2 active secondary sprockets, and the sleeve shaft 39 is fixed with corresponding 2 sprockets. Each driving secondary sprocket is meshed with a corresponding chain, and each chain is meshed with a corresponding driven secondary sprocket.

Embodiment 3

[0074] (Embodiment 3, the main body of the refuse incinerator)

[0075] See Figure 10 , Furnace base 2 is fixedly connected successively by four furnace base sections of furnace base front section 2-1, first furnace base middle section 2-2, second furnace base middle section 2-3 and furnace base tail section 2-4. Each furnace base section in turn comprises a left box beam 21, a right box beam 22, a cover plate 23, a bottom plate 25, a bracket support beam 28 and a bracket support 28-1. The furnace base front section 2-1 has a rear sealing plate 23, and all the other furnace base sections have two sealing plates 23, which are divided into a front sealing plate and a rear sealing plate. There is a gap for the passage of the fire grate under the sealing plate 23 within the fire grate operating range. The sealing plate 23 and the bottom plate 25 are fixedly connected with the left box beam 21 and the right box beam 22 at the same time. The sealing plate 23 not only plays the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com