Method for recovering rhodium from rhodium-containing waste liquid

A technology of waste liquid and concentrated liquid, which is applied in the field of rhodium recovery, can solve the problems of low loss of rhodium, large loss of rhodium, and high price of rhodium metal, and achieve the effects of reducing loss of rhodium, increasing incineration speed, and high degree of rhodium enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

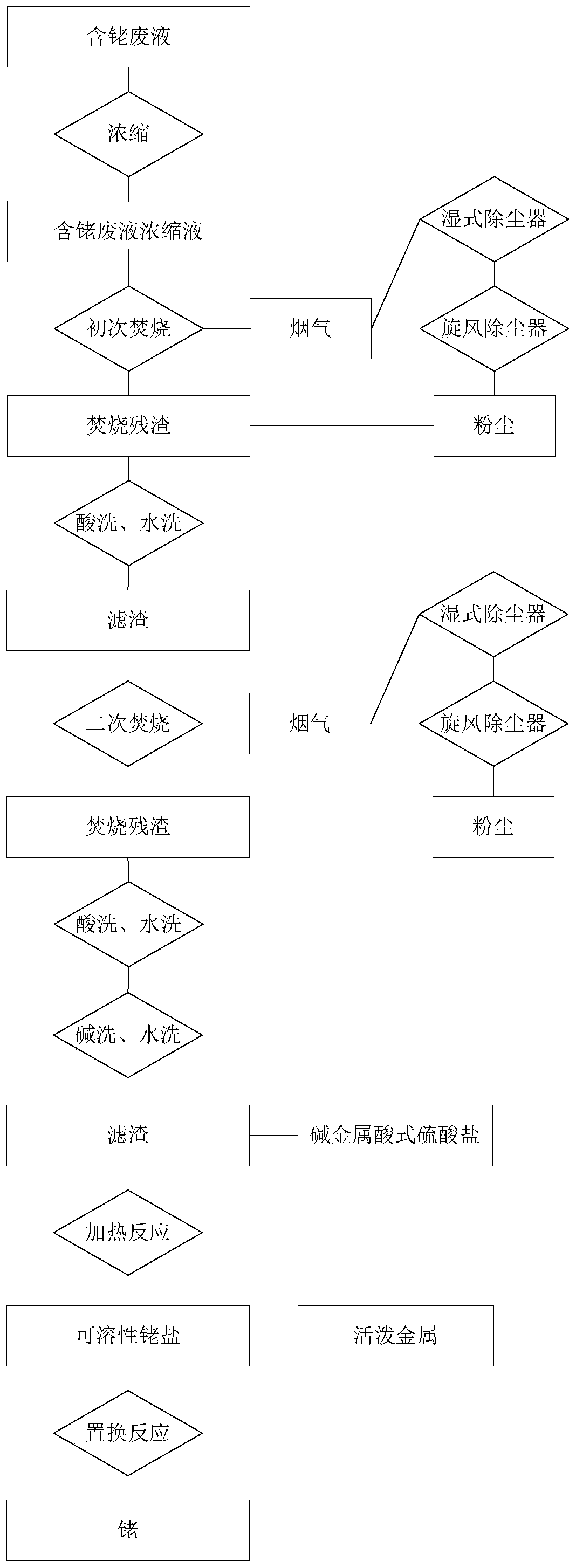

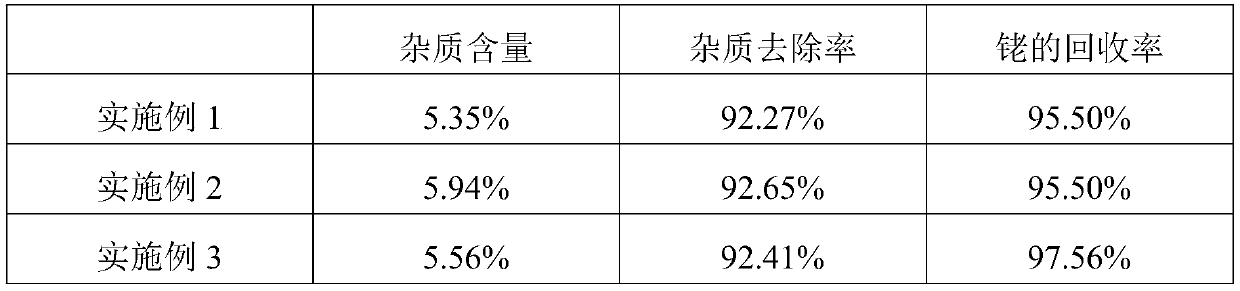

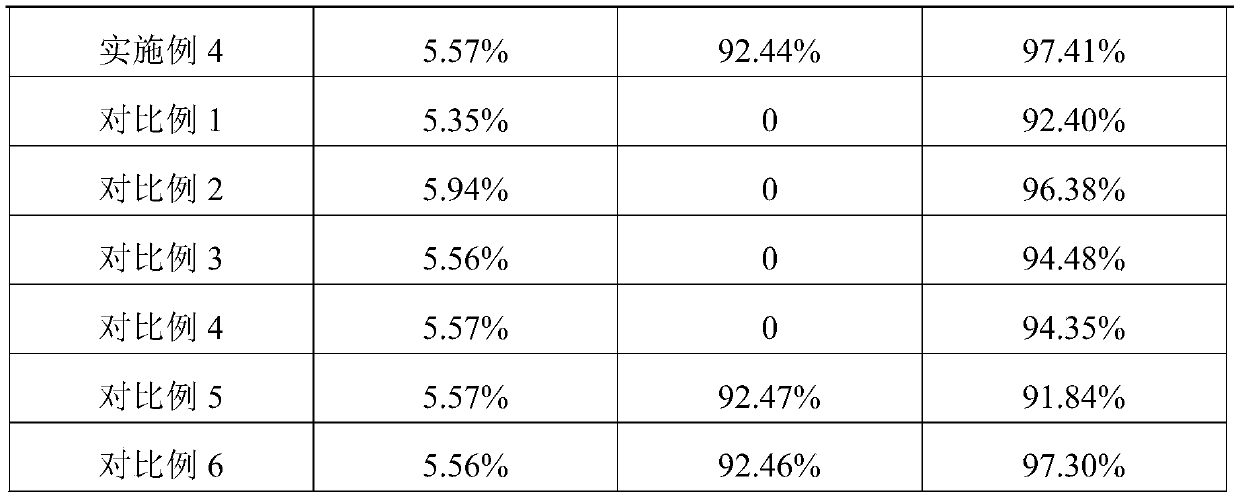

[0052] The method for reclaiming rhodium from rhodium-containing waste liquid comprises the following steps:

[0053] 1) Pour the rhodium-containing waste liquid into the concentration kettle to concentrate, and steam the light components; the concentration conditions are: vacuum degree 0.08MPa, concentration temperature 100°C, and the concentration end point is: the volume of the rhodium-containing waste liquid concentrate is 100°C. 20% of the total volume of waste liquid;

[0054] 2) Add wood chips to the rhodium-containing waste liquid concentrated solution obtained in step 1), the addition of wood chips is 10% of the quality of the rhodium-containing waste liquid concentrated liquid, after stirring evenly, put it into an incinerator for initial burning, the initial burning The temperature is 800°C, the incineration time is 8 hours, the incinerator is connected with a wet dust collector and a cyclone dust collector, the flue gas is collected through the wet dust collector a...

Embodiment 2

[0069] The method for reclaiming rhodium from rhodium-containing waste liquid comprises the following steps:

[0070] 1) Pour the rhodium-containing waste liquid into the concentration kettle to concentrate, and steam the light components; the concentration conditions are: vacuum degree 0.1MPa, concentration temperature 500°C, and the concentration end point is: the volume of the rhodium-containing waste liquid concentrate 30% of the total volume of waste liquid;

[0071] 2) add sawdust to the rhodium-containing waste liquid concentrate that step 1) obtains, the addition of sawdust is 100% of the quality of the rhodium-containing waste liquid concentrate, after stirring evenly, put into an incinerator and carry out initial incineration, the initial incineration The temperature is 1000°C, the incineration time is 12 hours, the incinerator is connected with a wet dust collector and a cyclone dust collector, the flue gas is collected through the wet dust collector and the cyclone...

Embodiment 3

[0086] The method for reclaiming rhodium from rhodium-containing waste liquid, comprises the following steps:

[0087] 1) pour the rhodium-containing waste liquid into the concentration kettle and concentrate, and steam out the light components; the concentration conditions are: vacuum tightness 0.1MPa, concentration temperature 300 ℃, and the concentration end point is: the volume of the rhodium-containing waste liquid concentrate is that the rhodium-containing waste liquid is concentrated. 25% of the total volume of waste liquid;

[0088] 2) in the rhodium-containing waste liquid concentrated solution obtained in step 1), add wood chips, the add-on of wood chips is 50% of the rhodium-containing waste liquid concentrated solution quality, after stirring, put into the incinerator and carry out initial incineration, the initial incineration of The temperature is 900°C, and the incineration time is 10h. The incinerator is connected to a wet dust collector and a cyclone dust coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com