Environmentally-friendly incinerator for solid waste product disposal

A technology for incinerators and waste products, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low combustion efficiency, easy accumulation of carbon ash, and difficulty in cleaning the furnace body, so as to enhance flexibility and improve incineration speed. , the effect of increasing the incineration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

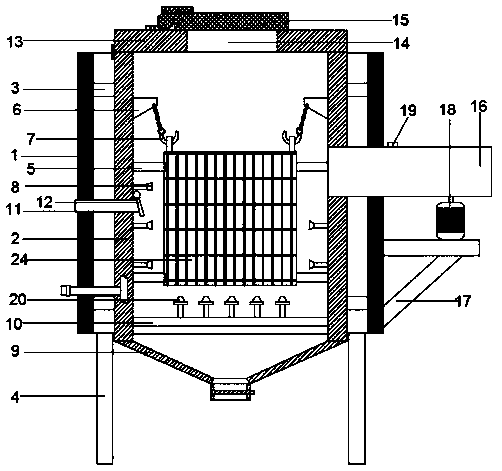

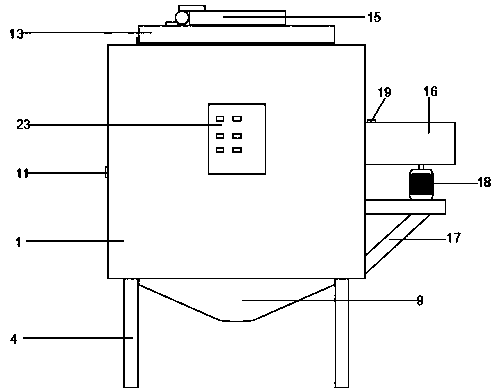

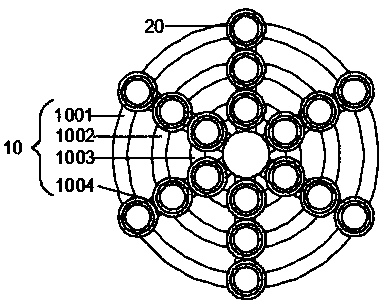

[0038] as attached figure 1 To attach Figure 9 Shown:

[0039]The invention provides an environmentally friendly incinerator for solid waste treatment, including a protective barrel 1, a combustion barrel 2, a connecting rod 3, a support column 4, a fixed ring 5, a fixed seat 6, a hook 7, a nozzle 8, and an ash discharge port 9. Nozzle seat 10, round pipe A1001, round pipe B1002, round pipe C1003, hollow cylinder 1004, air intake pipe 11, air inlet door 12, furnace cover 13, feed port 14, feed port cover 15, smoke exhaust pipe 16. Motor bracket 17, motor 18, filter sheet 19, 1901 iron gauze, 20 nozzle protection structure, cylindrical iron 2001, nozzle cover 2002, nozzle tray 2003, circular hole 2004, exhaust fan 21, bevel gear 22, control Box 23 and storage basket 24; the bottom end surface of the protective bucket 1 is welded with four support columns 4 in an annular array, and the outer wall of the right side of the protective bucket 1 is welded with a motor bracket 17; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com