Outdoor stalk incineration device and method convenient for clearing dust

A technology for incinerating devices and straws, which is applied in the direction of combustion methods, separation methods, chemical instruments and methods, etc., which can solve the problem of leaving a lot of dust on the filter screen, and achieve the effects of prolonging the service life, improving the use efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

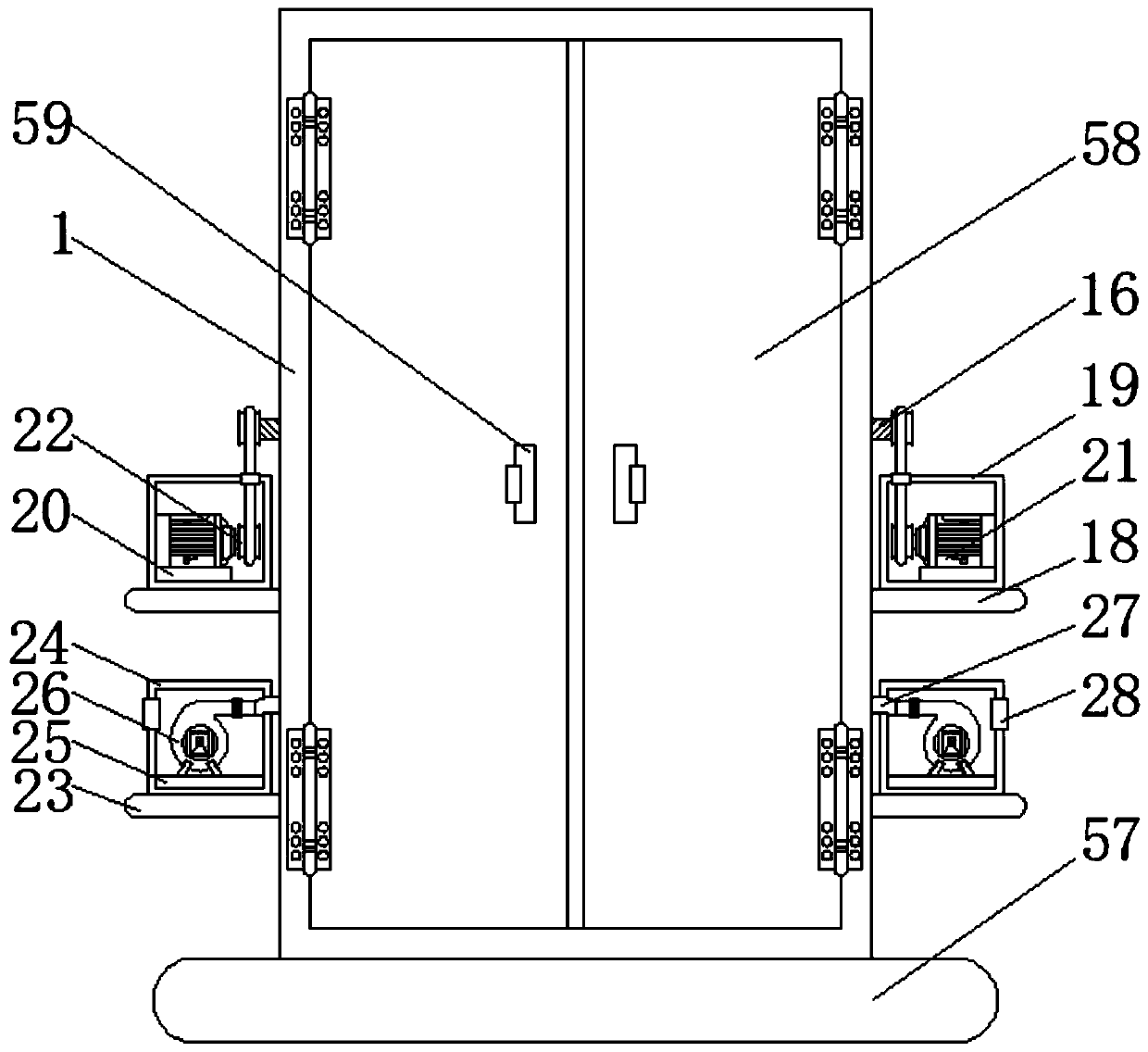

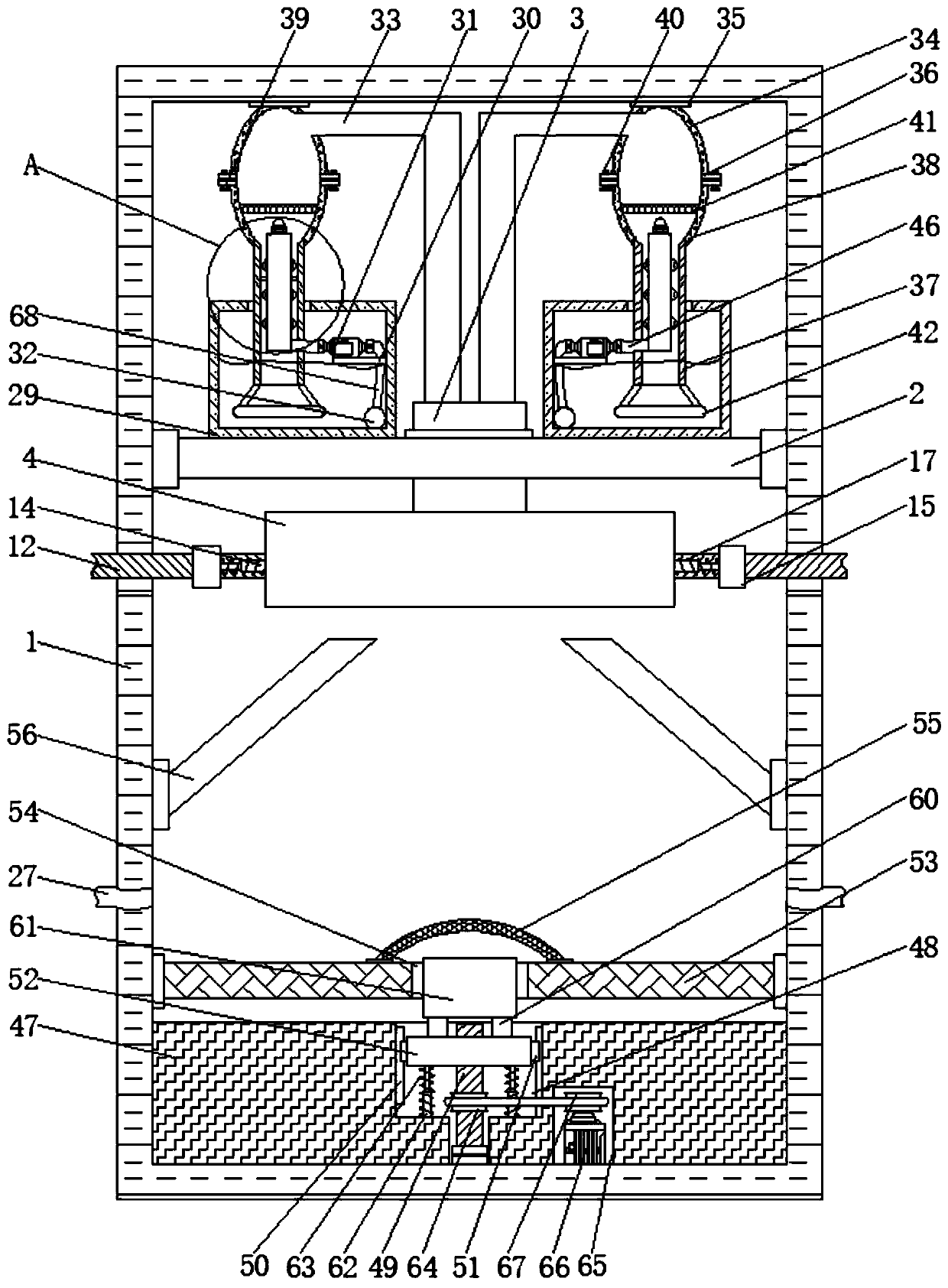

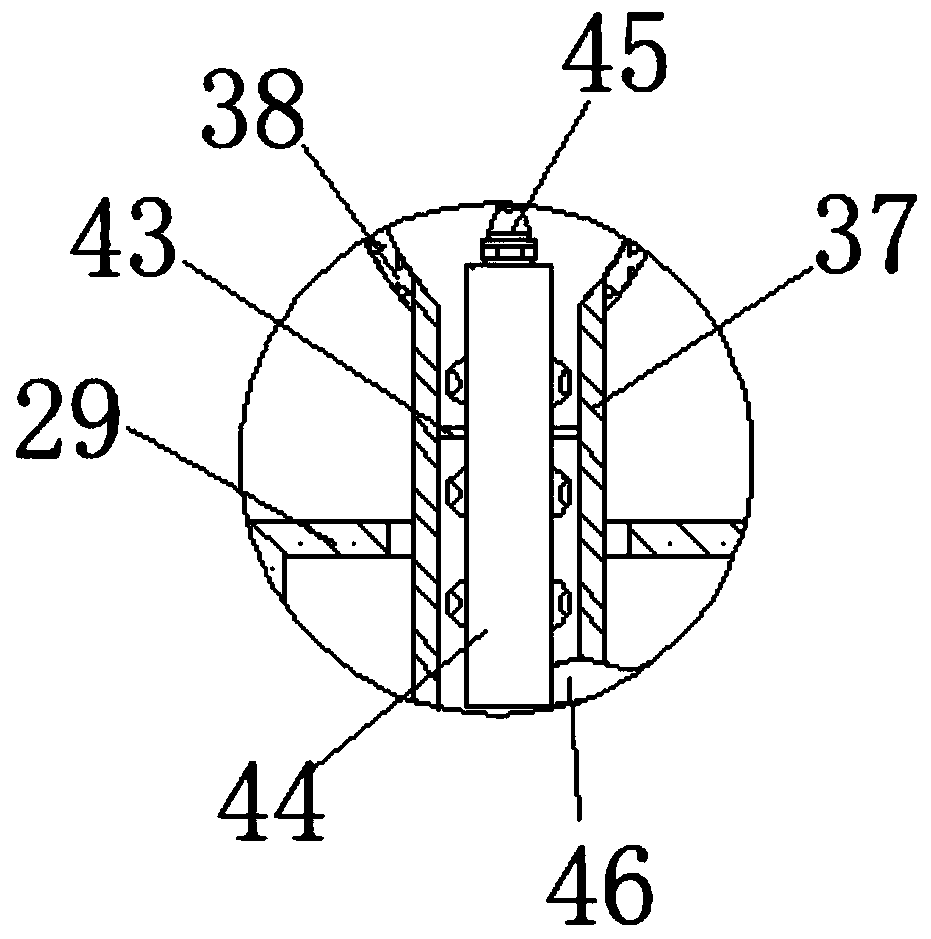

[0034] An outdoor straw incineration device for easy cleaning, comprising an incinerator body, a top plate is fixedly connected between the tops on both sides of the inner wall of the incinerator body, a thick tube is fixedly connected to the inside of the top plate, and the bottom of the thick tube The end is connected with a filter chamber, the interior of the filter chamber is fixedly connected with the first filter screen, and the top and bottom of the inner wall of the filter chamber are fixedly connected with sliding rods, and the two sides of the surface of the sliding rod are slidably connected There is a first slider, the surface of the slider is provided with a buffer spring between the opposite sides of the two first sliders, and the tops and bottoms of the two first sliders are fixedly connected There is a brush plate, and one side of the brush plate is fixedly connected with a brush, and the other side of the brush plate is fixedly connected with a moving plate, an...

Embodiment 2

[0037] An outdoor straw incineration device for easy cleaning, comprising an incinerator body, a top plate is fixedly connected between the tops on both sides of the inner wall of the incinerator body, a thick tube is fixedly connected to the inside of the top plate, and the bottom of the thick tube The end is connected with a filter chamber, the interior of the filter chamber is fixedly connected with the first filter screen, and the top and bottom of the inner wall of the filter chamber are fixedly connected with sliding rods, and the two sides of the surface of the sliding rod are slidably connected There is a first slider, the surface of the slider is provided with a buffer spring between the opposite sides of the two first sliders, and the tops and bottoms of the two first sliders are fixedly connected There is a brush plate, and one side of the brush plate is fixedly connected with a brush, and the other side of the brush plate is fixedly connected with a moving plate, an...

Embodiment 3

[0040] An outdoor straw incineration device for easy cleaning, comprising an incinerator body, a top plate is fixedly connected between the tops on both sides of the inner wall of the incinerator body, a thick tube is fixedly connected to the inside of the top plate, and the bottom of the thick tube The end is connected with a filter chamber, the interior of the filter chamber is fixedly connected with the first filter screen, and the top and bottom of the inner wall of the filter chamber are fixedly connected with sliding rods, and the two sides of the surface of the sliding rod are slidably connected There is a first slider, the surface of the slider is provided with a buffer spring between the opposite sides of the two first sliders, and the tops and bottoms of the two first sliders are fixedly connected There is a brush plate, and one side of the brush plate is fixedly connected with a brush, and the other side of the brush plate is fixedly connected with a moving plate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com