Garbage incinerator

A technology for waste incinerators and incinerators, which is applied to incinerators, combustion methods, combustion types, etc., can solve the problems of slow furnace heating rate, insufficient combustion of garbage, slow incineration, etc., to improve incineration speed, save energy, save energy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

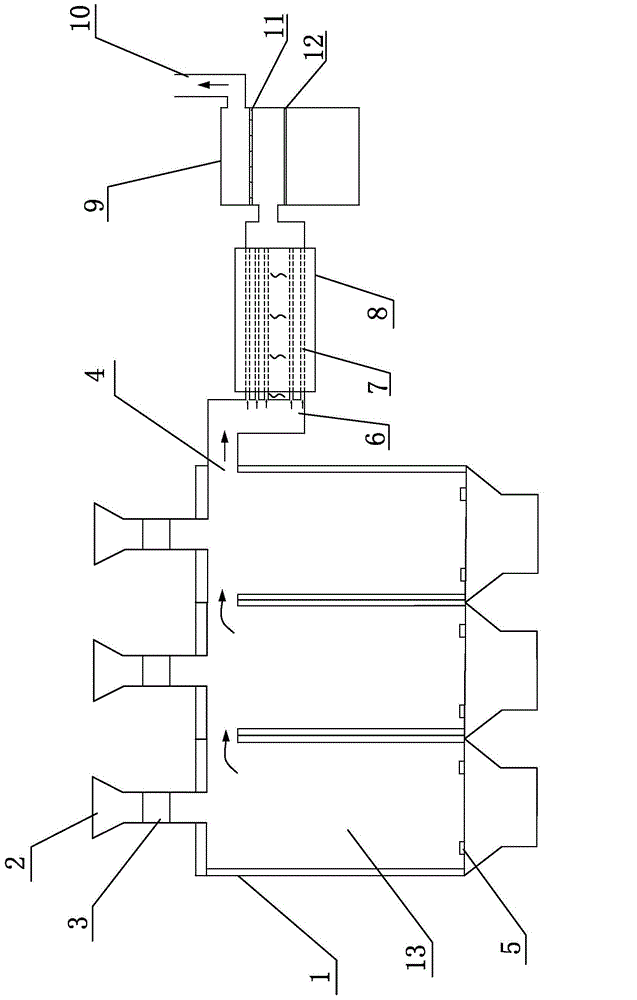

[0018] A garbage incinerator, comprising at least two incinerator bodies 1 arranged close to each other. The number of incinerator bodies 1 can be any integer number such as 2, 3, 4, etc. The present invention considers the actual needs and energy saving aspects Consider, preferred incinerator body 1 is 3, and its size is consistent, as figure 1 shown. Each incinerator body 1 is provided with a feed hopper 2 and a furnace 13, and the inner wall of the furnace 13 can be made of a metal material with good thermal conductivity coated with a refractory material, or other materials. The feed hopper 2 is arranged on the top of the incinerator body 1, and the feed hopper 2 is provided with an unloader 3, and further the unloader 3 is driven by a motor to automatically unload garbage. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com