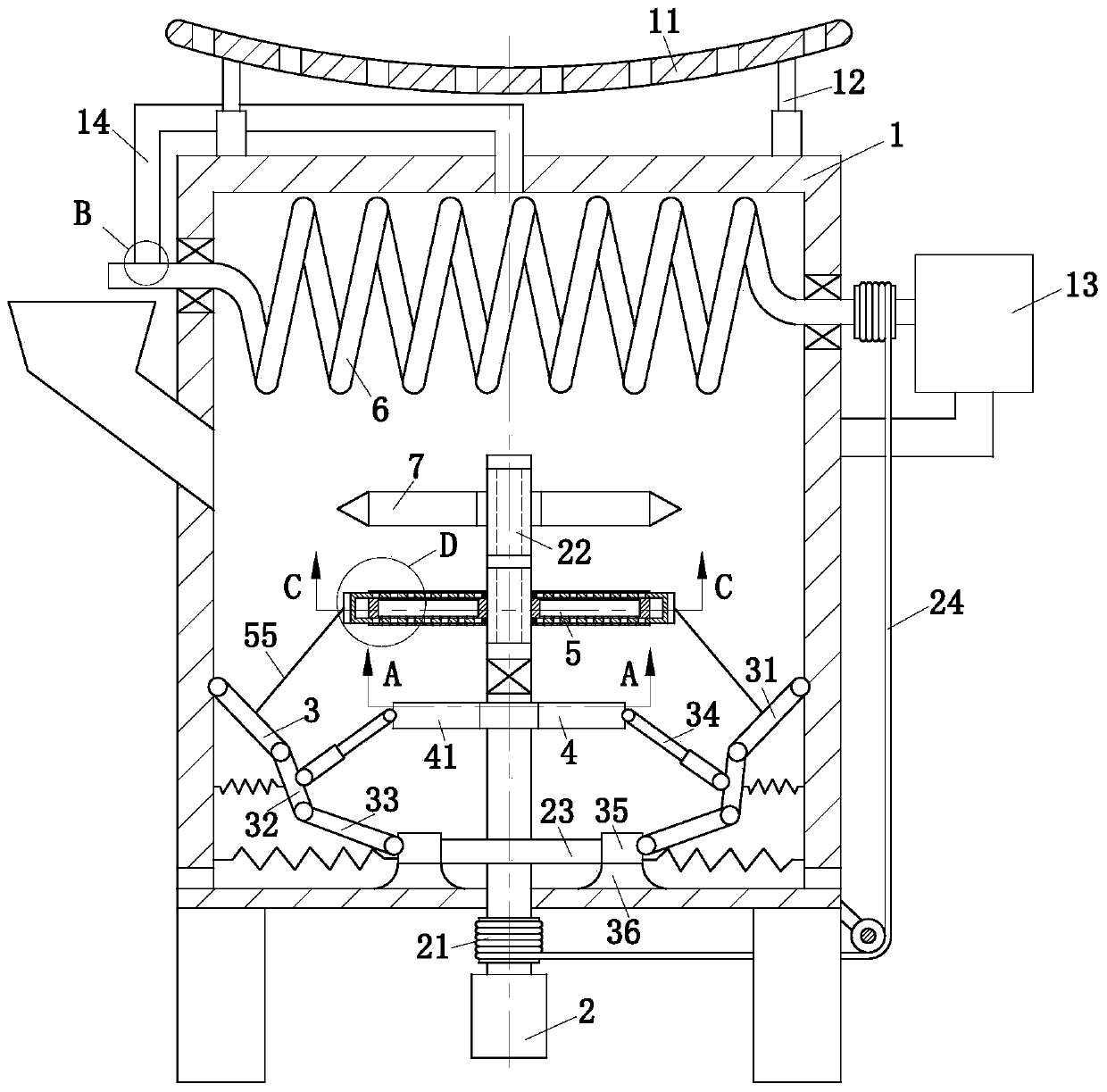

Environment-friendly heating furnace based on solar energy

A technology of solar energy and heating furnace, applied in the direction of air heater, fluid heater, lighting and heating equipment, etc., can solve the problems of insufficient burning of straw, affecting the quality and taste of grain, and bringing it into the grain drying device, etc. Increase the area of straw burning, improve the effect of straw burning, and improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

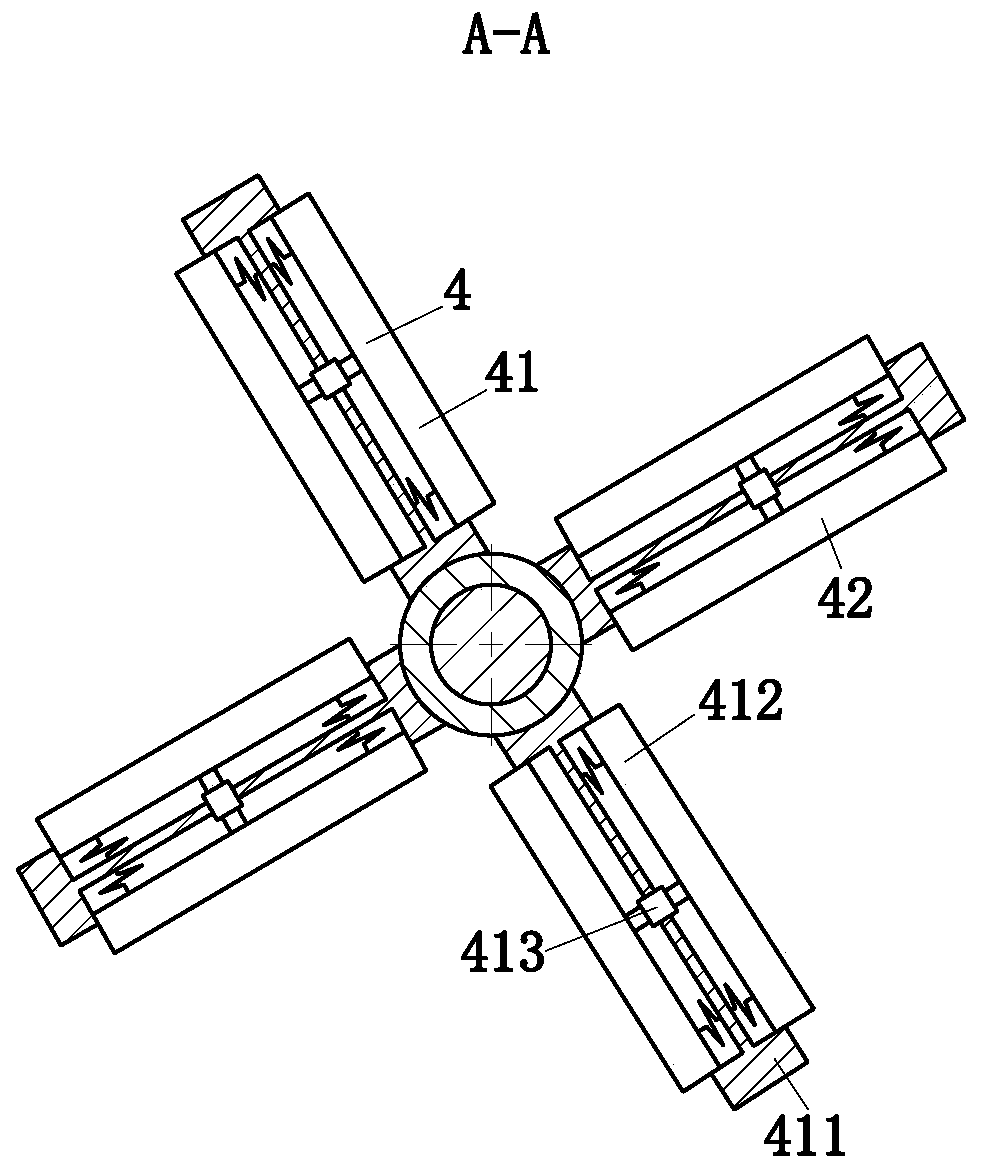

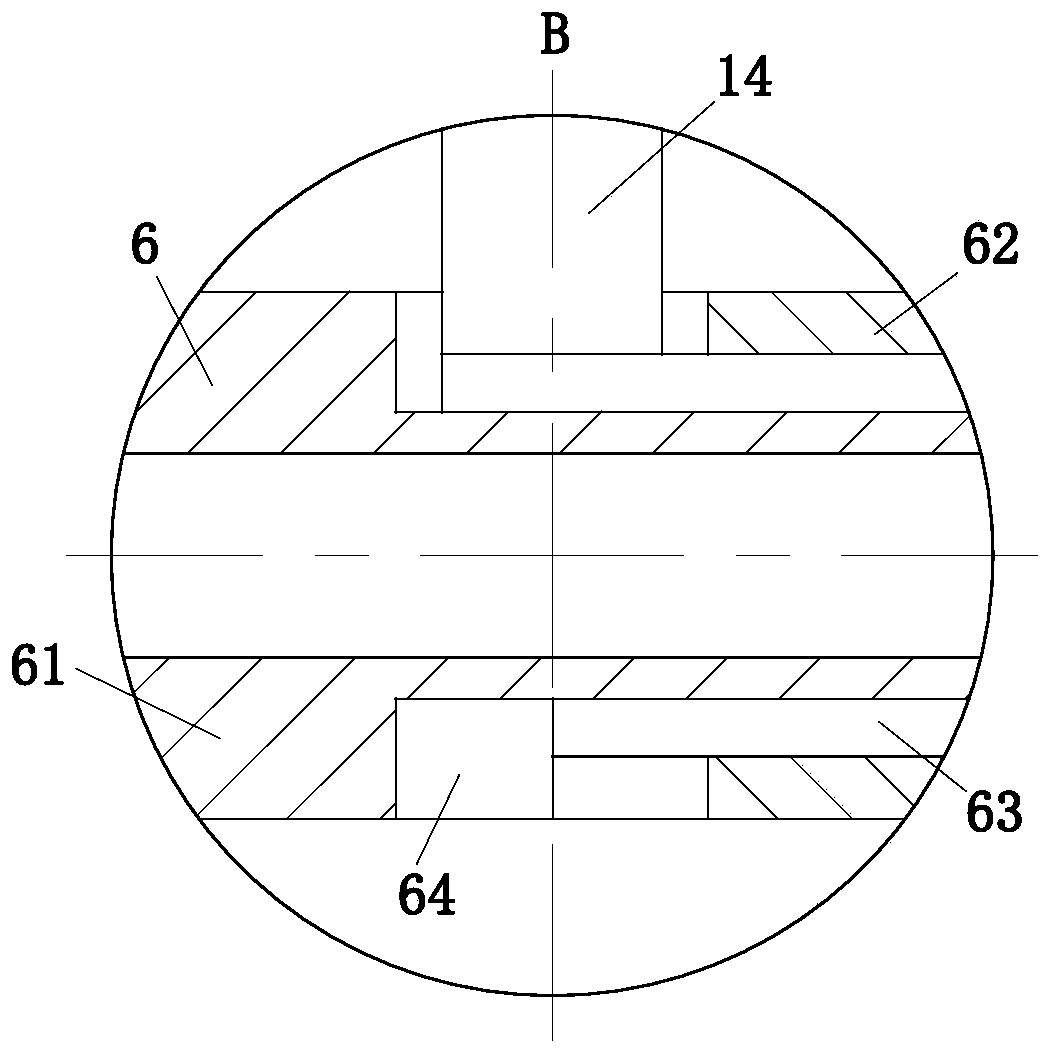

[0028] As an embodiment of the present invention, the No. 1 crushing knife 41 is composed of a crushing plate 411, a blade 412 and a double-headed cylinder 413; the crushing plate 411 is symmetrically provided with a No. 1 groove, and two No. 1 grooves are provided The connecting groove; the blade 412 is located at the No. 1 groove and is fixedly connected to the crushing plate 411 by a spring; the double-head cylinder 413 is located at the connecting groove and is fixedly connected to the side wall of the connecting groove, and the two ends of the double-head cylinder 413 are respectively Fixedly connected on the blade 412, the gas generated by the expansion and contraction of the telescopic rod 34 is sent to the double-headed cylinder 413 to control the expansion and contraction of the blade 412 and protect the blade 412. In the present invention, No. 1 crushing knife 41 is composed of crushing plate 411, blade 412 and double-headed cylinder 413; on the one hand, the gas powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com