Underground coal gasification

A process method, coal gasification technology, applied in coal gasification, underground mining, earth drilling and mining, etc., can solve problems such as airflow channel obstruction, gasification furnace deformation, energy consumption and drainage effect, etc., to reduce production costs and improve Drainage efficiency, the effect of improving the gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

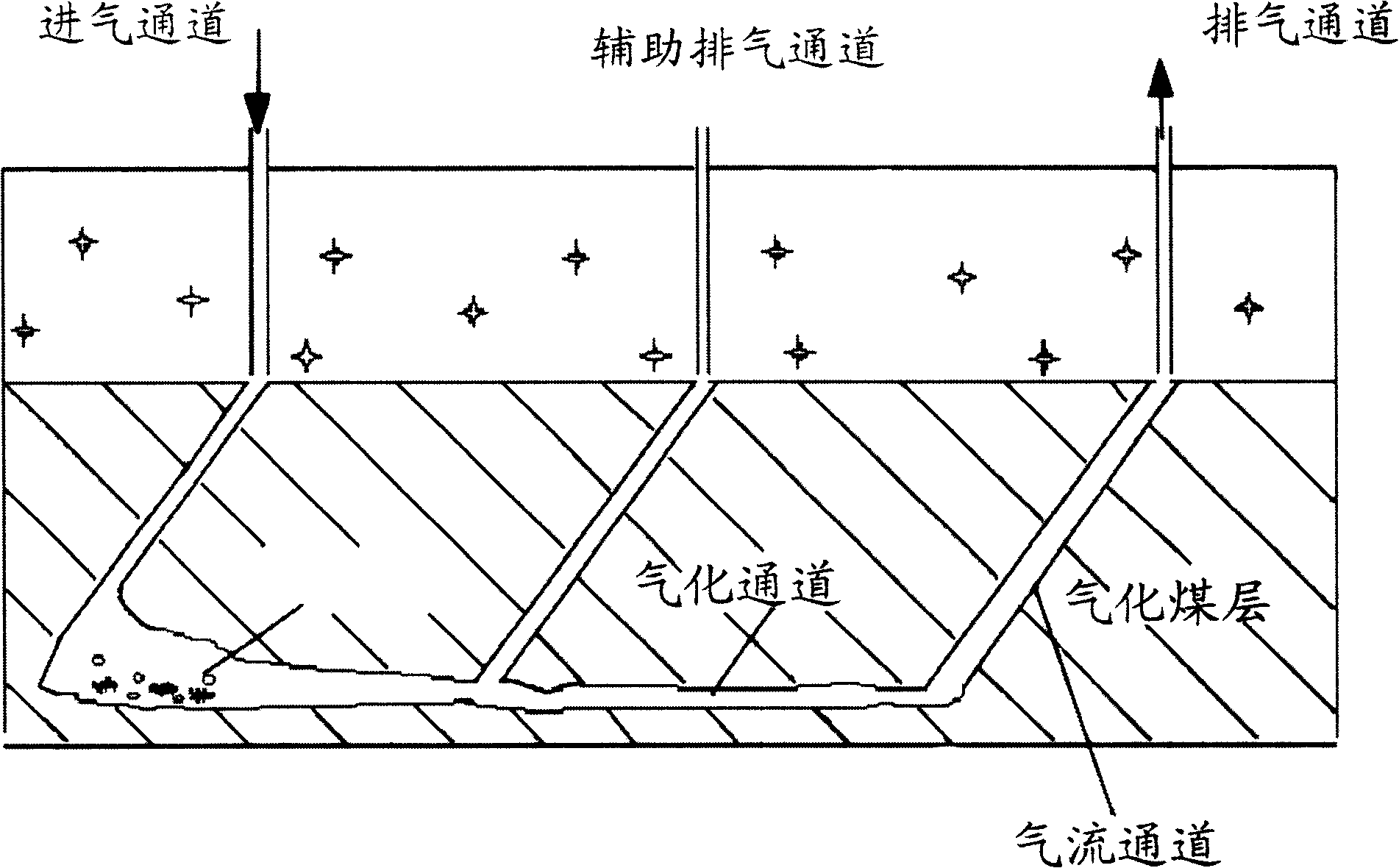

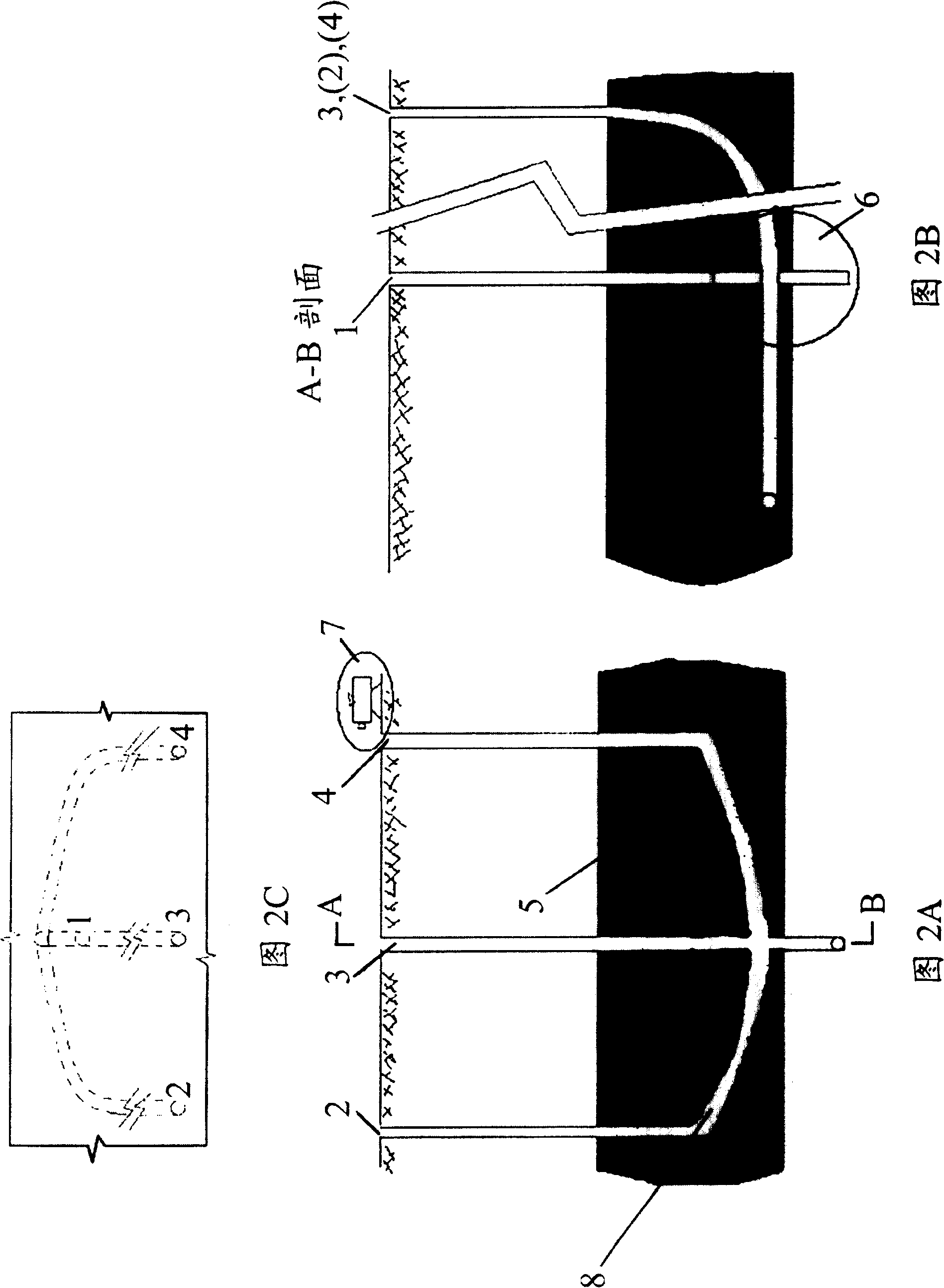

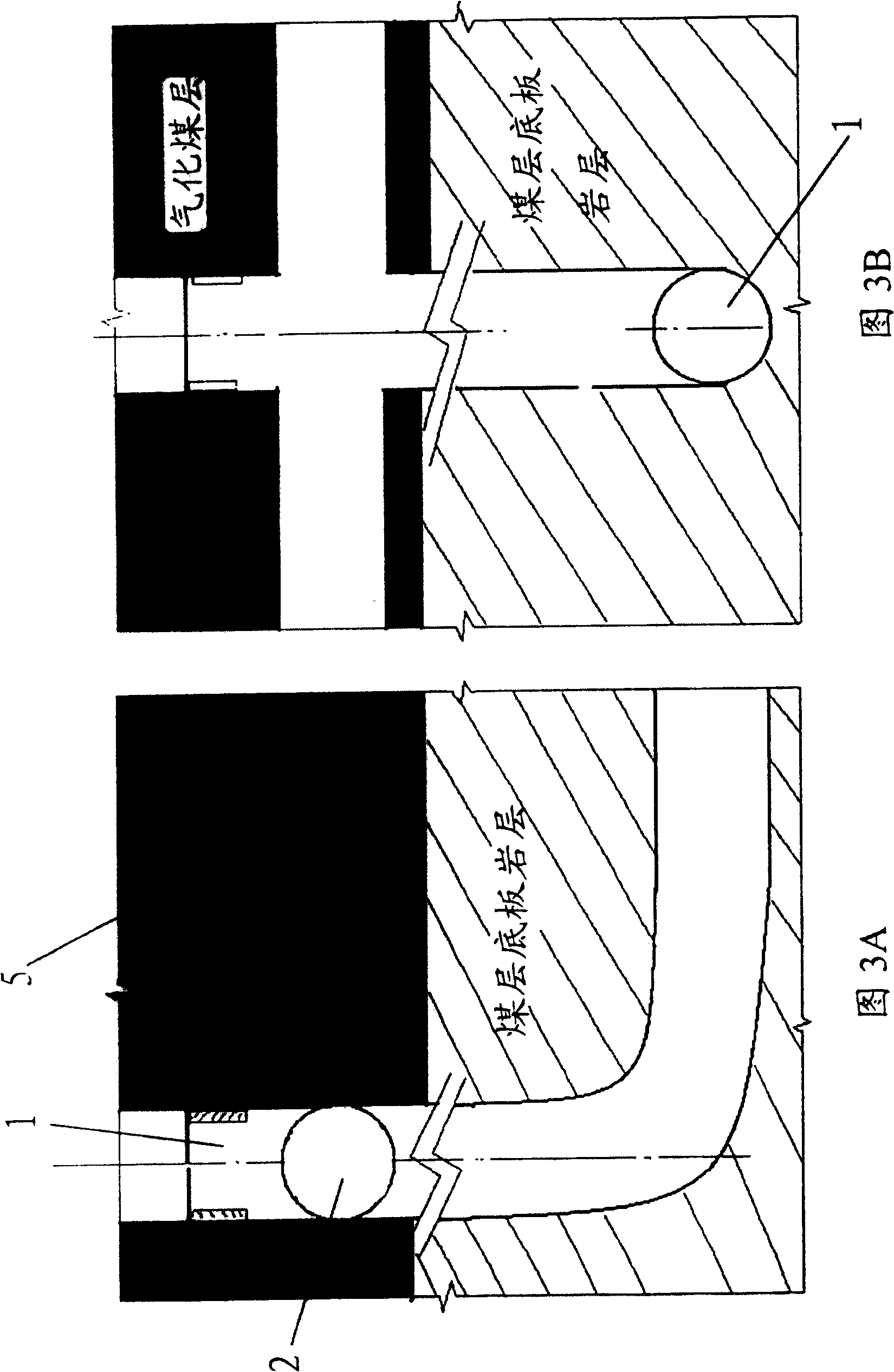

[0036] Please refer to Figures 2A, 2B, 3A, 3B and Figure 4 , The deep-seated (such as 1000 meters below) underground coal gasification process method of the present invention includes building an underground gasification furnace 8 in the coal seam 5 to be gasified, and drilling one end of the underground gasification furnace 8 to communicate with the ground The air inlet channel 2, and the air outlet channel 4 connected to the ground is drilled at the other end. The underground gasifier 8 forms a U-shaped structure with the air inlet channel 2 and the air outlet channel 4, and an auxiliary is provided in the middle of the U-shaped structure. Outlet channel 3. In fact, the shape formed between the gasifier 8 and the air inlet channel 2 and the air outlet channel 4 is not limited to the U shape, as long as the air inlet channel 2 and the air outlet channel 4 communicate with the gasifier 8 and are beneficial to coalbed methane. Chemical combustion and gas discharge are sufficient. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com