Energy-saving and environment-friendly boiler with preheating function

An energy saving, environmental protection, boiler technology, applied in the field of boilers, can solve the problems of inability to use heat, damage to the surrounding environment, low heat utilization rate, etc., and achieve the effects of reducing soot, large combustion area, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

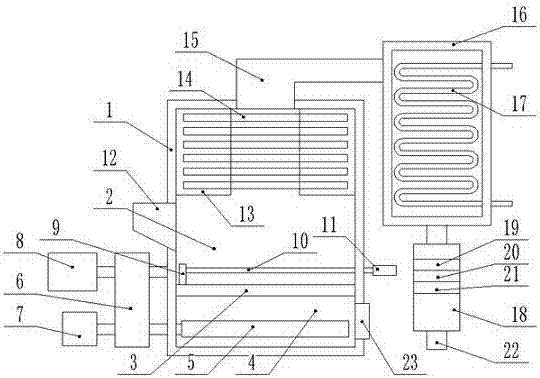

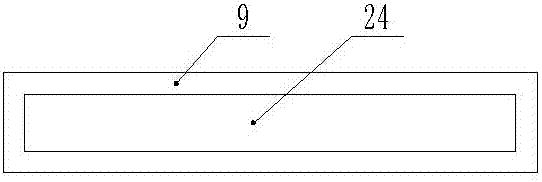

[0015] Please refer to the figure, in the embodiment of the present invention, an energy-saving and environment-friendly boiler with preheating includes a shell 1, a furnace grate 3, a slag collection tank 4, a circulation pump 7 and a fan 8; the furnace grate 3 is fixed Installed in the housing 1, the combustion chamber 2 is set above the grate 3, and the slag collection tank 4 is set below, and a vertical equalizing plate 9 is set on the upper surface of the grate 3, and the equalizing plate 9 is provided with a feed opening 24 that runs through both sides, so that the fuel can pass through the feed opening 24 when the uniform material plate 9 moves left and right. The uniform material plate 9 is fixedly connected with a horizontal connecting rod 10, and the connecting rod 10 passes through Out of the housing 1, a handle 11 is fixed on the outer end of the connecting rod 10. People manually pull the connecting rod 10 to move the equalizing plate 9 to scrape off the slag on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com