Patents

Literature

32results about How to "Effective use of volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

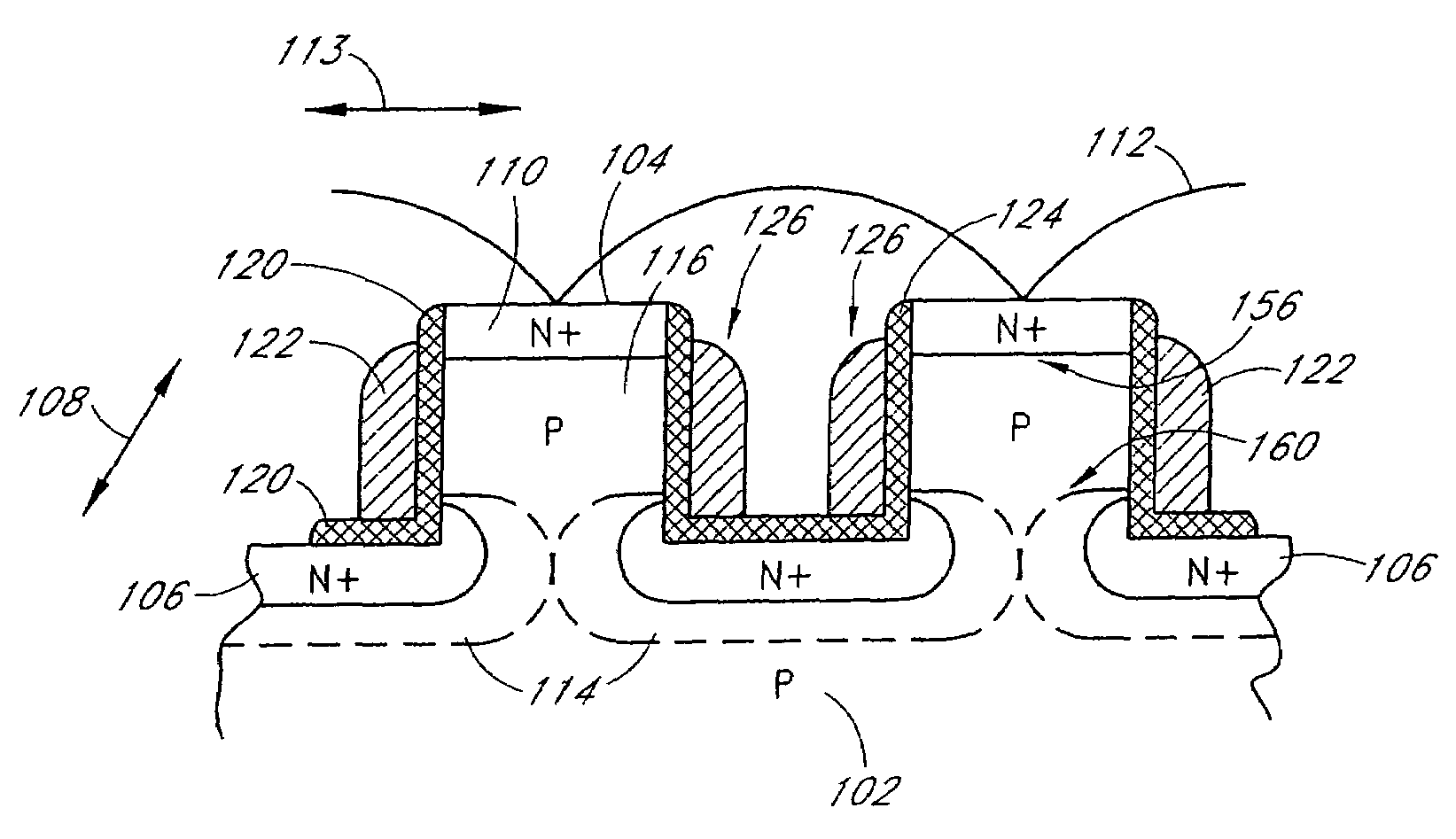

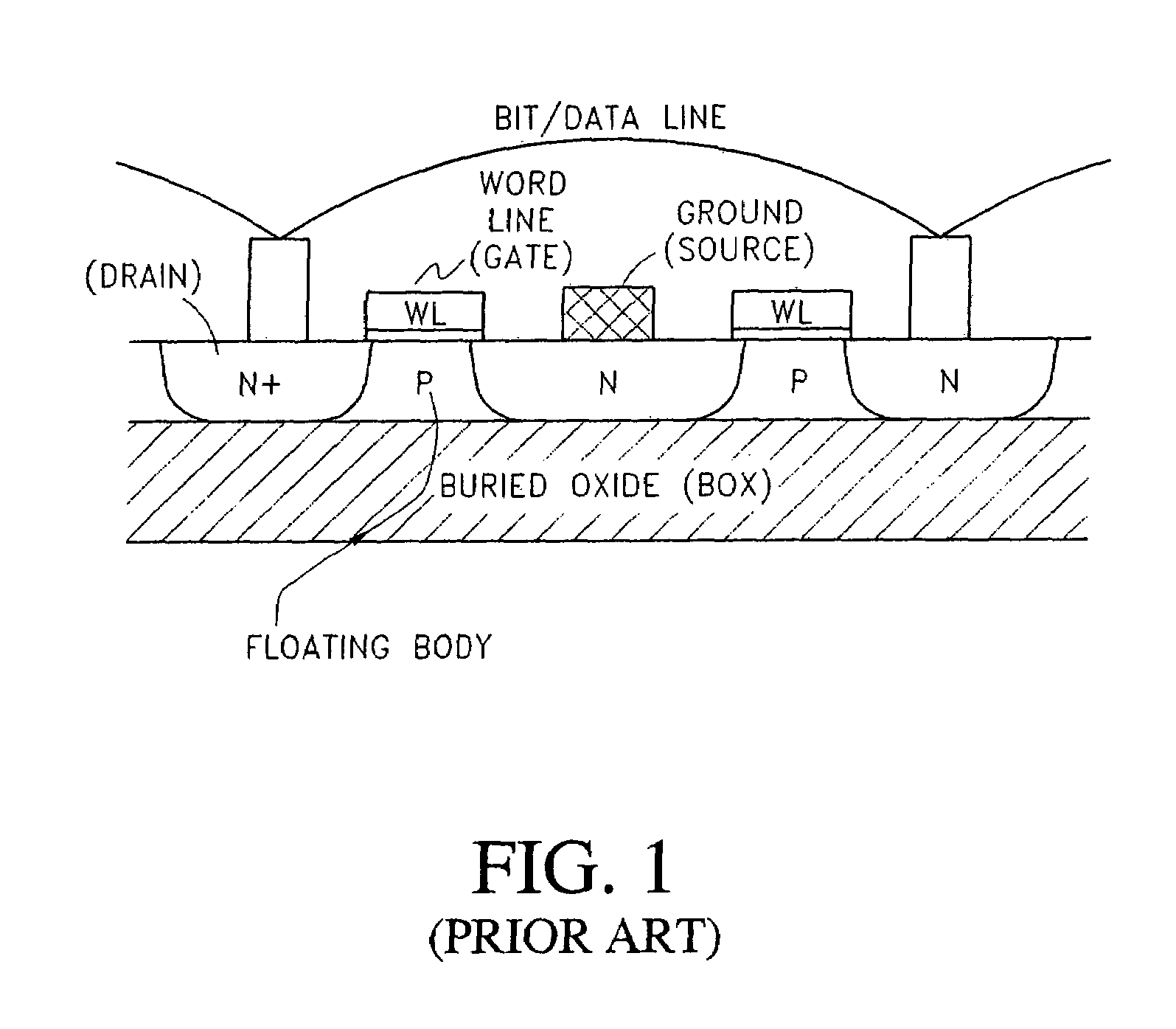

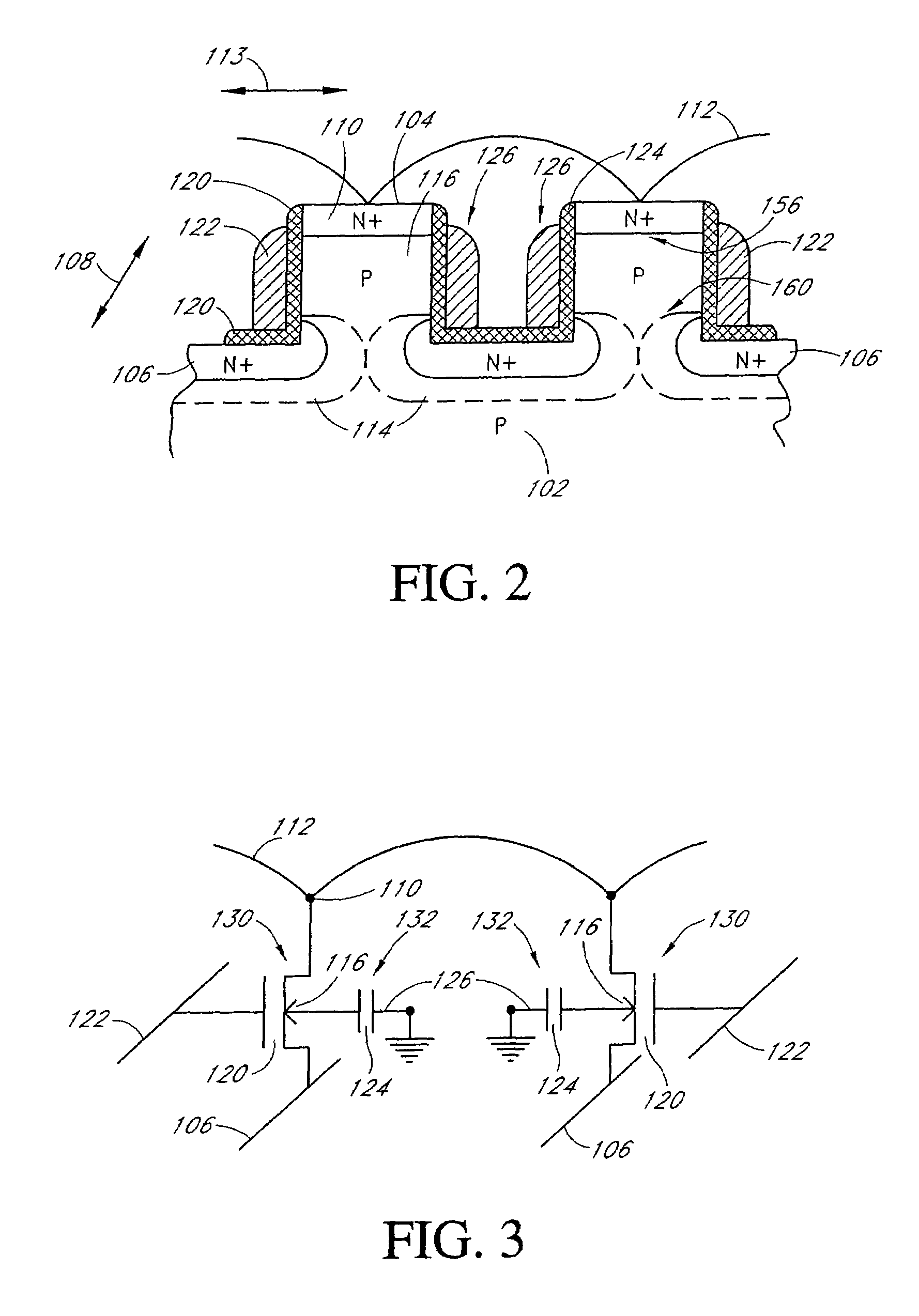

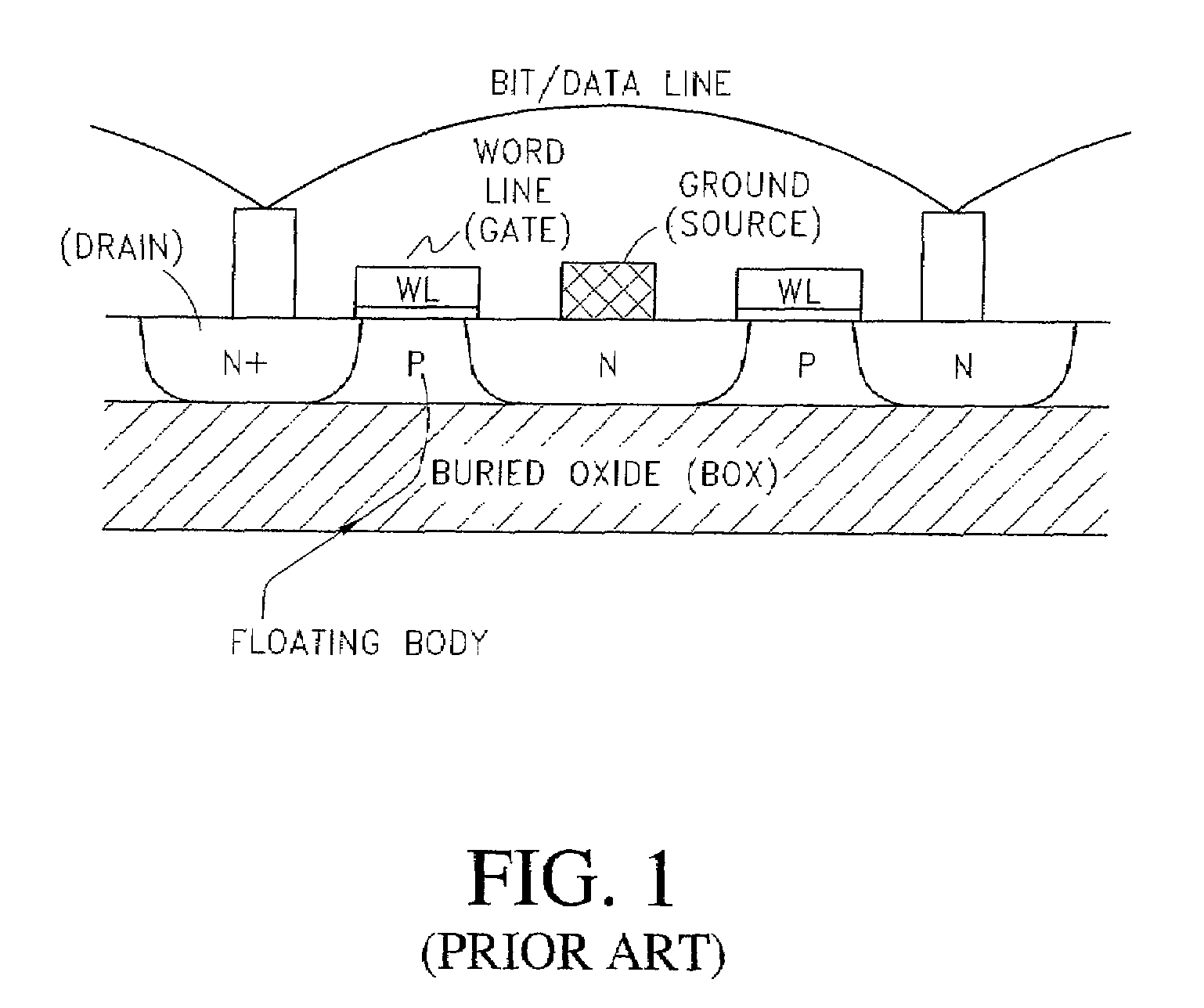

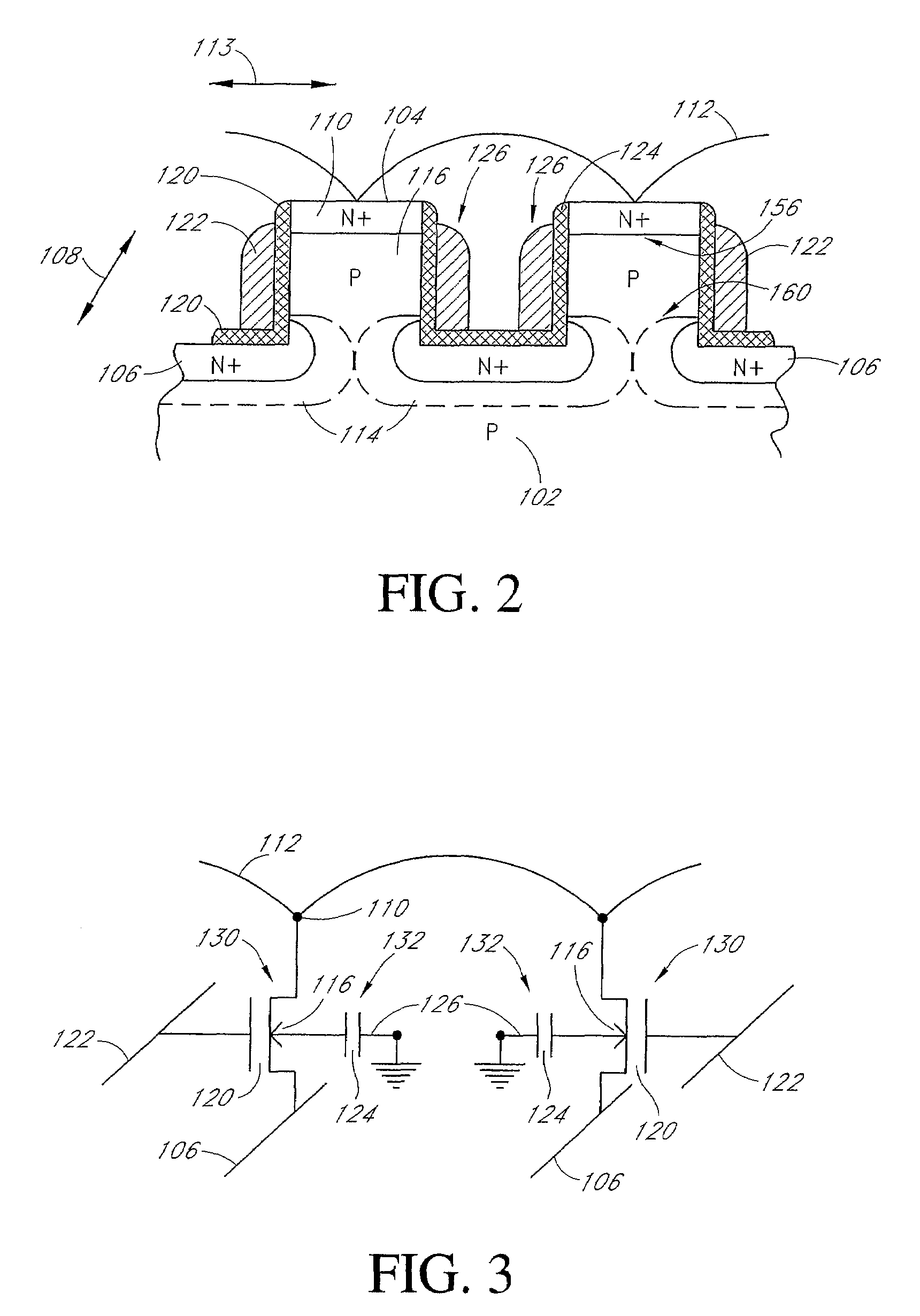

Long retention time single transistor vertical memory gain cell

ActiveUS7271052B1High band gap energyAvoid excessive leakage currentTransistorSolid-state devicesHigh cellRetention time

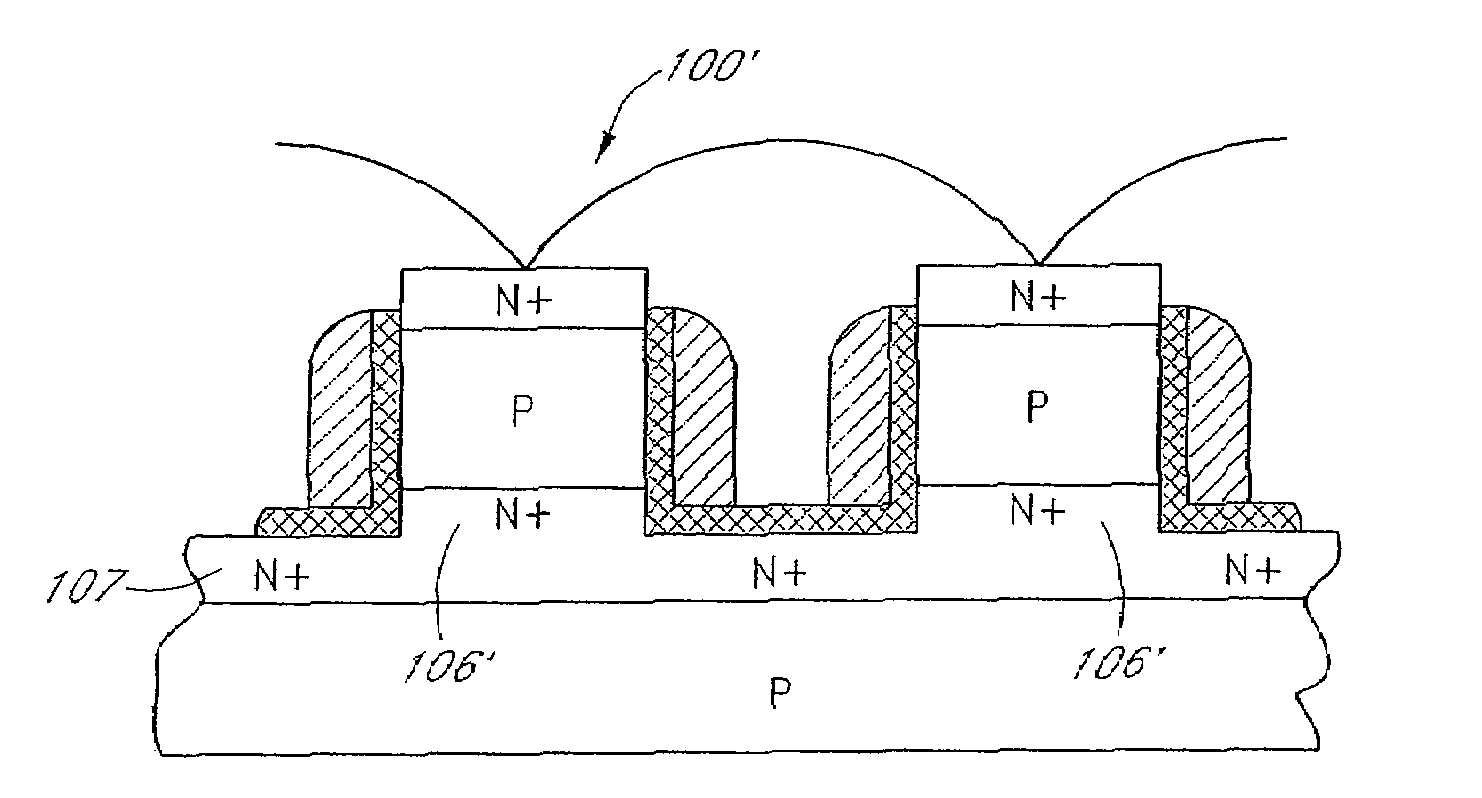

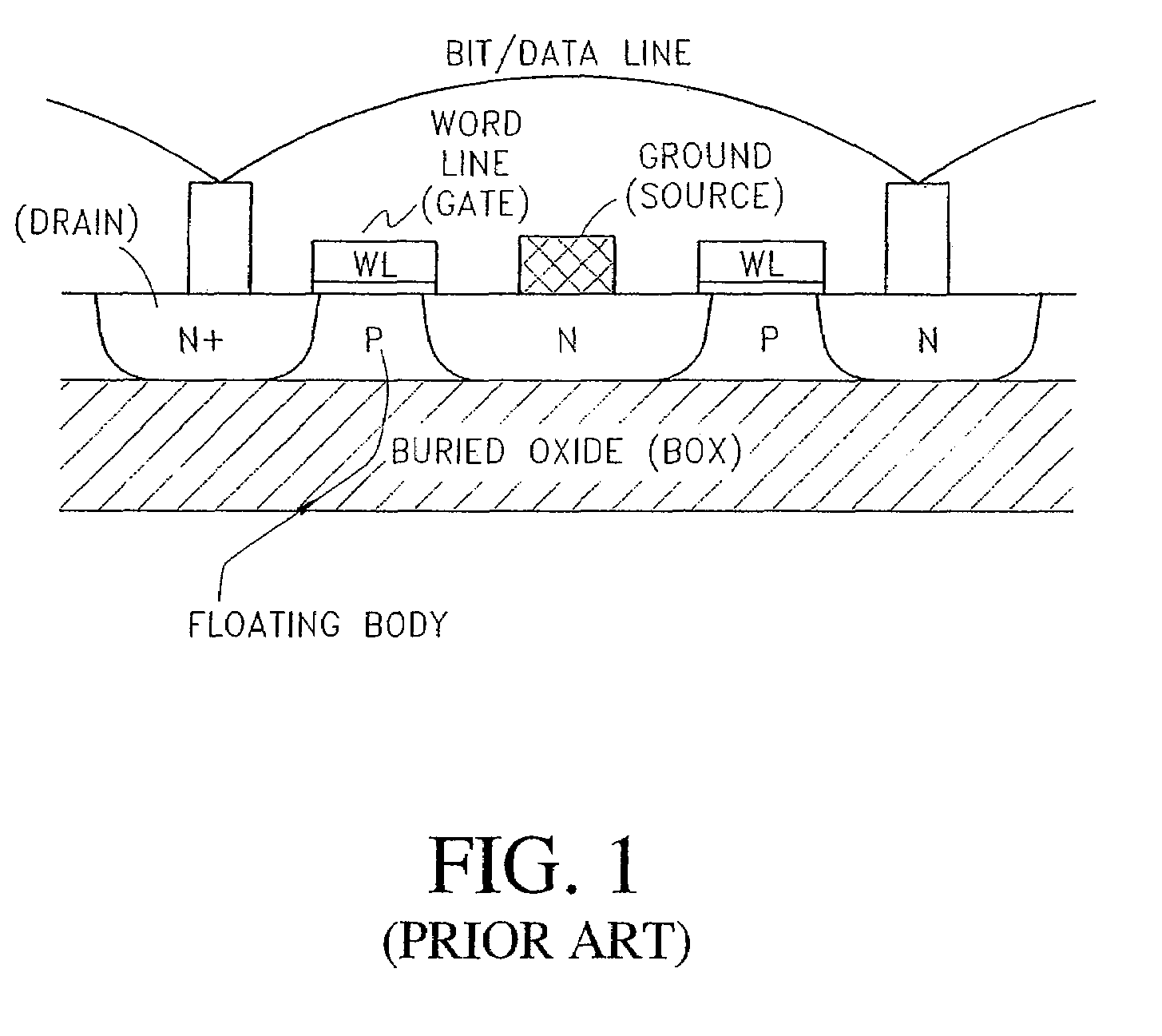

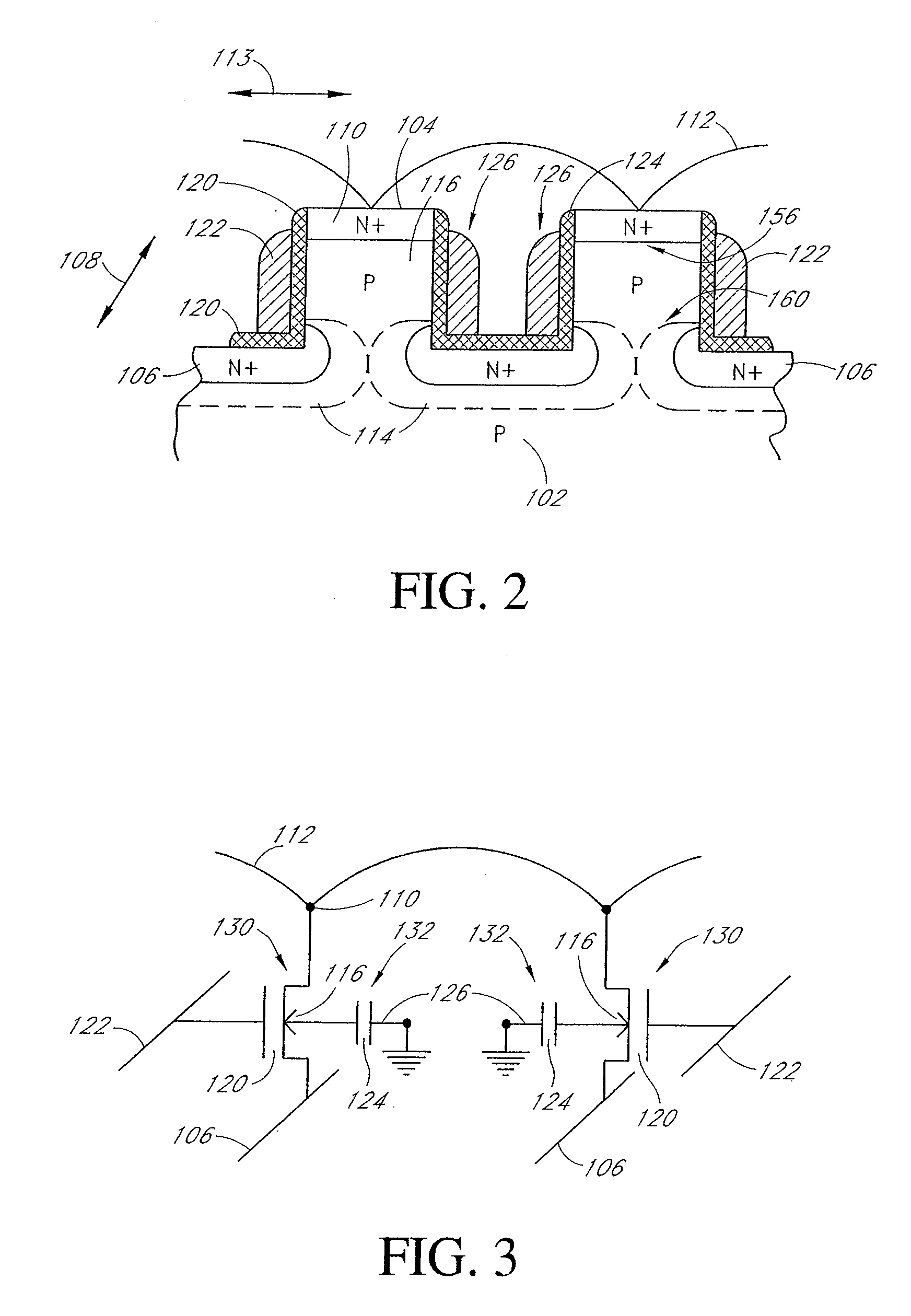

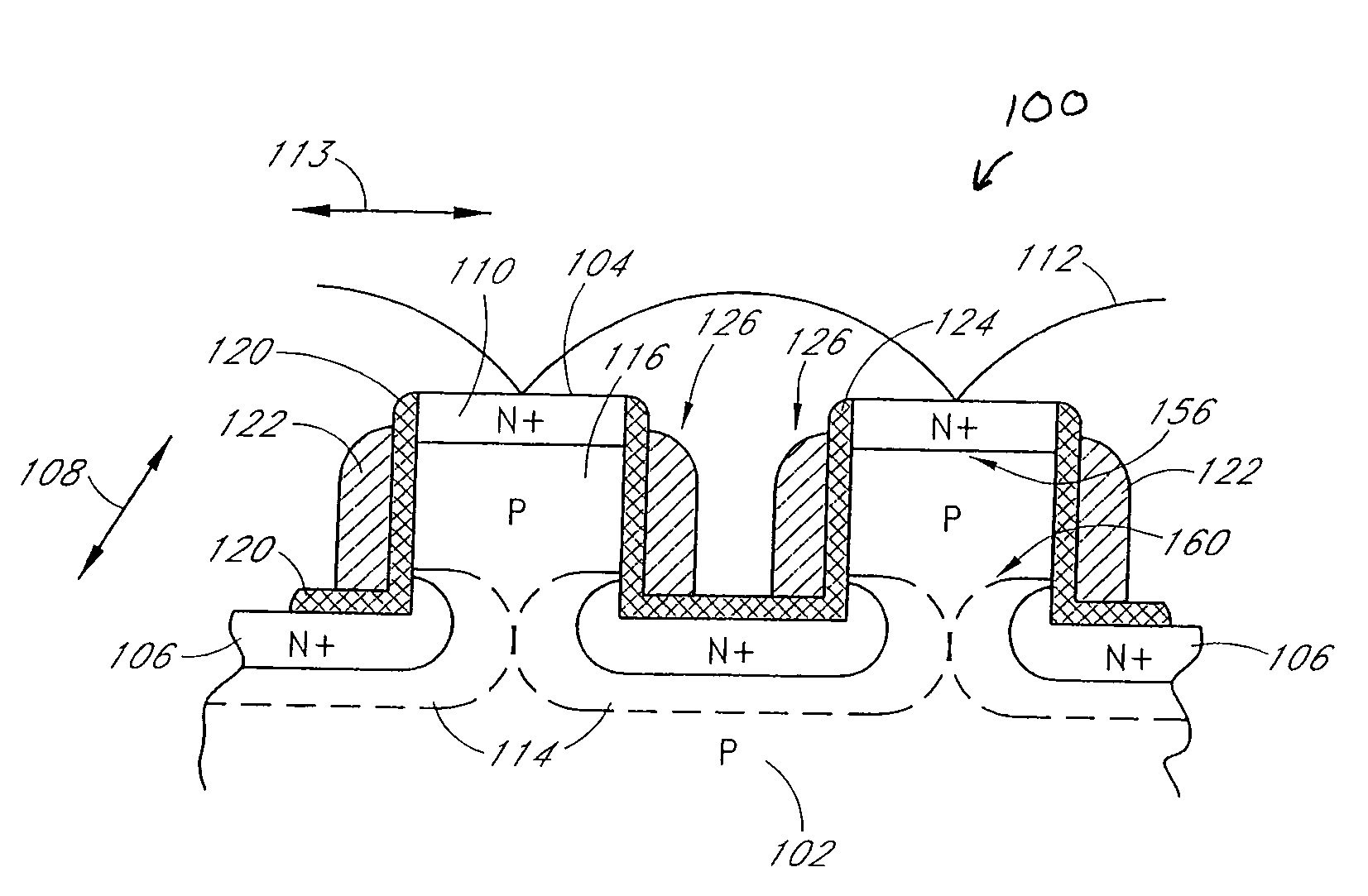

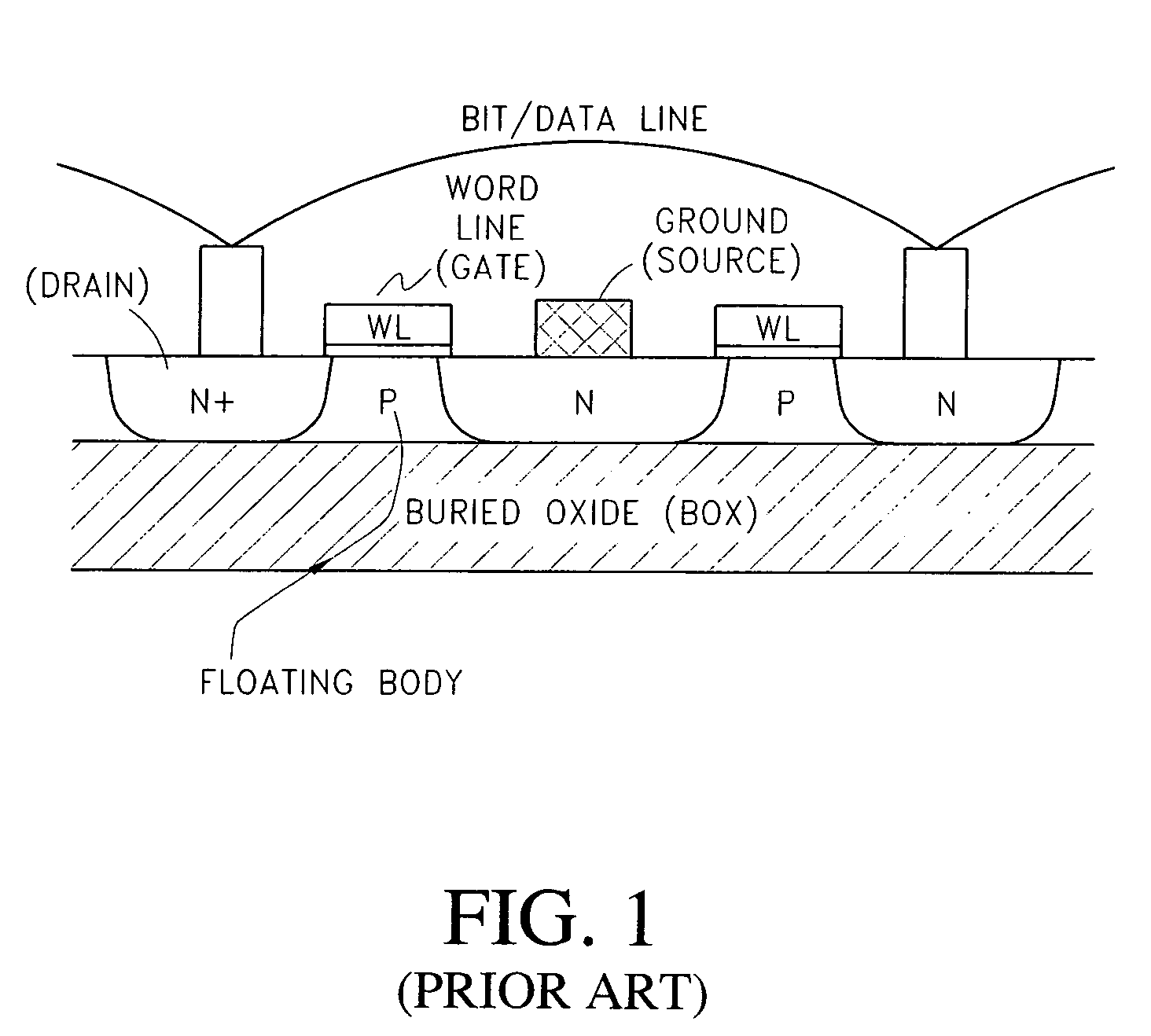

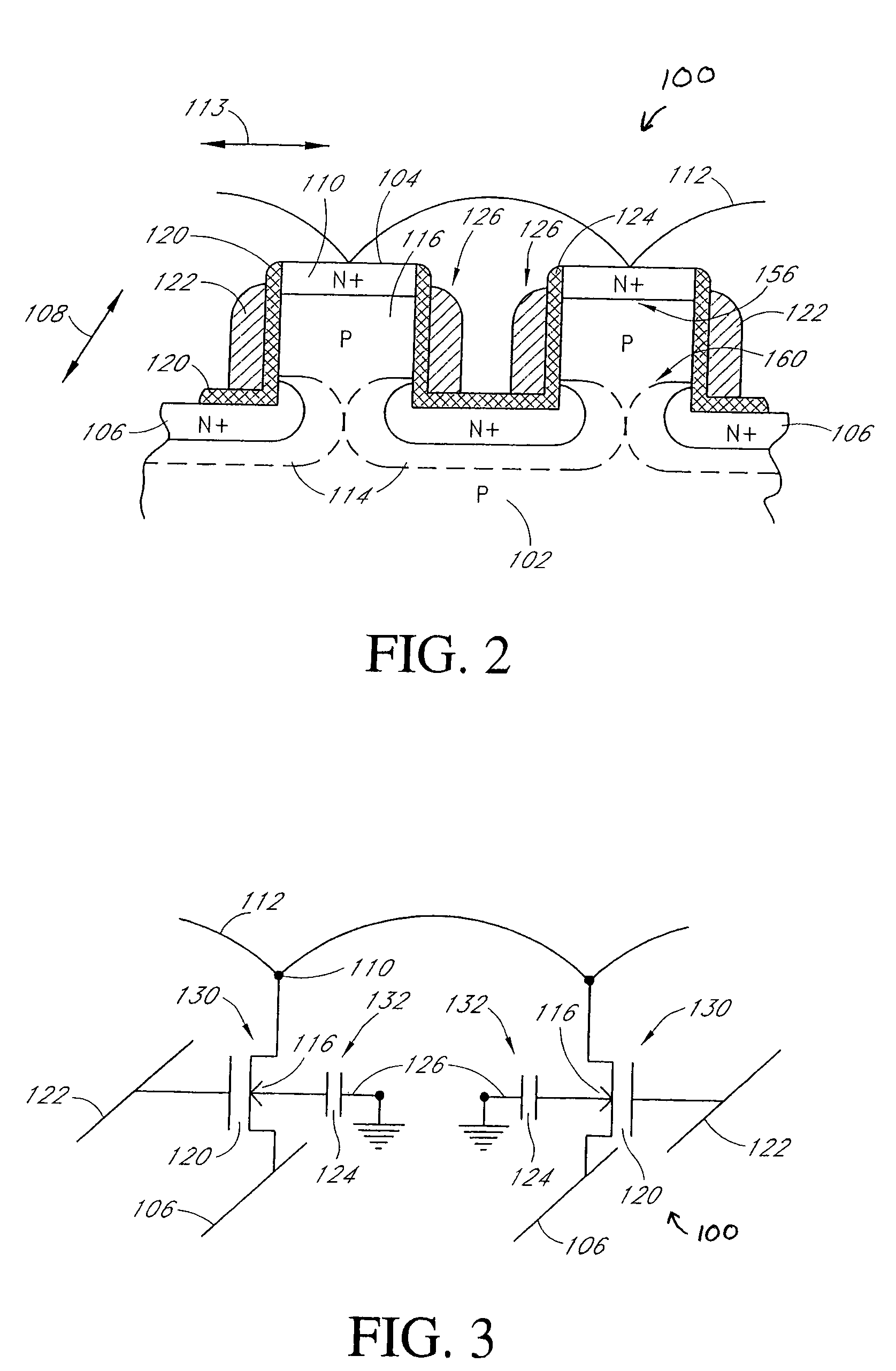

A single transistor vertical memory gain cell with long data retention times. The memory cell is formed from a silicon carbide substrate to take advantage of the higher band gap energy of silicon carbide as compared to silicon. The silicon carbide provides much lower thermally dependent leakage currents which enables significantly longer refresh intervals. In certain applications, the cell is effectively non-volatile provided appropriate gate bias is maintained. N-type source and drain regions are provided along with a pillar vertically extending from a substrate, which are both p-type doped. A floating body region is defined in the pillar which serves as the body of an access transistor as well as a body storage capacitor. The cell provides high volumetric efficiency with corresponding high cell density as well as relatively fast read times.

Owner:MICRON TECH INC

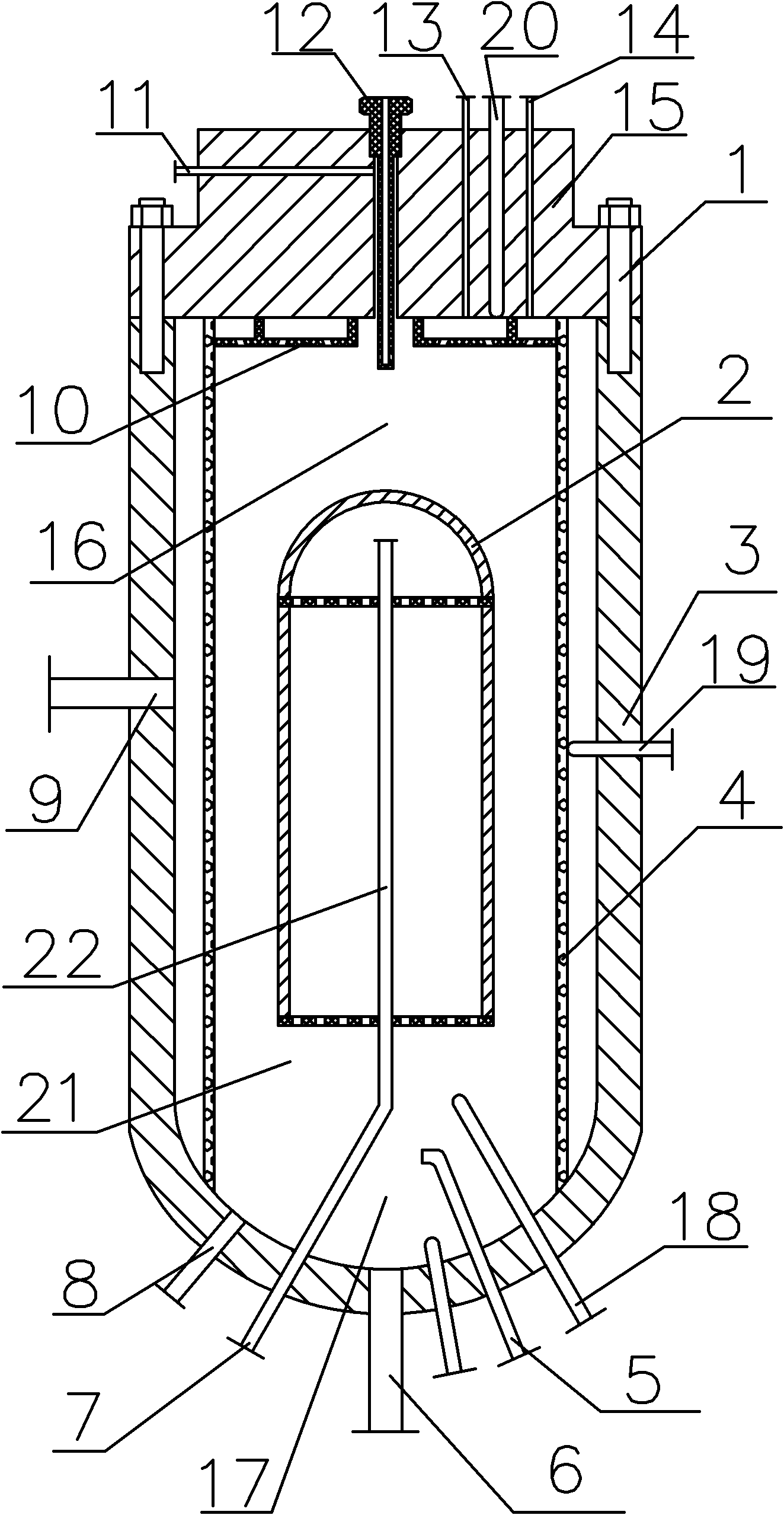

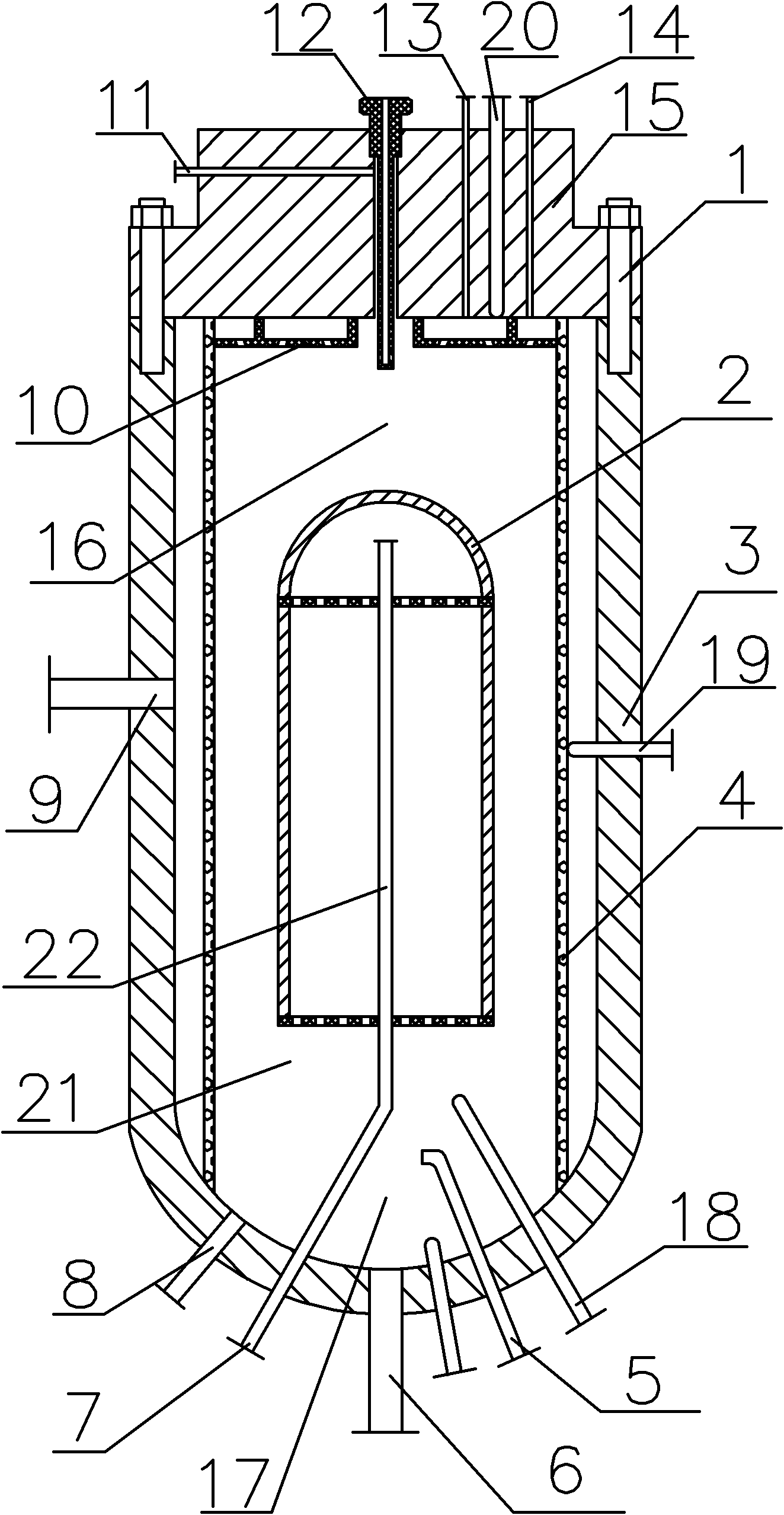

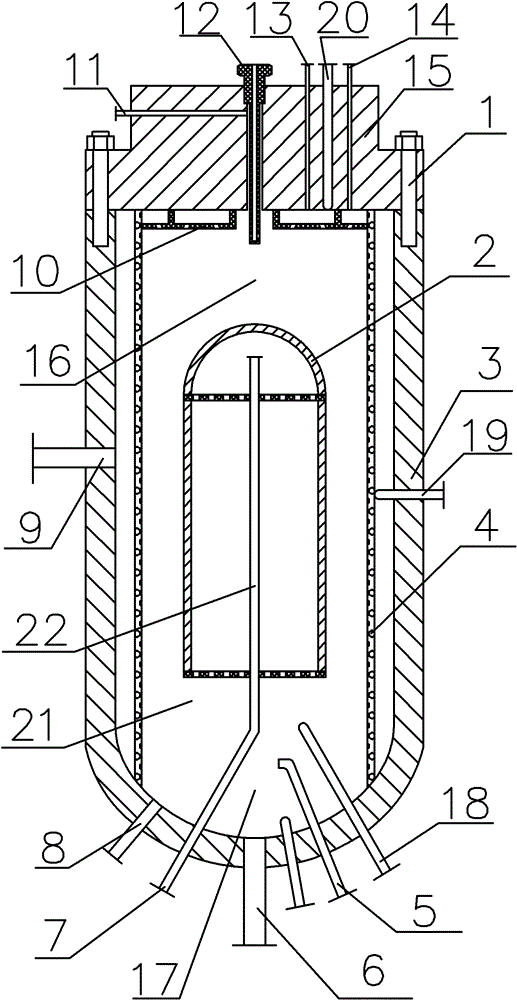

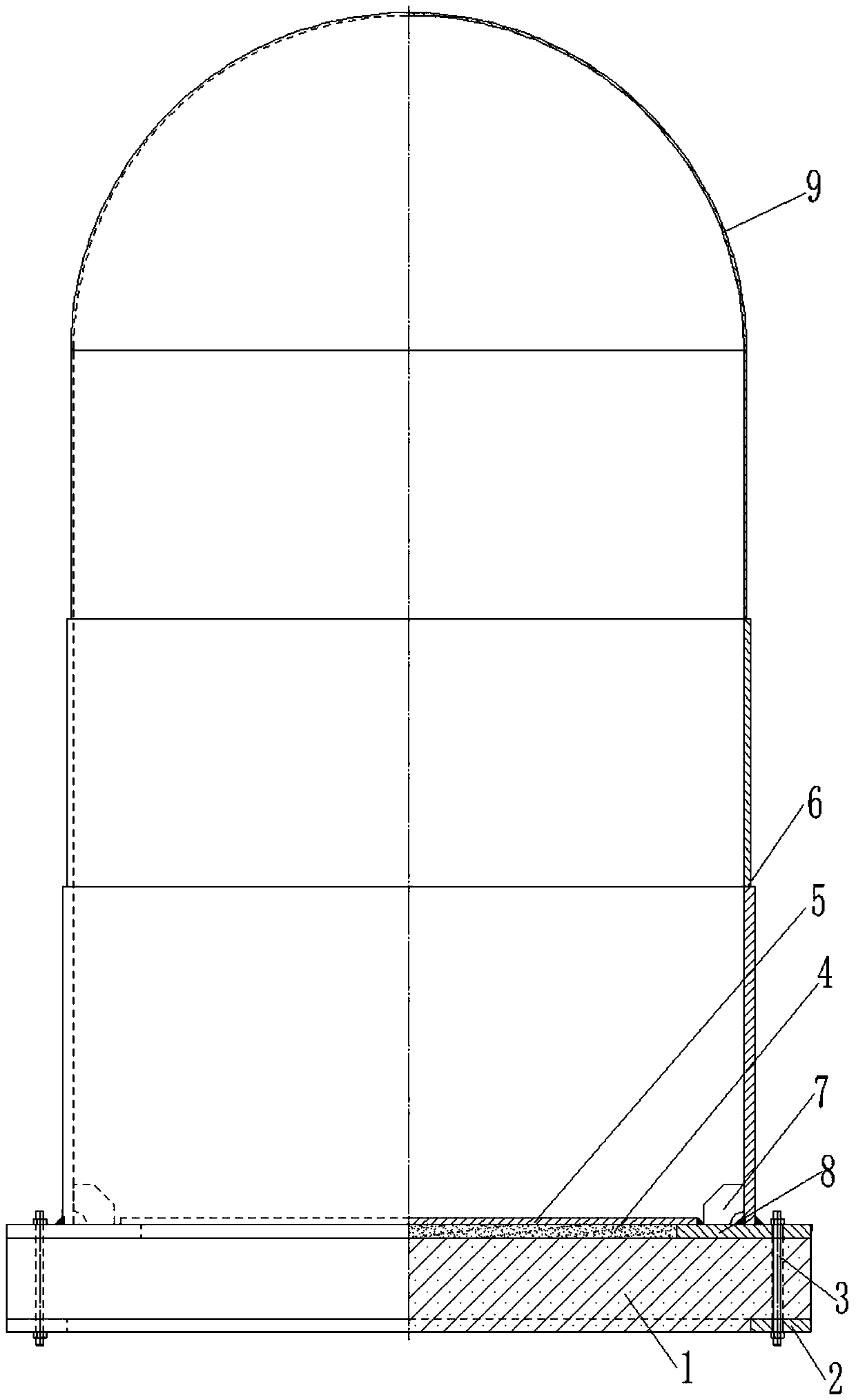

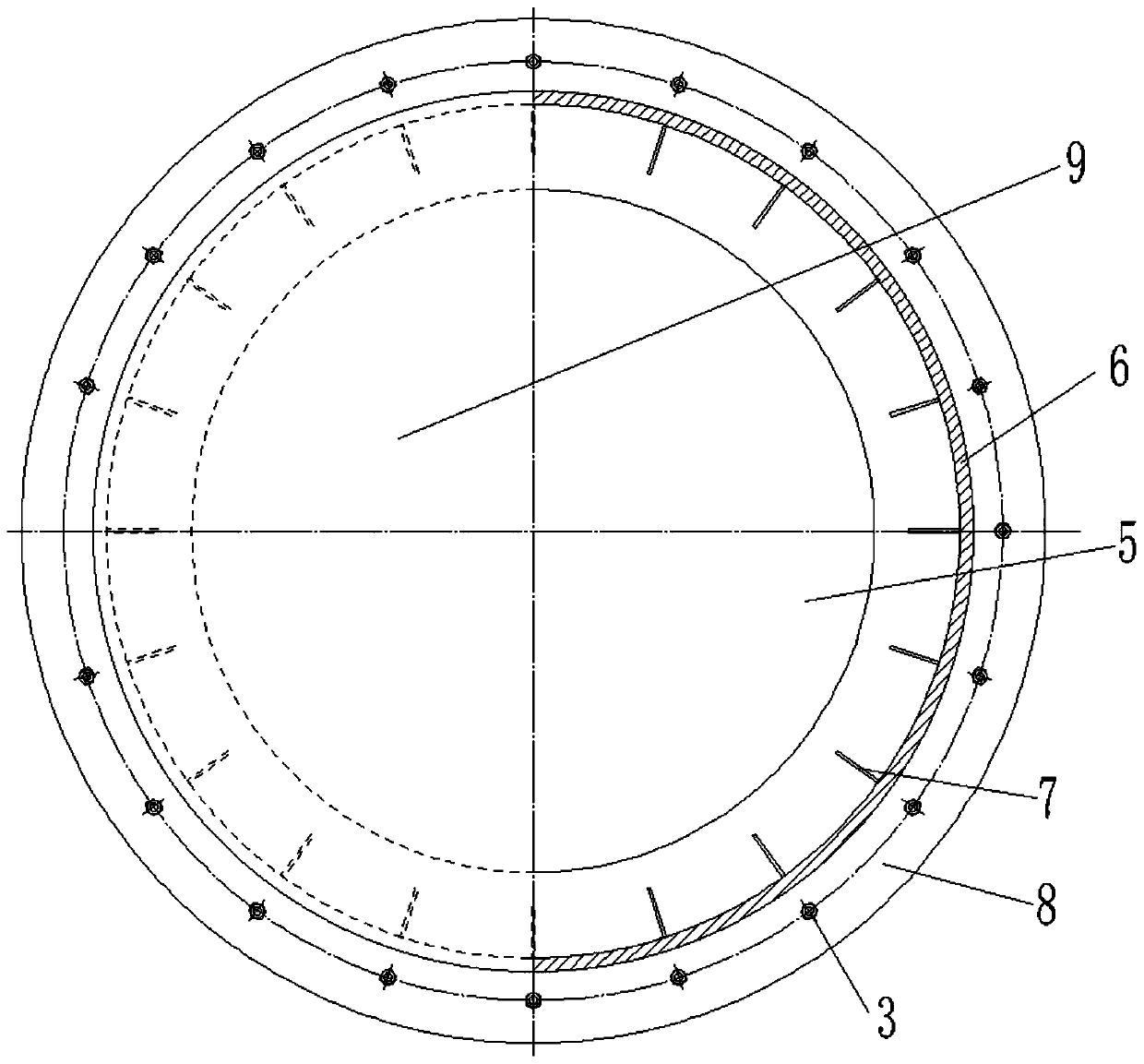

Supercritical water oxidation reactor by using auxiliary fuel for supplying heat

ActiveCN102190363AEfficient mixingEfficient combustionSludge treatmentWater/sewage treatment by oxidationNuclear engineeringOrganic fluid

The invention discloses a supercritical water oxidation reactor by using an auxiliary fuel for supplying heat, the heat required for a reaction can be supplied by using the auxiliary fuel, Material, fuel and an oxidizing agent (air or oxygen) are mixed with a high efficiency through the different directional jets for raising oxidation efficiency. According to the invention, the reactor employs a combination structure of evaporation wall and pot type backflow, the reaction vessel volume is effectively used and the reaction time is increased, the blockage problem generated by salt deposition can be also prevented, the corrosion problem of the reactor is effectively reduced. The temperature of the reactor bottom can be preciously controlled through a cooling water pipeline at the reactor bottom, thereby the safe operation of equipment is guaranteed. The reactor effectively solves the economic problem of a supercritical water reaction system by using the auxiliary fuel for supplying, the invention has the advantage of easy industrial amplification, and is widely applied to organic liquid such as high density and difficult biodegradation organic waste water / garbage leachate and the like for a harmlessness processing.

Owner:XI AN JIAOTONG UNIV

Long retention time single transistor vertical memory gain cell

ActiveUS7151024B1High band gap energyAvoid excessive leakage currentTransistorSolid-state devicesHigh cellRetention time

A single transistor vertical memory gain cell with long data retention times. The memory cell is formed from a silicon carbide substrate to take advantage of the higher band gap energy of silicon carbide as compared to silicon. The silicon carbide provides much lower thermally dependent leakage currents which enables significantly longer refresh intervals. In certain applications, the cell is effectively non-volatile provided appropriate gate bias is maintained. N-type source and drain regions are provided along with a pillar vertically extending from a substrate, which are both p-type doped. A floating body region is defined in the pillar which serves as the body of an access transistor as well as a body storage capacitor. The cell provides high volumetric efficiency with corresponding high cell density as well as relatively fast read times.

Owner:MICRON TECH INC

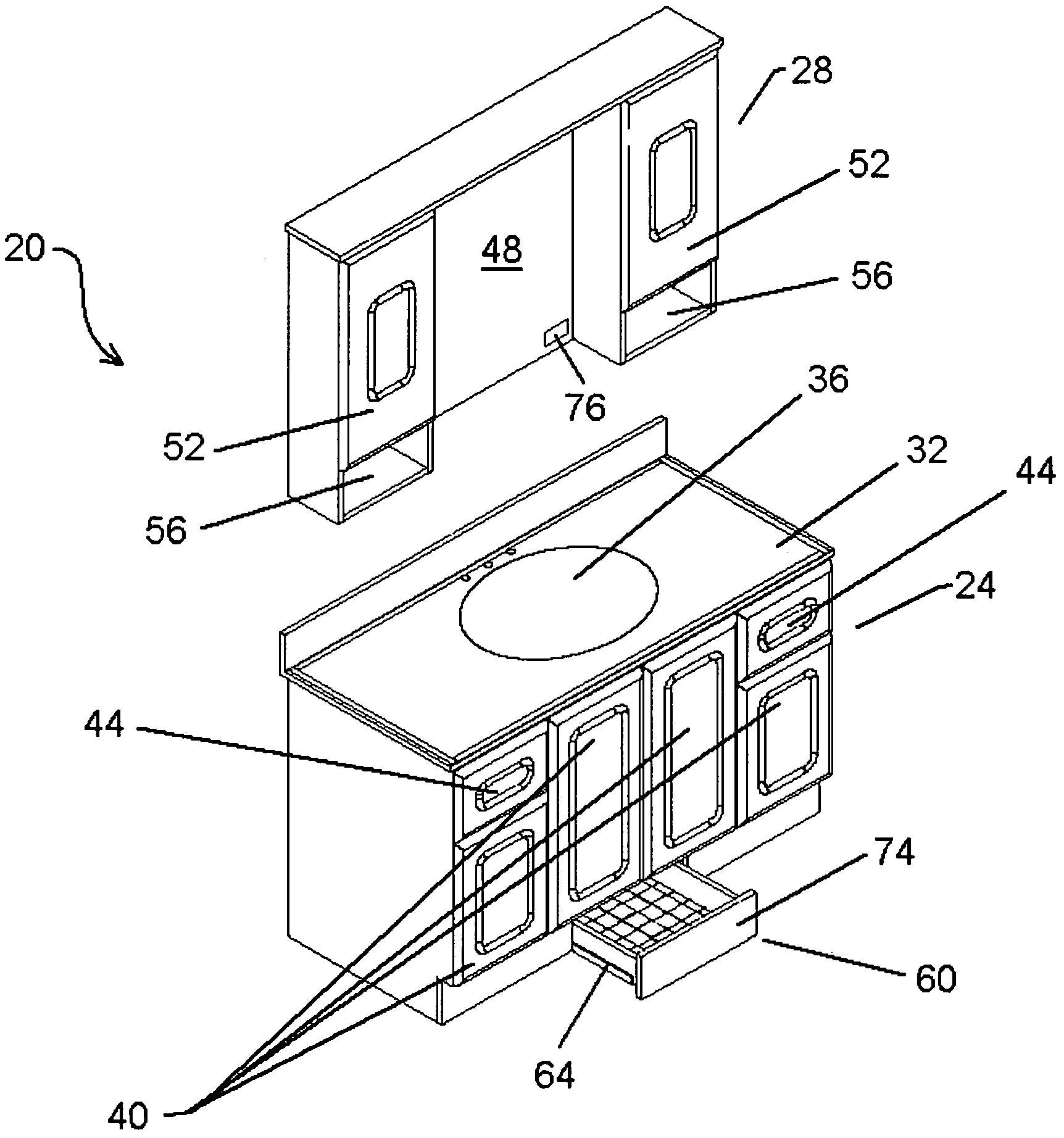

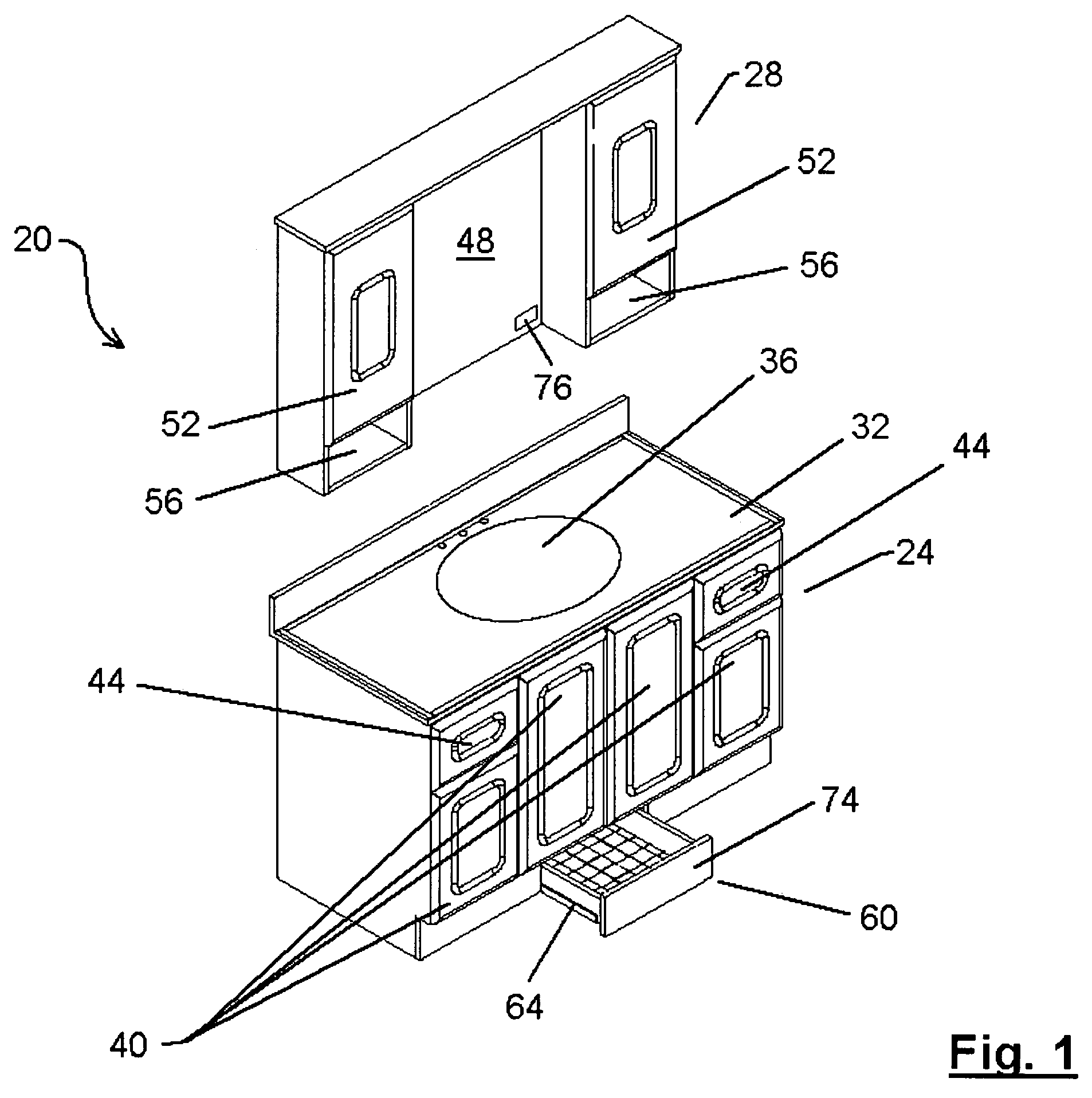

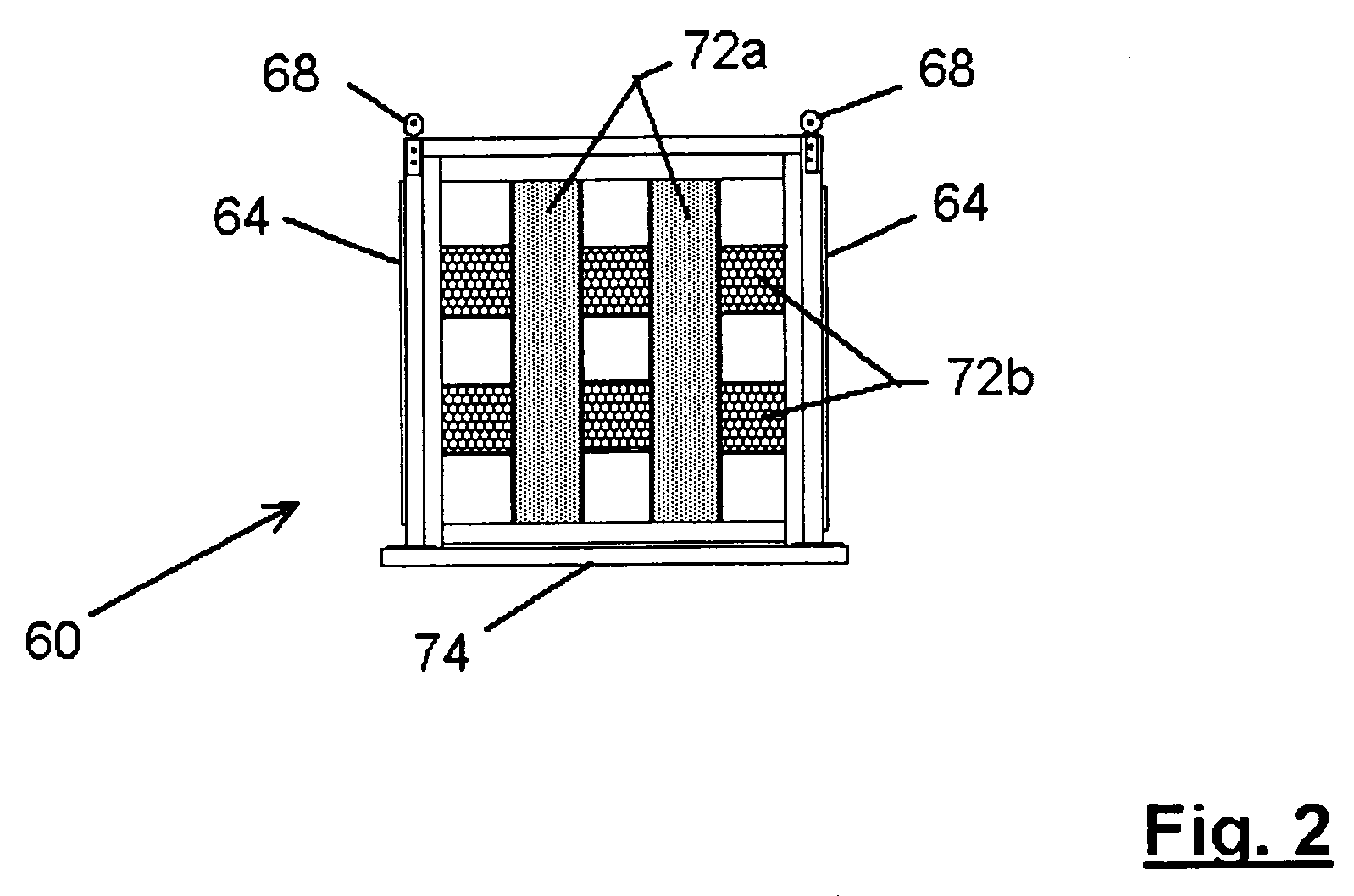

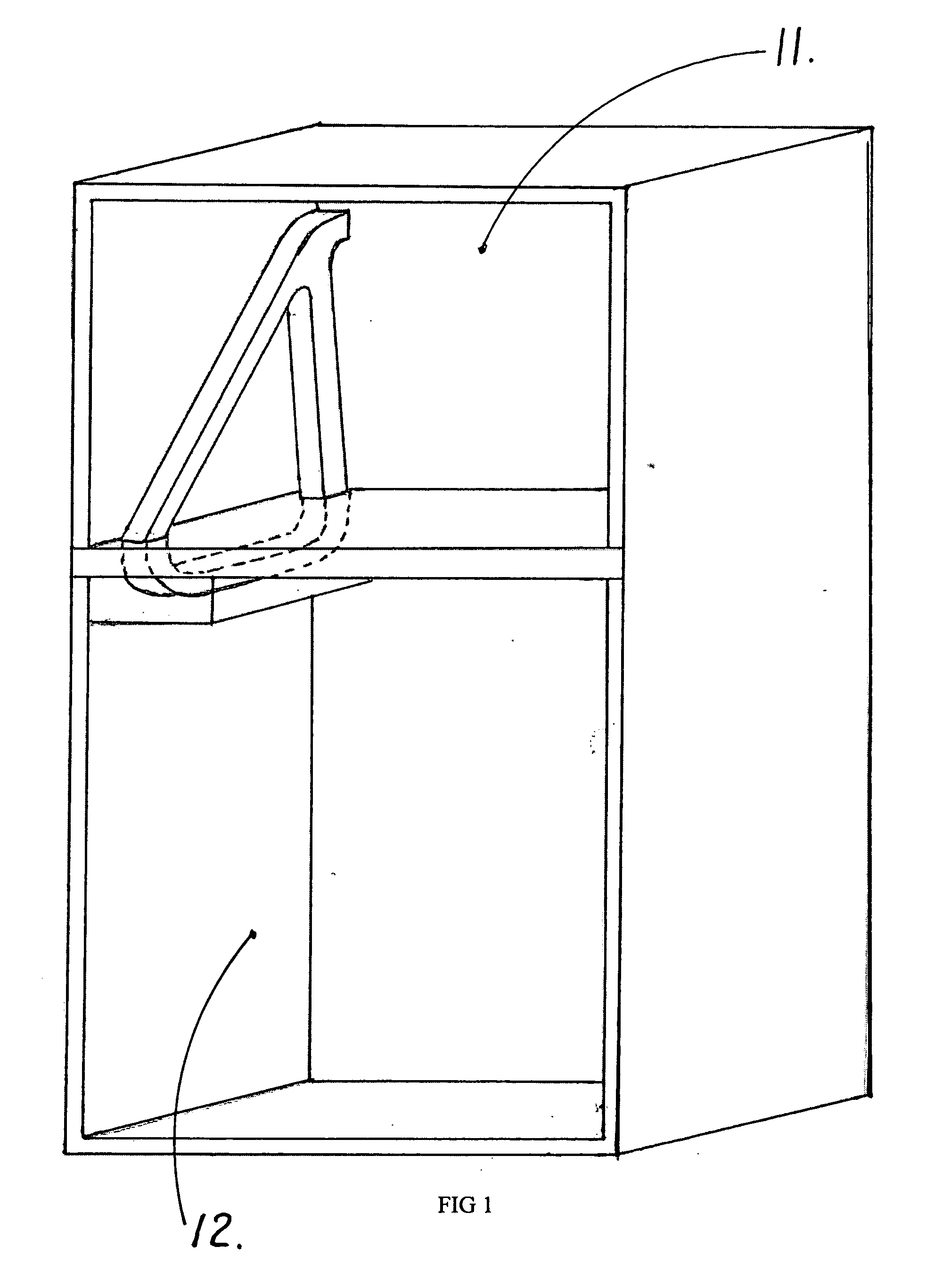

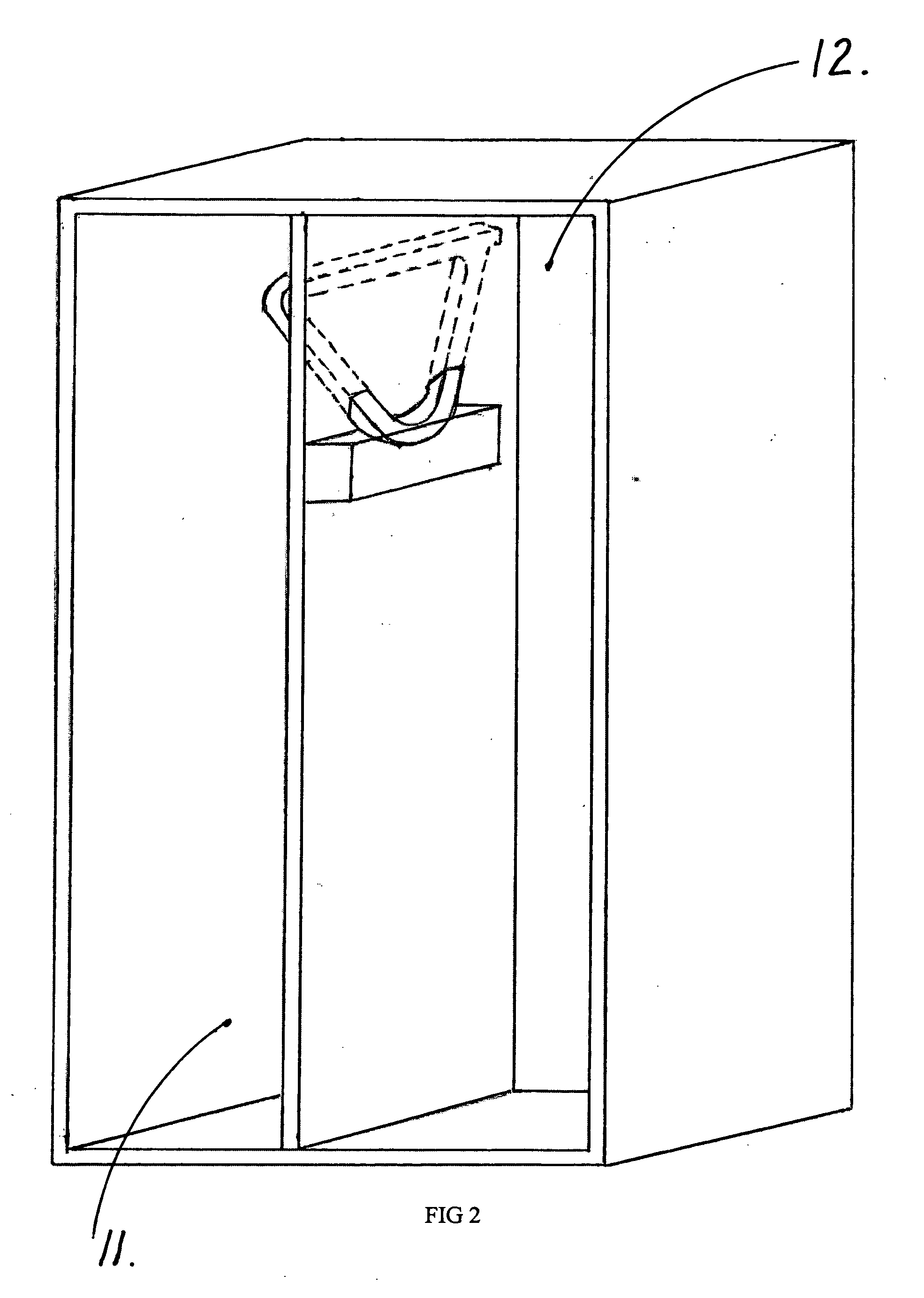

Bathroom vanity with storage for a weigh scale

Owner:MAGICK WOODS

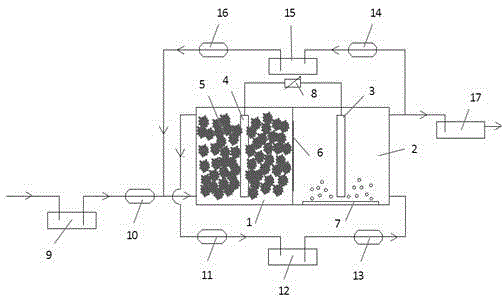

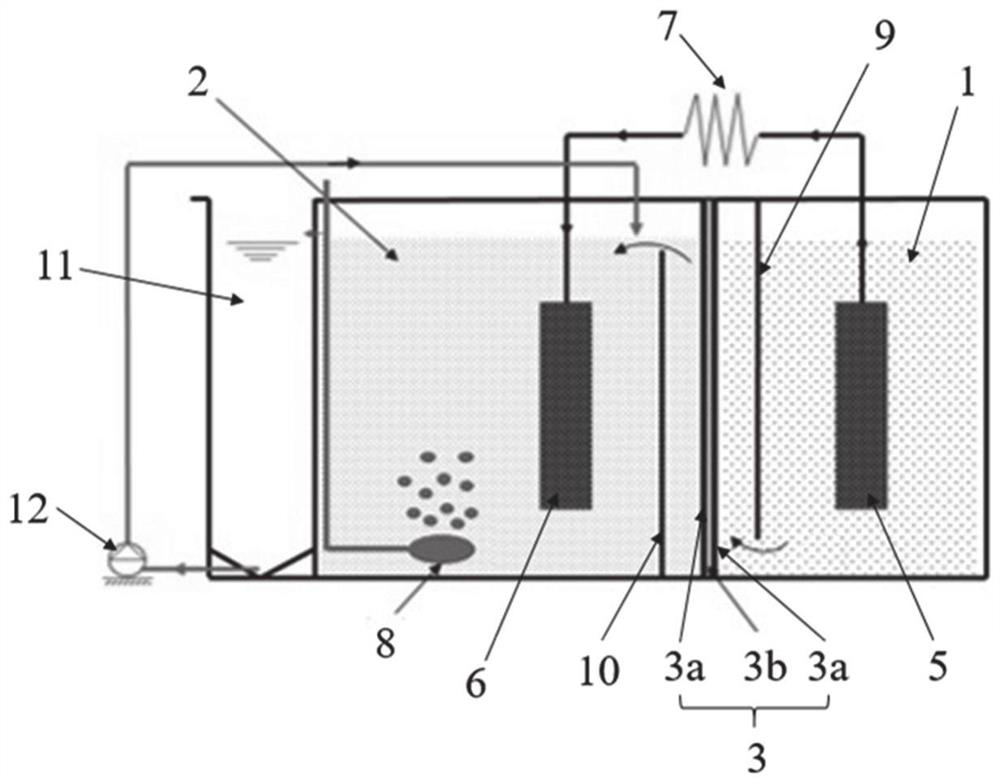

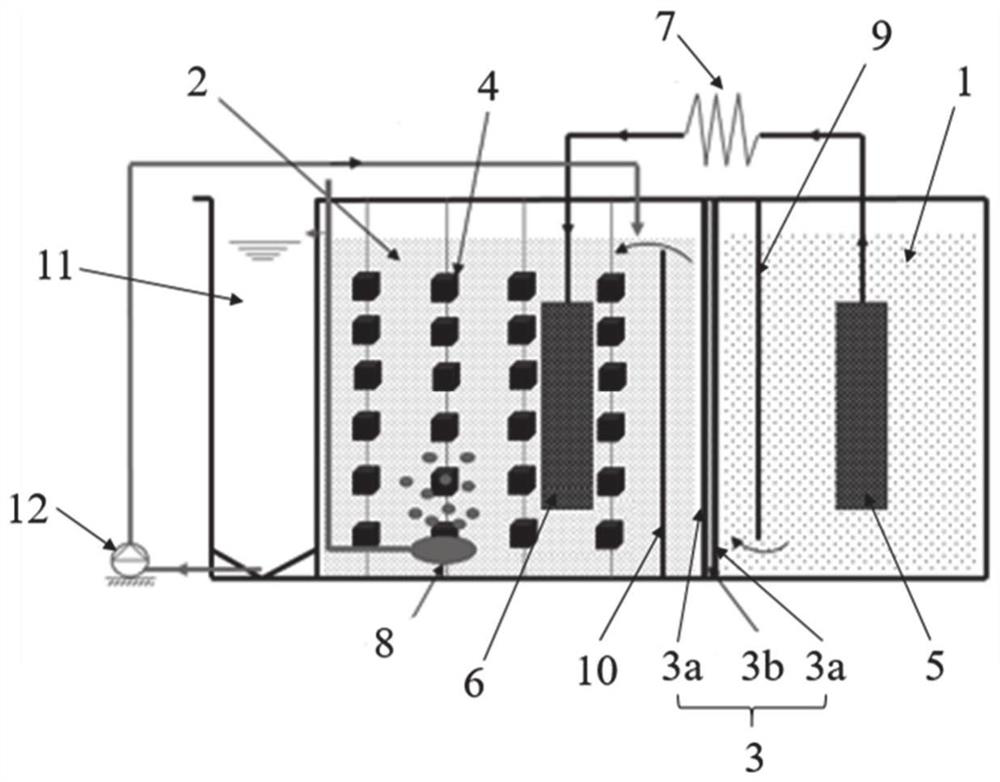

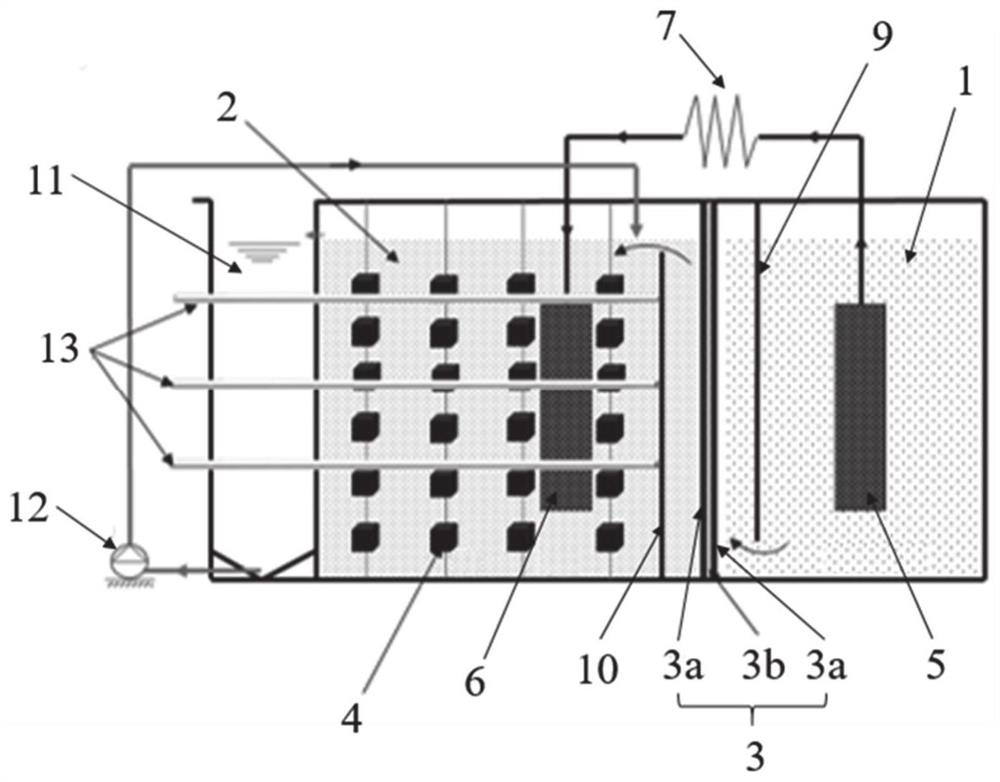

Wastewater treatment system and method employing dual-chamber MFC (microbial fuel cell) combined with A/O process

InactiveCN104386818AEffective volumeEffective use of volumeTreatment by combined electrochemical biological processesTreatment with aerobic and anaerobic processesPeristaltic pumpSewage treatment

The invention discloses a wastewater treatment system and method employing a dual-chamber MFC (microbial fuel cell) combined with an A / O process. An anode chamber is separated from a cathode chamber through a proton exchange membrane; a main anode and an auxiliary anode are arranged in the anode chamber, and are connected with each other through a lead; an aerating apparatus is arranged at the bottom of the cathode chamber; a cathode is arranged in the cathode chamber, and is connected with the main anode through a rheostatic box; a water outlet of the anode chamber is connected with a water inlet of the cathode chamber through a second peristaltic pump, a second settling pond and a third peristaltic pump; the first settling pond is connected with the water inlet of the anode chamber through a first peristaltic pump; a water outlet of the cathode chamber is connected with a water inlet of the anode chamber through a fourth peristaltic pump, a third settling pond and a fifth peristaltic pump; and the water outlet of the cathode chamber is connected with a fourth settling pond. According to the wastewater treatment system and method, two electrode chambers of the dual-chamber microbial fuel cell are effectively utilized; synchronous denitrification and phosphorus and carbon removal are achieved; lasting stable current is generated; unification of sewage treatment and energy recovery is achieved; and the wastewater treatment process employing the microbial fuel cell is further improved.

Owner:ZHEJIANG UNIV

Long retention time single transistor vertical memory gain cell

ActiveUS7259415B1High energyAvoid excessive currentTransistorSolid-state devicesHigh cellRetention time

A single transistor vertical memory gain cell with long data retention times. The memory cell is formed from a silicon carbide substrate to take advantage of the higher band gap energy of silicon carbide as compared to silicon. The silicon carbide provides much lower thermally dependent leakage currents which enables significantly longer refresh intervals. In certain applications, the cell is effectively non-volatile provided appropriate gate bias is maintained. N-type source and drain regions are provided along with a pillar vertically extending from a substrate, which are both p-type doped. A floating body region is defined in the pillar which serves as the body of an access transistor as well as a body storage capacitor. The cell provides high volumetric efficiency with corresponding high cell density as well as relatively fast read times.

Owner:MICRON TECH INC

Vacuum microwave segmented combined drying manufacturing method of instant crisp dehydrated fish ball

InactiveCN102423087APromote circulationEffective use of volumeFood preparationNutritive valuesAdditive ingredient

A vacuum microwave segmented combined drying manufacturing method of an instant crisp dehydrated fish ball belongs to the technical field of aquatic food processing. The invention comprises the following steps: processing fresh or frozen fresh fish to obtain pure fish flesh, performing deodorization of the pure fish flesh by a composite rinsing solution, grinding the fish flesh, adding ingredients, immediately performing ball forming, gelation, heating and curing of the ground raw material, finally performing vacuum microwave segmented combined drying of the cured fish balls so as to obtain the high-quality instant crisp dehydrated fish ball product. Vacuum microwave segmented combined drying allows the materials to be dehydrated in vacuum environment, prevents the materials from contacting oxygen, and maintains the original color, profile, flavor, and nutrients of the raw material to a maximum extent; with the vacuum environment, the boiling point of water is decreased, and with the microwave volume heating, the heat efficiency is significantly improved; the drying time is greatly reduced; after drying, the product has a porous structure, good crispness, excellent color, flavor, taste, and shape, low water content, high nutritive value, and is high-protein healthy leisure food suitable for people of all ages.

Owner:JIANGNAN UNIV +1

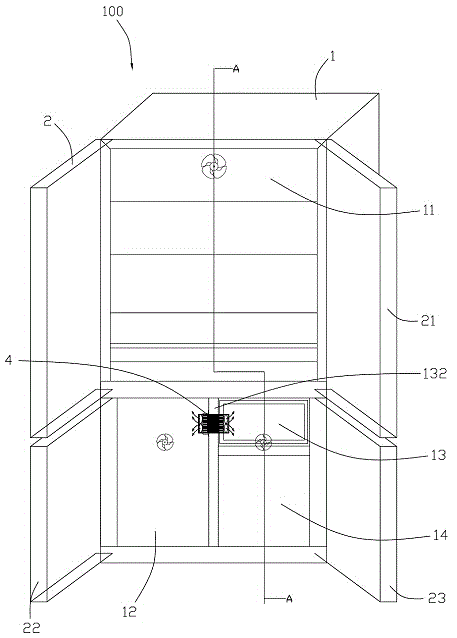

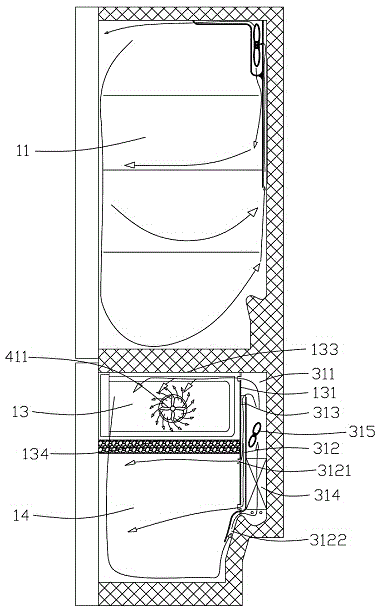

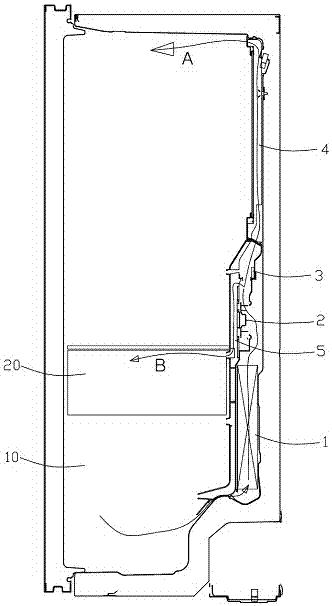

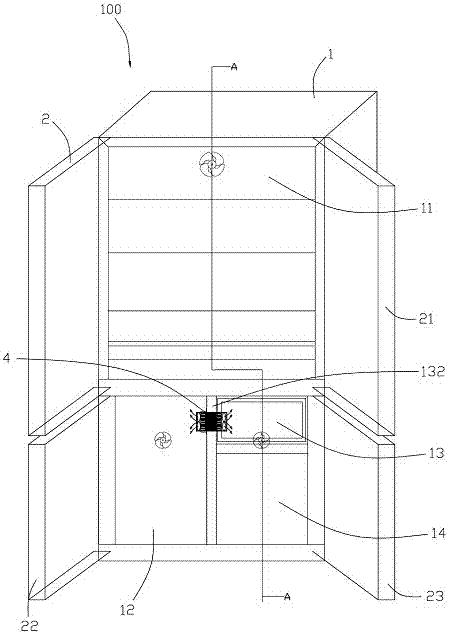

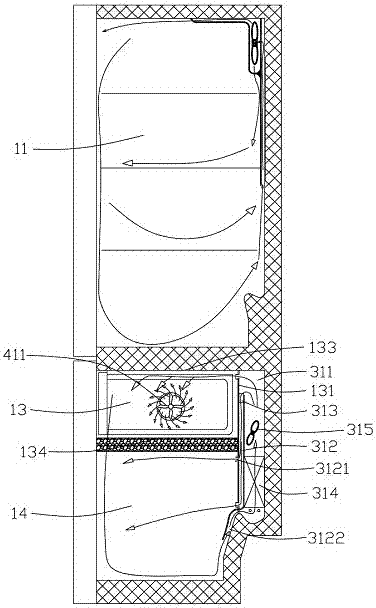

Refrigerator

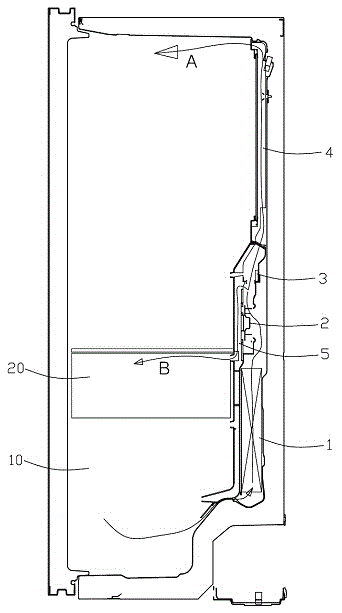

ActiveCN105222459AKeep the service lifeUse capacityLighting and heating apparatusDomestic refrigeratorsFreezing chamberEngineering

The invention provides a refrigerator which comprises a refrigerator body, a first refrigerating system and a second refrigerating system, wherein the refrigerator body is provided with a freezing chamber and / or a temperature varying chamber and a low temperature chamber not communicated with the freezing chamber and / or the temperature varying chamber; the first refrigerating system comprises a first refrigerating component for providing cold quantity for the low temperature chamber by adopting a direct cooling or air cooling refrigerating way; the second refrigerating system is provided with a semiconductor refrigerating module arranged on the peripheral wall of the low temperature chamber. The cold end of the semiconductor refrigerating module is arranged in the low temperature chamber, and the hot end of the semiconductor refrigerating module is arranged outside the peripheral wall.

Owner:HAIER SMART HOME CO LTD

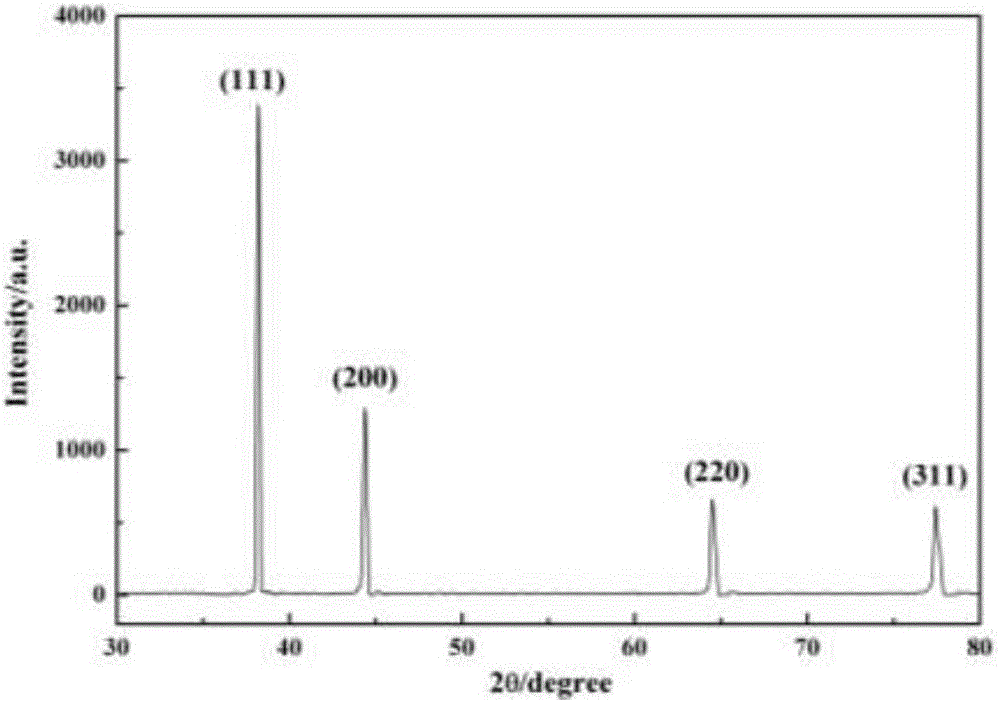

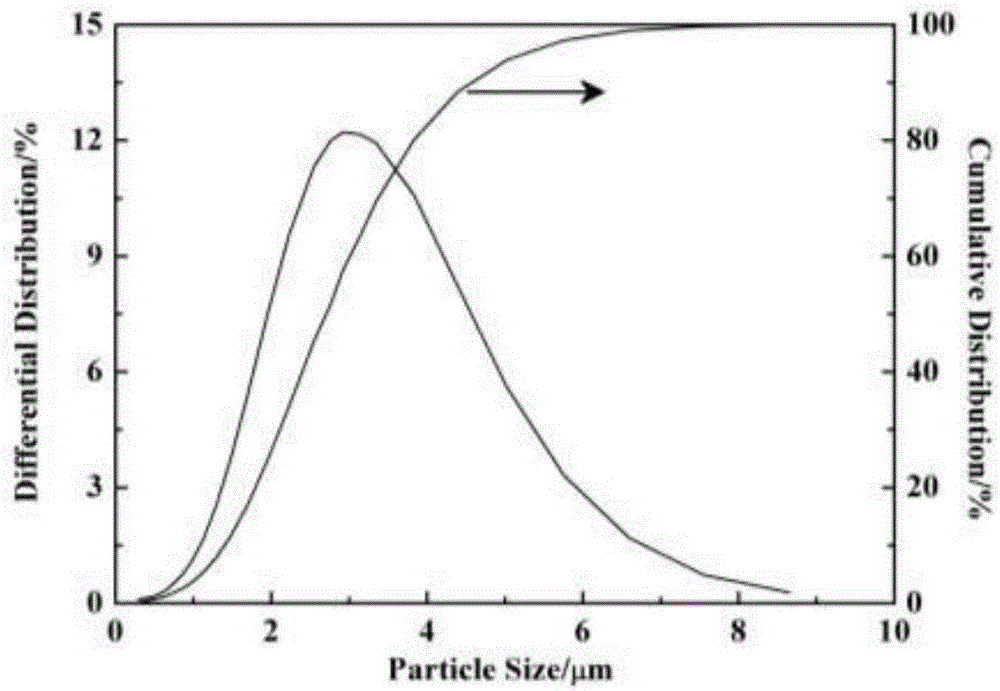

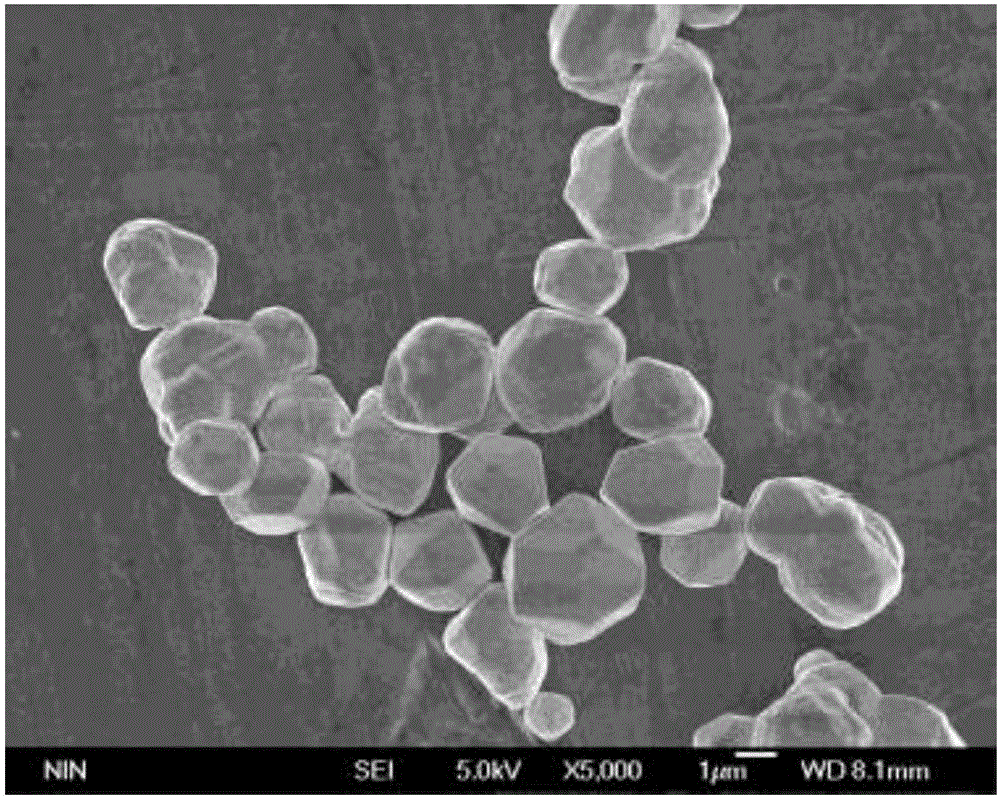

Method for preparing metal silver powder with high tap-density and high crystallinity degree

The invention discloses a method for preparing metal silver powder with the high tap-density and high crystallinity degree. The method includes the steps that a silver nitrate solution and an addition agent solution are evenly mixed, the pH value is adjusted to be 0.1-3 by the adoption of ammonium hydroxide, and the solutions are prepared into an oxidizing agent solution in a constant volume mode; under the temperature condition of 20-40 DEG C, the oxidizing agent solution and a reducing agent ascorbic acid solution of the equal volume are mixed evenly to carry out an oxidation-reduction reaction, so that sediment is generated; and the sediment is cleaned and dried so that the metal silver powder with high tap-density and high crystallinity degree can be obtained. By the adoption of the method, the silver nitrate and the ascorbic acid solution are subjected to the oxidation-reduction reaction, the following reaction equation of 2AgNO3+C6H8O6=2Ag+C6H6O6+2HNO3 is abided by, an addition agent used in the reaction plays the effects of dispersing the silver powder and adjusting the shape and grain size of the silver powder; moreover, the addition amount is small, the oxidation-reduction reaction temperature is low, energy is saved, and the reaction process can be controlled easily; and the grain size and surface shape of the prepared metal silver powder can both meet the requirements and quality is stable.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

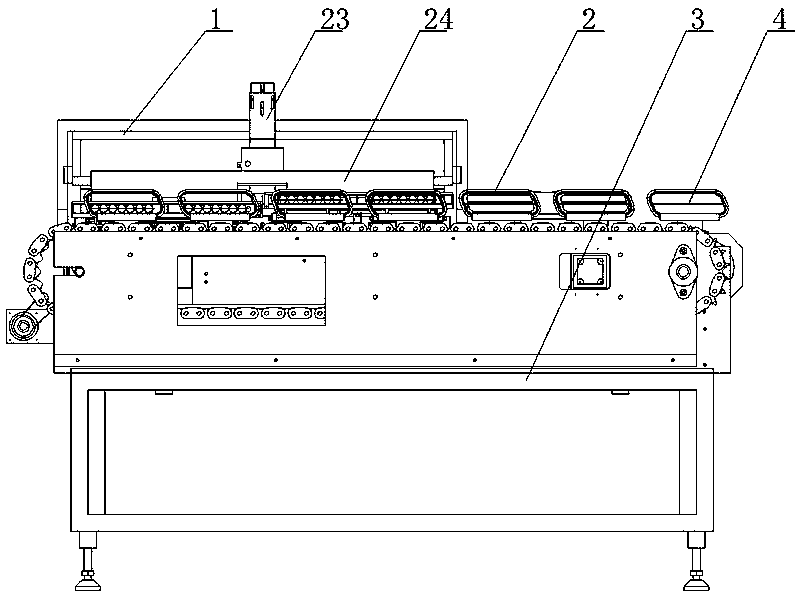

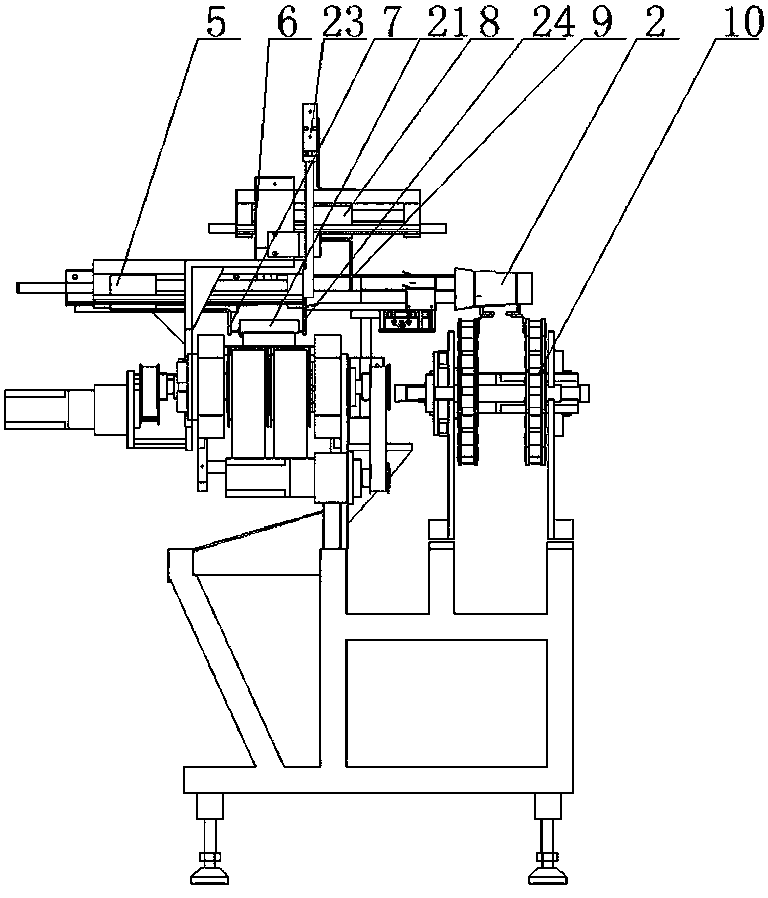

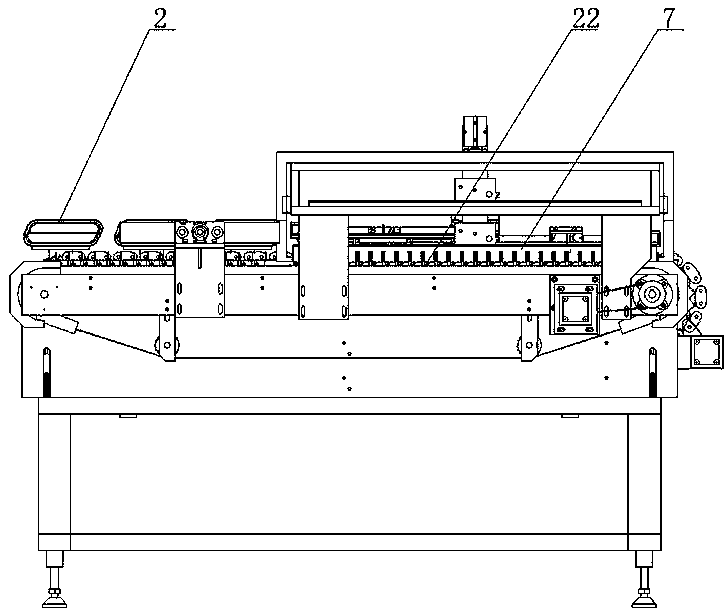

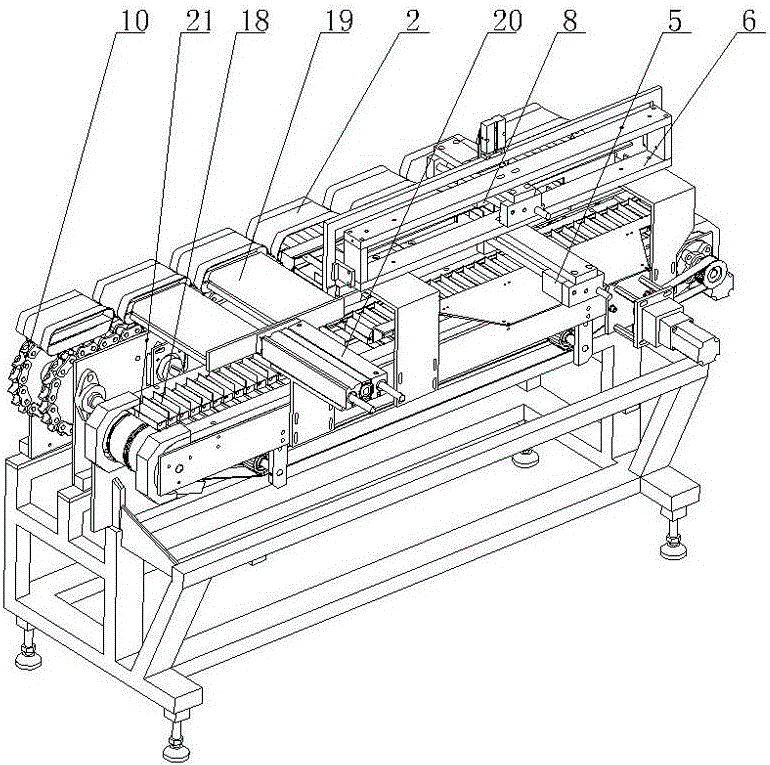

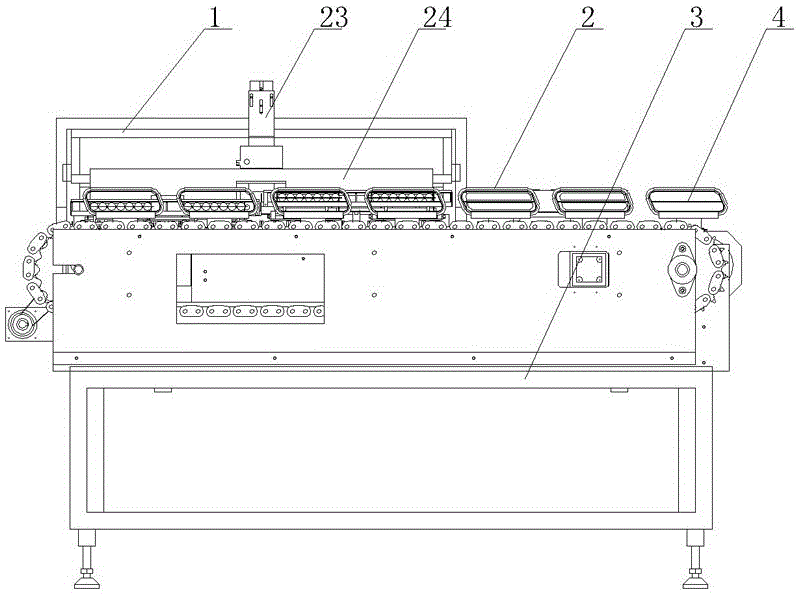

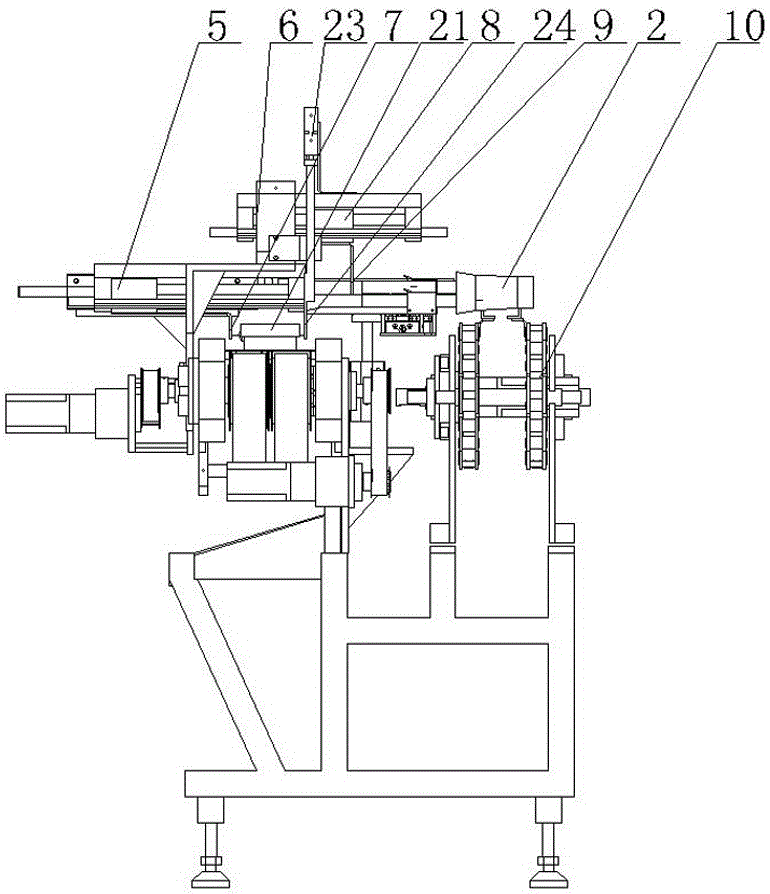

Feeding mechanism of packaging machine

ActiveCN104709508AImprove packaging efficiencyEffective use of volumePackagingEngineeringPackaging machine

The invention discloses a feeding mechanism of a packaging machine. The feeding mechanism comprises a machine body, a feeding belt and a plurality of material receiving boxes and is characterized in that the machine body is provided with a fixing frame; the fixing frame is provided with a first air cylinder and a second air cylinder; a push rod of the first air cylinder is provided with a first material push plate; the machine body is provided with liftable transition material tables corresponding to the material receiving boxes; the transition material tables are flush with the feeding belt when located at the lowest position; a second material push plate corresponding to the material receiving boxes is arranged above the transition material tables and connected with a push rod of the second air cylinder; the material receiving boxes are movably arranged on one side of each transition material table. According to the feeding mechanism, materials can be fed through the feeding belt, are transferred to the transition material table through the first material push plate, are lifted through the transition material tables, and then are pushed into the material receiving boxes through the second material push plate; the feeding mechanism can push the materials in a layered mode, has the advantage of being stable and quick in feeding and greatly improves the reliability and the stability of packaging of the materials in cooperation with a bagging machine, thereby improving bagging efficiency.

Owner:WENZHOU RUIDA MACHINERY

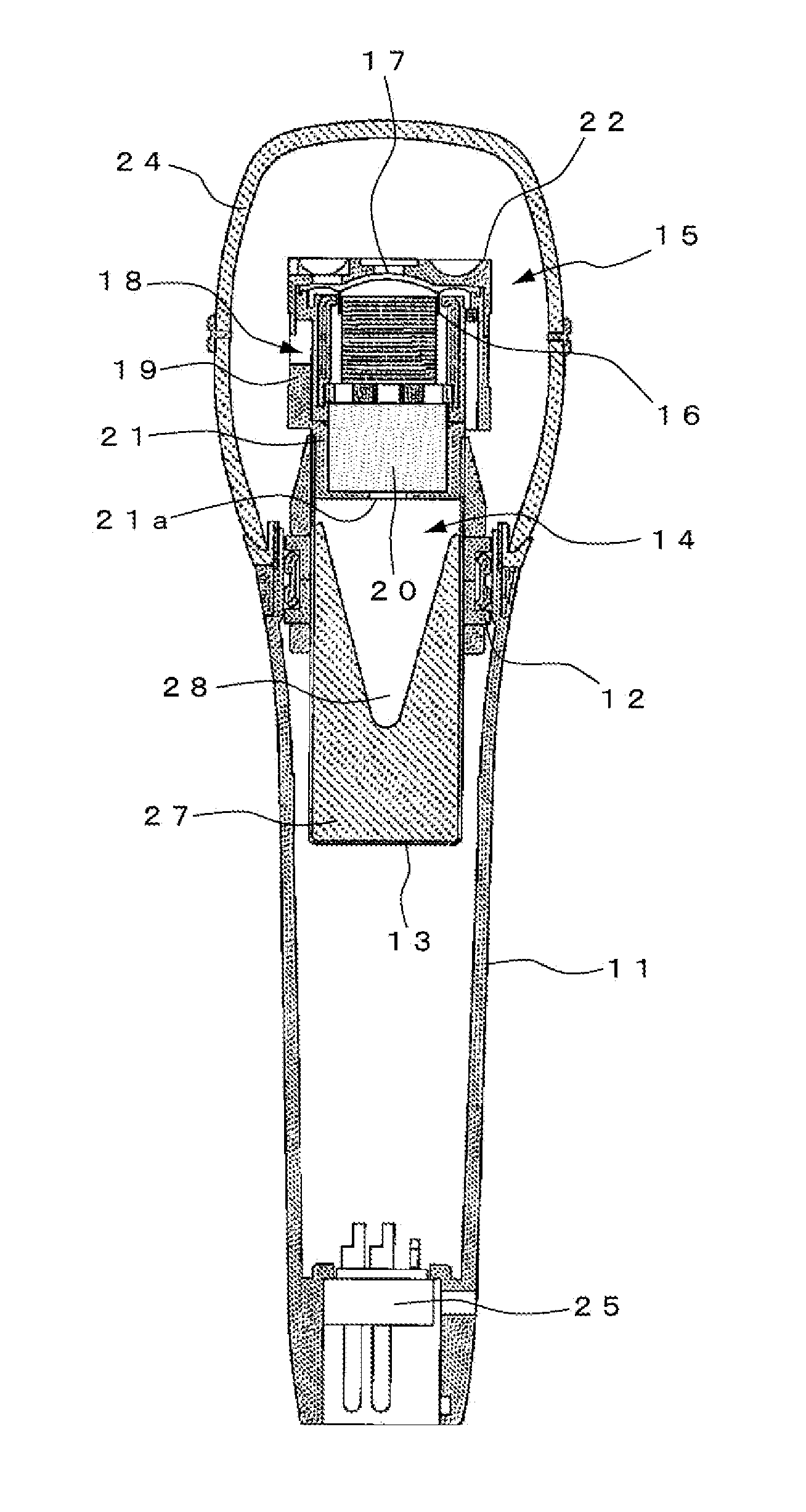

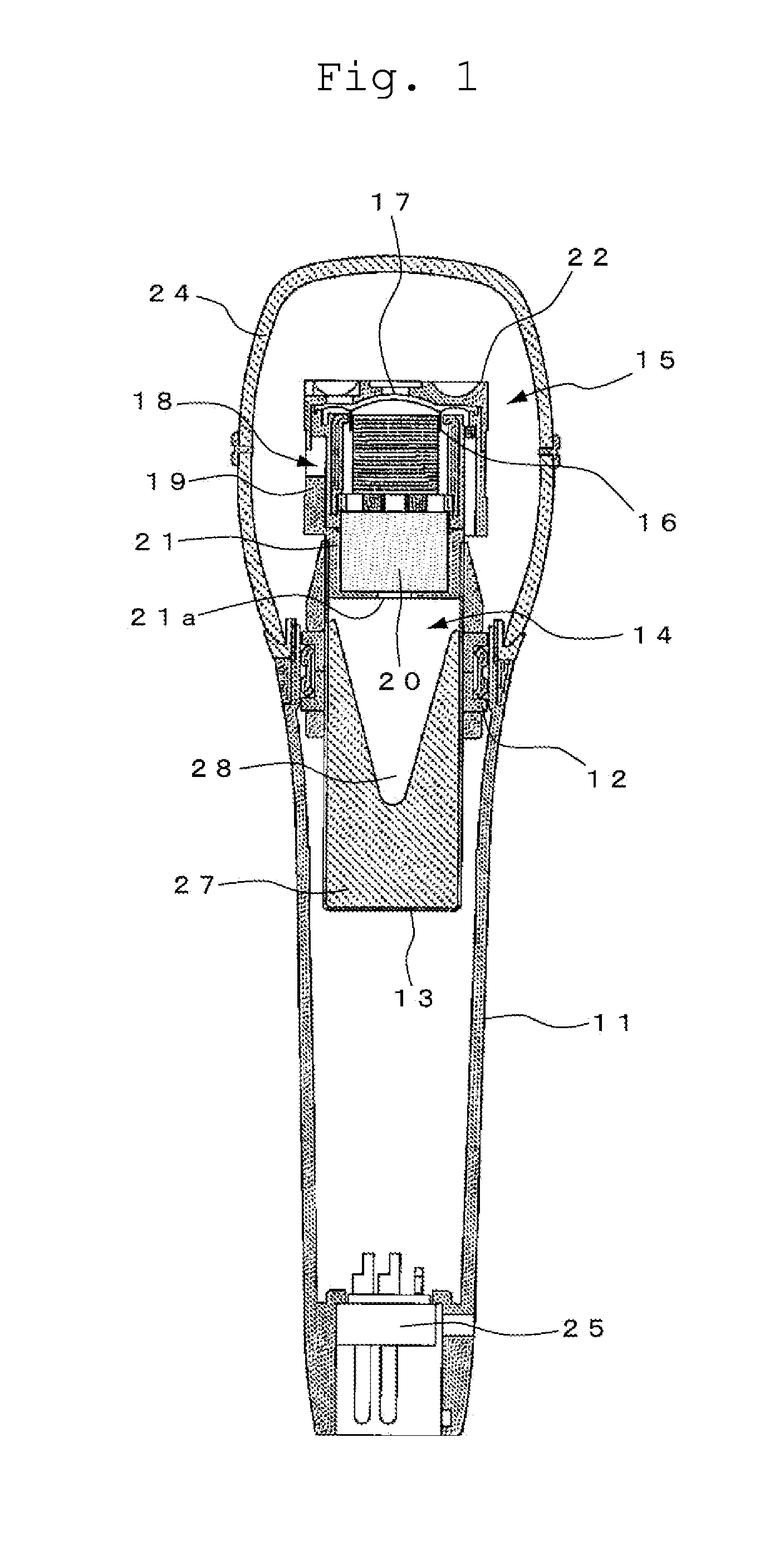

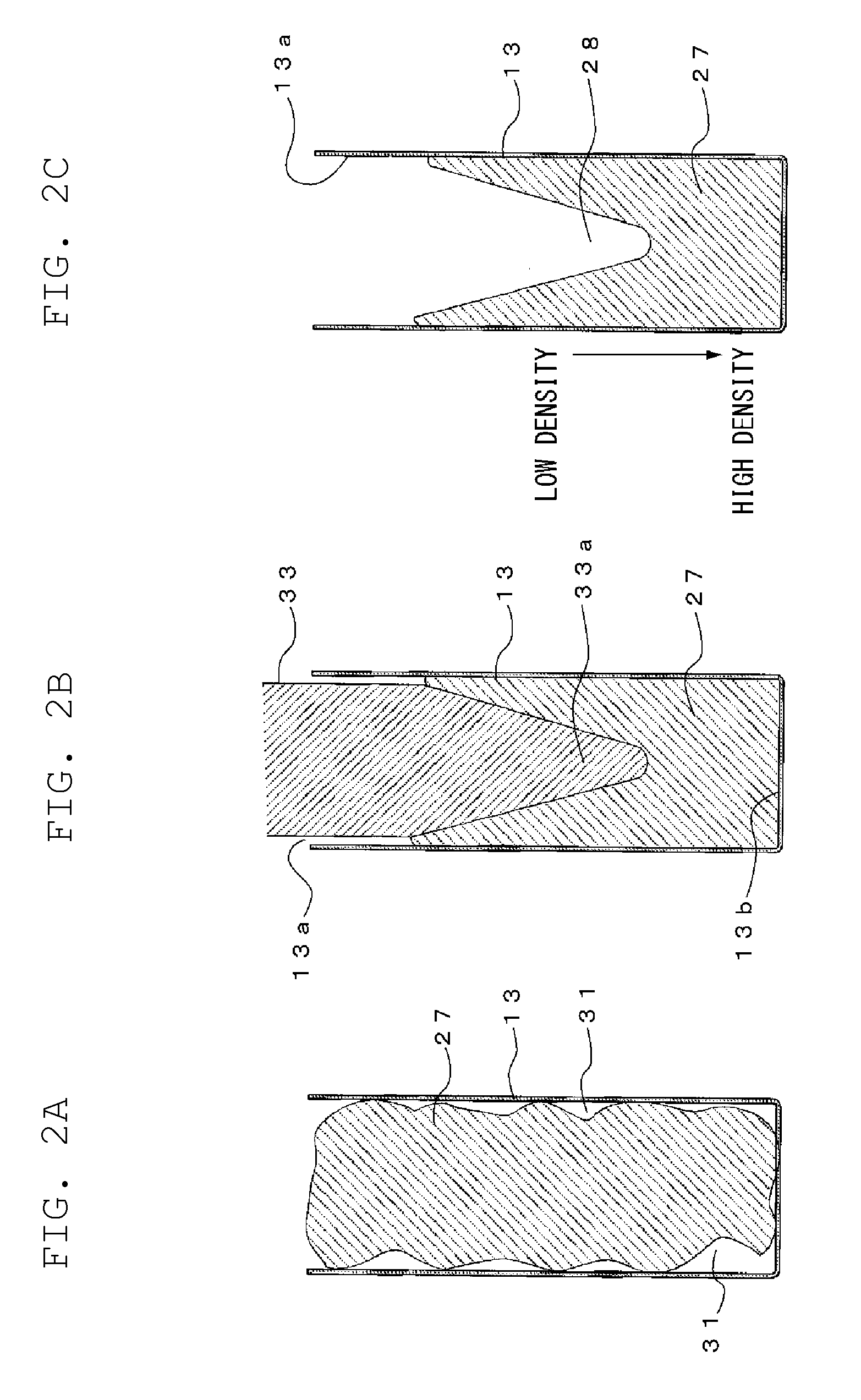

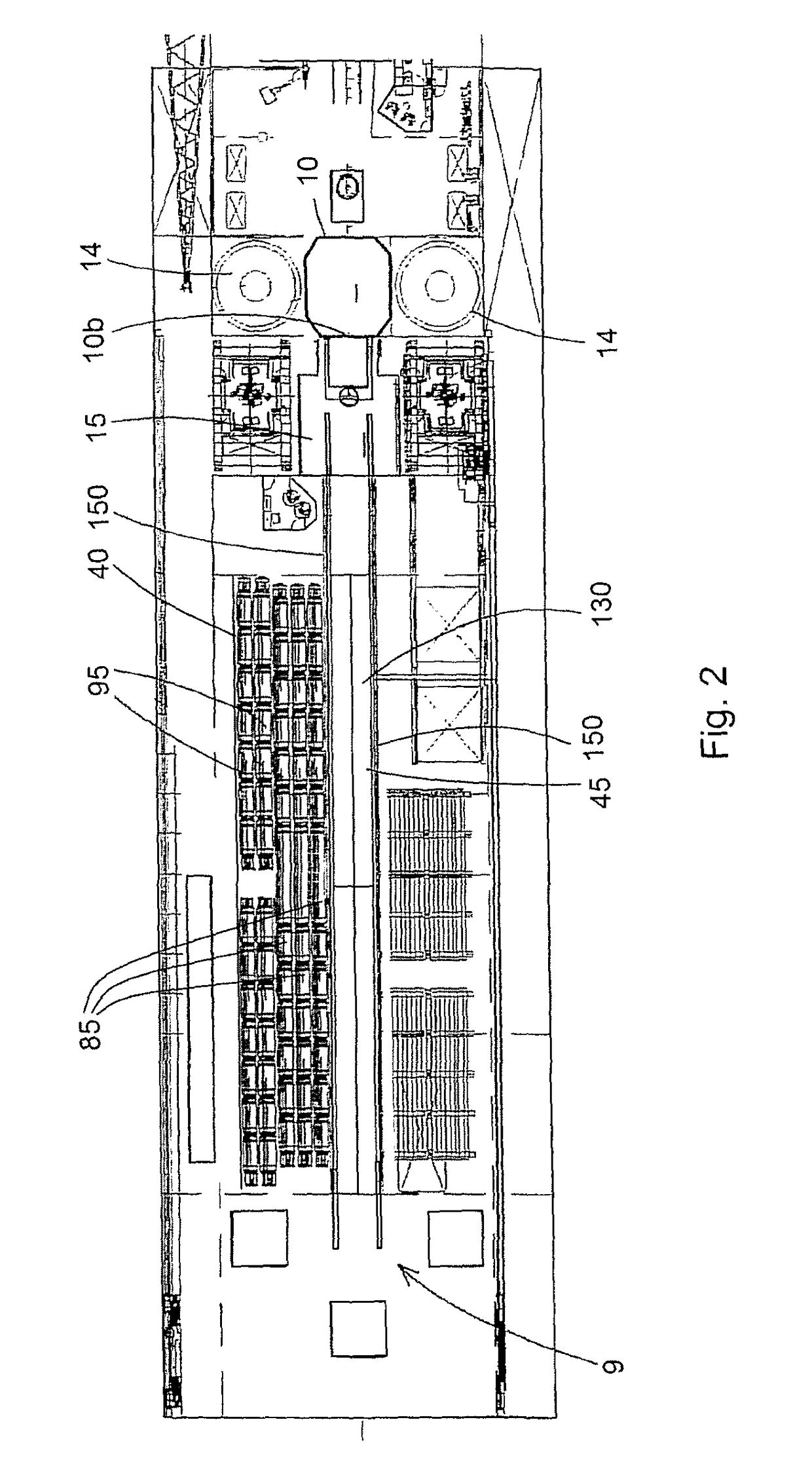

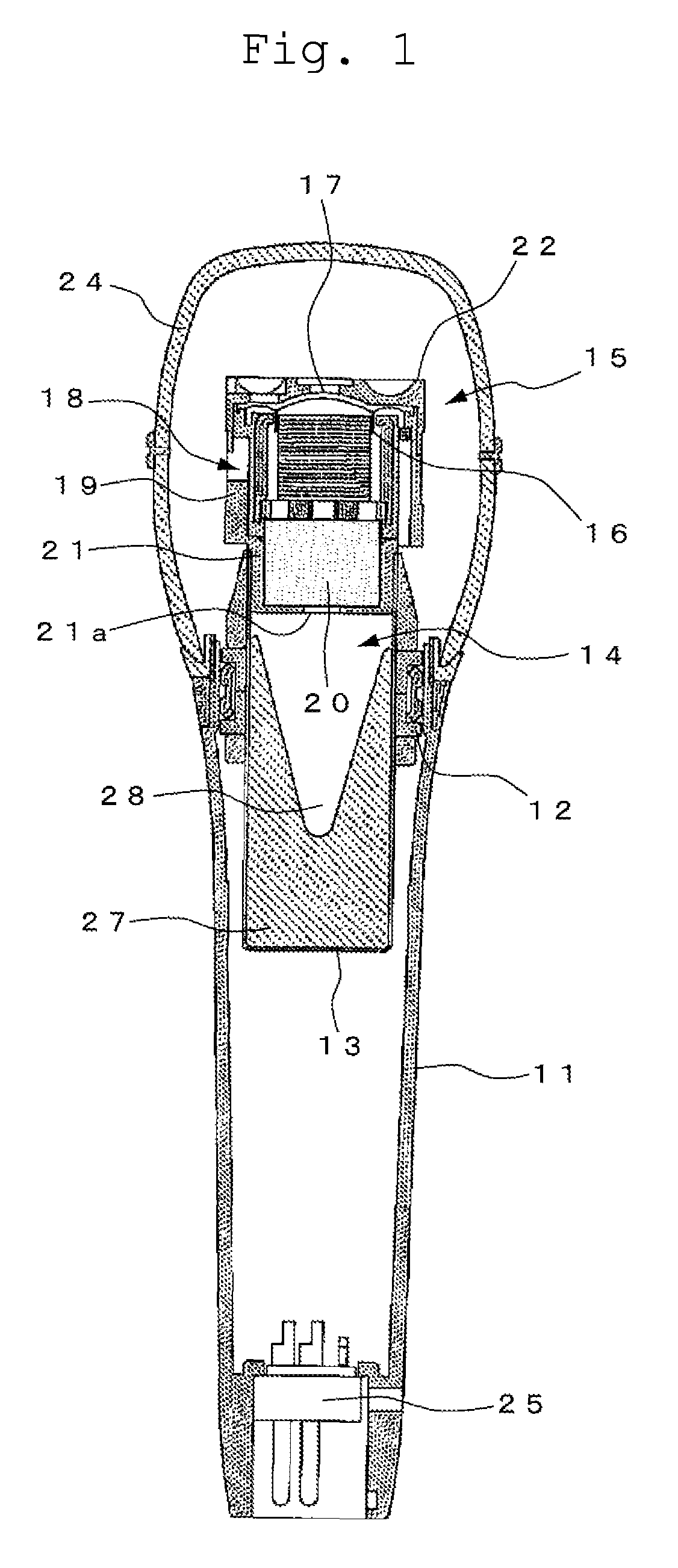

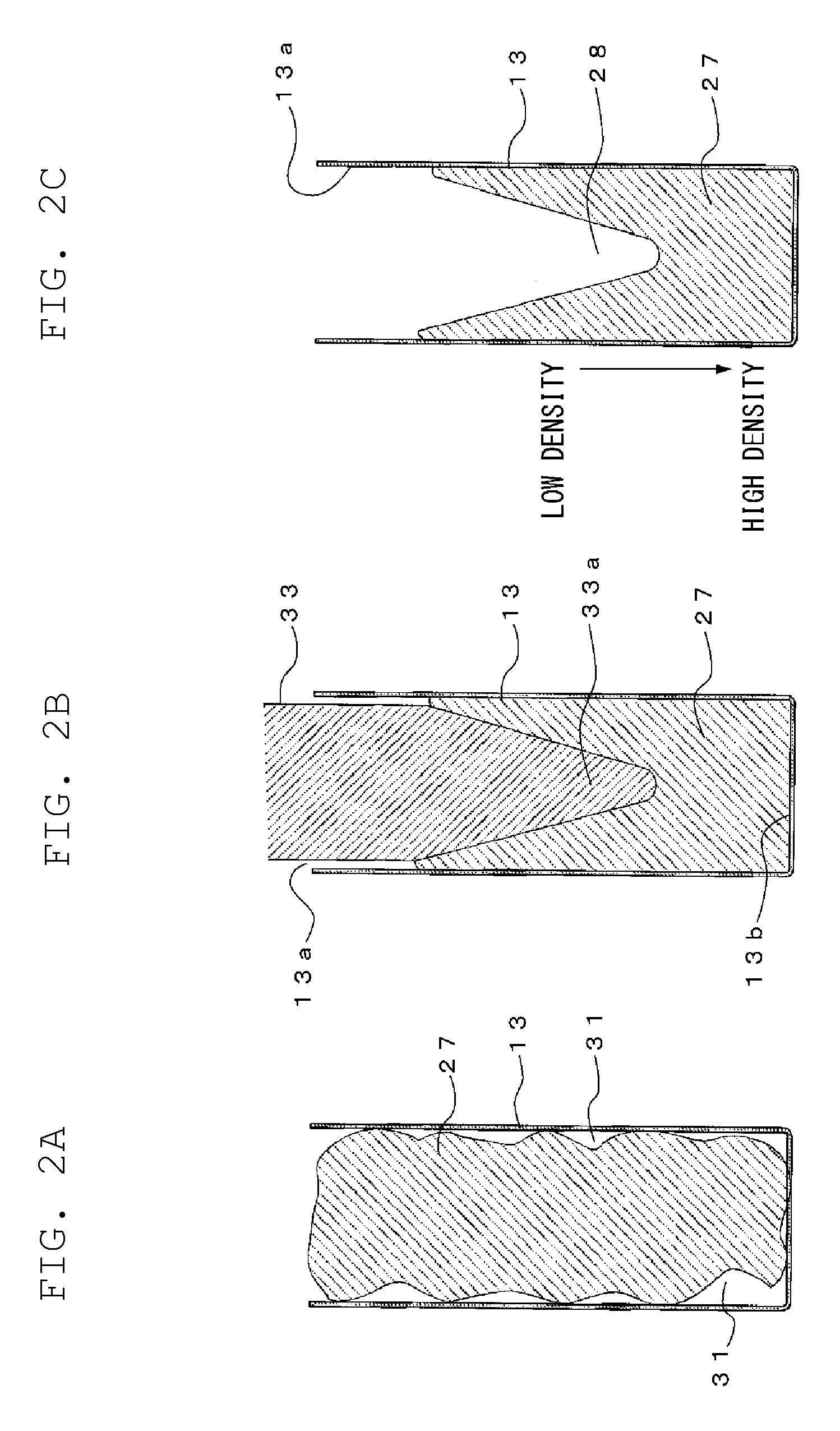

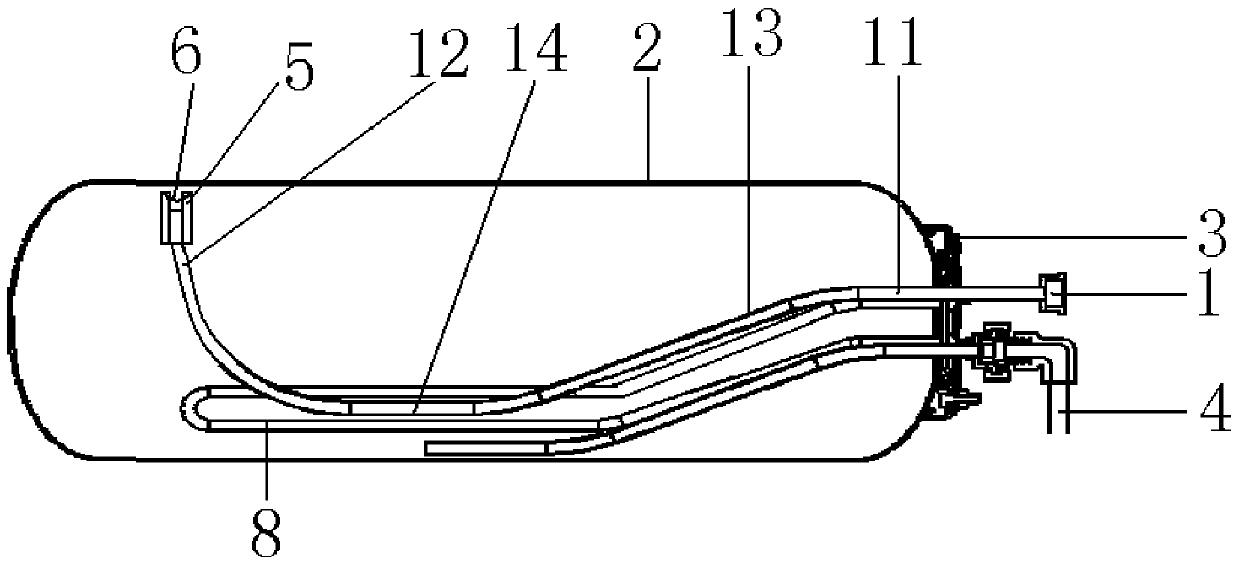

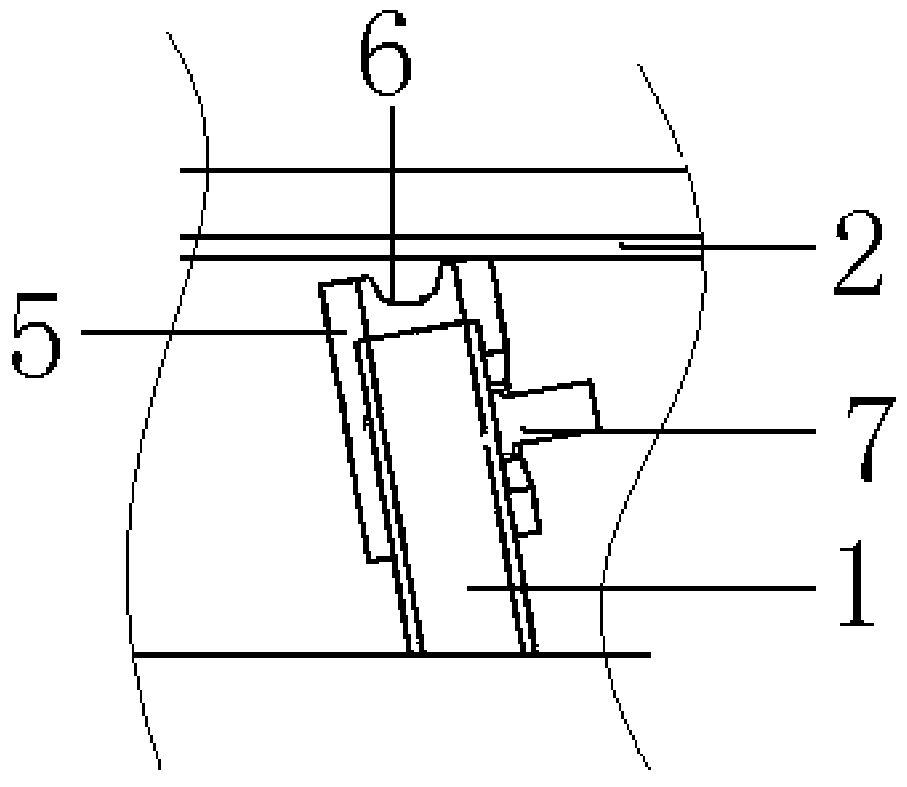

Dynamic microphone and method of forming back-side air chamber

InactiveUS20150382102A1Reduces open cross-sectional areaImproved acoustic resistanceRecord carriersFrequency/directions obtaining arrangementsResonanceEngineering

A dynamic microphone which prevents a wall forming a back-side air chamber from having a certain resonance frequency and effectively prevents the generation of standing waves in the back-side air chamber is provided. A dynamic microphone includes a dynamic microphone unit including a diaphragm configured with a voice coil and a magnetic circuit having a magnetic gap provided so as to allow the voice coil to vibrate, a bottomed case which is coupled to the dynamic microphone unit and forms a back-side air chamber communicating with back side of the diaphragm, and an acoustic resistance body which is pressingly attached in the case and composed of metal fiber including a pocket, an open cross sectional area of the pocket gradually decreasing toward the direction remote from the dynamic microphone unit.

Owner:AUDIO-TECHNICA

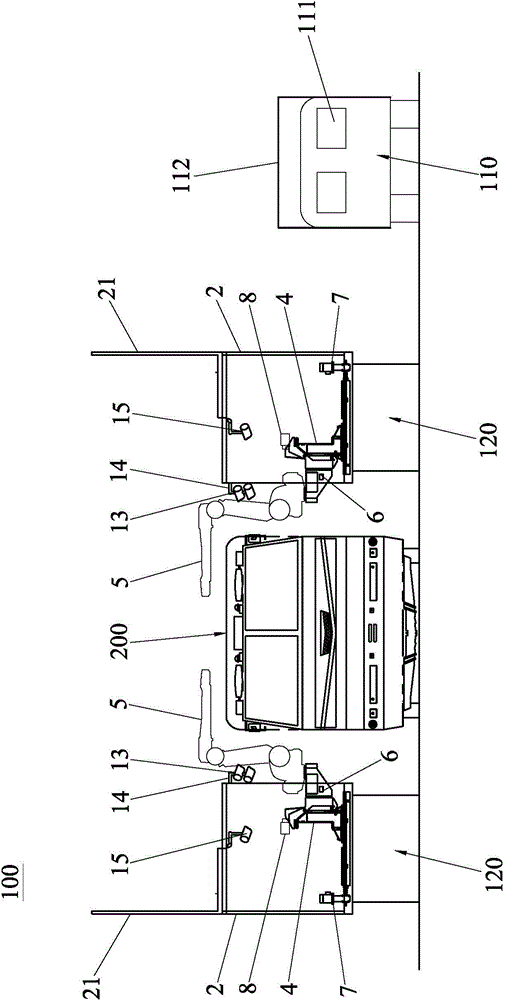

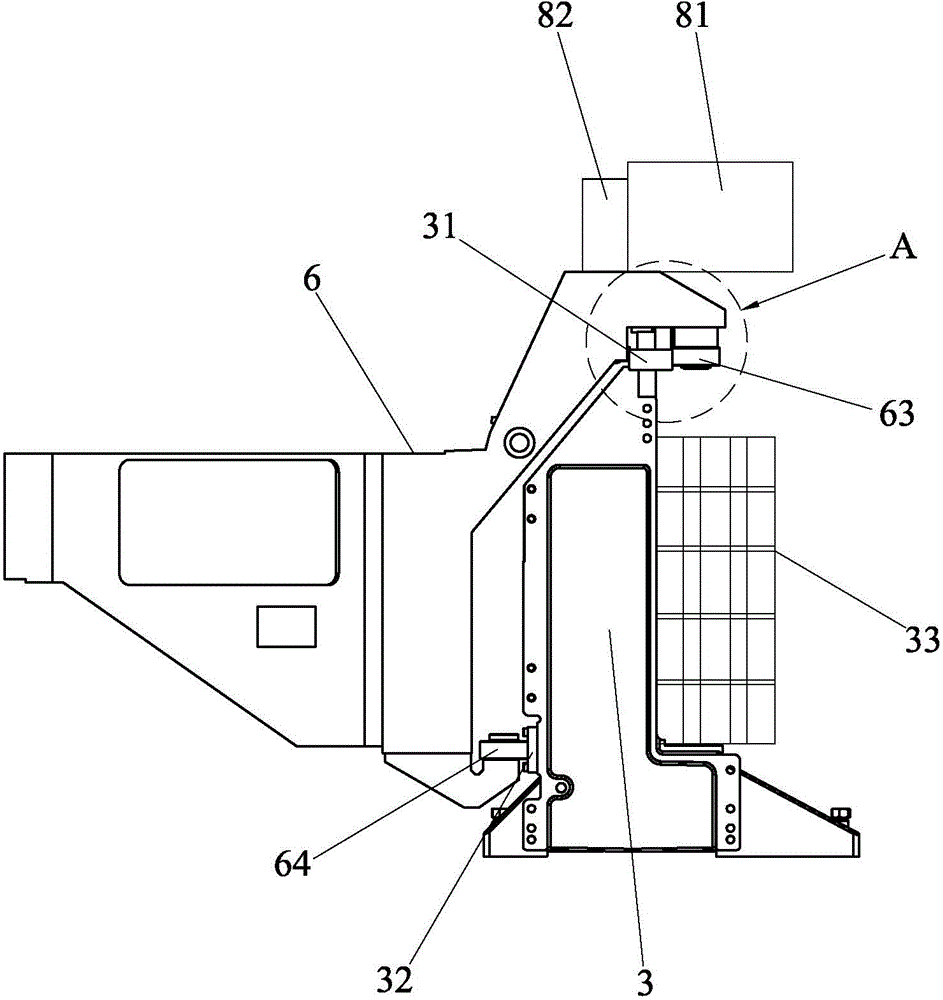

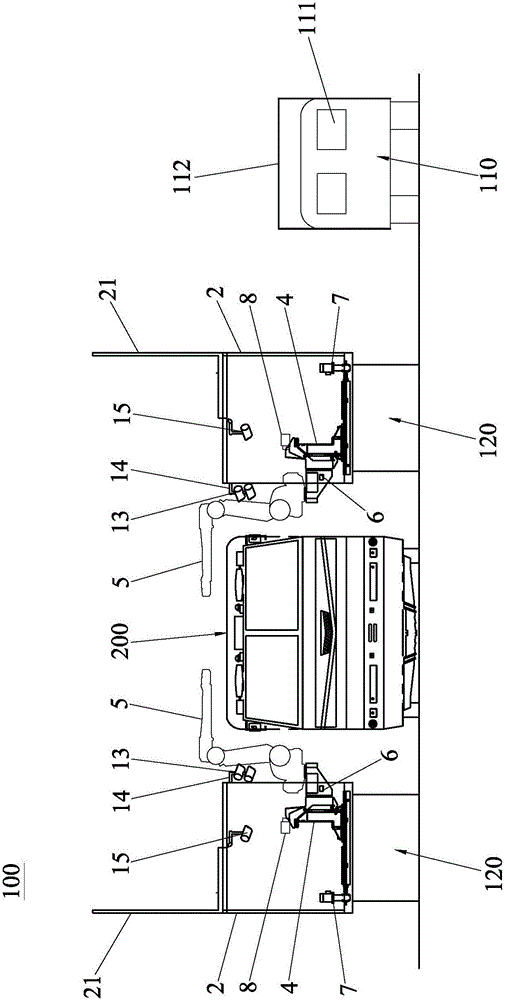

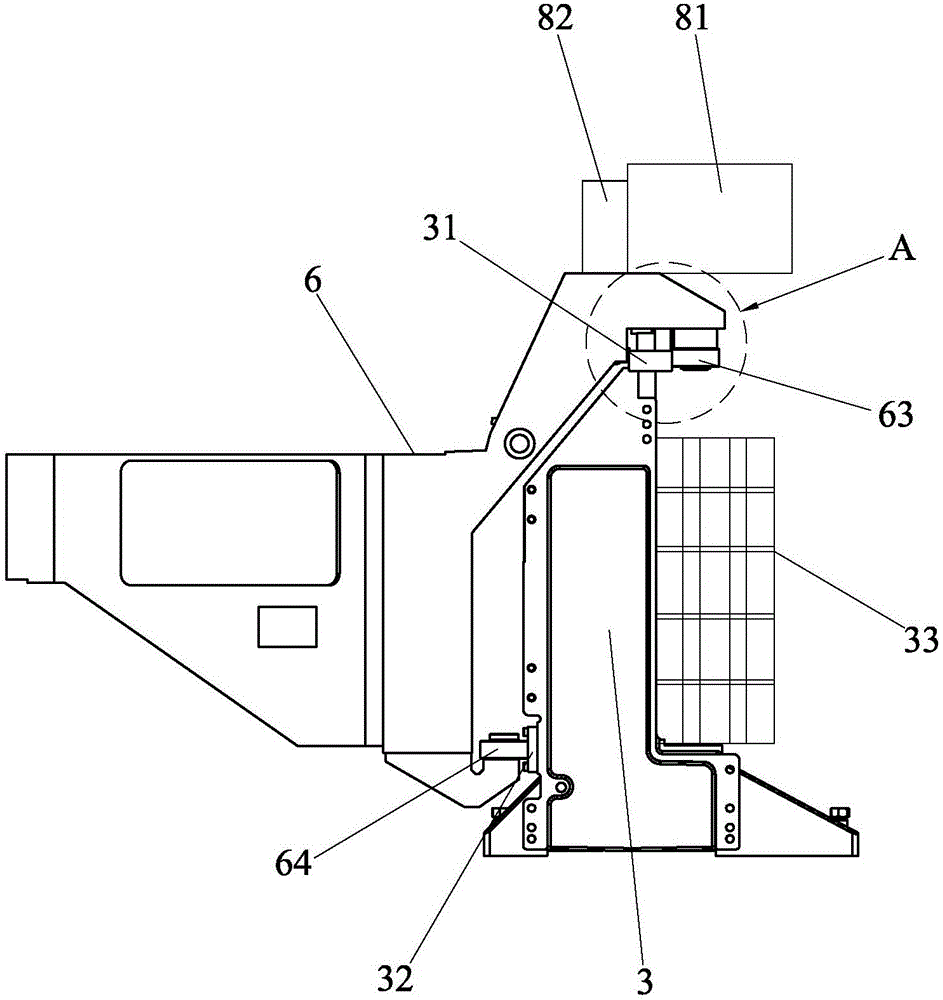

Mobile spray coating system

InactiveCN104588242AEffective use of volumeIncrease in sizeSpraying apparatusSpray coatingEngineering

The invention discloses a mobile spray coating system. The mobile spray coating system comprises a mobile control unit and a mobile executing unit, wherein the mobile executing unit comprises a first mobile carrying tool, a first container, a first guide rail, a second guide rail, a spray coating robot, a cart, a translation mechanism, a driving mechanism, a gas supply system, a paint supply system and an electric control box, wherein the first guide rail is arranged in the first container and is fixed to the first side in the first container; the cart is glidingly arranged on the first guide rail; the spray coating robot is fixed on the cart; the driving mechanism drives the cart to move; the second guide rail is glidingly arranged on one end of the first guide rail; the gliding direction of the second guide rail is vertical to the guidance direction of the second guide rail; the translation mechanism pushes the second guide rail to be spliced to the end part of the first guide rail; the gas supply system, the paint supply system and the electric control box are arranged on the second side of the first container. The mobile spray coating system can be moved outdoors and can perform spray coating to an outdoor large workpiece.

Owner:东莞丰裕电机有限公司

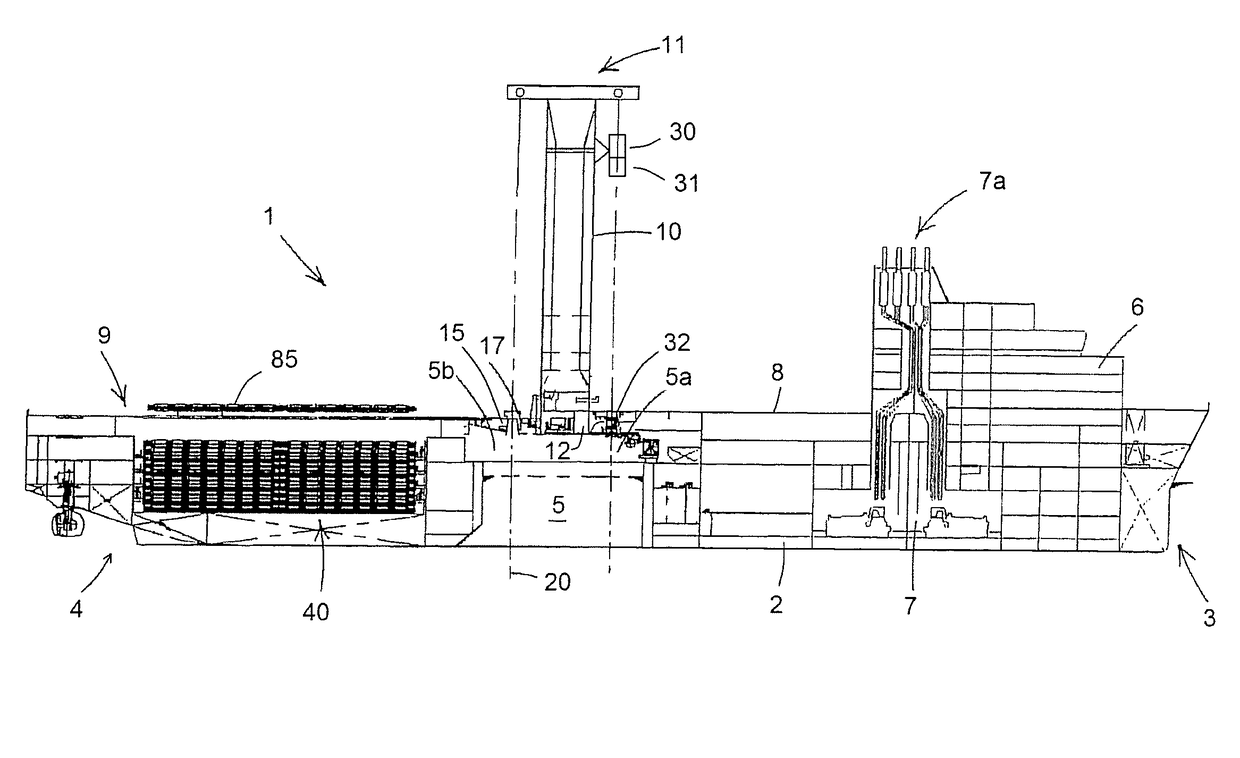

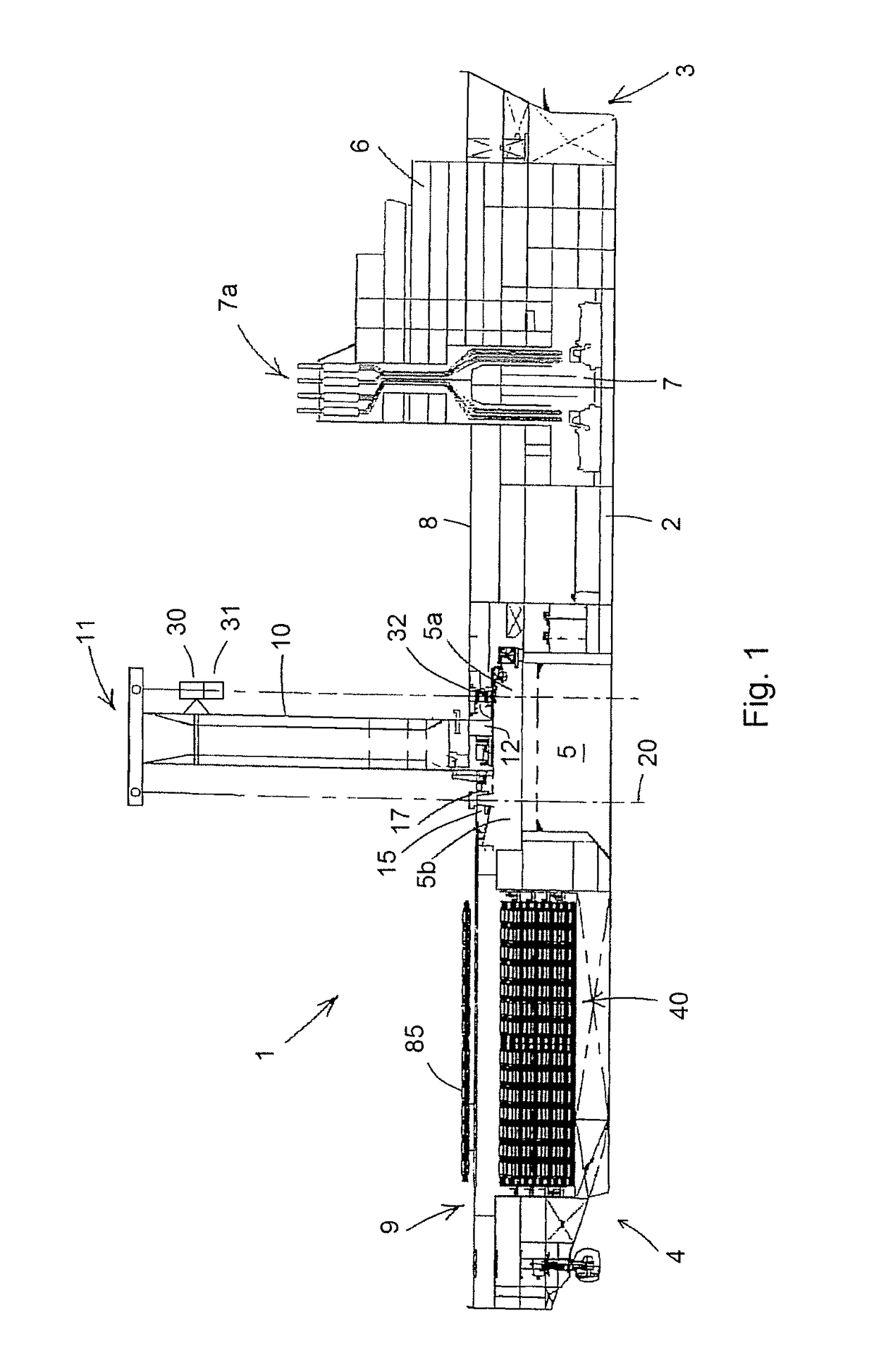

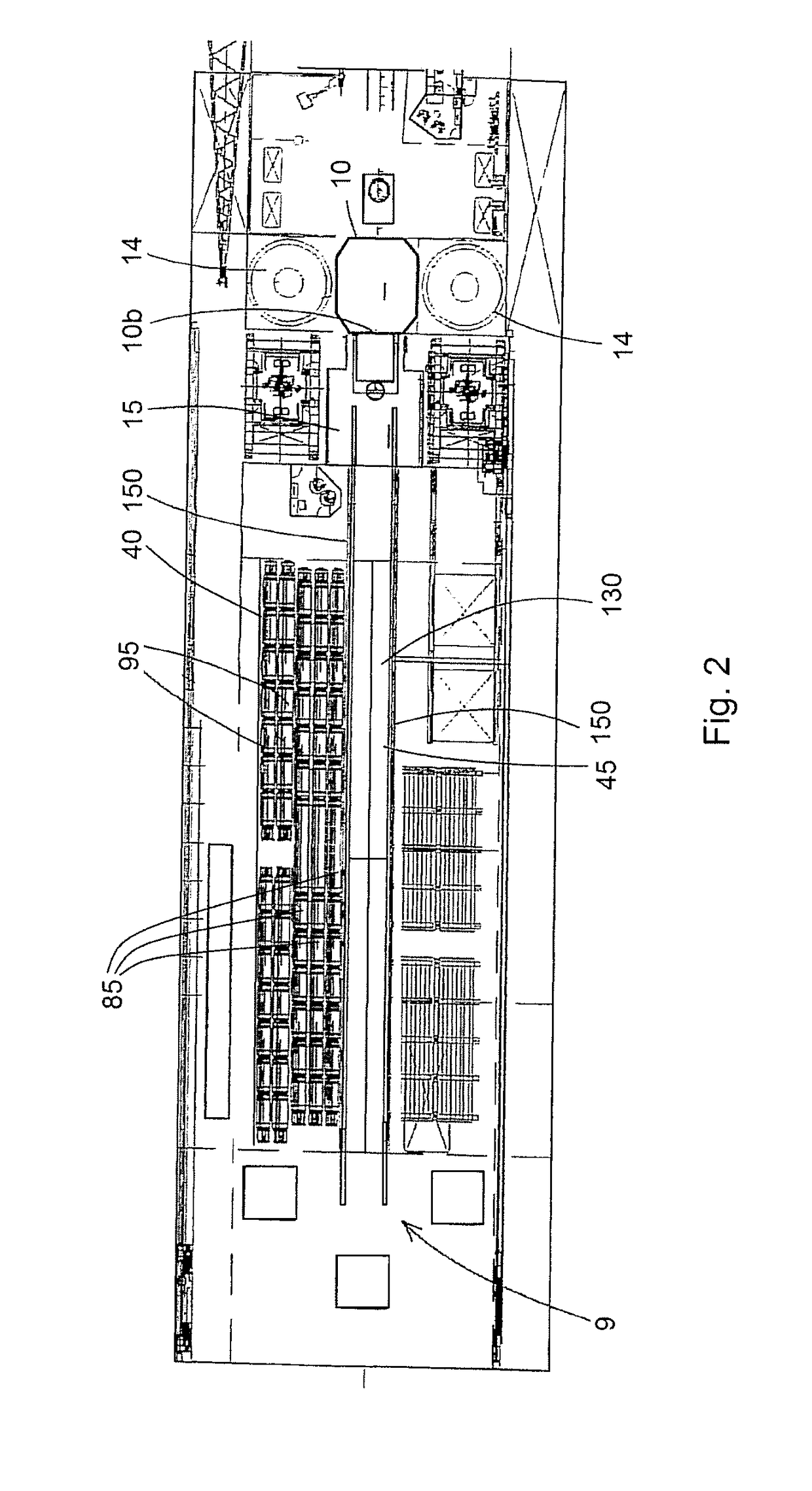

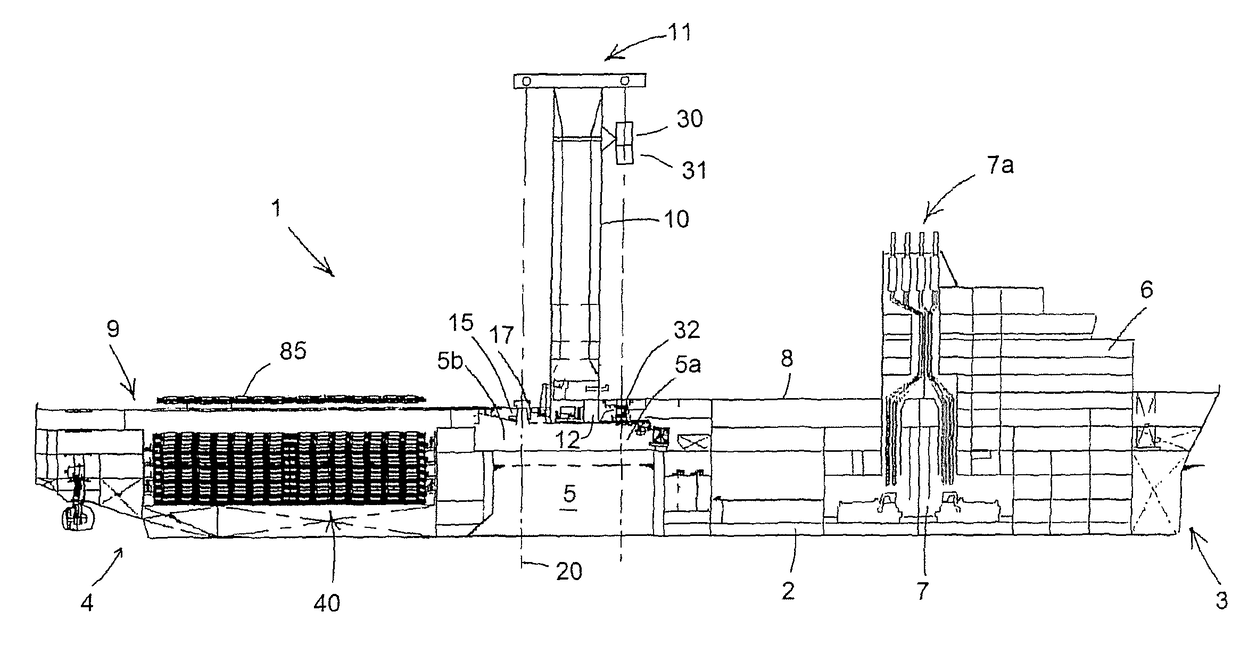

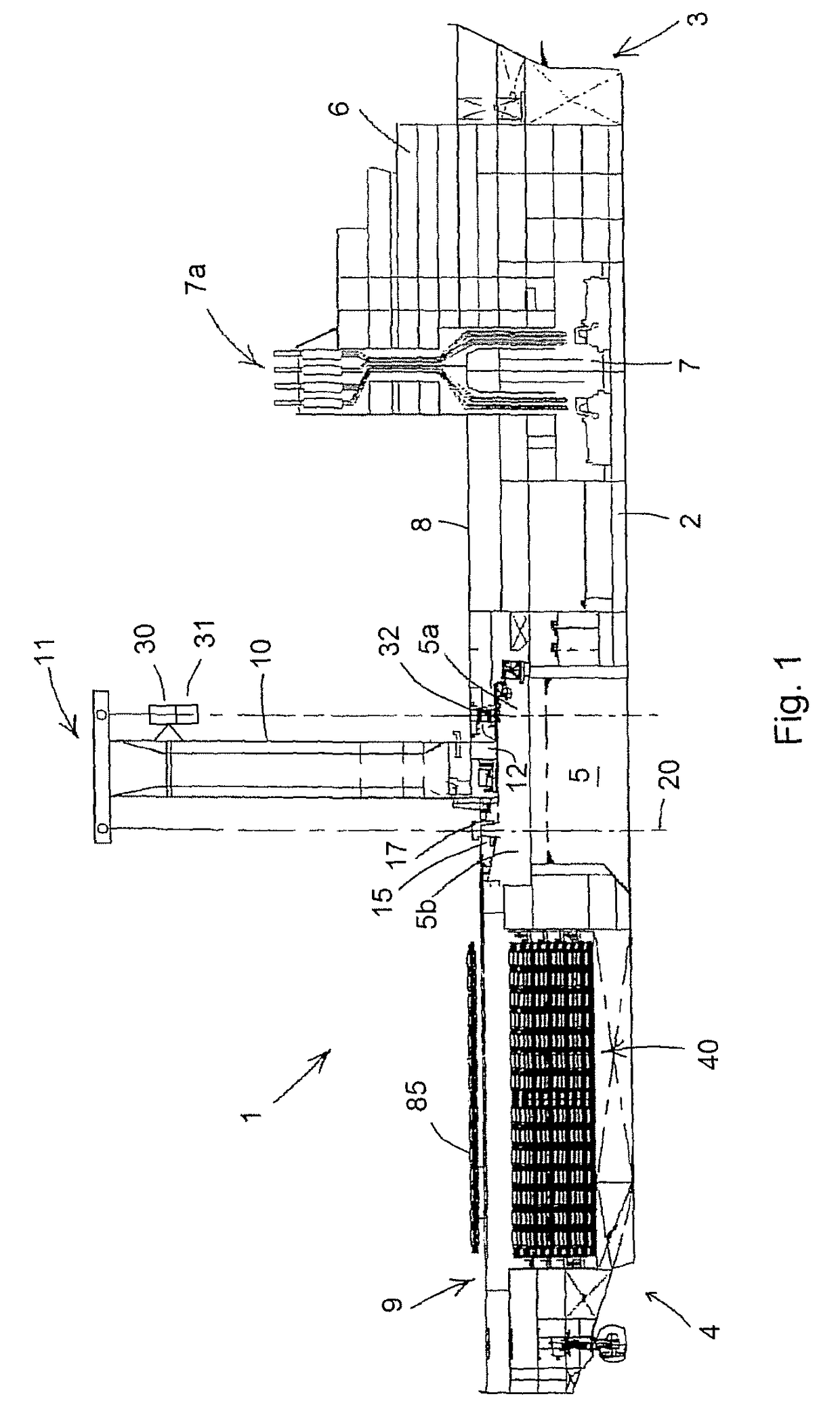

Subsea wellbore operations vessel

ActiveUS20170305510A1Effective use of volumeDrilling rodsWaterborne vesselsOcean bottomMarine engineering

A vessel is adapted to perform subsea wellbore related operations involving a riser string between the subsea wellbore and the vessel, e.g. drilling and / or wellbore intervention. The vessel includes a hull having a deck, and a riser storage hold present within the hull below the deck. The riser storage hold includes storage racks adapted to store therein parallel stacks of multiple riser sections and / or pre-assembled riser stands in horizontal orientation. The vessel has an elongated riser transfer opening between the deck and the roof, the riser transfer opening extending in a direction parallel to the storage racks, the riser transfer opening having a length and a width so as to allow for transfer of a single riser section or a single riser stand in horizontal orientation via the riser transfer opening out of and into the riser storage hold, wherein the risers' handling system is suitable to work at the same time with two different lengths.

Owner:ITREC BV

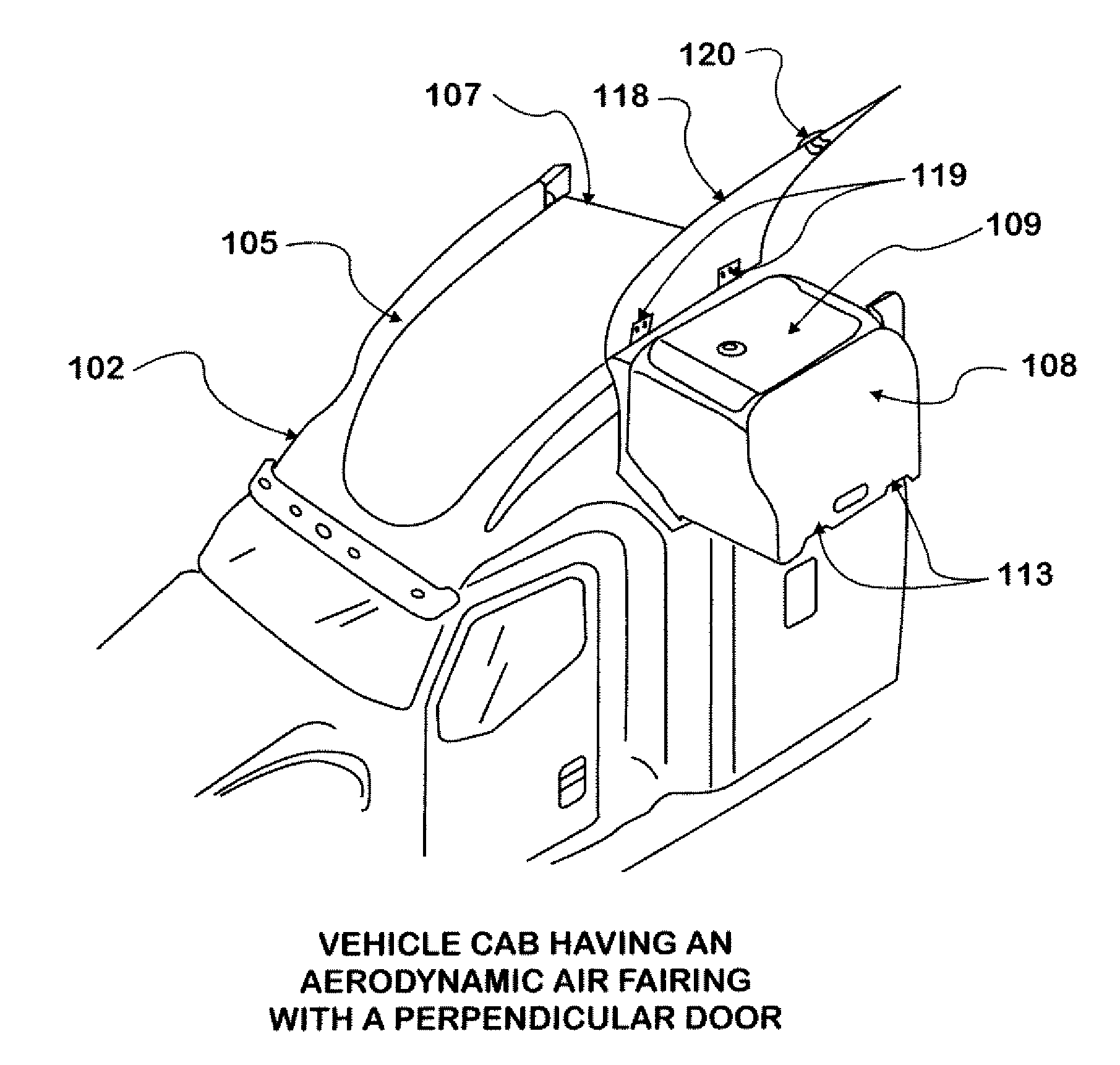

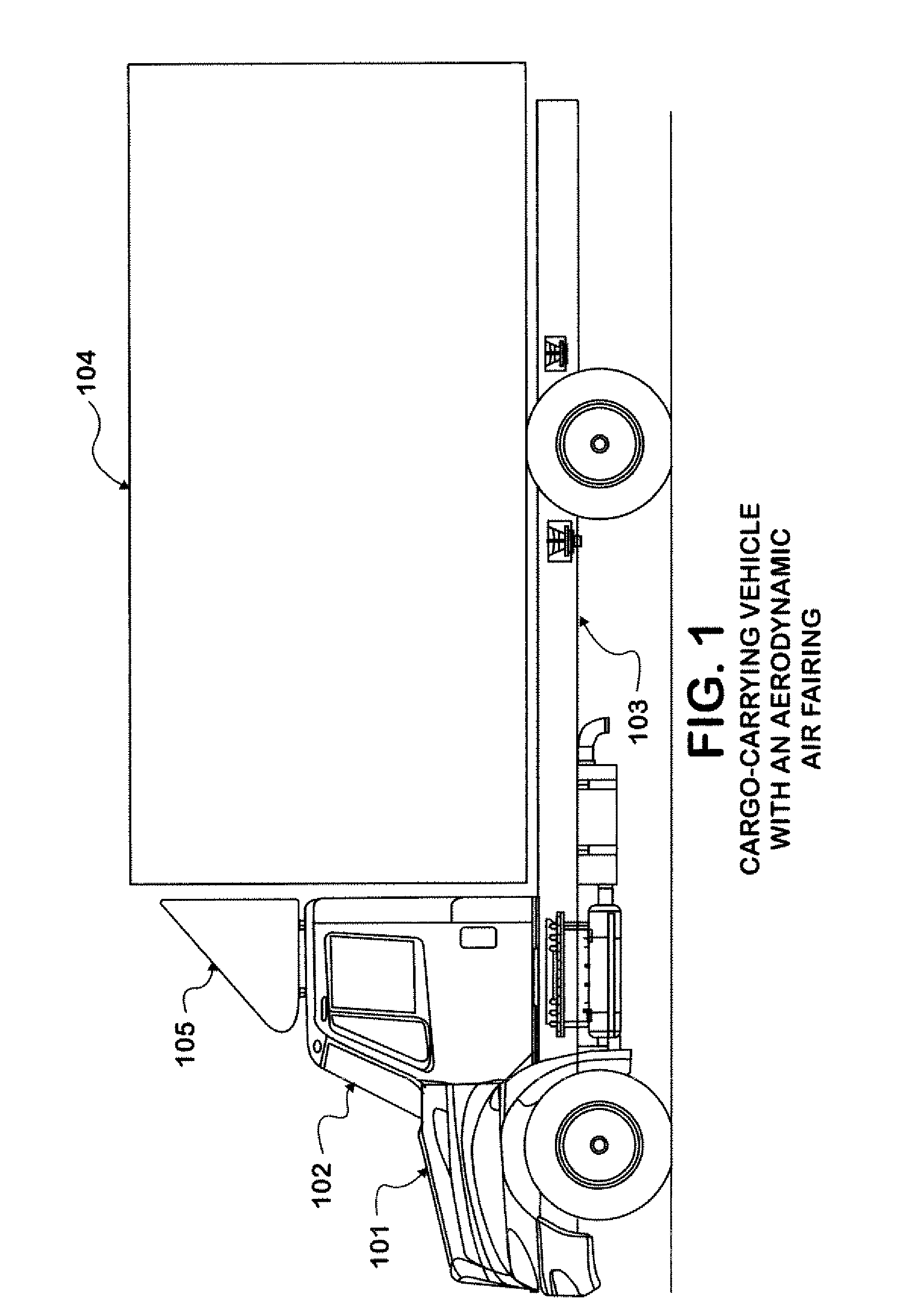

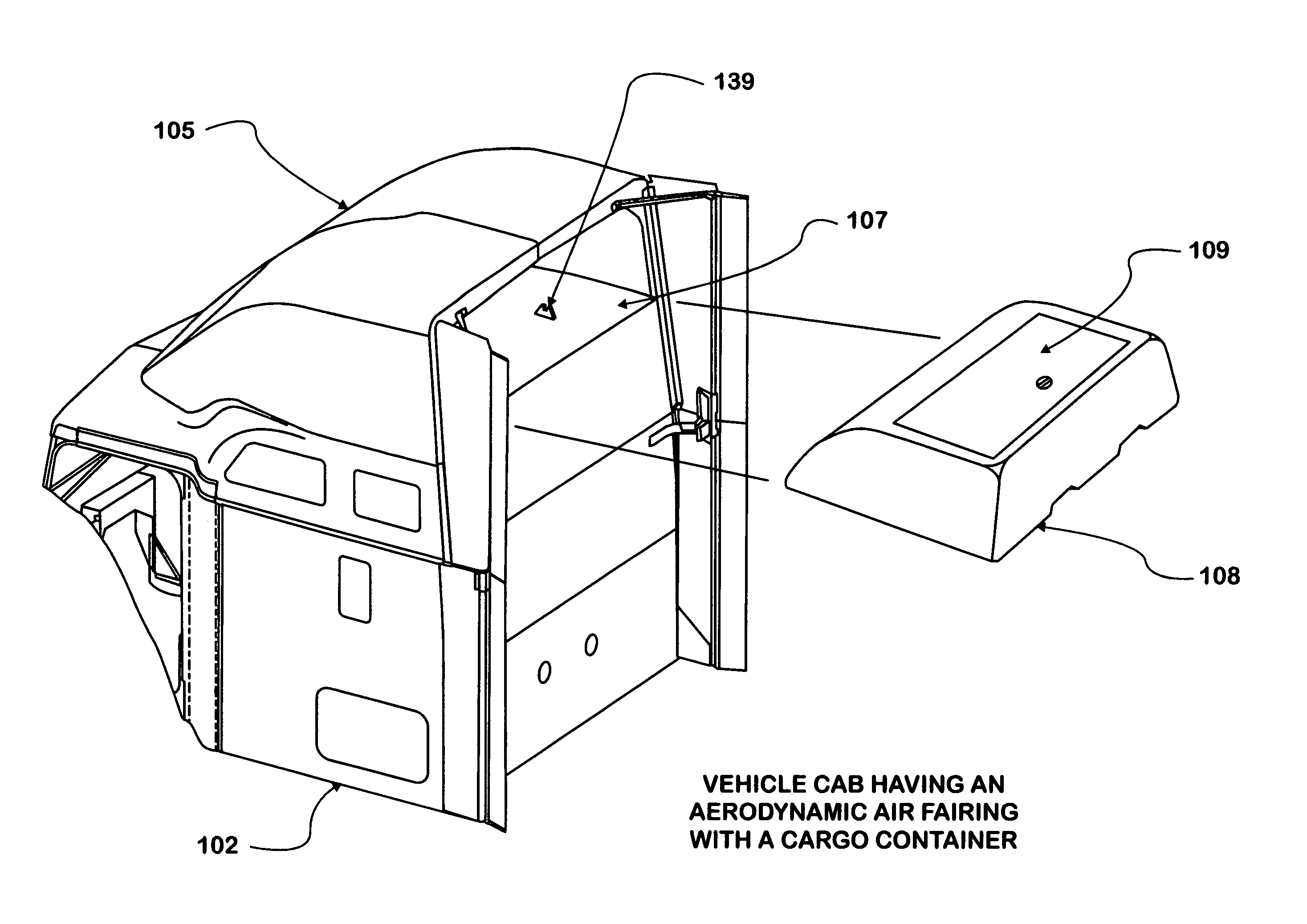

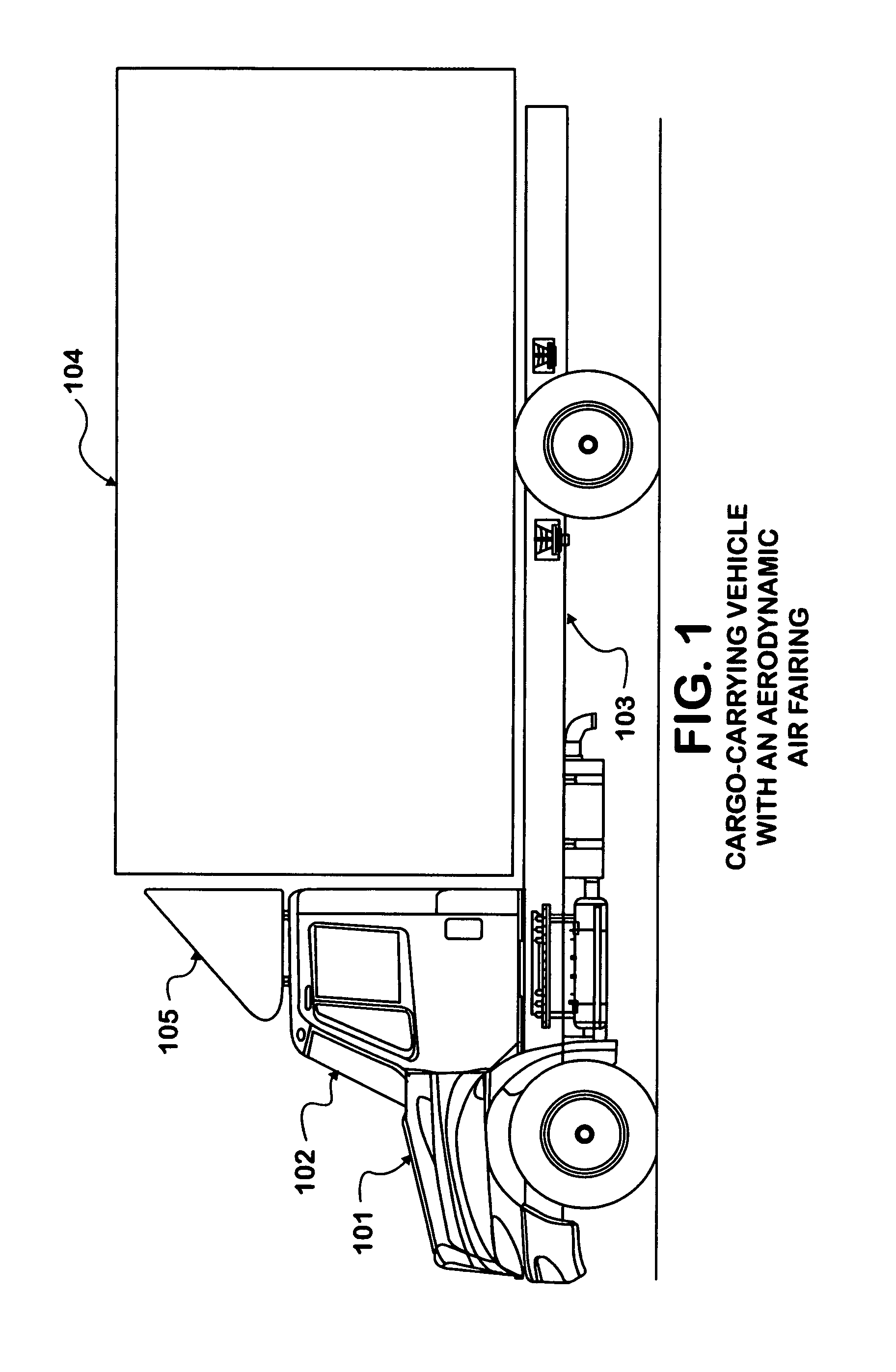

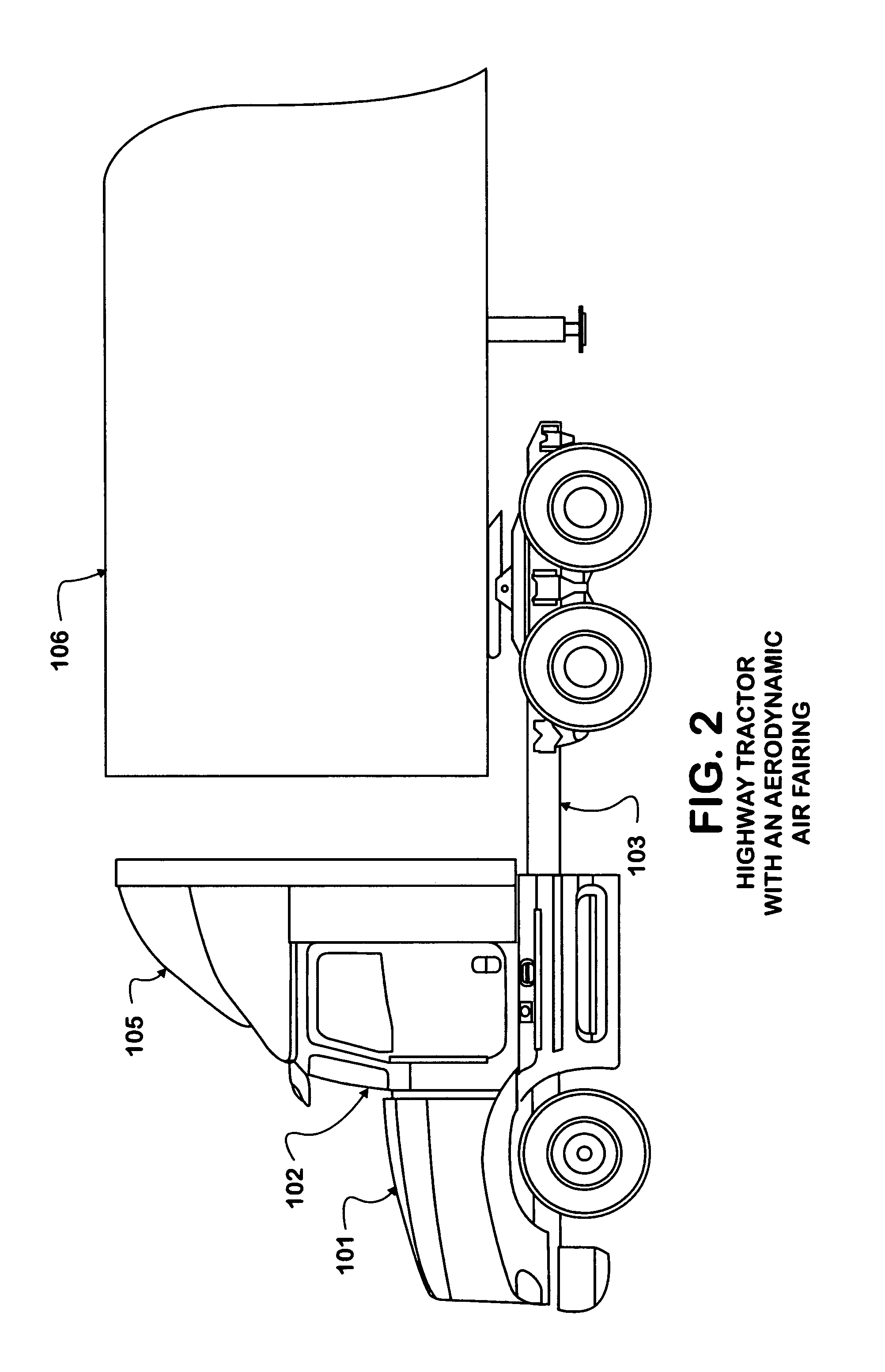

Cab air fairing cargo caddy system

InactiveUS7100957B1Low production costIncreased vehicle productivitySupplementary fittingsMonocoque constructionsSystems designEngineering

A storage or cargo caddy system designed to fit into or supplant an air fairing of a ground traveling vehicle. Means for loading, unloading, attachment, and access to the storage system are disclosed. Use of the storage or cargo caddy system more efficiently utilizes the space occupied by air fairings on cargo-carrying vehicles currently, and provides for Less Than full-Load capacity.

Owner:INT TRUCK INTPROP LLC

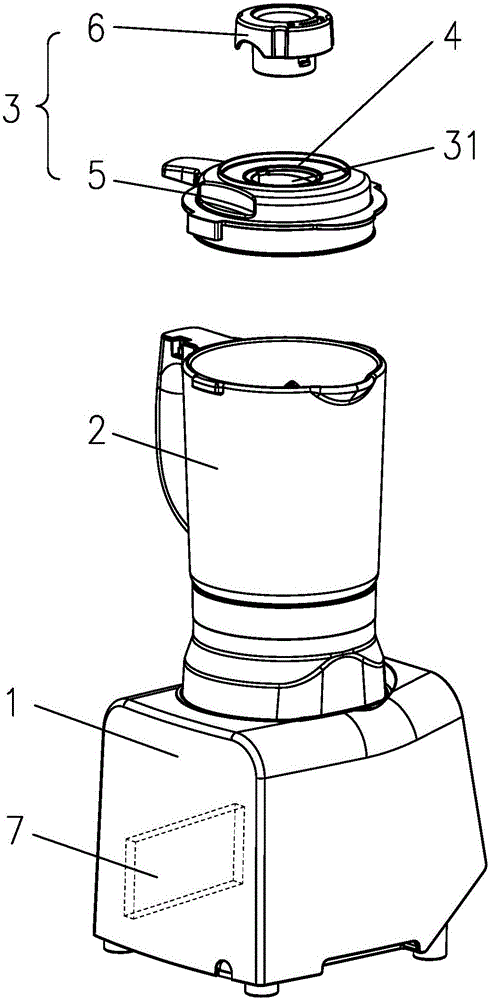

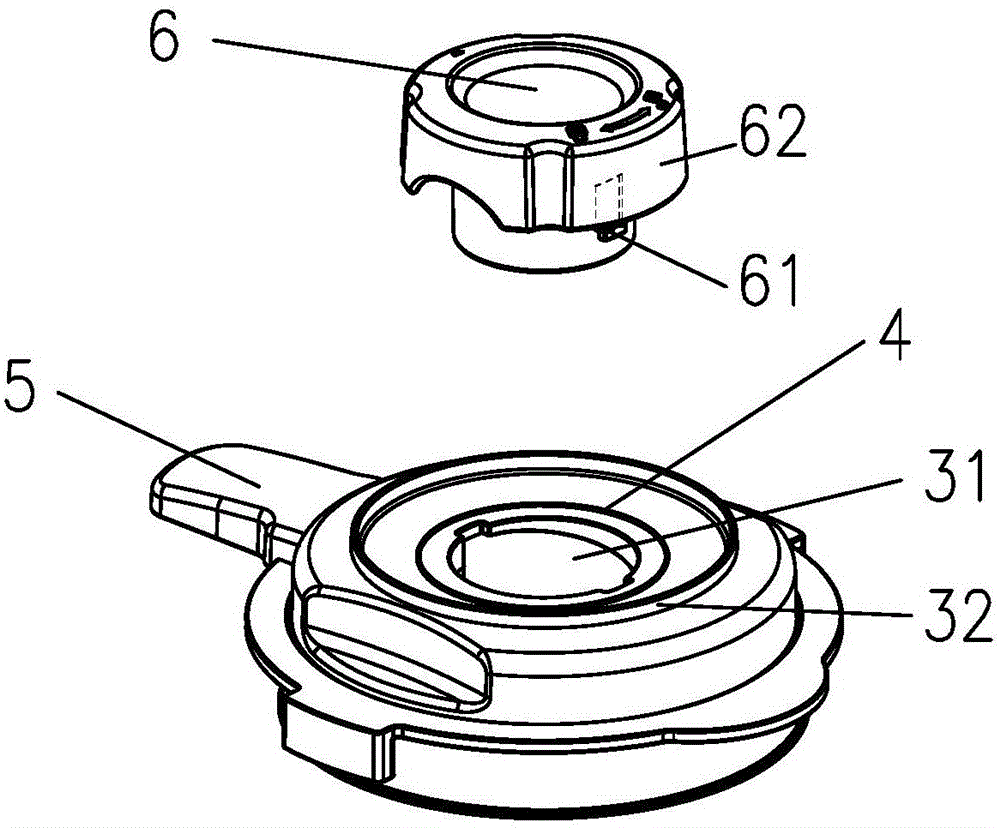

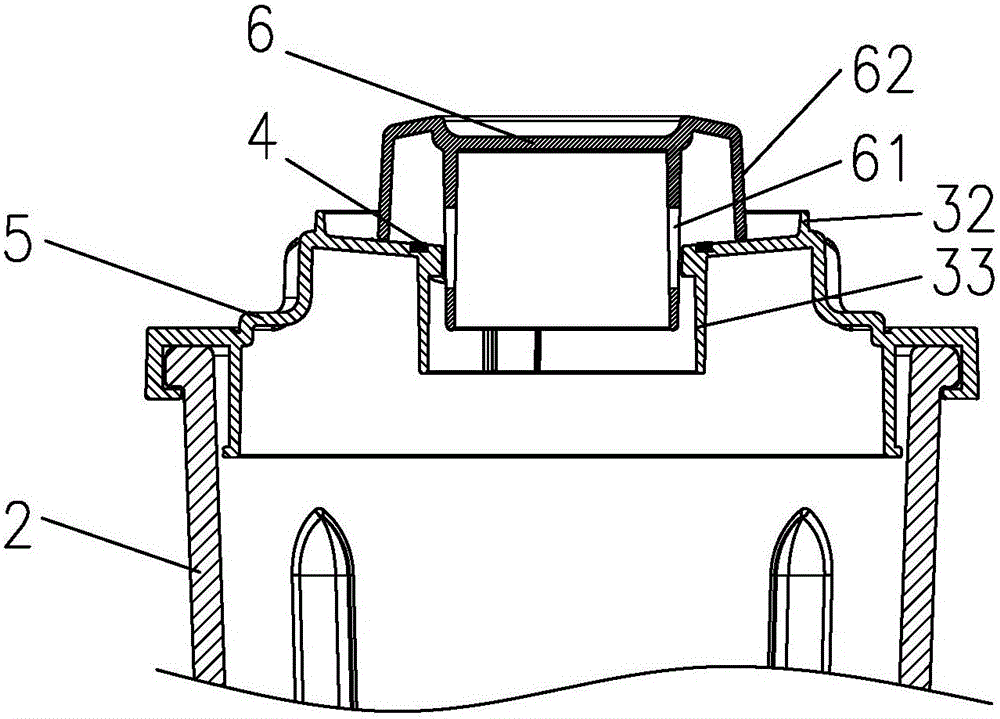

Anti-overflow food processor

PendingCN106691240ADecrease productivityAvoid volume inflatedBoiling over preventionEngineeringSlurry

The invention discloses an anti-overflow food processor; a sensing probe is disposed at the outer surface of a cup cover close to an exhaust port, slurry never contacts the sensing probe at the outer surface during normal stirring of the processor, the slurry can contact the sensing probe at the outer surface only when overflowing through the exhaust port, a control unit is then triggered to output a stop signal to prevent overflow, and stopping of the processing, affected material crushing effect and reduced working efficiency of the processor due to misjudgment under non-overflow condition are avoided; in addition, the anti-overflow requirements in stirring crushing stage and heating stage are met, whole-course overflow prevention is truly achieved, the volume of a stirring cup may be effectively utilized, virtual increase in the volume of the stirring cup due to the failure of effective utilization of an anti-overflow rod and space below the same in the prior art is avoided, product cost is reduced, and the anti-overflow food processor is safer and more sanitary, more reliable to use, and is widely applicable to various types of food processors.

Owner:江门市贝尔斯顿电器有限公司

Mobile spraying system

InactiveCN104998787AEffective use of volumeIncrease in sizeSpraying apparatusSpray coatingExecution unit

The invention discloses a mobile spray coating system. The mobile spray coating system comprises a mobile control unit and a mobile executing unit, wherein the mobile executing unit comprises a first mobile carrying tool, a first container, a first guide rail, a second guide rail, a spray coating robot, a cart, a translation mechanism, a driving mechanism, a gas supply system, a paint supply system and an electric control box, wherein the first guide rail is arranged in the first container and is fixed to the first side in the first container; the cart is glidingly arranged on the first guide rail; the spray coating robot is fixed on the cart; the driving mechanism drives the cart to move; the second guide rail is glidingly arranged on one end of the first guide rail; the gliding direction of the second guide rail is vertical to the guidance direction of the second guide rail; the translation mechanism pushes the second guide rail to be spliced to the end part of the first guide rail; the gas supply system, the paint supply system and the electric control box are arranged on the second side of the first container. The mobile spray coating system can be moved outdoors and can perform spray coating to an outdoor large workpiece.

Owner:陈煜达

Cab air fairing cargo caddy system

InactiveUS7114757B1Effective use of volumeThe process is convenient and fastVehicle seatsWindowsTruckCargo container

A storage or cargo container designed to fit into an air fairing of a ground traveling vehicle having a cab with mounting points with a latching system to which the cargo container is adapted to be attached. Use of the storage or cargo container more efficiently utilizes the space occupied by air fairings on cargo-carrying vehicles currently, and provides for Less Than full-Load capacity.

Owner:INT TRUCK INTPROP LLC

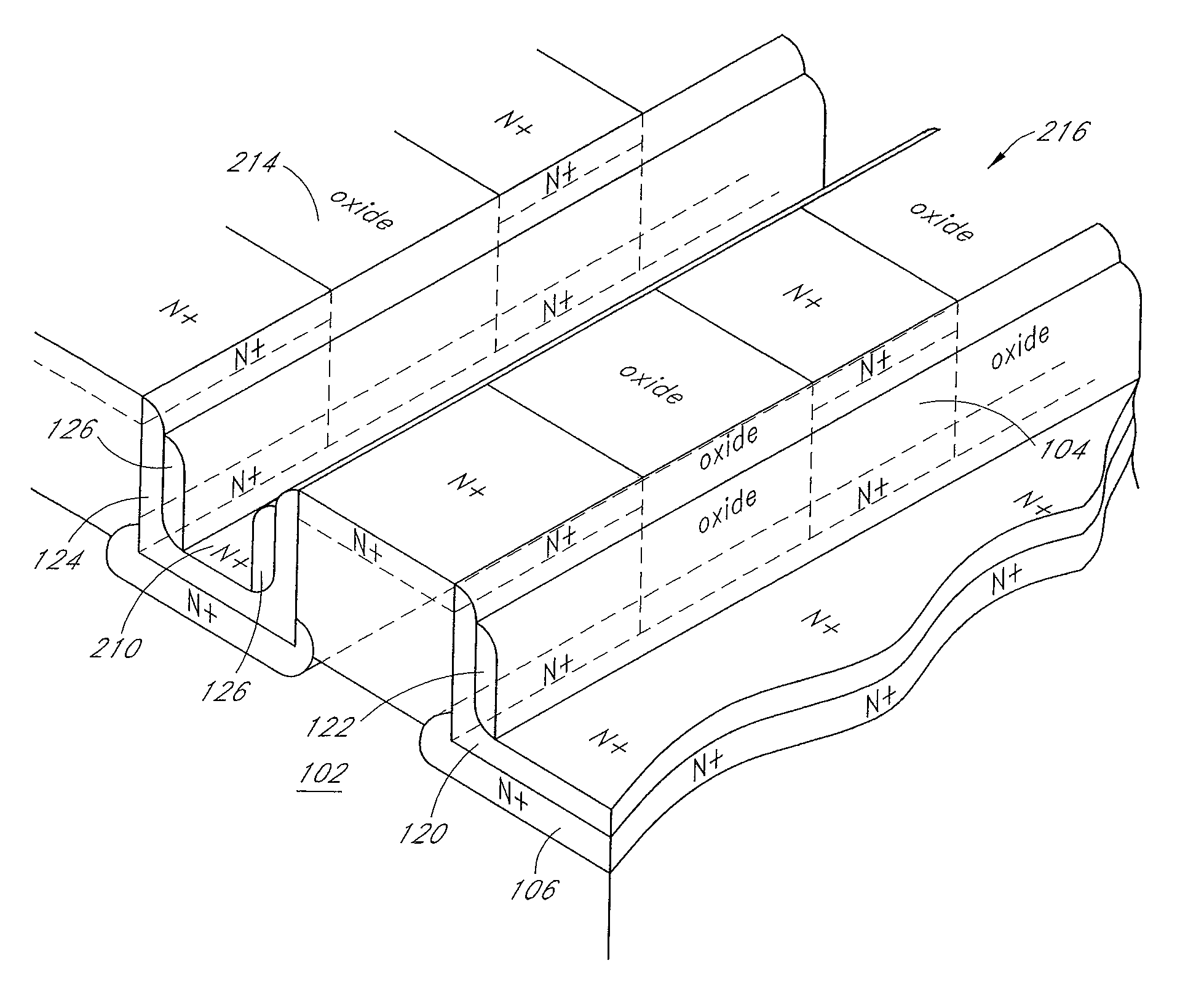

High-density single transistor vertical memory gain cell

ActiveUS7332418B1Easy to adaptEffective use of volumeTransistorSolid-state devicesDielectricElectrical conductor

A memory cell which is formed on a substrate of a first conductivity type. A pillar of the first conductivity type extends vertically upward from the substrate. A source region of a second conductivity type is formed in the substrate extending adjacent to and away from a base of the pillar. A drain region of the second conductivity type is formed in an upper region of the pillar. A gate dielectric and conductor are arranged along a first side of the pillar. A capacitor dielectric and body capacitor plate are arranged along an opposite, second side of the pillar. A depletion region around the source region defines a floating body region within the pillar which forms both a body of an access transistor structure and a plate of a capacitor structure. The cell also provides gain with respect to charge stored within the floating body.

Owner:MICRON TECH INC

Supercritical water oxidation reactor by using auxiliary fuel for supplying heat

ActiveCN102190363BEfficient mixingEfficient combustionSludge treatmentPressure vessels for chemical processNuclear engineeringOrganic fluid

The invention discloses a supercritical water oxidation reactor by using an auxiliary fuel for supplying heat, the heat required for a reaction can be supplied by using the auxiliary fuel, Material, fuel and an oxidizing agent (air or oxygen) are mixed with a high efficiency through the different directional jets for raising oxidation efficiency. According to the invention, the reactor employs a combination structure of evaporation wall and pot type backflow, the reaction vessel volume is effectively used and the reaction time is increased, the blockage problem generated by salt deposition can be also prevented, the corrosion problem of the reactor is effectively reduced. The temperature of the reactor bottom can be preciously controlled through a cooling water pipeline at the reactor bottom, thereby the safe operation of equipment is guaranteed. The reactor effectively solves the economic problem of a supercritical water reaction system by using the auxiliary fuel for supplying, the invention has the advantage of easy industrial amplification, and is widely applied to organic liquid such as high density and difficult biodegradation organic waste water / garbage leachate and the like for a harmlessness processing.

Owner:XI AN JIAOTONG UNIV

Vacuum microwave segmented combined drying manufacturing method of instant crisp dehydrated fish ball

InactiveCN102423087BPromote circulationEffective use of volumeFood preparationNutritive valuesFresh fish

A vacuum microwave segmented combined drying manufacturing method of an instant crisp dehydrated fish ball belongs to the technical field of aquatic food processing. The invention comprises the following steps: processing fresh or frozen fresh fish to obtain pure fish flesh, performing deodorization of the pure fish flesh by a composite rinsing solution, grinding the fish flesh, adding ingredients, immediately performing ball forming, gelation, heating and curing of the ground raw material, finally performing vacuum microwave segmented combined drying of the cured fish balls so as to obtain the high-quality instant crisp dehydrated fish ball product. Vacuum microwave segmented combined drying allows the materials to be dehydrated in vacuum environment, prevents the materials from contacting oxygen, and maintains the original color, profile, flavor, and nutrients of the raw material to a maximum extent; with the vacuum environment, the boiling point of water is decreased, and with the microwave volume heating, the heat efficiency is significantly improved; the drying time is greatly reduced; after drying, the product has a porous structure, good crispness, excellent color, flavor, taste, and shape, low water content, high nutritive value, and is high-protein healthy leisure food suitable for people of all ages.

Owner:JIANGNAN UNIV +1

Conditioning and making method and high-efficiency even drying method for small trash fish marine product

The invention provides a conditioning and making method and a high-efficiency even drying method for a small trash fish marine product, belonging to the technical fields of food conditioning and aquatic product processing. The main process of the invention comprises the following steps of: removing three parts (fish scale, fish head and viscera) of a fresh or iced and fresh small trash fish marine product, washing the small trash fish marine product with clear water, slicing the small trash fish marine product into fish chips with the length of 6-10cm, deodorizing preprocessed fish meat for 4hours with compound rinsing fluid, then carrying out ultrasonic assisted vacuum impregnation conditioning (pickling and seasoning), secondary rinsing, draining, medium-short wave infrared drying pre-dehydrating, pulse spraying negative pressure microwave drying, packaging and sterilizing, thus the small trash fish dried fish prepared food product is obtained. The small trash fish marine product disclosed by the invention has good colour, fragrance and taste, beautiful appearance, low moisture content and complete nutrition, is a high-protein and low-fat food, is beneficial to reducing cholesterol and preventing cardiovascular and cerebrovascular diseases after being eaten for a long time, can be used for adjuvant therapy on leukaemia, stomach cancer and the like and is a high-quality leisure food for both the old and the young.

Owner:JIANGNAN UNIV +1

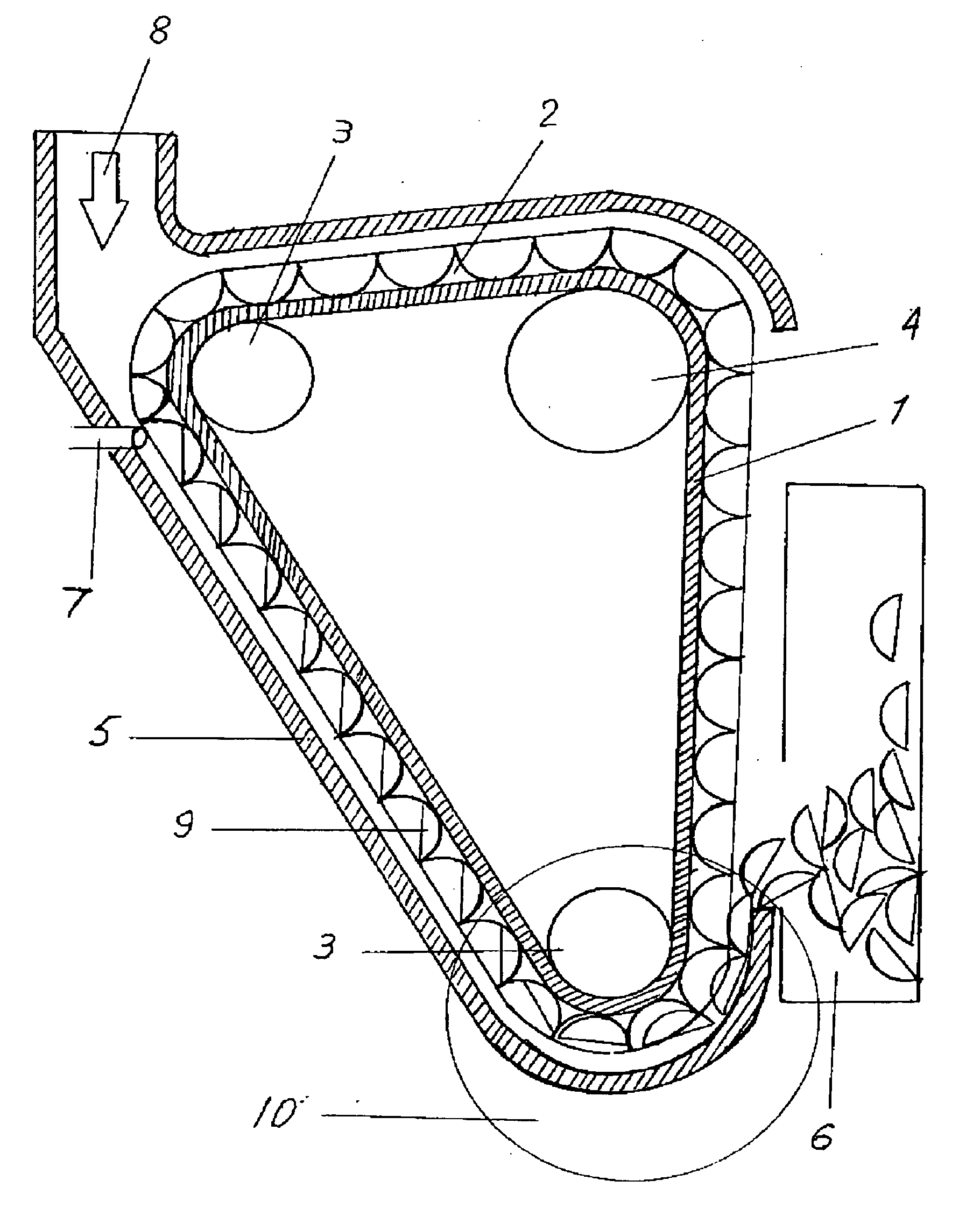

Ice conveyer

InactiveUS20110094253A1Easy and inexpensive and safe and cleanEffective use of volumeLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

An ice making conveyer producing ice cubes in any size and form designed to be utilized in household or commercial units. This conveyer having three possible shapes: triangle shape of the ice making conveyer, square shape of ice making conveyer and oval or circular shape of the ice making conveyer. Conveyer might be utilized in three types of the refrigerators: where freezer is located on the top of food section of the refrigerator, where freezer is located side by side, no matter on the right or left side of the food section of the refrigerator, where freezer is located underneath the food section of the refrigerator. Present conveyer includes a plastic frame and conveyer device that traverse between freezer and food section of the refrigerator or inside of the freezer. This conveyer allows easy, inexpensive, safe, clean, and compact way of producing ice cubes in any size and form.

Owner:ARTUR ASHKINAZI

Subsea wellbore operations vessel

ActiveUS10071790B2Effective use of volumeDrilling rodsWaterborne vesselsOcean bottomMarine engineering

A vessel is adapted to perform subsea wellbore related operations involving a riser string between the subsea wellbore and the vessel, e.g. drilling and / or wellbore intervention. The vessel includes a hull having a deck, and a riser storage hold present within the hull below the deck. The riser storage hold includes storage racks adapted to store therein parallel stacks of multiple riser sections and / or pre-assembled riser stands in horizontal orientation. The vessel has an elongated riser transfer opening between the deck and the roof, the riser transfer opening extending in a direction parallel to the storage racks, the riser transfer opening having a length and a width so as to allow for transfer of a single riser section or a single riser stand in horizontal orientation via the riser transfer opening out of and into the riser storage hold, wherein the risers' handling system is suitable to work at the same time with two different lengths.

Owner:ITREC BV

Dynamic microphone and method of forming back-side air chamber

InactiveUS9584902B2Effective use of volumeReduce areaFrequency/directions obtaining arrangementsResonanceEngineering

A dynamic microphone which prevents a wall forming a back-side air chamber from having a certain resonance frequency and effectively prevents the generation of standing waves in the back-side air chamber is provided. A dynamic microphone includes a dynamic microphone unit including a diaphragm configured with a voice coil and a magnetic circuit having a magnetic gap provided so as to allow the voice coil to vibrate, a bottomed case which is coupled to the dynamic microphone unit and forms a back-side air chamber communicating with back side of the diaphragm, and an acoustic resistance body which is pressingly attached in the case and composed of metal fiber including a pocket, an open cross sectional area of the pocket gradually decreasing toward the direction remote from the dynamic microphone unit.

Owner:AUDIO-TECHNICA

IFAS-combined double-chamber MFC landfill leachate treatment system and method

PendingCN113697940AEffective use of volumeImprove processing efficiencyTreatment by combined electrochemical biological processesWater contaminantsActivated sludgeMicrobial fuel cell

The invention belongs to the technical field of sewage treatment and energy recovery, and particularly discloses an IFAS-combined double-chamber MFC landfill leachate treatment system and method. The system comprises an anode chamber, a cathode chamber, a membrane separator and a porous carrier; the anode chamber and the cathode chamber are separated through a membrane separator, an anode is arranged in the anode chamber, a cathode is arranged in the cathode chamber, and the anode is connected with the cathode through a wire via an external resistor; the porous carrier is fixedly arranged in the cathode chamber, an active biological membrane is attached to the porous carrier, and the active biological membrane comprises microbial flora in activated sludge. The IFAS and the microbial fuel cell are combined, the two electrode chambers of the MFC are effectively utilized, the cathode chamber is provided with suspended activated sludge and an attached active biological membrane and shows excellent electrochemical behavior and nitrogen removal capacity, the wastewater treatment process of the MFC is further improved, and the application value is high.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Water heater water level maintenance system

ActiveCN105352183BIncrease temperatureSave energyFluid heatersWater storageArchitectural engineering

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Feeding mechanism of packaging machine

ActiveCN104709508BImprove packaging efficiencyEffective use of volumePackagingFixed frameEngineering

The invention discloses a feeding mechanism of a packaging machine. The feeding mechanism comprises a machine body, a feeding belt and a plurality of material receiving boxes and is characterized in that the machine body is provided with a fixing frame; the fixing frame is provided with a first air cylinder and a second air cylinder; a push rod of the first air cylinder is provided with a first material push plate; the machine body is provided with liftable transition material tables corresponding to the material receiving boxes; the transition material tables are flush with the feeding belt when located at the lowest position; a second material push plate corresponding to the material receiving boxes is arranged above the transition material tables and connected with a push rod of the second air cylinder; the material receiving boxes are movably arranged on one side of each transition material table. According to the feeding mechanism, materials can be fed through the feeding belt, are transferred to the transition material table through the first material push plate, are lifted through the transition material tables, and then are pushed into the material receiving boxes through the second material push plate; the feeding mechanism can push the materials in a layered mode, has the advantage of being stable and quick in feeding and greatly improves the reliability and the stability of packaging of the materials in cooperation with a bagging machine, thereby improving bagging efficiency.

Owner:WENZHOU RUIDA MACHINERY

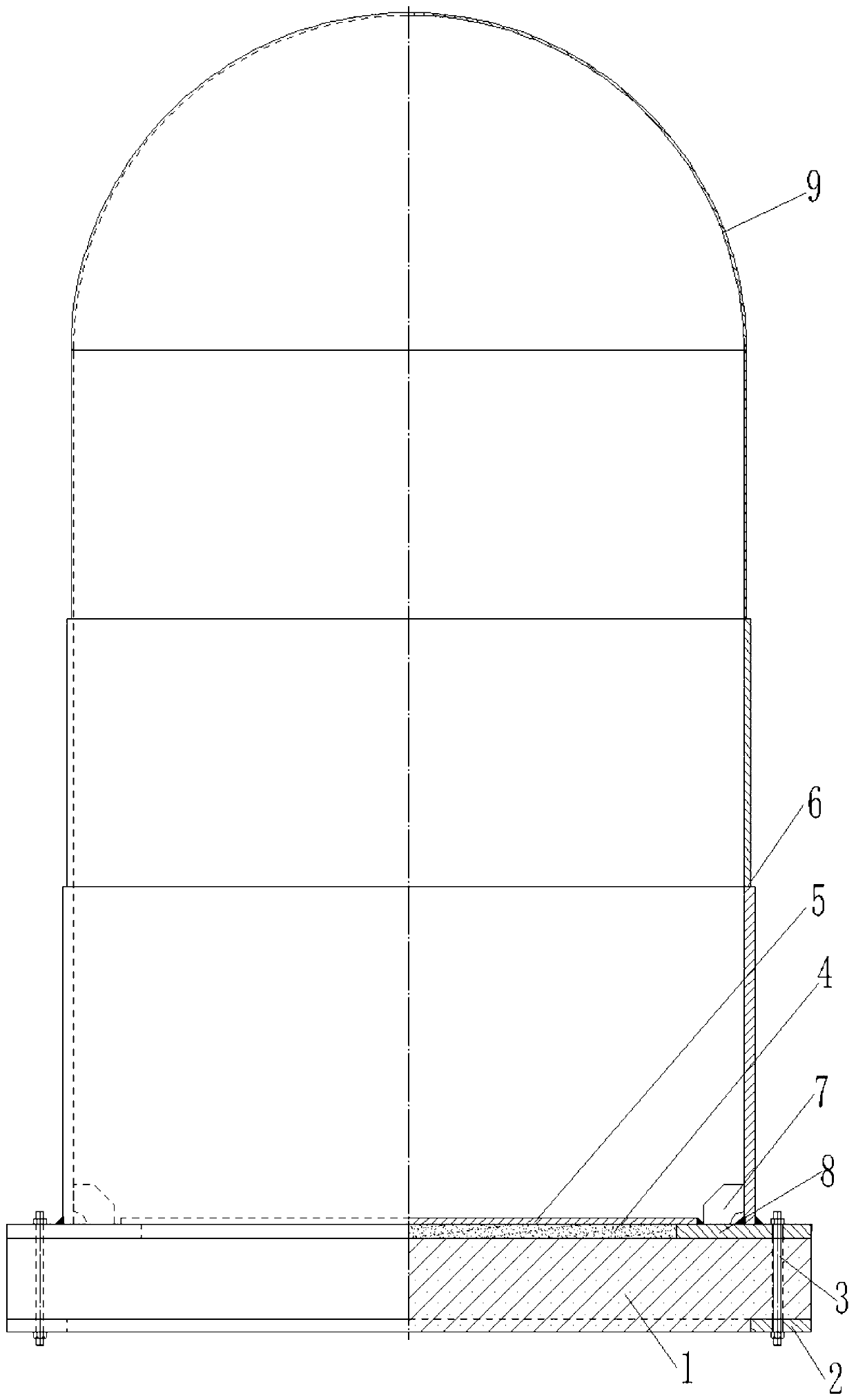

Flat-bottom pressure-bearing tank with bearing base

The invention relates to a flat-bottom pressure-bearing tank with a bearing base. The flat-bottom pressure-bearing tank with the bearing base comprises a boss disc-type base, a plurality of anchor bolts which connect a bearing ring plate arranged at a boss of the lower part of the boss disc-type base, an annular base plate arranged on the upper plane of the boss disc-type base and the boss disc-type base together, an isolation layer arranged in an inner hole of the annular base plate, a tank bottom center plate pressed against the upper plane of the isolation layer and fixed to the annular base plate, a cylindrical flat-bottom pressure-bearing tank body arranged on the annular base plate and a reinforcing connecting plate. The anchor bolts are uniformly arranged along the circumference ofthe tank wall. The flat-bottom pressure-bearing tank with the bearing base is simple in structure, easy to process and install and large in bearing pressure, and buffering and pressure relief, reduction of tank body consumables, cost reduction, material saving, easy construction, small occupied space and good stability are achieved. The flat-bottom pressure-bearing tank with the bearing base can be widely applied to cylindrical pressure-bearing tanks with higher temperature, especially to the flat-bottom pressure bearing tanks with the bearing base taking liquid storage, fused salt and the like as media.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

refrigerator

ActiveCN105222459BEffective use of volumeGuaranteed service lifeLighting and heating apparatusDomestic refrigeratorsGreenhouseEngineering

The invention provides a refrigerator which comprises a refrigerator body, a first refrigerating system and a second refrigerating system, wherein the refrigerator body is provided with a freezing chamber and / or a temperature varying chamber and a low temperature chamber not communicated with the freezing chamber and / or the temperature varying chamber; the first refrigerating system comprises a first refrigerating component for providing cold quantity for the low temperature chamber by adopting a direct cooling or air cooling refrigerating way; the second refrigerating system is provided with a semiconductor refrigerating module arranged on the peripheral wall of the low temperature chamber. The cold end of the semiconductor refrigerating module is arranged in the low temperature chamber, and the hot end of the semiconductor refrigerating module is arranged outside the peripheral wall.

Owner:HAIER SMART HOME CO LTD

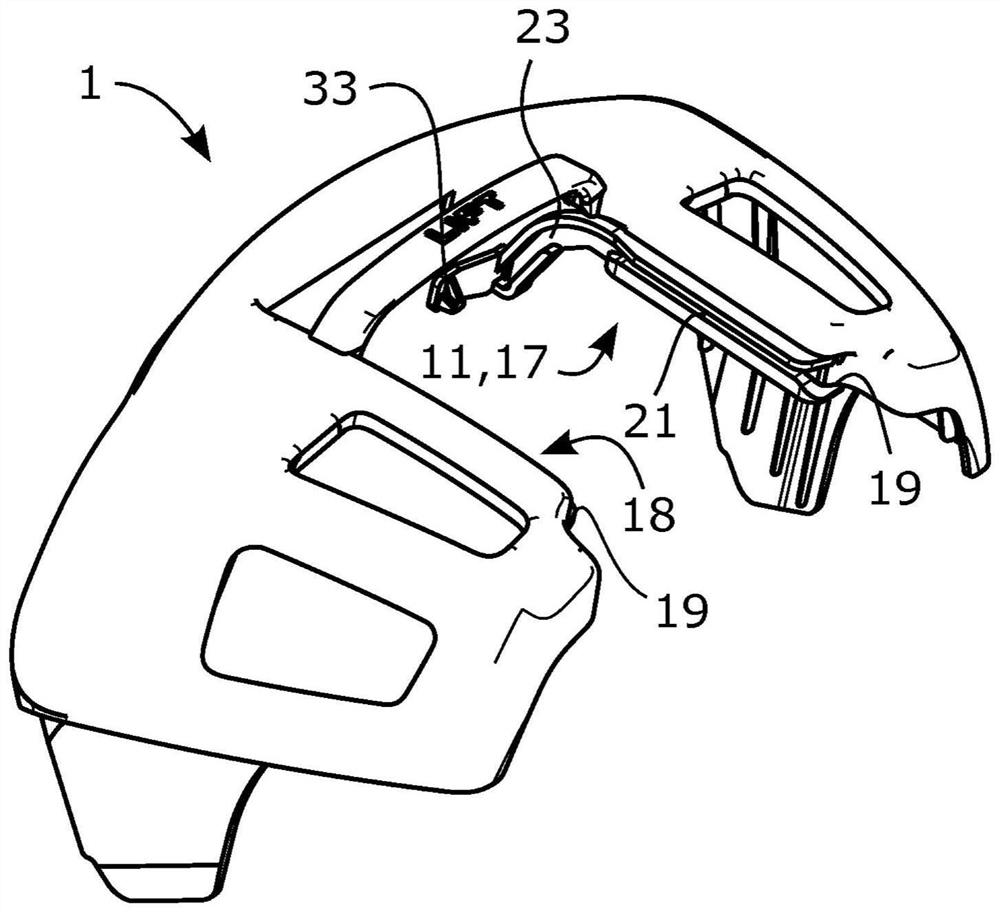

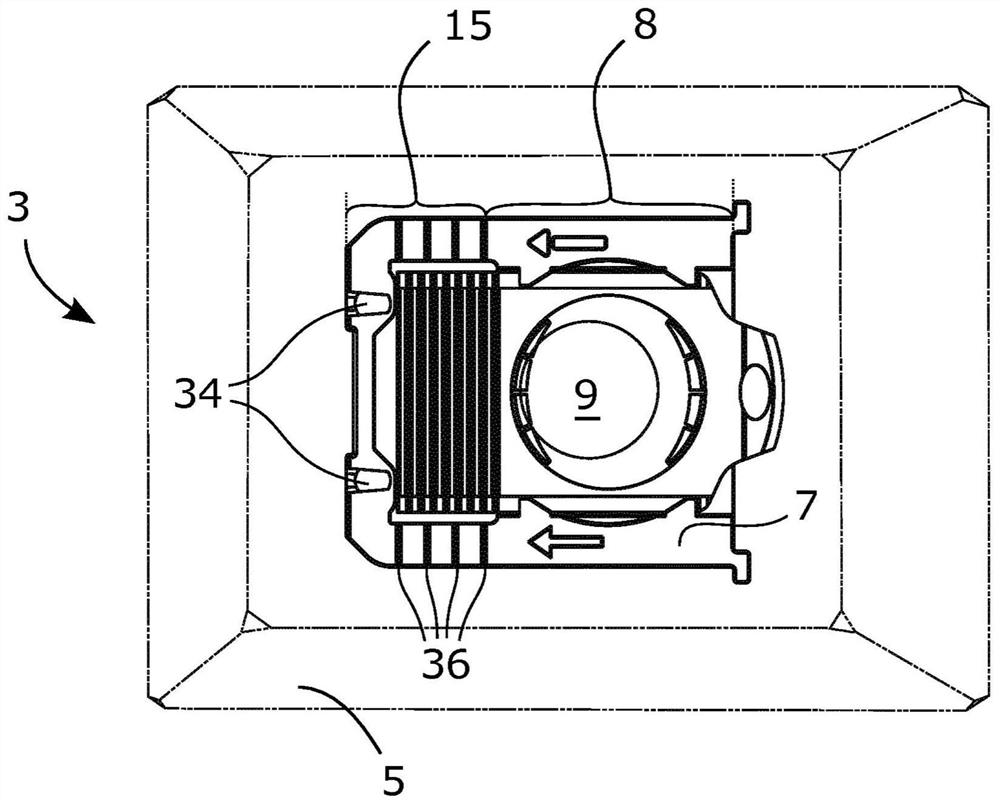

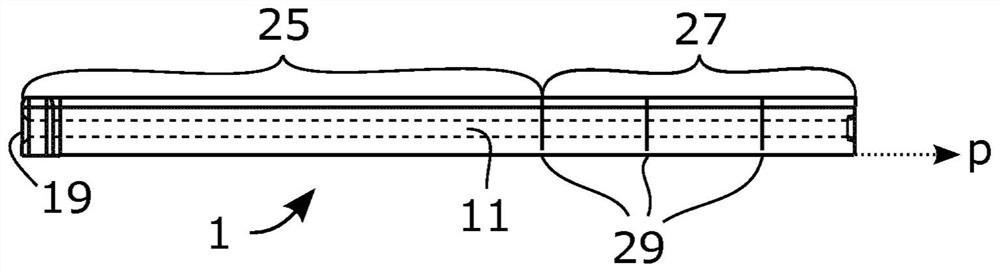

Holder for vacuum cleaner dust container

Owner:AB ELECTROLUX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com