Ice conveyer

a conveyer and ice cube technology, applied in domestic cooling devices, lighting and heating devices, domestic cooling devices, etc., can solve the problems of corrosion electronic components are exposed to splashing water and humidity, and internal components of ice cube makers also suffer from corrosion, etc., to achieve convenient, convenient, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

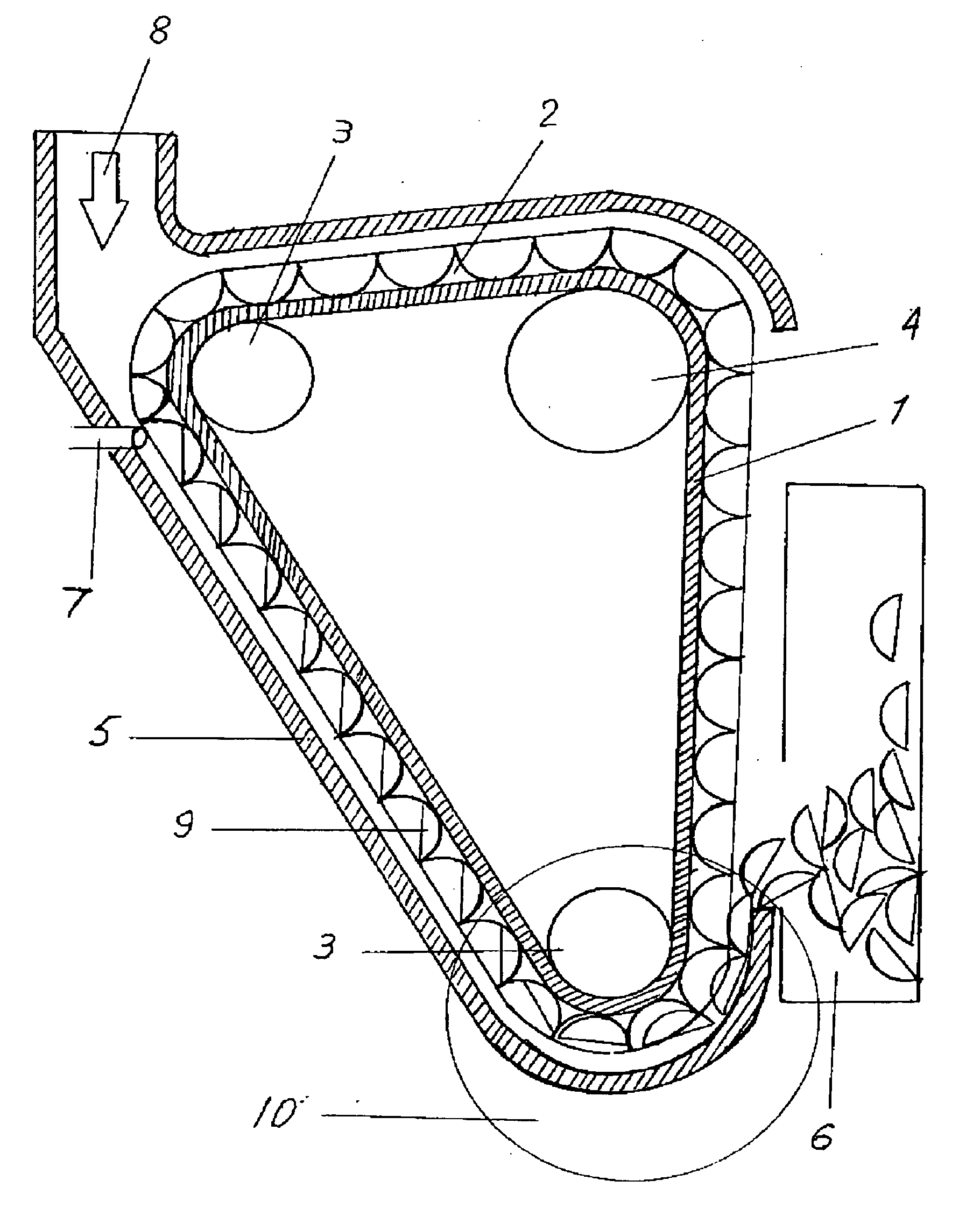

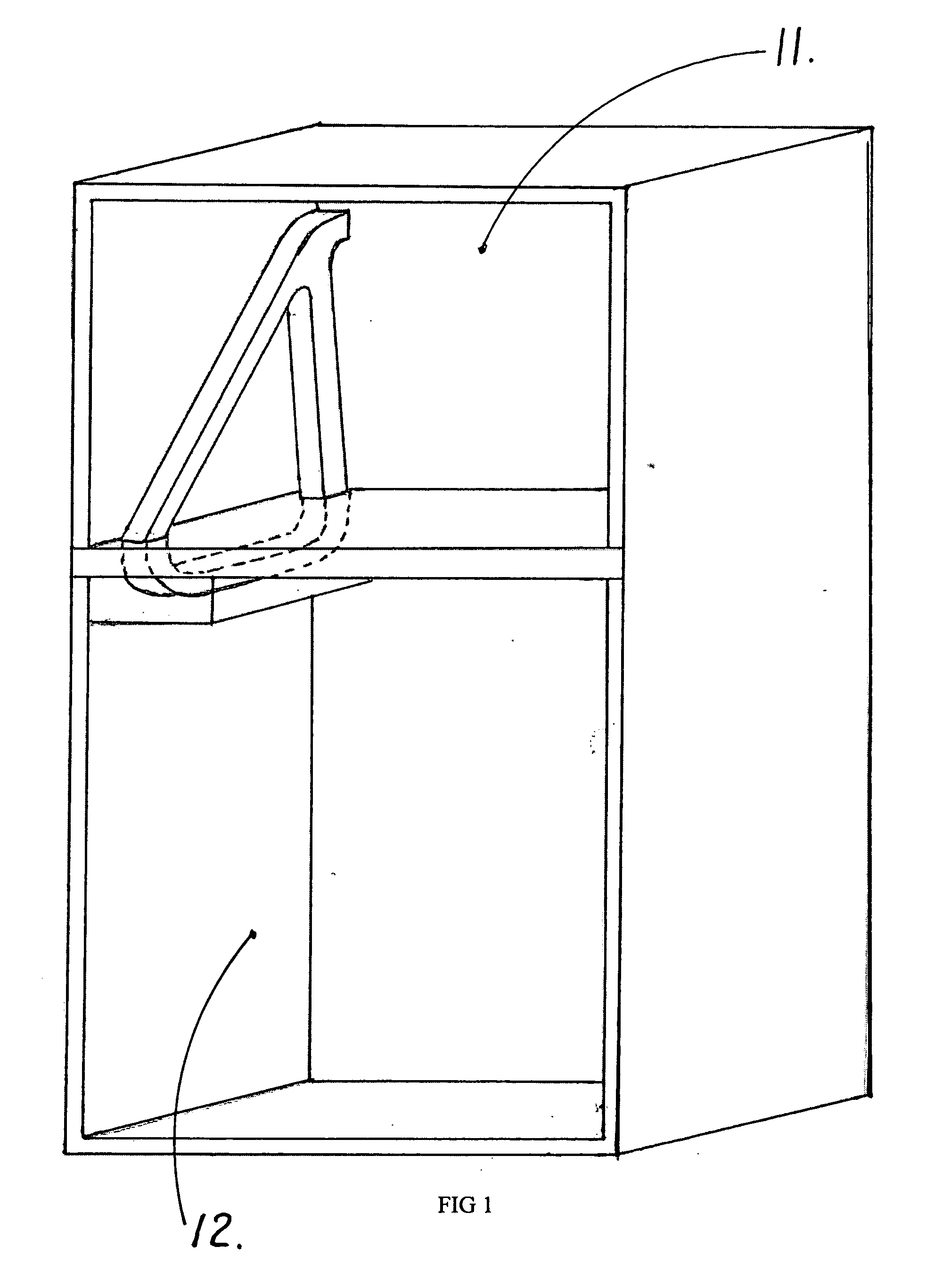

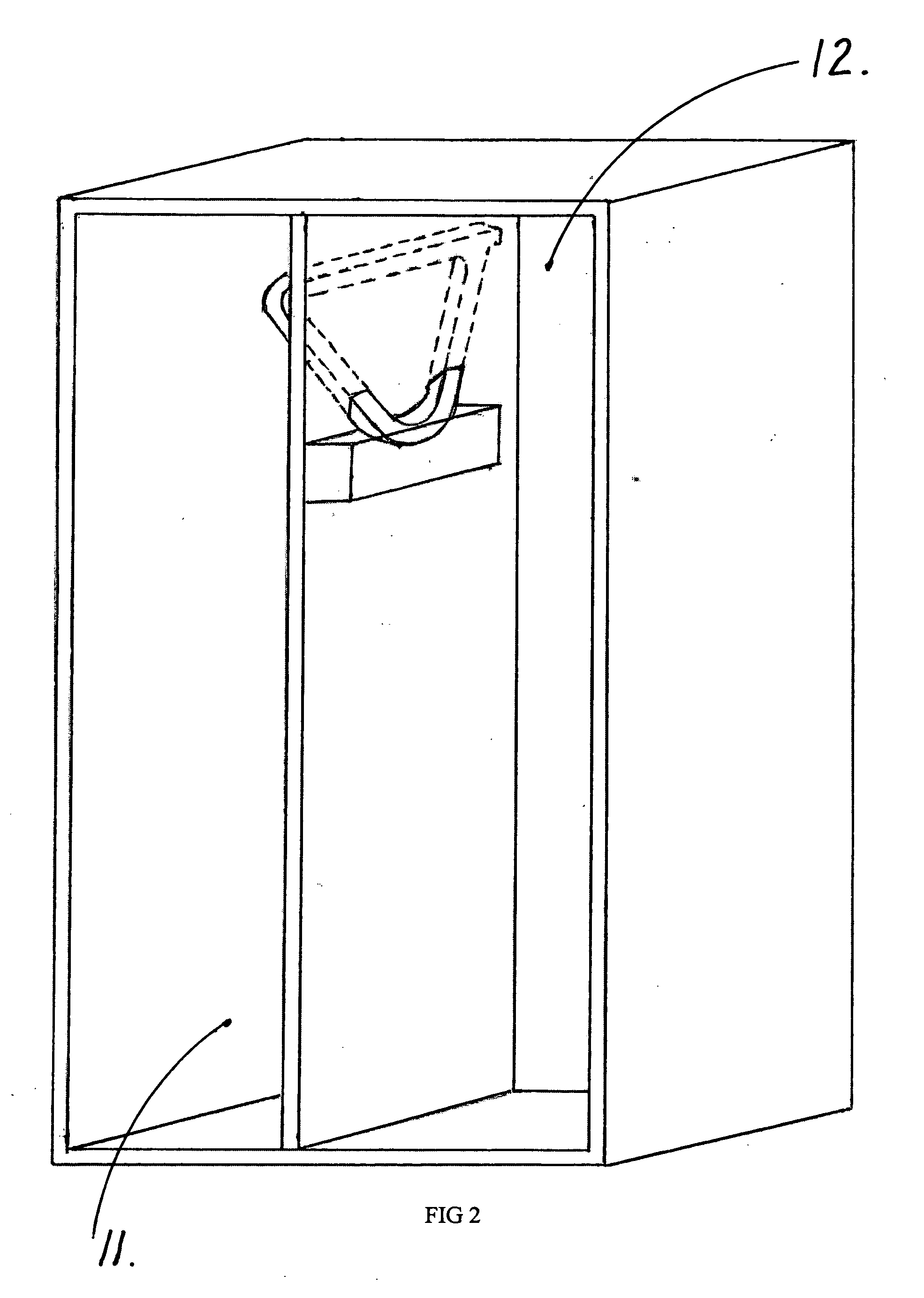

Present invention intended to be utilized for the ice cube making conveyer 15, FIG. 4-6, which includes a plastic frame 5 and conveyer device that traverse between freezer 11, FIG. 1-3, and food section of the refrigerator 12, FIG. 1-3, or inside of the freezer. This ice making conveyer 15, FIG. 1-3, is designed to be utilized in household or commercial units. This conveyer allows easy, inexpensive, safe, clean, and compact way of producing ice cubes in any size and form.

Reference will now be made in detail to the present preferred embodiment of the present invention, examples of which are illustrated in the accompanying drawings, FIG. 1 through 3, wherein like reference numerals refer to the elements throughout.

The embodiment of the device 15 is illustrated in FIGS. 1 through 9 includes:

Embodiment of present invention of the ice making conveyer 15 might be utilized in particular types of the refrigerators where freezer 11 is located on the top of the food section of the refrigerato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com