Feeding mechanism of packaging machine

A technology of feeding mechanism and packaging machine, applied in packaging and other directions, can solve problems such as low efficiency and inability to meet industrialized large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

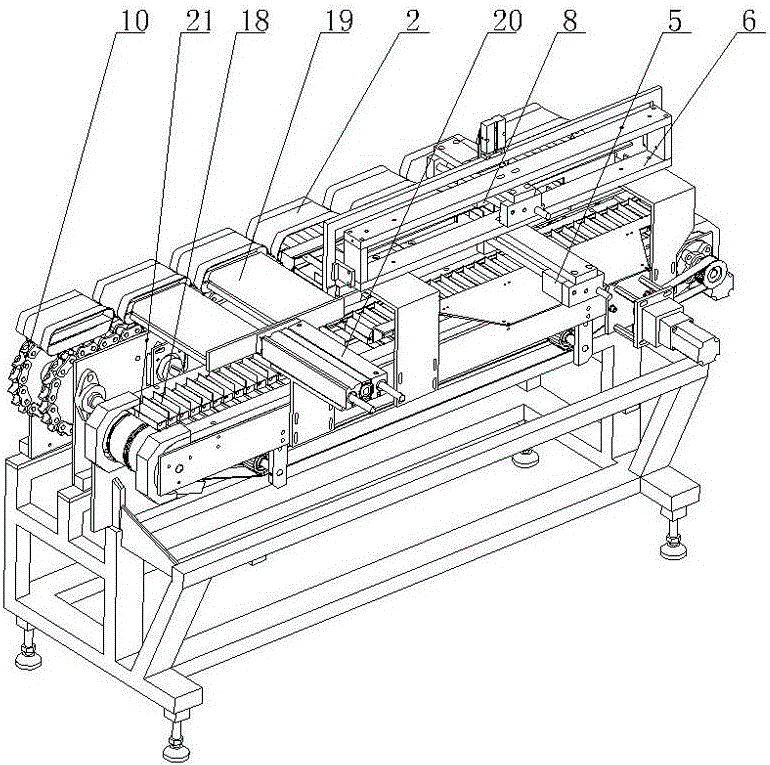

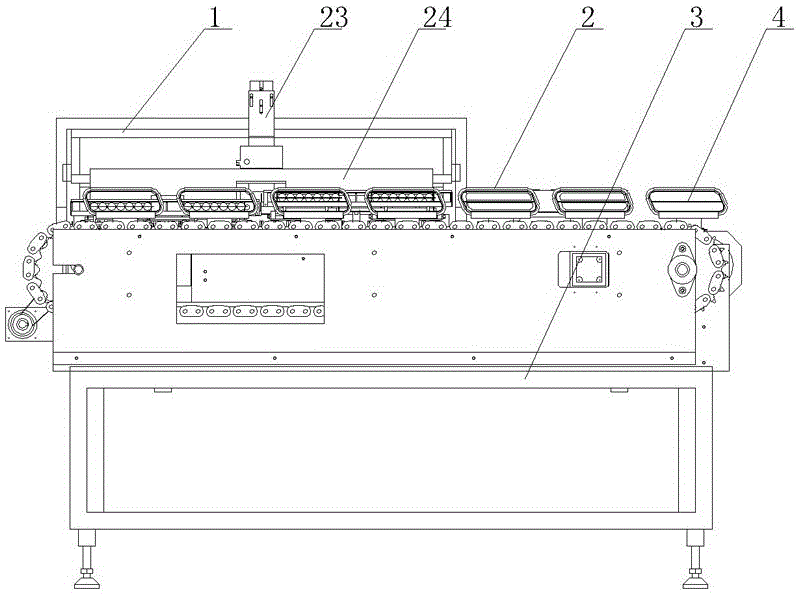

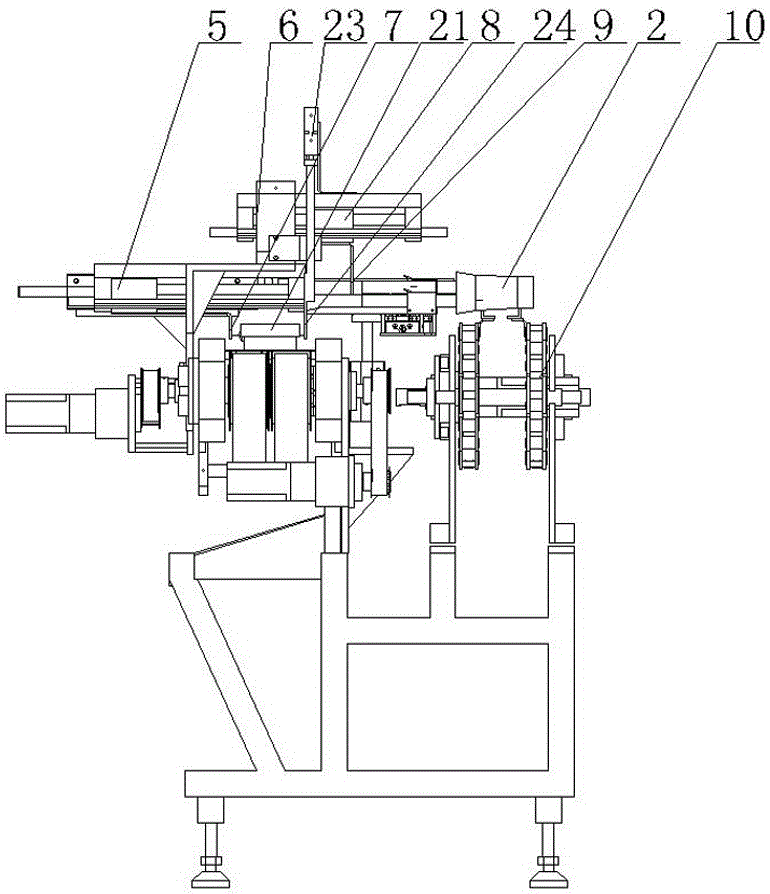

[0019] With reference to the drawings, the feeding mechanism of this packaging machine includes a body 3, a feeding belt 21, and a number of receiving boxes 2. The receiving box 2 is mounted on a transmission chain 10, and the body 3 is provided with a fixing frame 6. The fixing frame 6 is provided with a first cylinder 5 and a second cylinder 8, the push rod of the first cylinder 5 is provided with a first pushing plate 7, and the feed belt 21 is provided with an equidistant grid 18, The first pusher plate 7 is provided with comb teeth 22 matched with the grid 18. The body 3 is provided with a liftable transition table corresponding to the receiving box 2. The transition table is level with the feeding belt 7 when the transition table is in the lowest position, and the transition table has different height positions. Each group is connected to the corresponding cylinder, and the stroke of each cylinder is different. In this embodiment, the transition material table has a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com