Flat-bottom pressure-bearing tank with bearing base

A technology of pressure tanks and flat bottoms, which is applied in the field of flat bottom pressure tanks, can solve the problems of difficult construction, poor stability, and many consumables, and achieve the effects of saving materials, good stability, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

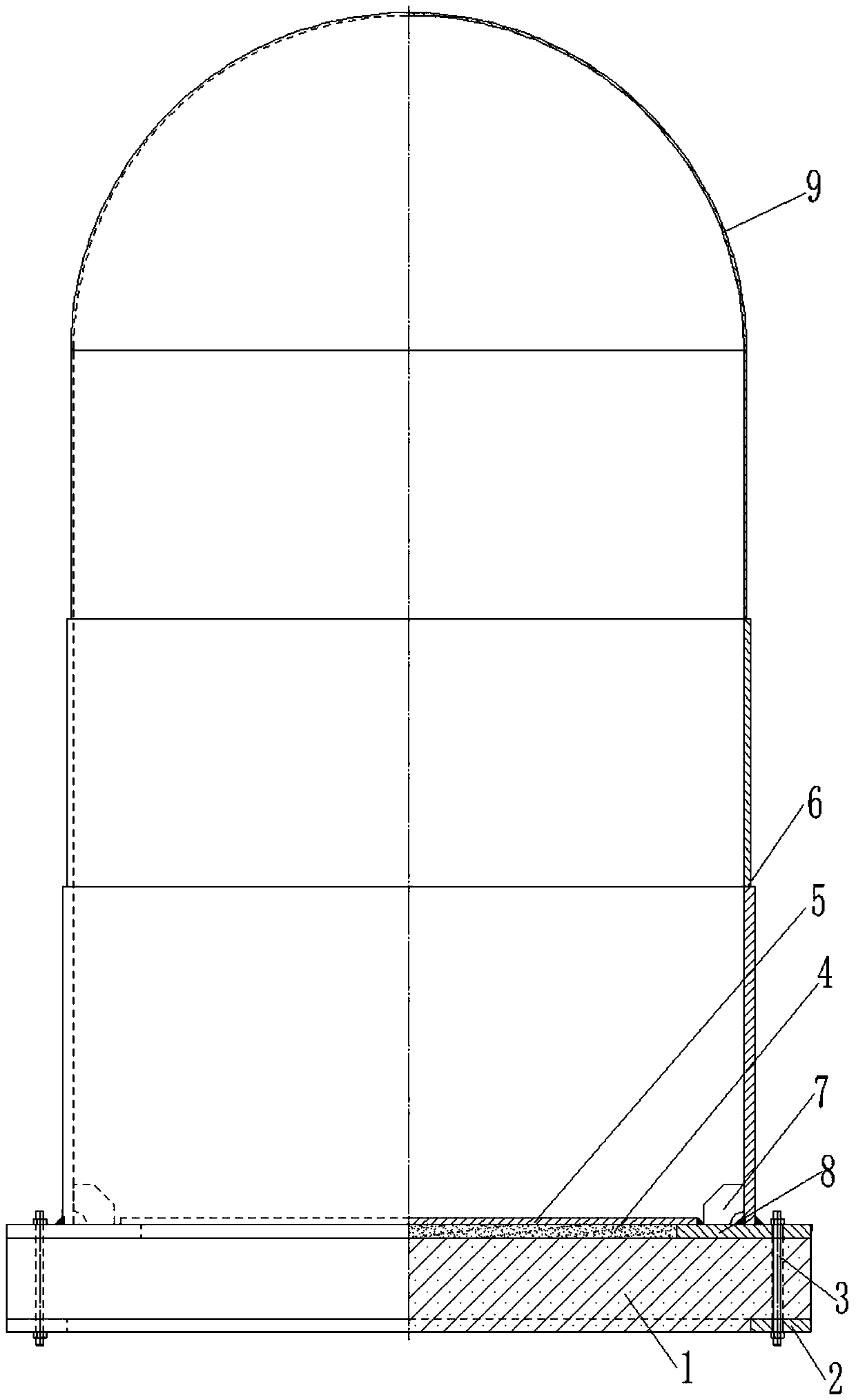

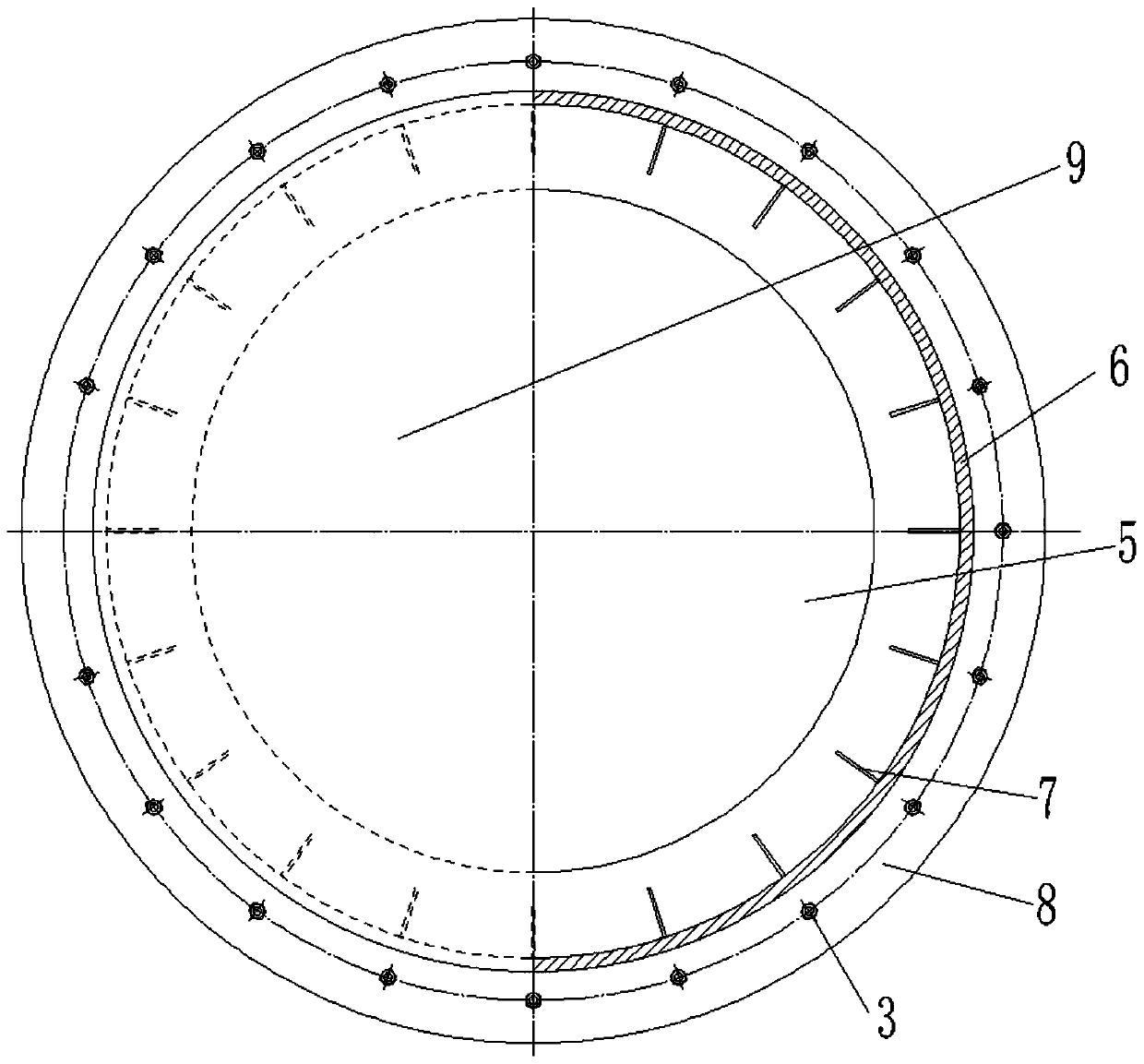

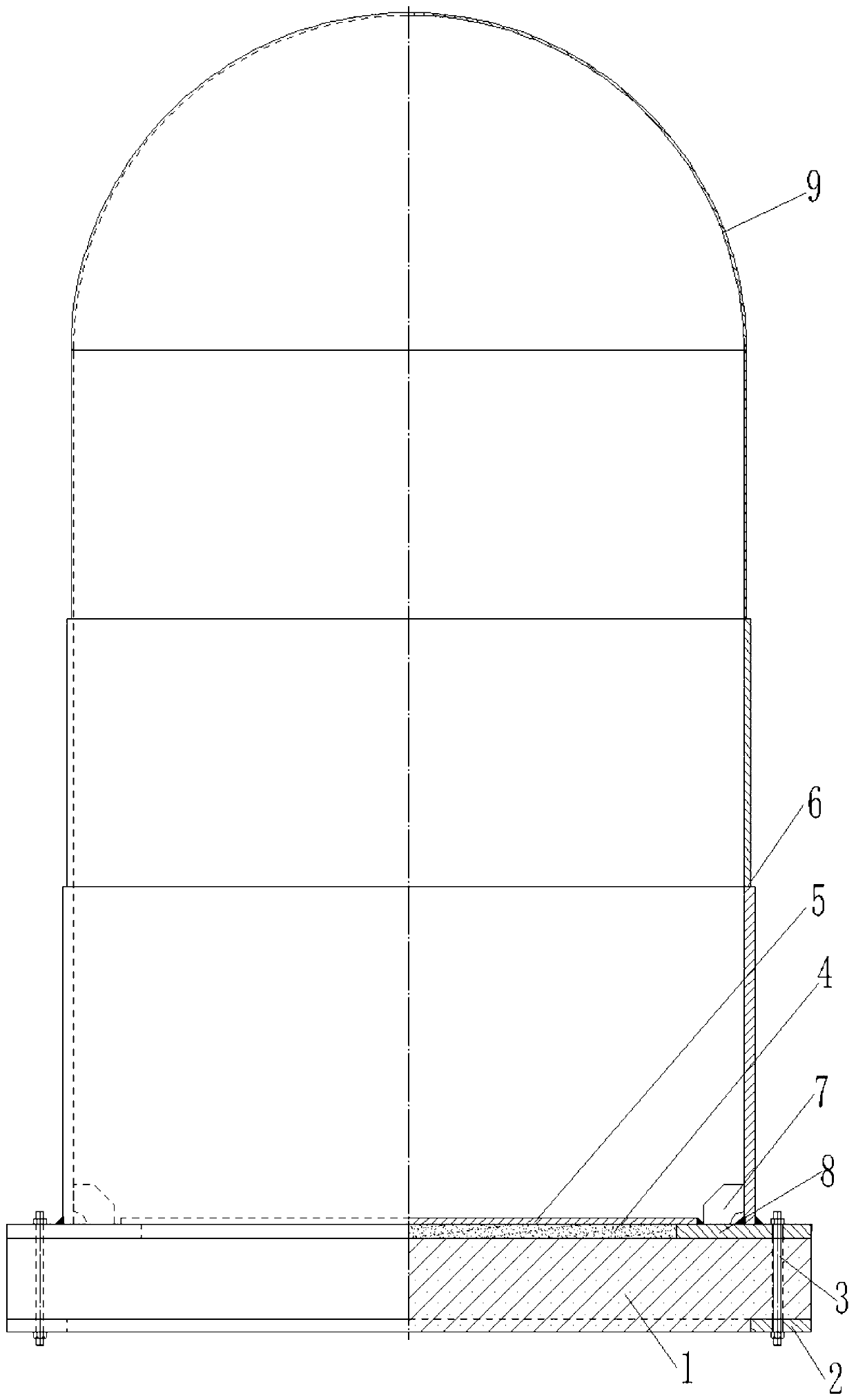

[0020] exist figure 1 , figure 2 Among them, the flat-bottomed pressure tank with bearing base of the present invention includes a boss disc-type base 1, and the tension ring plate 2 installed at the boss of the lower part of the boss disc-type base and the upper plane of the boss disc-type base are installed The annular bottom plate 8 and the several anchor bolts 3 that are connected together with the boss disc type base, the isolation layer 4 installed in the inner hole of the annular bottom plate, and the middle width of the tank bottom that is pressed against the upper plane of the isolation layer and fixed to the annular bottom plate Plate 5, a cylindrical flat-bottom pressure-bearing tank body 6 installed on the annular bottom plate, a reinforcing connecting plate 7 located at the bottom of the cylindrical flat-bottom pressure-bearing tank body and fixed on the annular bottom plate and the inner wall of the cylindrical flat-bottom pressure-bearing tank ; The anchor bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com