IFAS-combined double-chamber MFC landfill leachate treatment system and method

A landfill leachate and treatment system technology, which is applied in the field of sewage treatment and energy recovery, can solve the problems of large footprint and complex installation of MFC wastewater treatment system, so as to reduce the cost of land occupation, improve energy recovery efficiency, and improve the removal of organic matter and the effect of the capacity of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

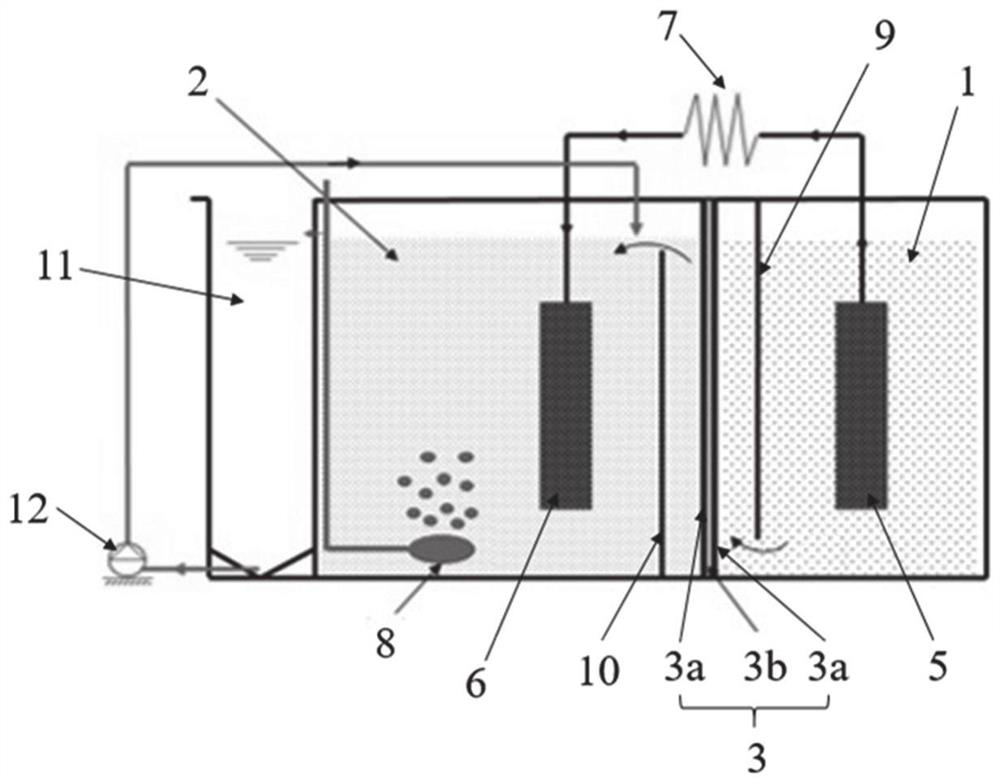

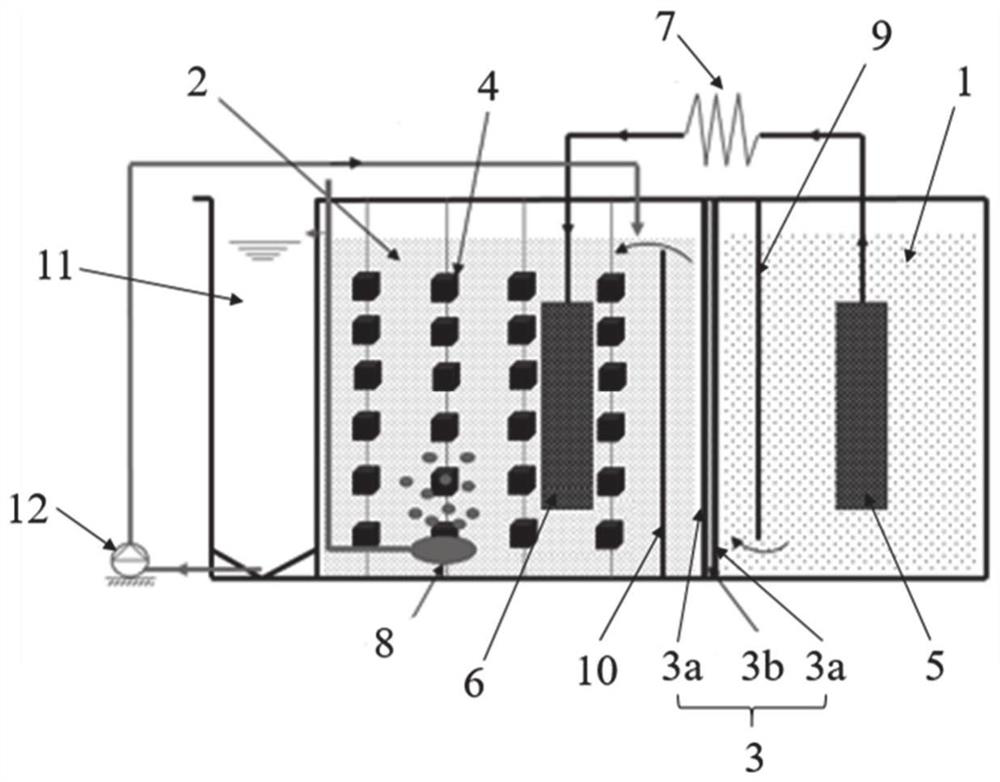

[0084] In this example, a fixed biofilm-activated sludge process is combined with a microbial fuel cell to obtain an MFC-IFAS system, and this system is used to treat landfill leachate. The specific operation steps are as follows:

[0085] (1) Acclimatization of activated sludge bacteria: inoculate the activated sludge into the same volume of acclimatization medium, and culture it with intermittent aeration at 28°C for one week before it is used in the MFC experiment, so that the bacteria in the activated sludge can adapt to the environment .

[0086] (2) MFC-IFAS system construction: the MFC reactor is made of 6mm thick acrylic glass, see figure 2 , the working volume of the anode chamber 1 is 600mL, and the working volume of the cathode chamber 2 is 800mL. The diaphragm 3b in this embodiment is a carbon felt sheet of 8cm×12cm, which is inserted between the two diaphragm baffles 3a as the anode chamber 1 and the membrane separator 3 that physically separates the cathode cha...

Embodiment 2

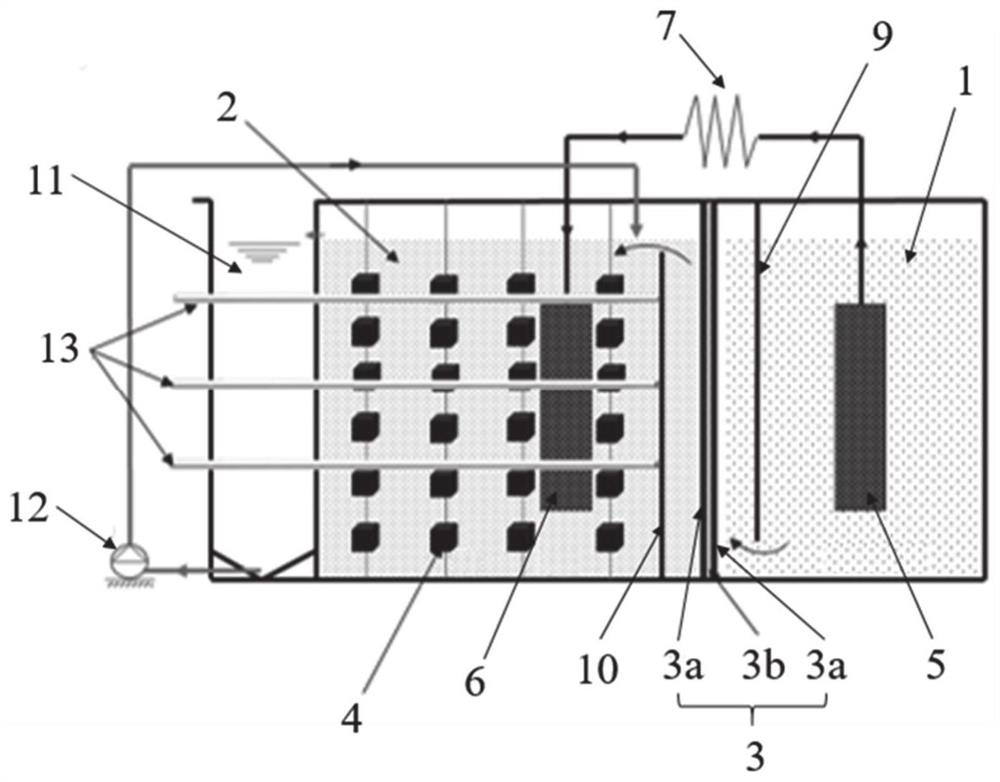

[0091] In this example, fixed biofilm-activated sludge is used to couple algae and combine with microbial fuel cell to obtain MFC-IFAS / algae system, and use this system to treat landfill leachate. The specific operation steps are as follows:

[0092] (1) Acclimatization of activated sludge bacteria: inoculate the activated sludge into the same volume of acclimatization medium, and culture it with intermittent aeration at 28°C for one week before it is used in the MFC experiment, so that the bacteria in the activated sludge can adapt to the environment .

[0093] (2) Algae acclimatization: on a clean bench (Bio-II-A, Telstar, Spain), inoculate 40mL of algae into 400mL (v / v ratio 1:10) of sterilized BG11 medium, in 0.5L Algae culture in Erlenmeyer flasks. The Erlenmeyer flasks were cultured for 5 days in a continuous lighting mode (synthetic light) with a light intensity of 1600 lux and a constant room temperature of 28°C. Additionally, air supply (100 mL / min) was used to prom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com