Anti-overflow food processor

A cooking machine and anti-overflow technology, which is applied in the field of cooking machines, can solve the problems of small effective volume, inconvenient cleaning of the work surface, and the amount of water added exceeds the standard water level, so as to avoid the effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

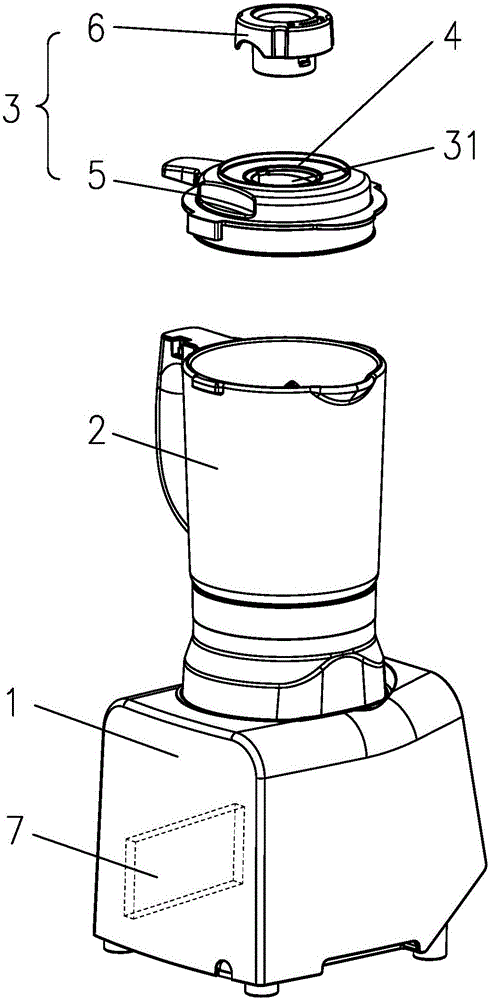

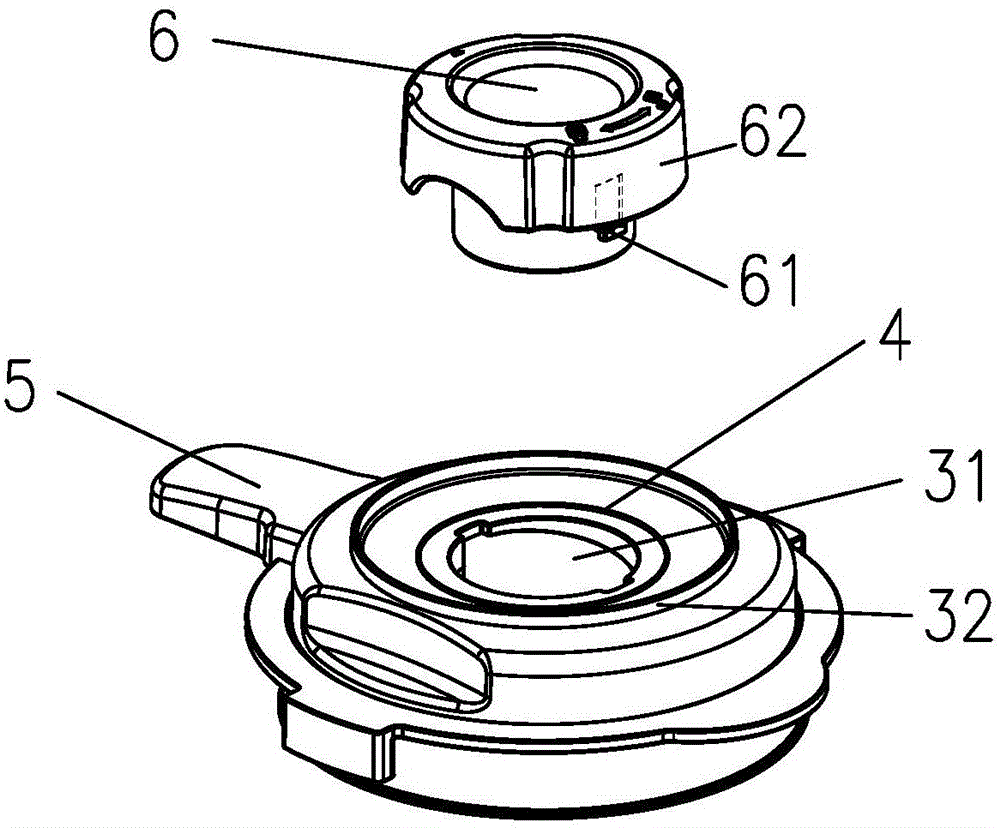

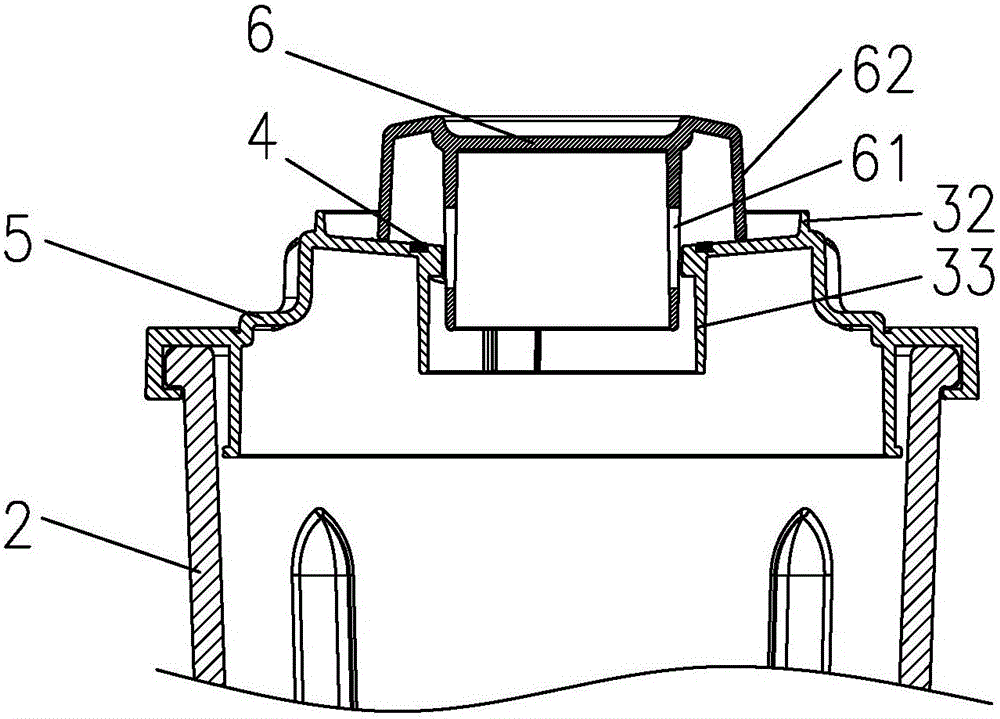

[0023] refer to figure 1 , an anti-spill cooking machine, comprising a base 1, the motor in the base 1 drives the blade in the stirring cup 2 through the motor shaft, the stirring cup 2 is provided with a cup cover 3; An exhaust port 31 communicating with the outside world and an anti-overflow sensing element electrically connected to the cooking machine control unit 7 are provided. The sensing probe 4 of the sensing element is located on the outer surface of the cup cover 3 and is close to the exhaust port 31. The induction probe 4 can be in contact with the liquid overflowing from the exhaust port 31 immediately, thereby triggering the control unit 7 to stop the cooking machine. The induction probe 4 can be made of conductive material in the form of flakes, blocks, rings, etc., and is arranged on the outer surface of the cup cover 3 in a tiled manner.

[0024] By arranging the induction probe 4 on the outer surface of the cup cover 3 and close to the air outlet 31, the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com