Burner of energy-saving stove

A stove and cast iron technology, which is applied in the field of the burner of the stove, to achieve the effects of improving thermal efficiency, reducing weathering speed, and large combustion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

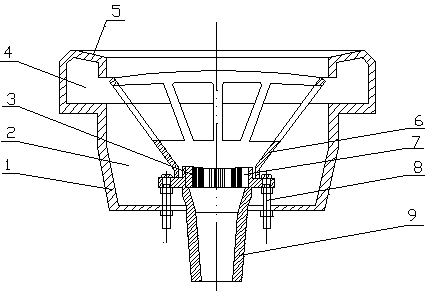

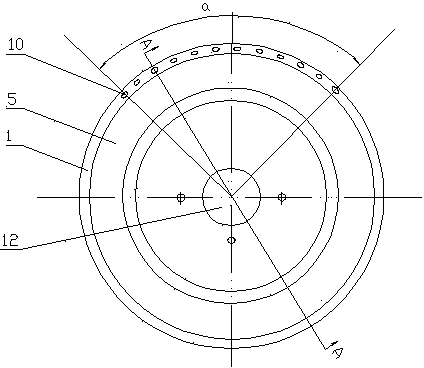

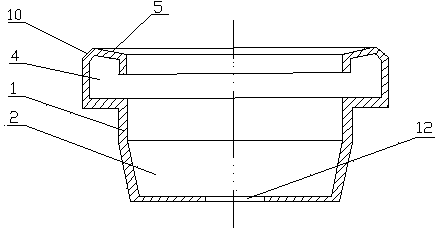

[0022] Such as Figure 1~Figure 8 As shown, 1—cast iron ring, 2—combustion chamber, 3—ceramic core, 4—intake chamber, 5—slope structure, 6—bracket, 7—discus, 8—bolt, 9—mixing cylinder, 10—air outlet , 11 an ignition device, 12 a gas inlet, 13 a flame eye, 14 a concave spherical surface, 15 a round hole, 16 a convex shoulder, 17 a flame vent.

[0023] An energy-saving stove burner, comprising a cast iron ring 1 formed by casting, such as image 3 , Figure 4 As shown, it has an inner chamber structure, which is composed of a combustion chamber 2 in the middle of the cast iron ring and an annular air intake chamber 4 communicated with the combustion chamber on the upper part of the cast iron ring, and an air outlet channel communicated with the annular air intake chamber 4 is provided on the top of the cast iron ring , the air outlet channel is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com