Environment-friendly auxiliary system for assisting efficient combustion of biomass in combustion equipment

A technology of combustion equipment and auxiliary systems, applied in the removal of solid waste, chemical instruments and methods, transportation and packaging, etc., can solve the problems of pollution and low biomass combustion efficiency, reduce pollution, increase area, and improve combustion. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

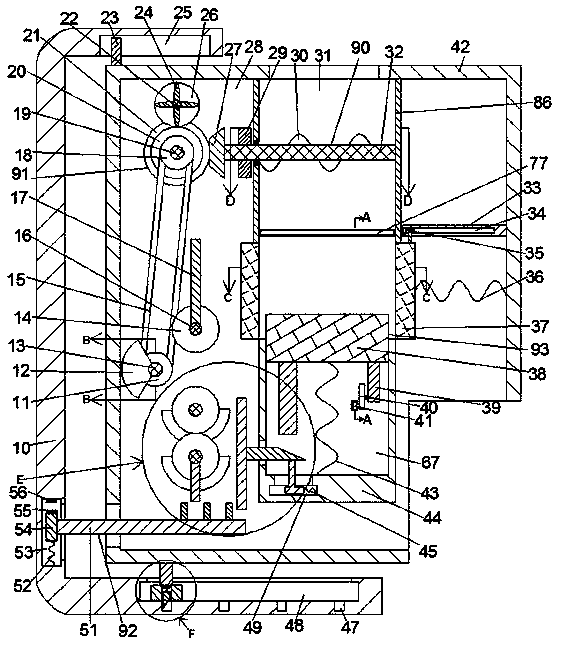

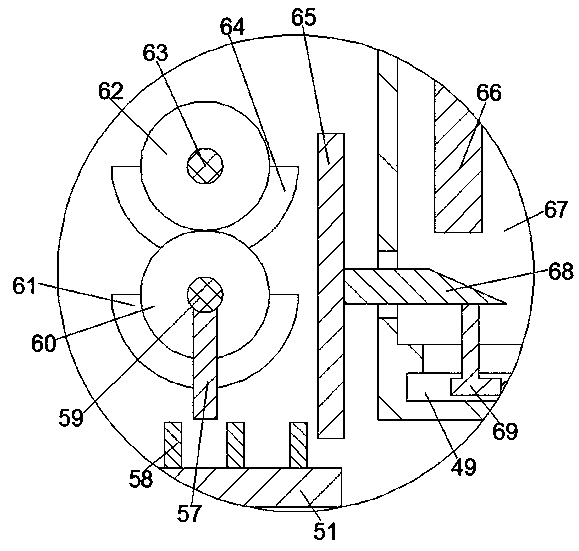

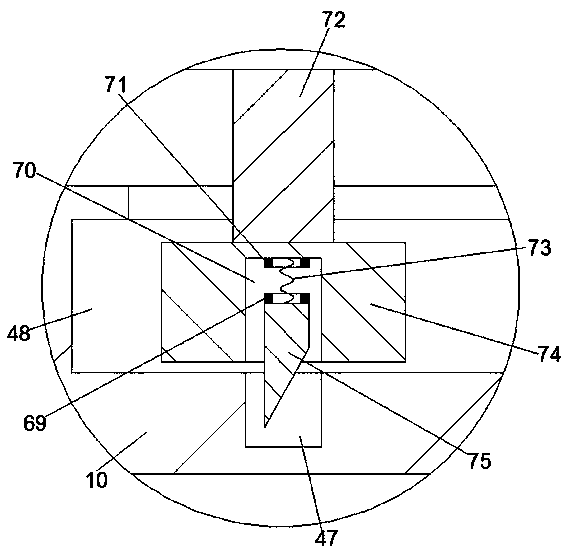

[0026] Combine below Figure 1-7 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are now defined as follows: figure 1 The projection relationship of itself is the same as the up, down, left, right, front, and rear directions.

[0027] A schematic diagram of the mechanical mechanism of an environmentally friendly auxiliary system for efficient combustion of biomass in combustion equipment described in conjunction with Figures 1-7, including a biomass processing box 42, the biomass processing box 42 is provided with an opening facing downward to the right The processing groove 28 is fixedly installed with a driving mechanism 91;

[0028] A feeding block 86 is fixed on the rear wall of the processing tank 28 , and a crushing mechanism 90 for crushing biomass is installed in the feeding block 86 , and the crushing mechanism 90 is powered by the driving mechanism 91 ;

[0029] The lower side of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com