Incinerator for processing smoke gas generated by waste incineration by utilizing incineration method

An incinerator and flue gas technology, applied in the field of incinerators, can solve problems such as increasing costs and achieve high removal rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

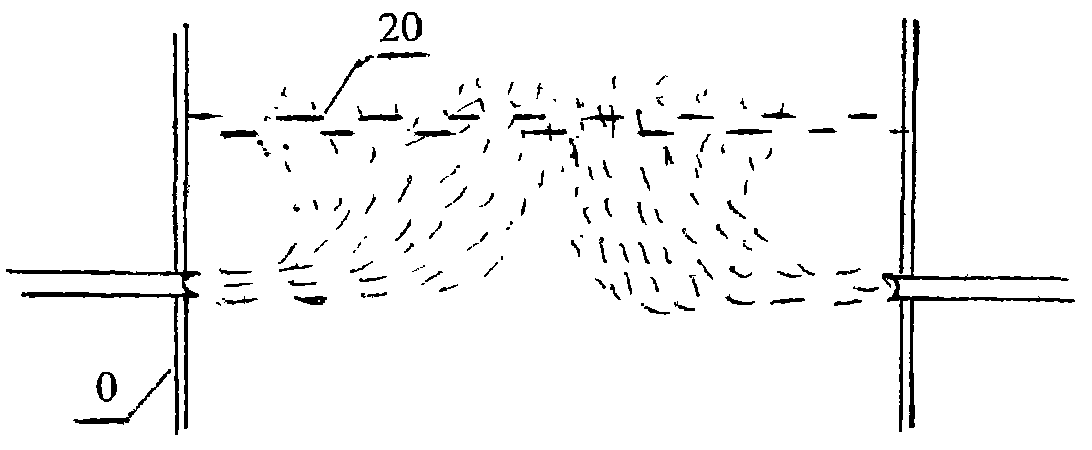

[0013] figure 1 As shown, the principle diagram of the existing burning method to treat the flue gas produced by garbage incineration. The raging flame of gas or fuel burning in the flue 0 is more fully burned after being intercepted by the double-layer metal mesh 20, the burning area in the flue 0 is larger, and more dioxins are ignited.

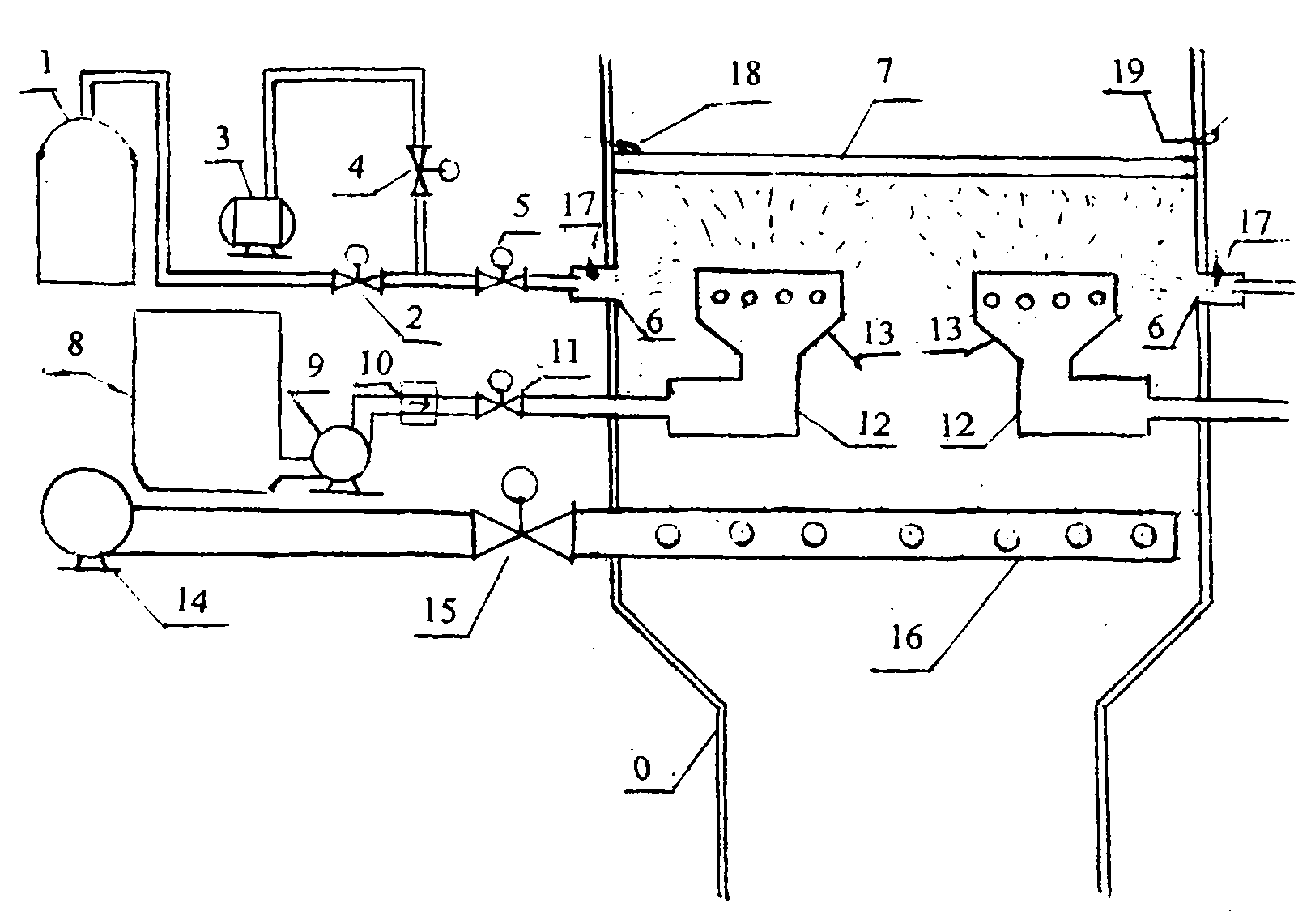

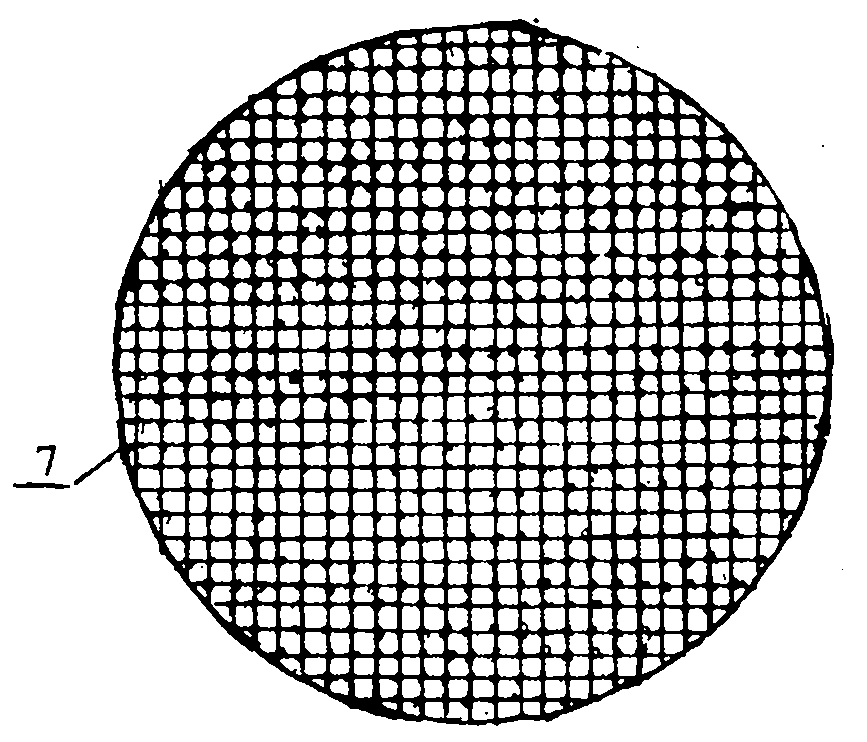

[0014] figure 2 , image 3 , Figure 4 with Figure 5 As shown, the incinerator for processing flue gas of the present invention includes: a flue 0, a fuel tank 8, an oil pump 9, a flow sensor 10, a fuel electric control valve 11, at least one fuel nozzle 13, a blower 14, an air outlet electric control valve 15, Air outlet pipe 16, gas storage tank 1, gas electric control valve 2, air compressor 3, compressed air electric control valve 4, mixed gas electric control valve 5, at least one gas nozzle 6, at least one spark plug 17 and an electrical control system . Flue 0 is installed vertically. The flue pipe is divided into two sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com