Cooking fume purifier

A technology for oil fume purification and oil fume, which is applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as unfavorable environmental protection, limitation of the suction port of the range hood, and inability to set the oil fume suction port, so as to achieve good suction ability and overcome The effect of noise defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

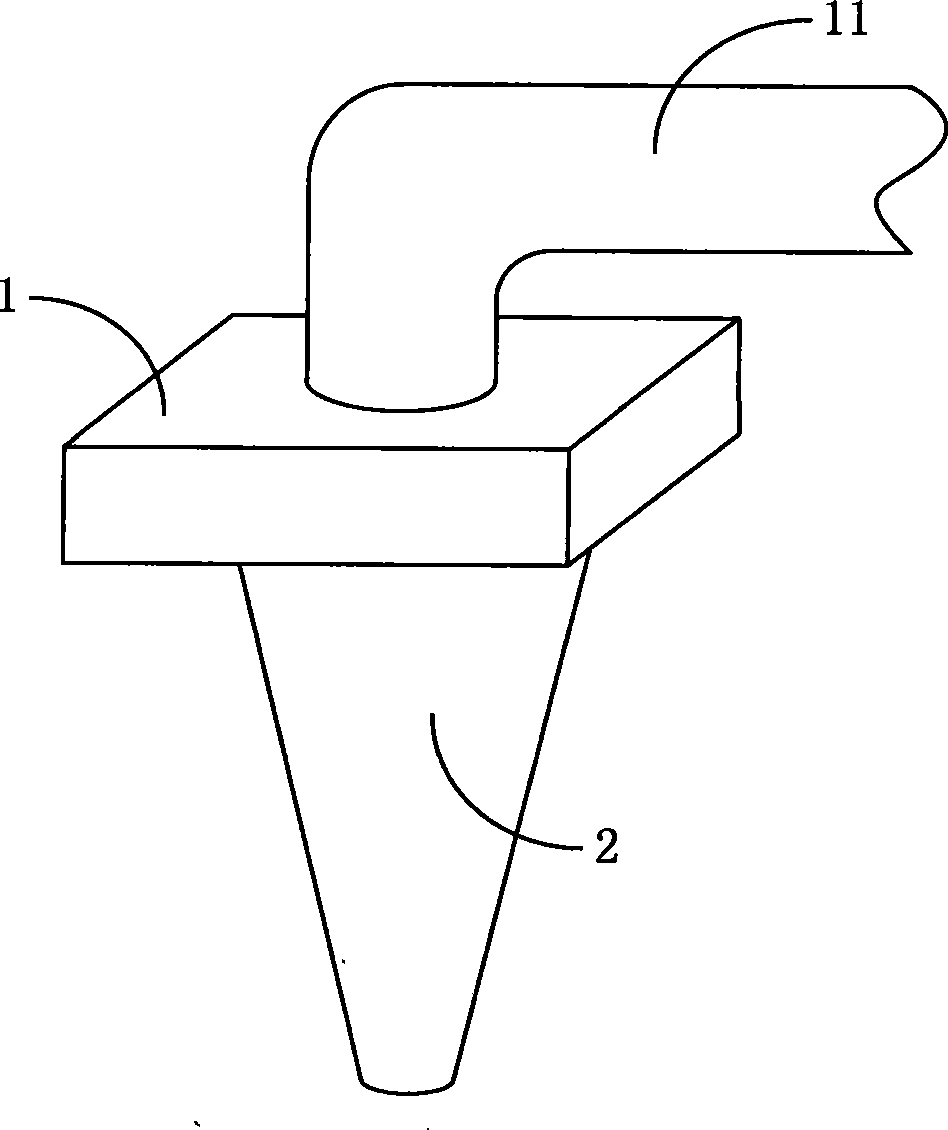

[0051] Such as image 3 As shown, this embodiment includes a fan 1 for exhausting gas through an exhaust pipe 11 . It also includes a conical cyclone pipe 2 , and the end of the cyclone pipe 2 with a larger diameter is connected to the air inlet of the fan 1 . The cyclone pipe 2 is provided with a purification component for purifying the oil fume gas flowing therethrough.

[0052] Figure 4 Shown is the internal structure of the cyclone tube 2 in this embodiment. In the figure, the purification component is a convex strip 21 spirally arranged on the inner surface of the cyclone pipe 2 . The convex strips 21 are arranged in a spiral manner.

[0053] The conical cyclone pipe 2 is a reducing pipe. When the power of the fan is constant, the air flow at both ends of the variable-diameter exhaust pipe is equal. Therefore, the end of the variable-diameter pipe with a smaller diameter generates a stronger negative pressure, thereby forming a stronger negative pressure area on the...

Embodiment 2

[0059] Such as Figure 8 As shown, the difference between this embodiment and the first embodiment above is that the end of the cyclone tube 2 with a larger diameter is connected to the air inlet of the fan 1 through a separate pipe 12 .

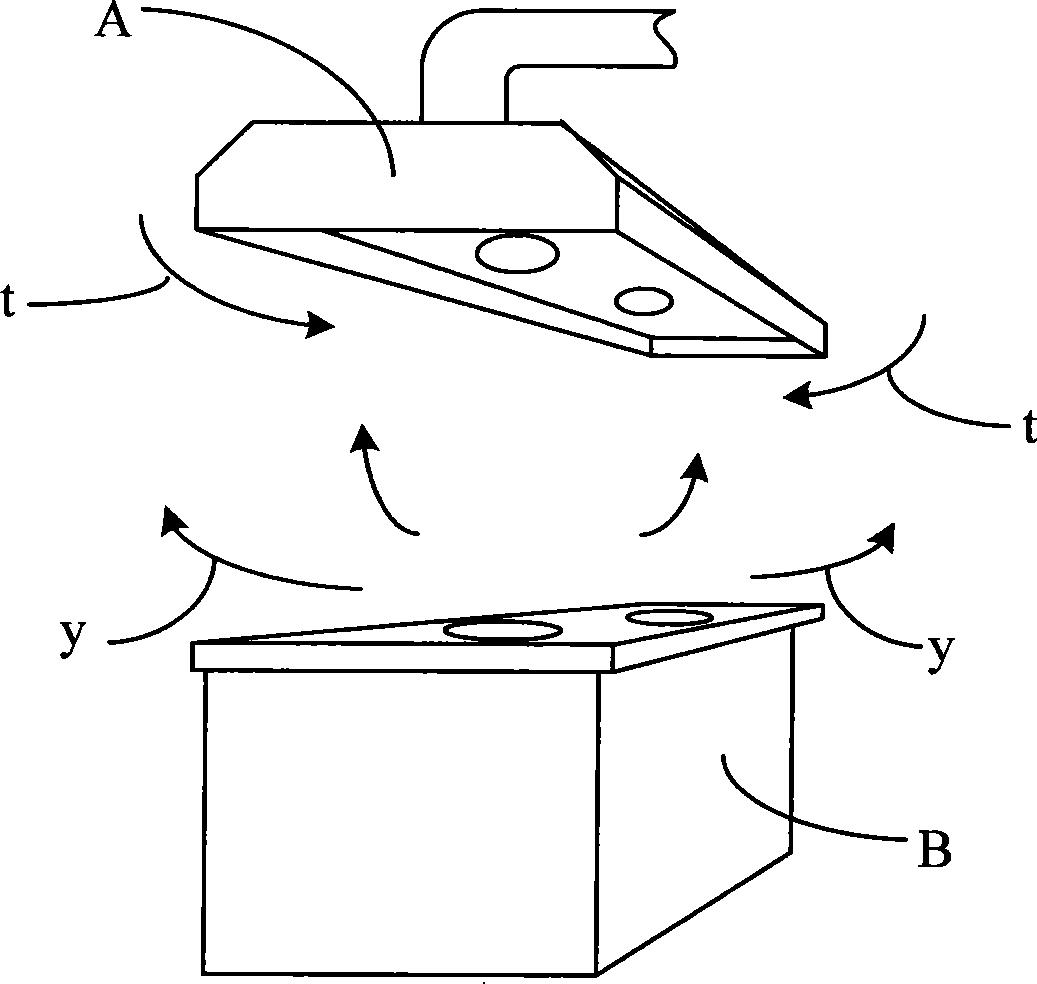

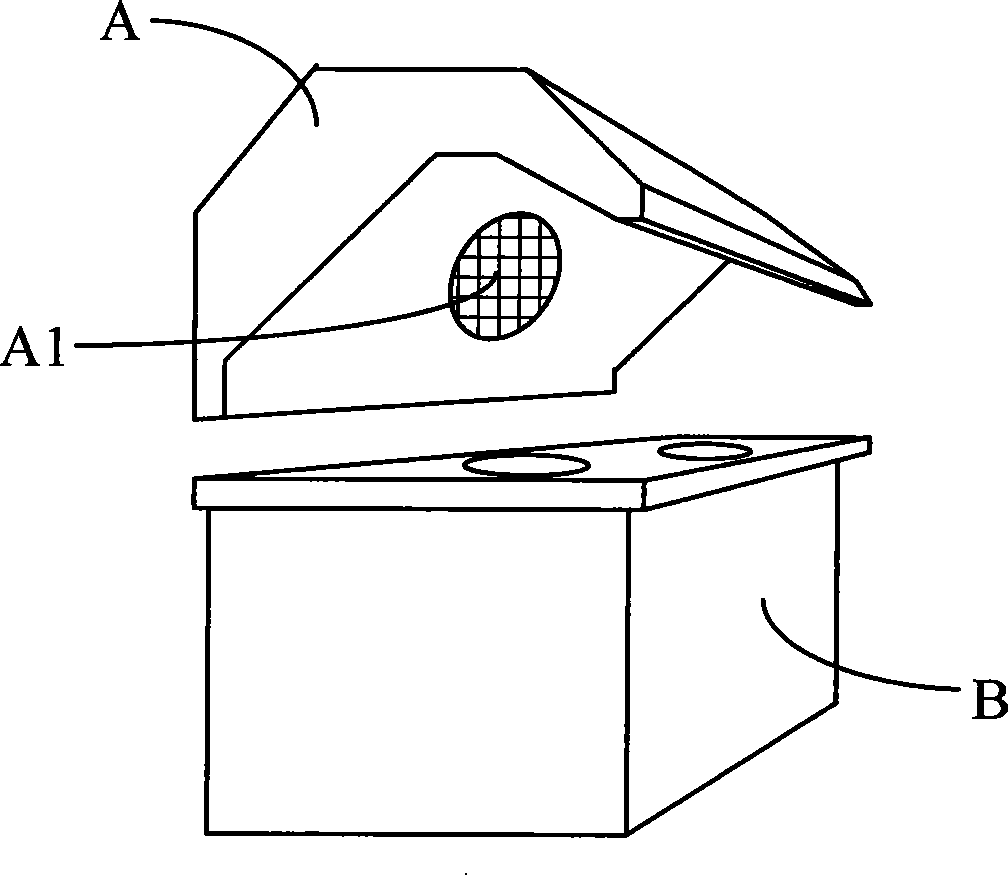

[0060] The cyclone pipe 2 and the fan 1 can be separated by the pipe 12 to form a split-type oil fume purification device. During installation, the blower fan 1 can be installed outdoors, and the cyclone pipe 2 can be installed at the stove top indoors, thereby forming a silent smoke exhaust, which overcomes the noise defect existing in the traditional range hood. In addition, in this embodiment, the end of the whirlwind pipe 2 with a smaller diameter is also connected with an oil fume suction part for capturing oil fume gas. The oil fume suction part is a cylindrical box body 3, and the surface of the box body 3 is distributed with A plurality of suction holes 31 .

[0061] The box body 3 can form a large negative pressure area in the sur...

Embodiment 3

[0068] Such as Figure 12 As shown, the difference between this embodiment and the above-mentioned two embodiments is that: a straight tube 5 is also connected to the larger end of the cyclone tube 2, and a fan impeller 4 is arranged in the straight tube 5, and on the fan impeller 4 surface A plurality of guide vanes 41 are arranged in a row.

[0069] The end with a larger diameter of the cyclone pipe 2 is the outlet of the oil fume gas, and the fan impeller 4 is arranged at the outlet to forcibly promote the rotation of the oil fume gas or enhance the rotation effect of the oil fume gas.

[0070] In order to further increase the rotational speed of the soot gas, this embodiment can also be as follows Figure 13 As shown, the fan wheel 4 is provided with a motor 42 for driving the fan wheel 4 to rotate. The fan impeller 4 installed with the motor 42 can not only provide and enhance the power of rotation, but also accelerate the flow of soot gas.

[0071] Considering the impac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com