Method and apparatus for totally-closed garbage emission and transmission atomization and comprehensive utilization

A fully enclosed and garbage technology, applied in the direction of chemical instruments and methods, applications, energy input, etc., can solve the problems of increasing urban sewage load, wasting water sources, and easy jamming machines, so as to increase urban sewage load, reduce wastewater discharge, prevent The effect of wasting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

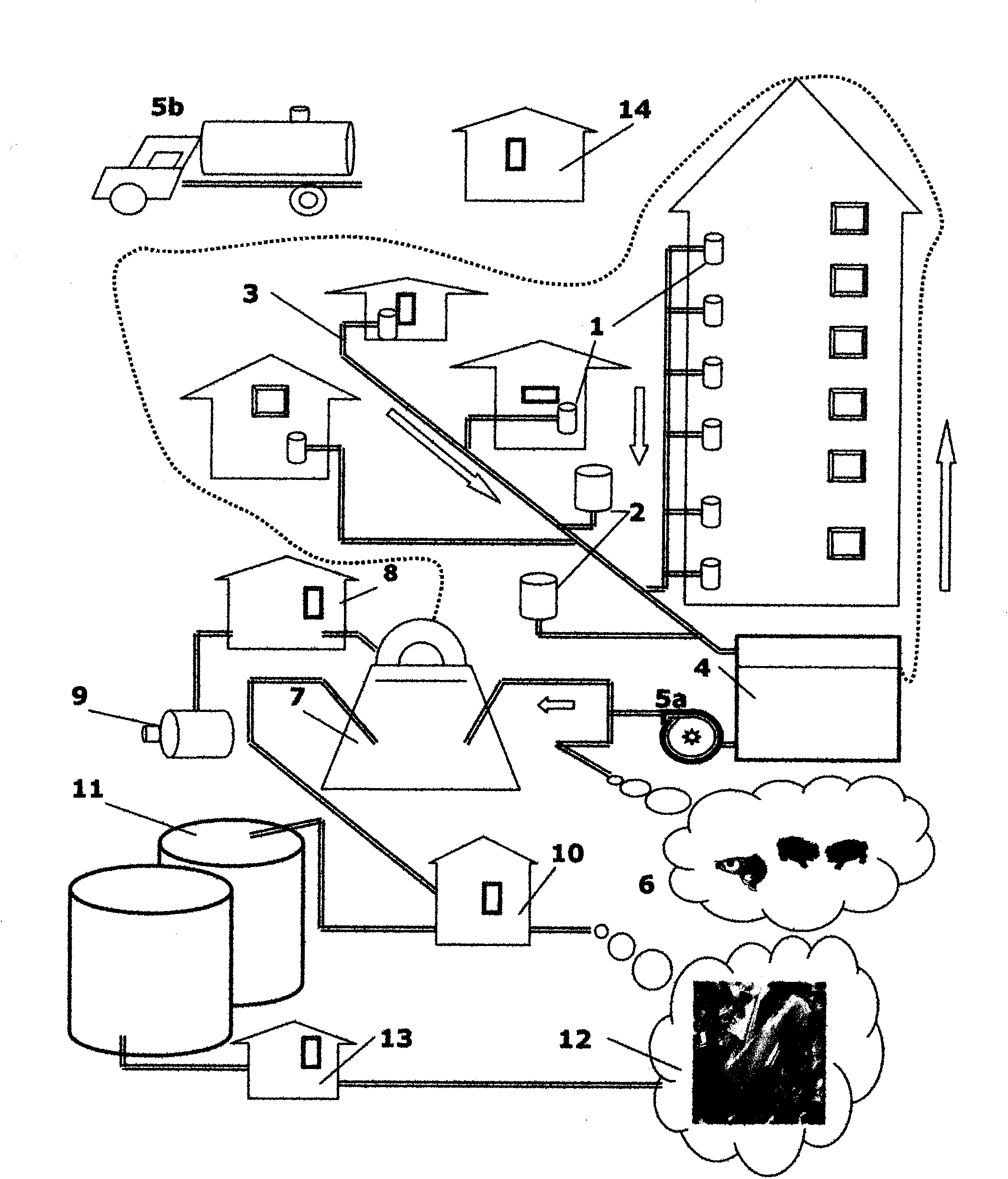

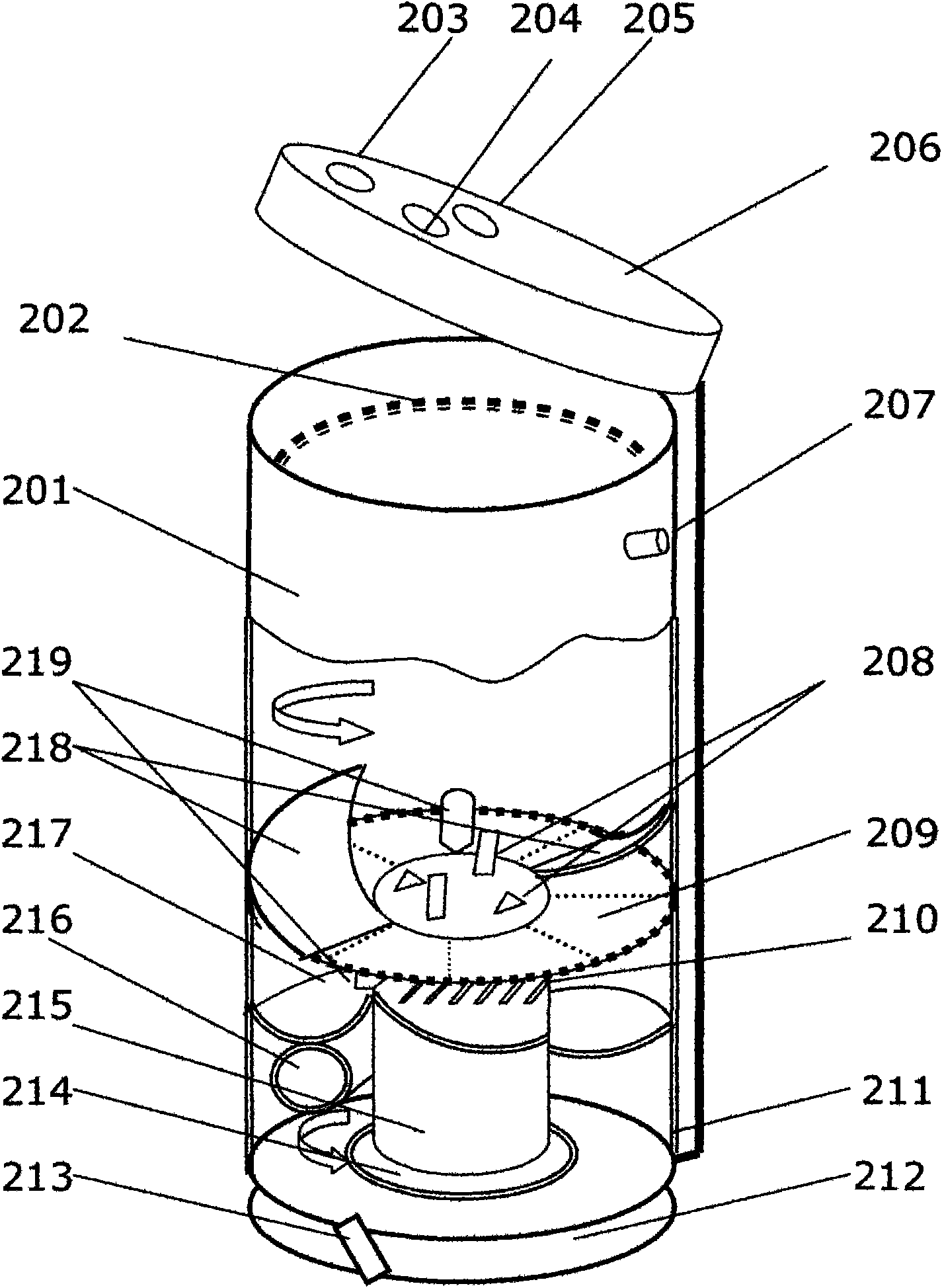

[0043] Embodiment 1, first put the rubbish into the multi-functional mechanical beating trash can 1-2, after a certain amount is accumulated, the multi-functional mechanical beating trash can is automatically mixed with water according to the set ratio, and a flowable substance is formed by stirring, cutting and grinding. It is discharged, concentrated, and transported to the collection pool 4 through the pipeline 3 connecting each trash can. In order to save water, the water that joins the garbage can be domestic and production waste water to reduce the amount of urban sewage, and it can also be tap water, but the consumption is seldom. Because the moisture content of the garbage is 50-80%, the garbage slurry itself has a certain fluidity. Adding a small amount of water is actually to increase the fluidity and meet the conditions for pipeline transportation. The specific operation is to open various garbage, such as bones, potatoes, wood, pumpkins, paper, fiber, pasture, etc....

Embodiment 2

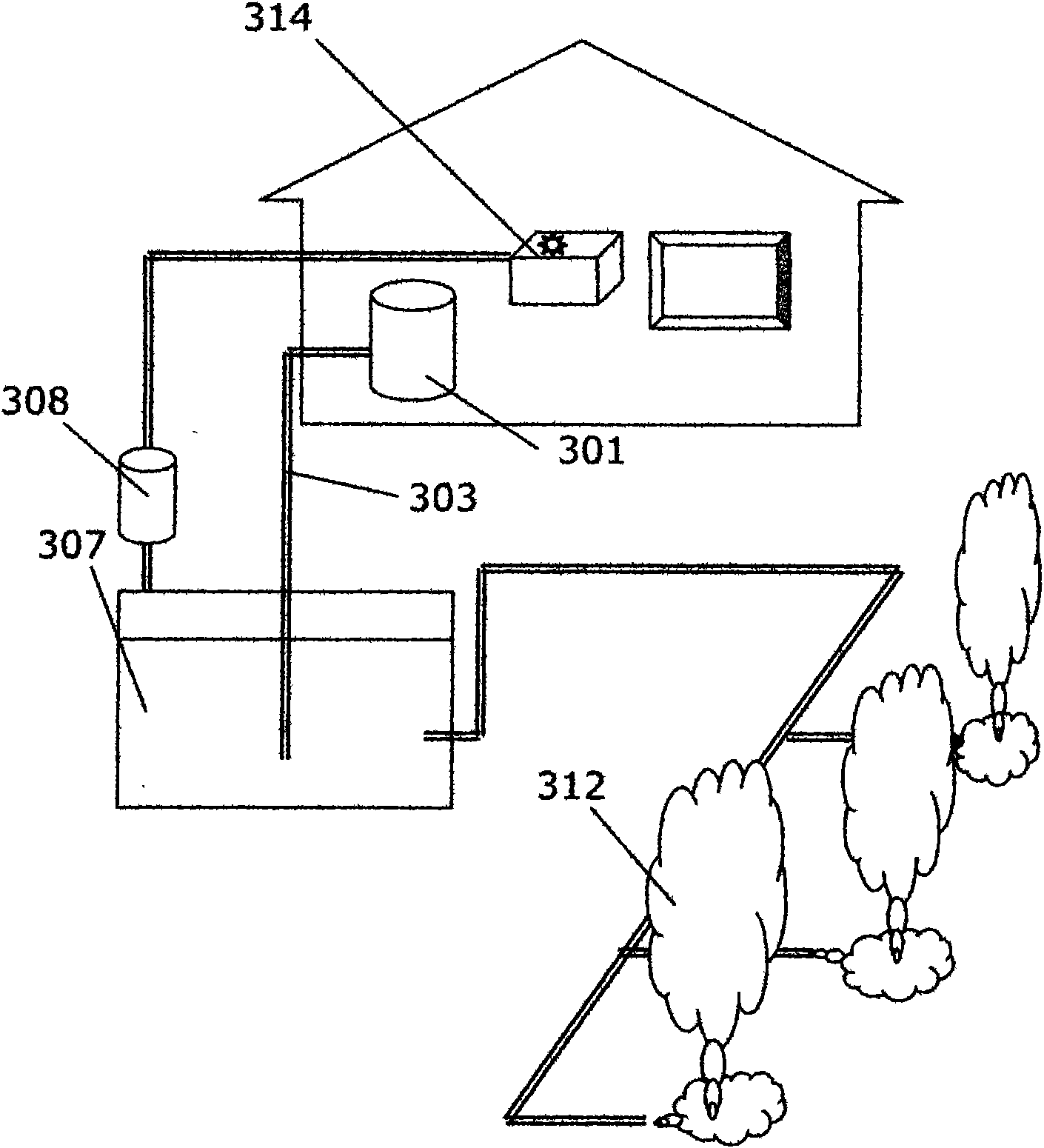

[0046] Direct irrigation and drainage type for small residential buildings: image 3 It is a model diagram of waste liquefaction, methane production and product utilization in independent residential areas. Put all kinds of domestic waste into the multi-functional mechanical beating trash can 301 set in the residence or residential area, through the multi-functional mechanical beating trash can 301, the garbage is liquefied or fluidized and then collected into the methane (biogas) fermentation tank 307 through the pipeline 303 , the methane (biogas) obtained from the production is purified by the purifier 308 and used as fuel. Biogas residue and biogas slurry are sterilized and introduced into the garden 312 by pipelines for direct drainage and irrigation.

Embodiment 3

[0048] Breeding and protein reproduction; put the kitchen waste and food processing residues in various living areas into the multifunctional mechanical beating garbage bin 1 set in the residence or factory, and use the multifunctional mechanical beating garbage bin 1 to liquefy or liquefy the garbage Fluidized, collected into the disinfection pool 10 through pipelines, and used as feed for breeding 6 and ecological natural purification after sterilization and purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com