Method for making water-transfer printing paper by using printer to make pattern

A technology of water transfer printing paper and production method, which is applied in the direction of transferring ink from original manuscripts, chemical instruments and methods, flat products, etc., which can solve the problems of easy diffusion of patterns, inapplicability to small batch production, inconvenience, etc., and achieve graphic modification Easy to adjust with graphic layout, save production time and cost, and eliminate time-consuming and cost-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

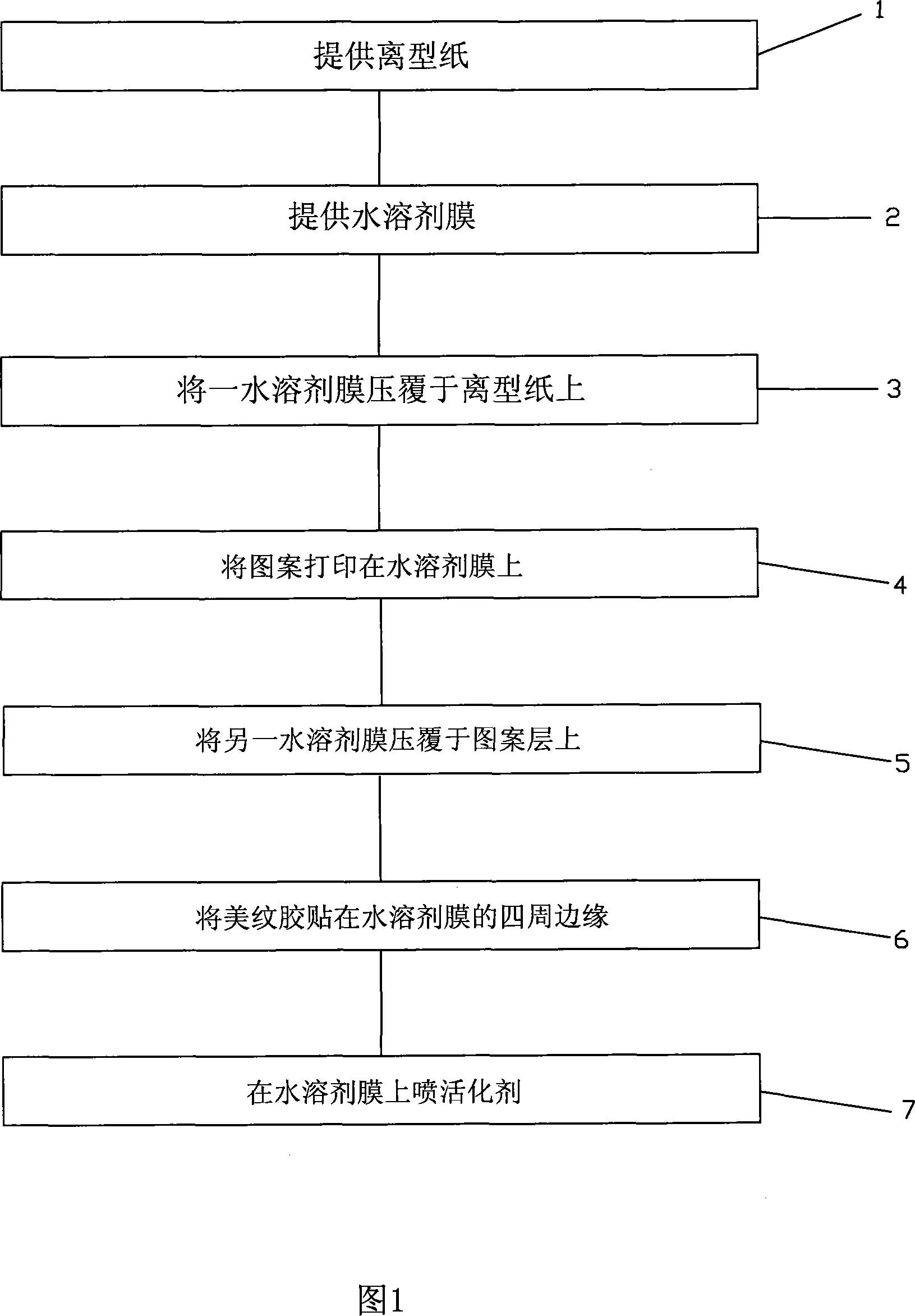

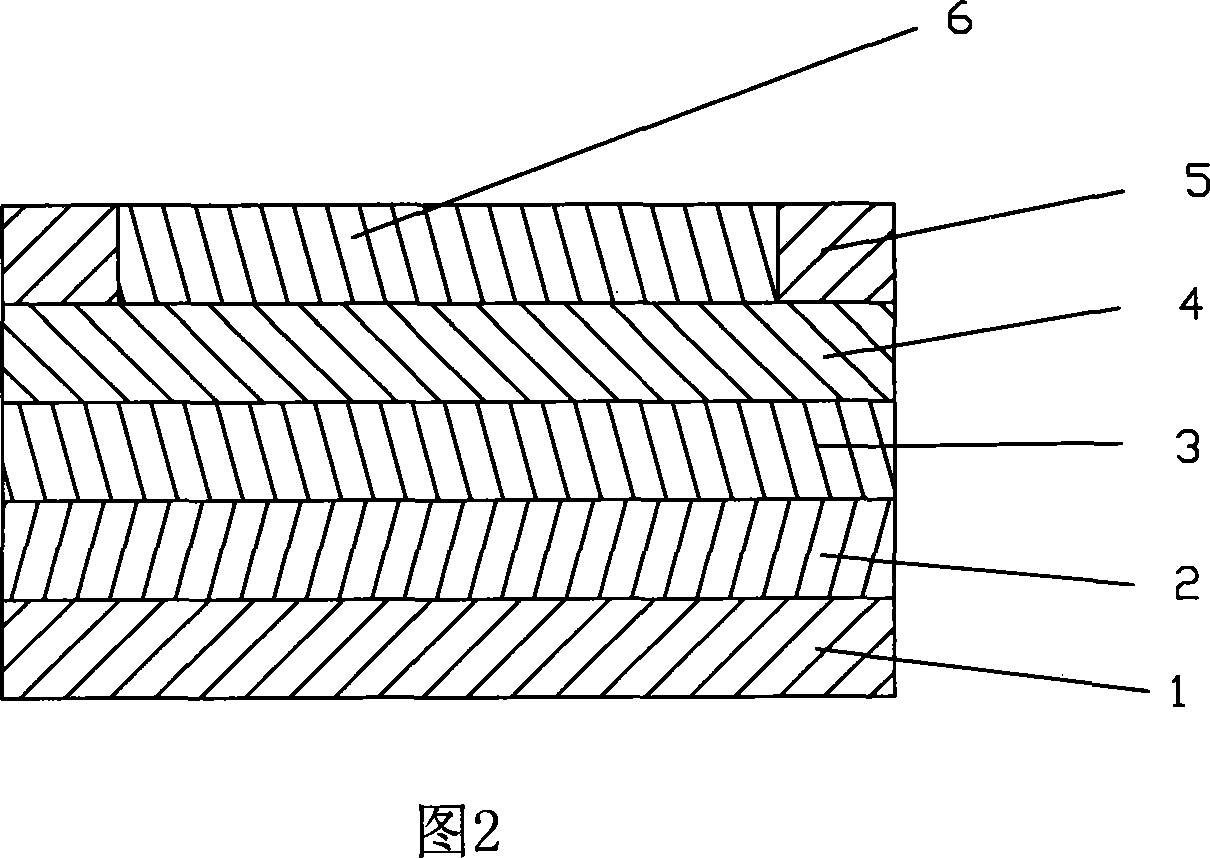

[0012] Referring to FIG. 1 , it is a flow chart of a method for making water transfer paper with a pattern by a printer according to the present invention. The method includes the following steps:

[0013] Step 1: Provide release paper;

[0014] The release paper is made of peelable plastic paper, which is used as the carrier of the water solvent film, and rolled into a standard paper roll by a roller, or cut into a standard sheet.

[0015] Step 2: providing an aqueous solvent film;

[0016] In this step, the production steps of the water solvent film include: selecting a synthetic resin with good water solubility; making the synthetic resin into a film by extrusion molding, calendering or tape casting; curling the obtained film into a standard Standard film rolls, or cut into standard specification single film.

[0017] Step 3: Laminate a water solvent film on the release paper;

[0018] The lamination of the water solvent film and the release paper is carried out by lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com