Patents

Literature

44 results about "Graphic simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

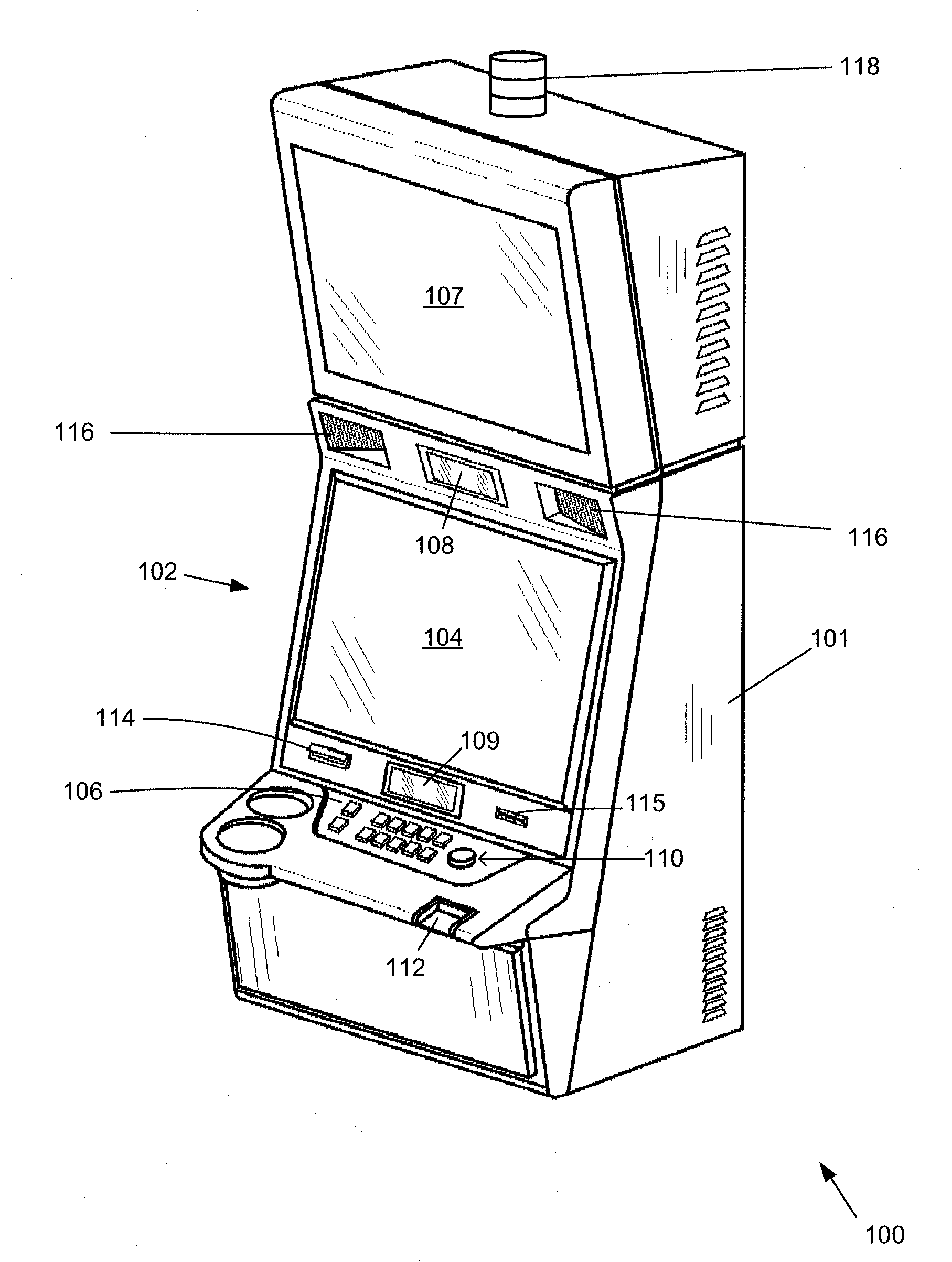

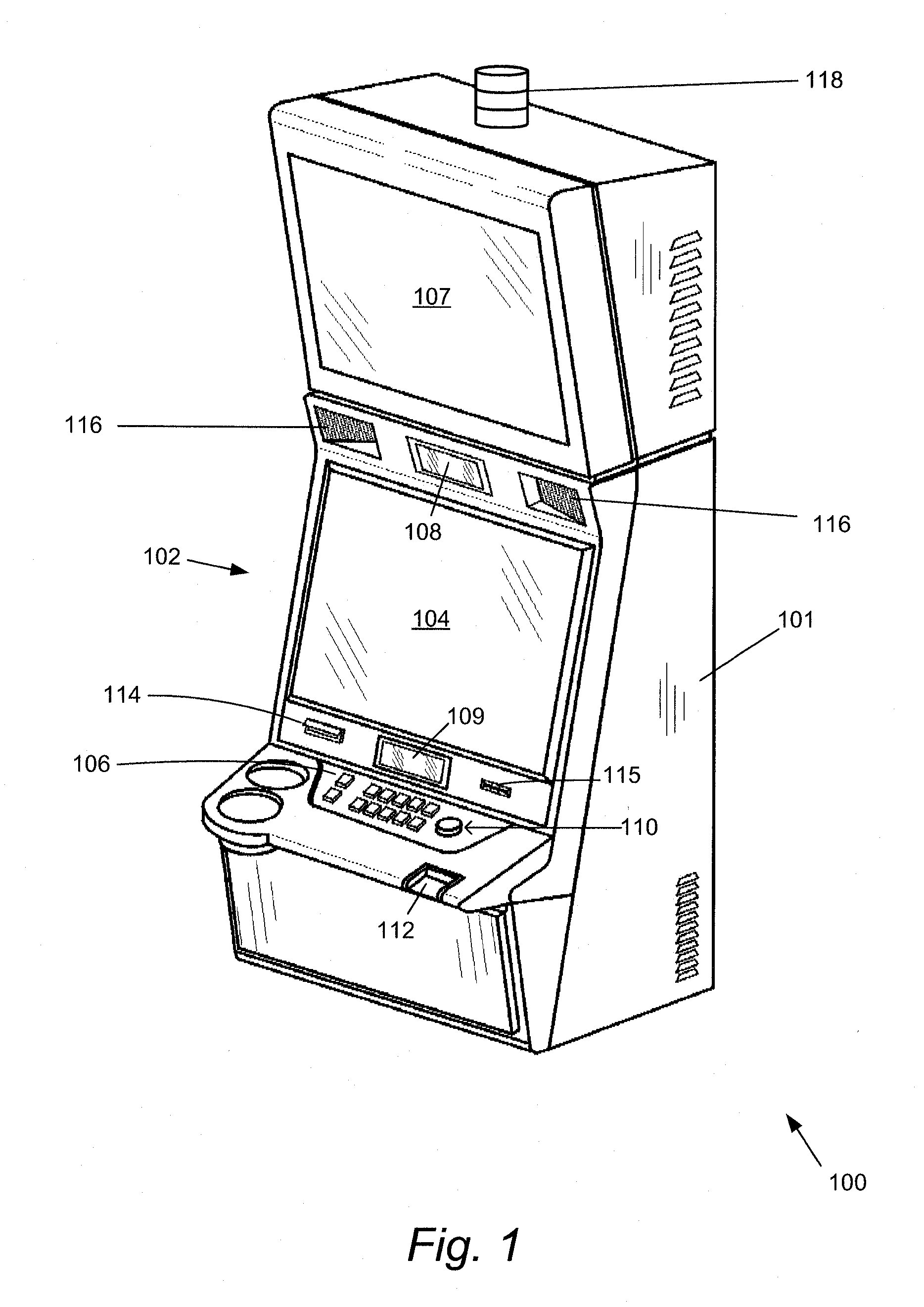

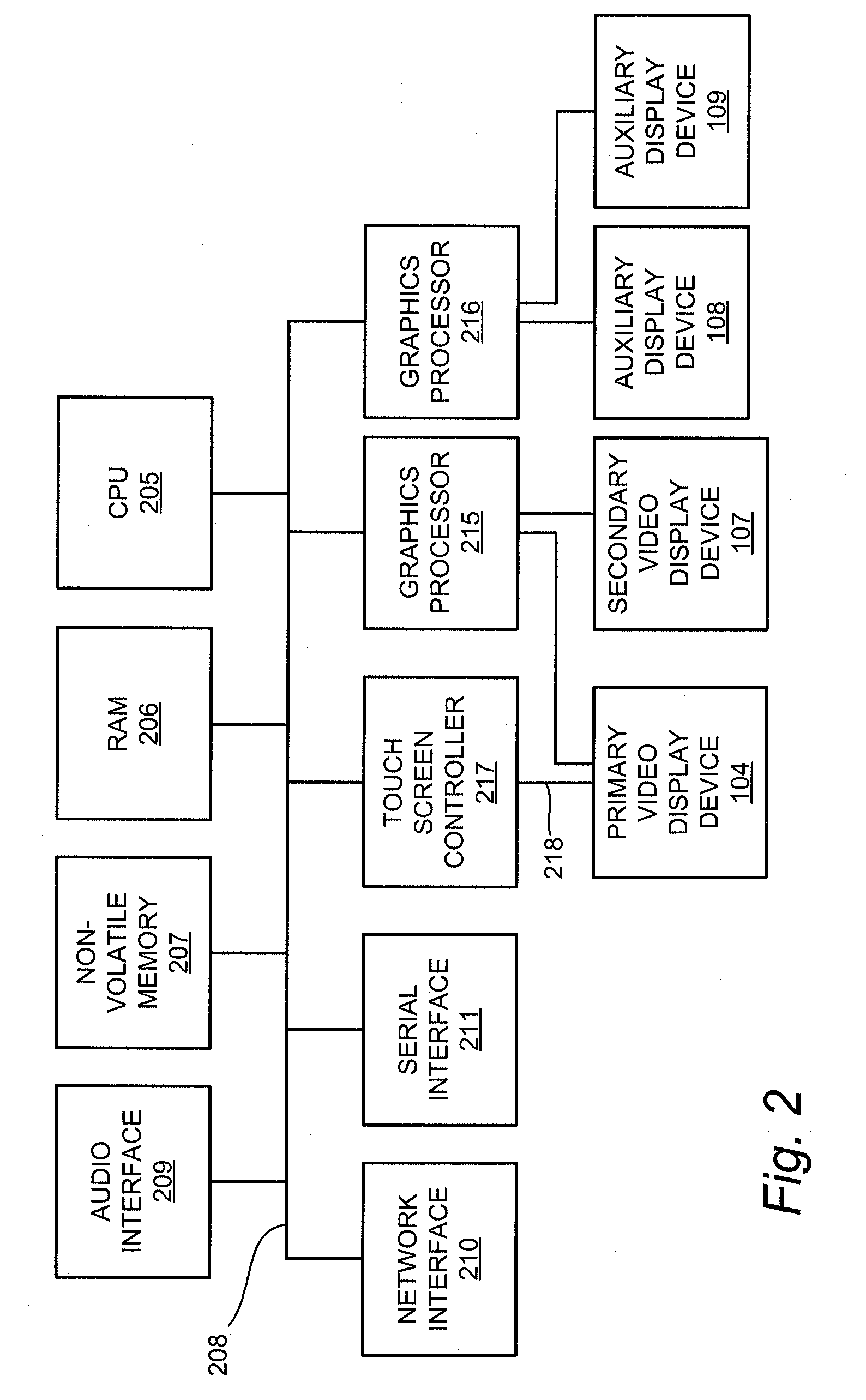

Method, apparatus, and program product for producing and applying a graphic simulation across multiple gaming machines

InactiveUS20090124345A1Reduce brightnessChange colorApparatus for meter-controlled dispensingVideo gamesGraphicsDisplay device

An apparatus for producing shared image games includes a number of gaming machines, with each gaming machine having a respective video display device. The apparatus also includes a shared image display control arrangement and a shared image prize controller. The shared image display control arrangement controls the respective video display device associated with each gaming machine in the number of gaming machines to produce a shared image graphic effect such as a multi-segmented prize reel that appears to extend across the different video display devices. The shared image prize controller operates to award a shared image prize for at least one of the gaming machines. This shared image prize corresponds to a prize represented at least in part by a respective one of the reel segments displayed at the video display device of the respective gaming machine when the reel segments appear to come to a stop. For example, a given reel segment may show a prize value that is awarded to the player at the particular gaming machine, or may show a multiplier value that is applied to some value accumulated for the player at the particular gaming machine.

Owner:MULTIMEDIA GAMES

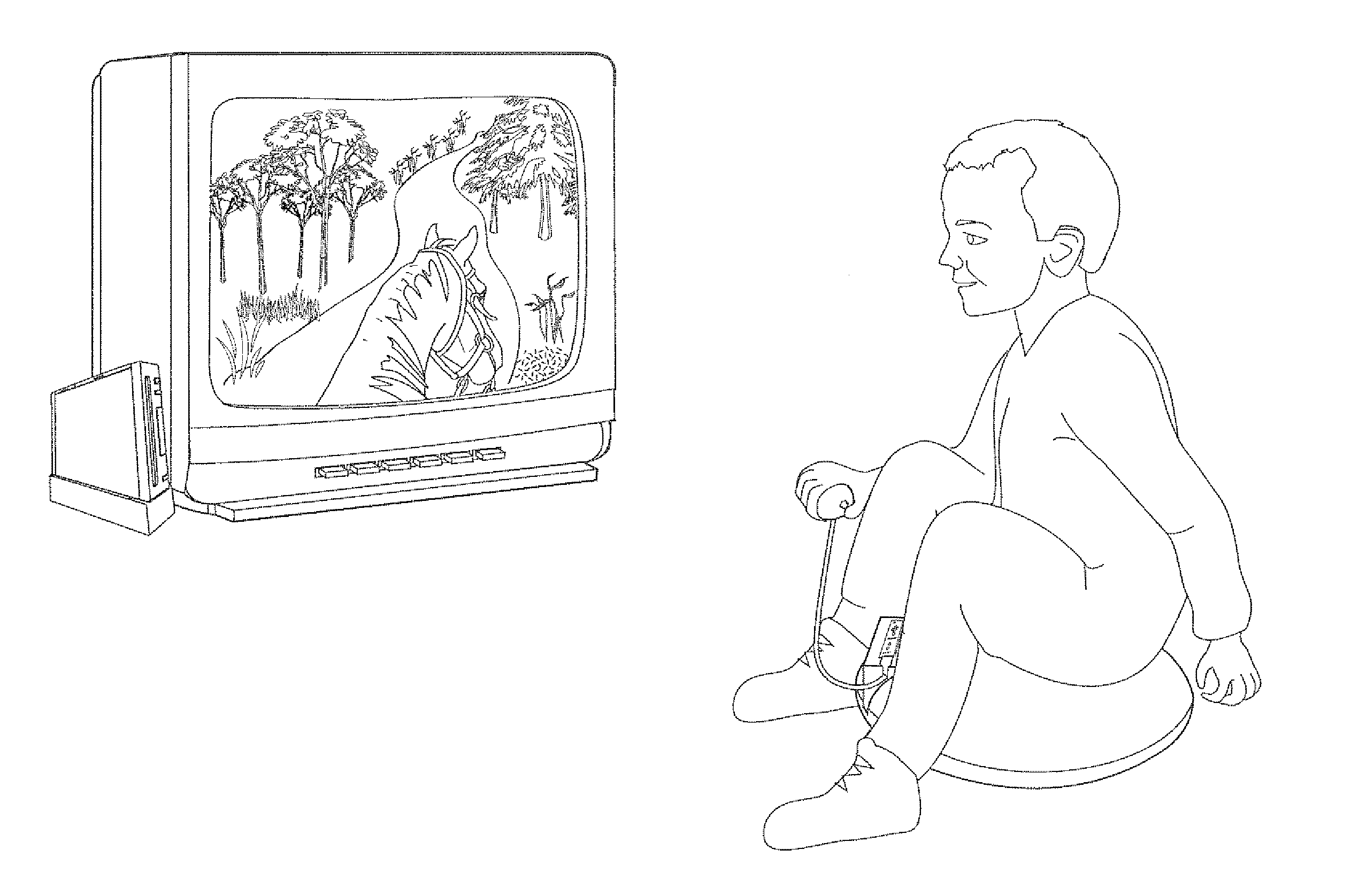

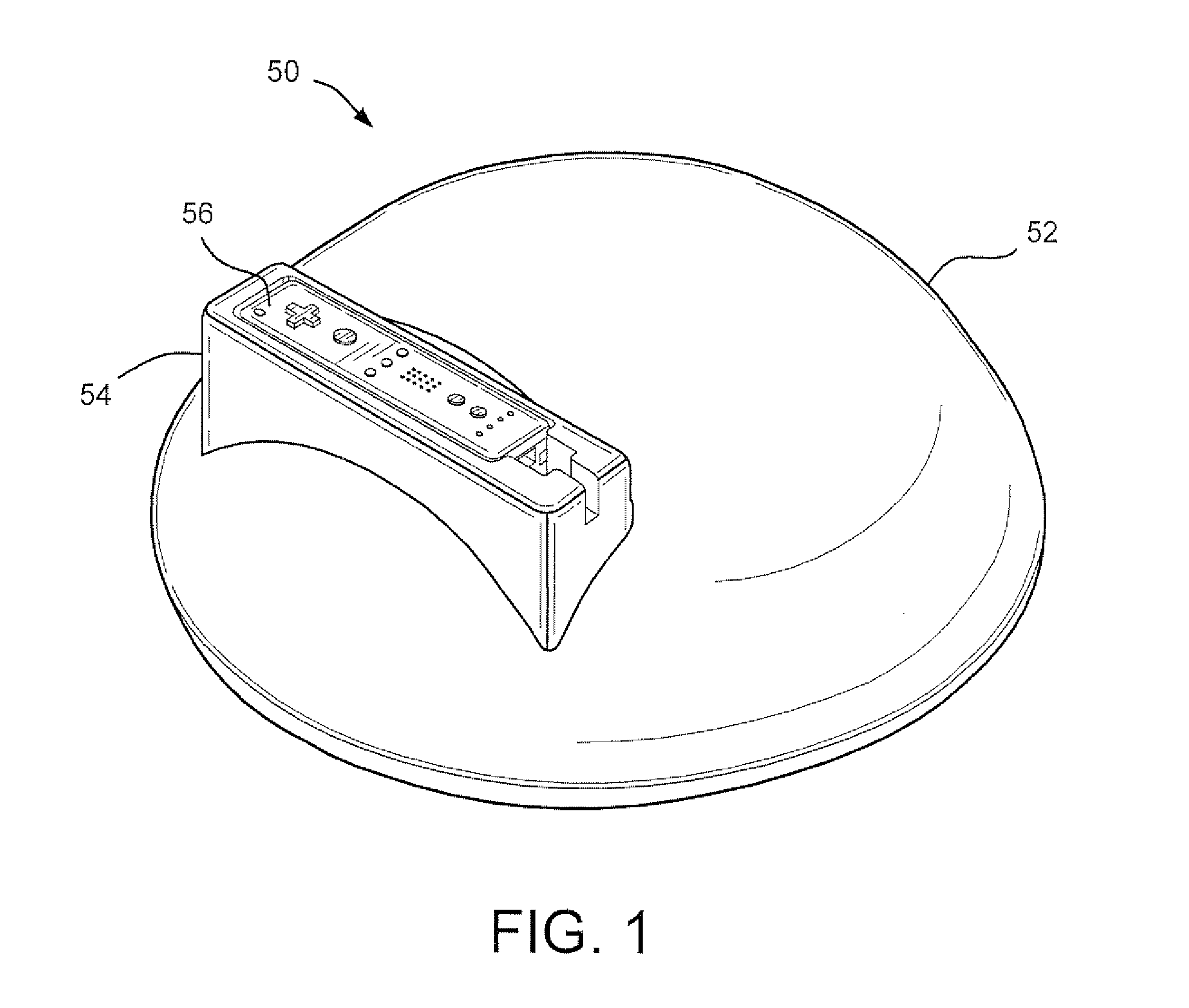

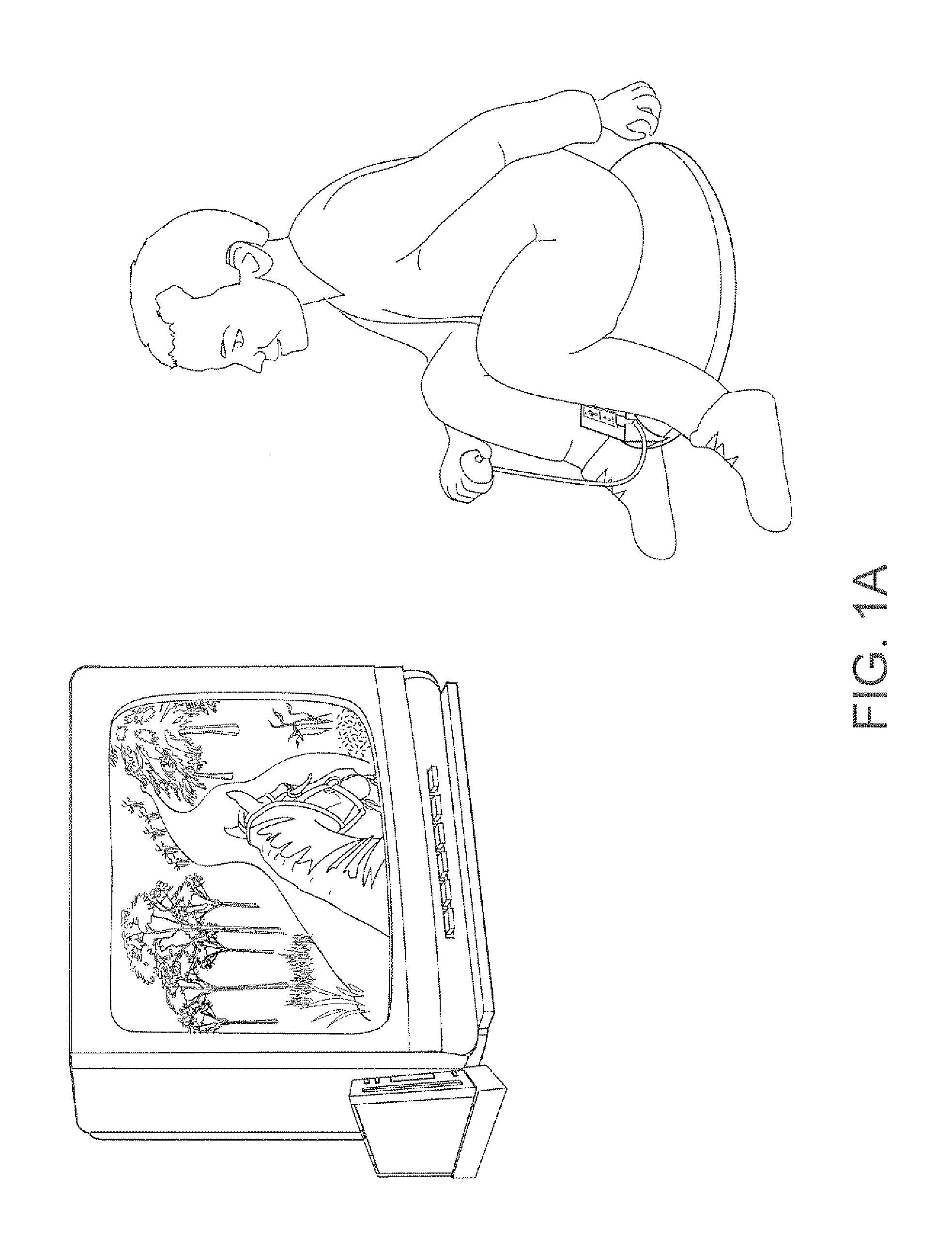

Horseback riding simulation

ActiveUS20100009762A1Display realisticVideo gamesSpecial data processing applicationsGraphicsGraphic system

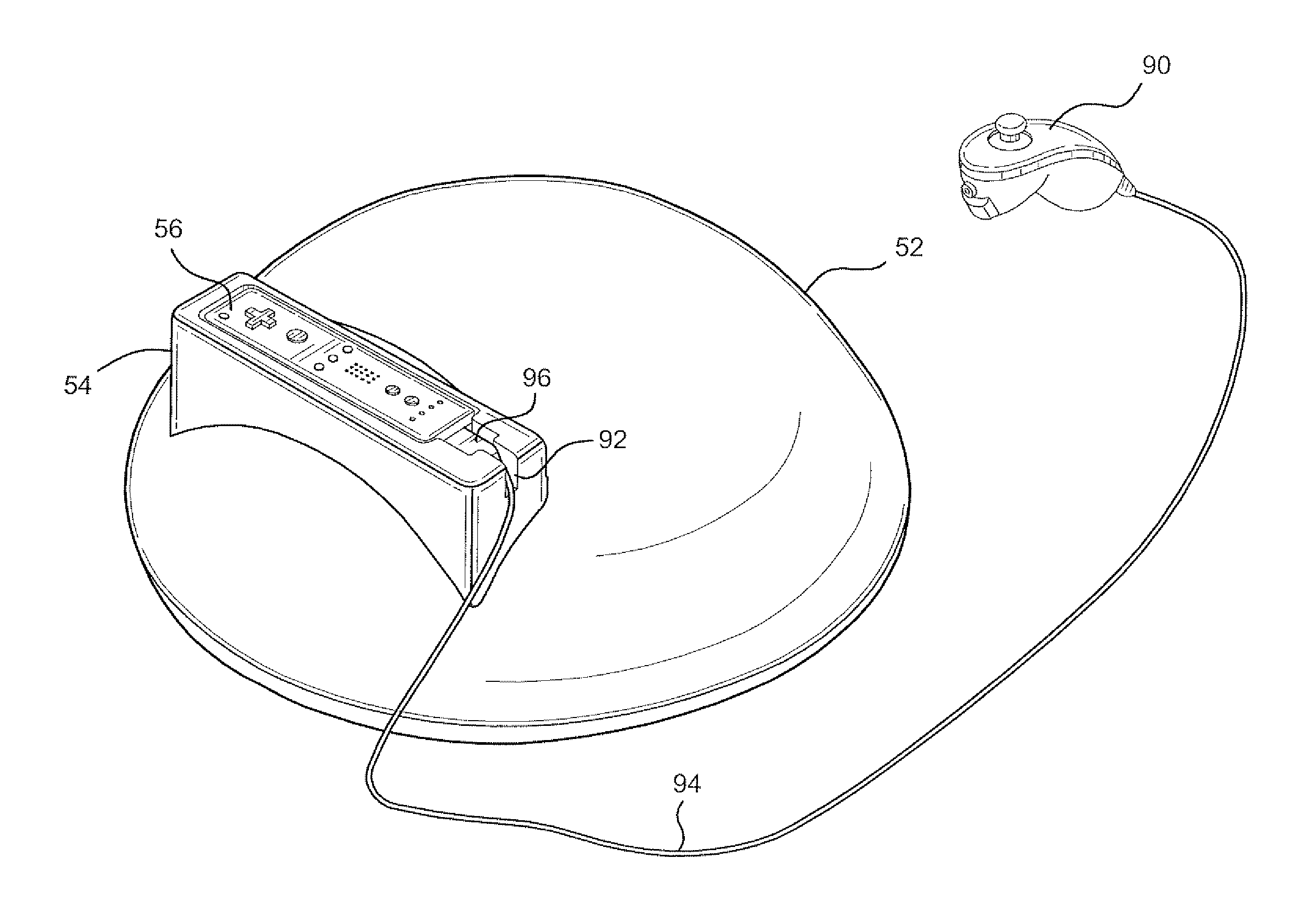

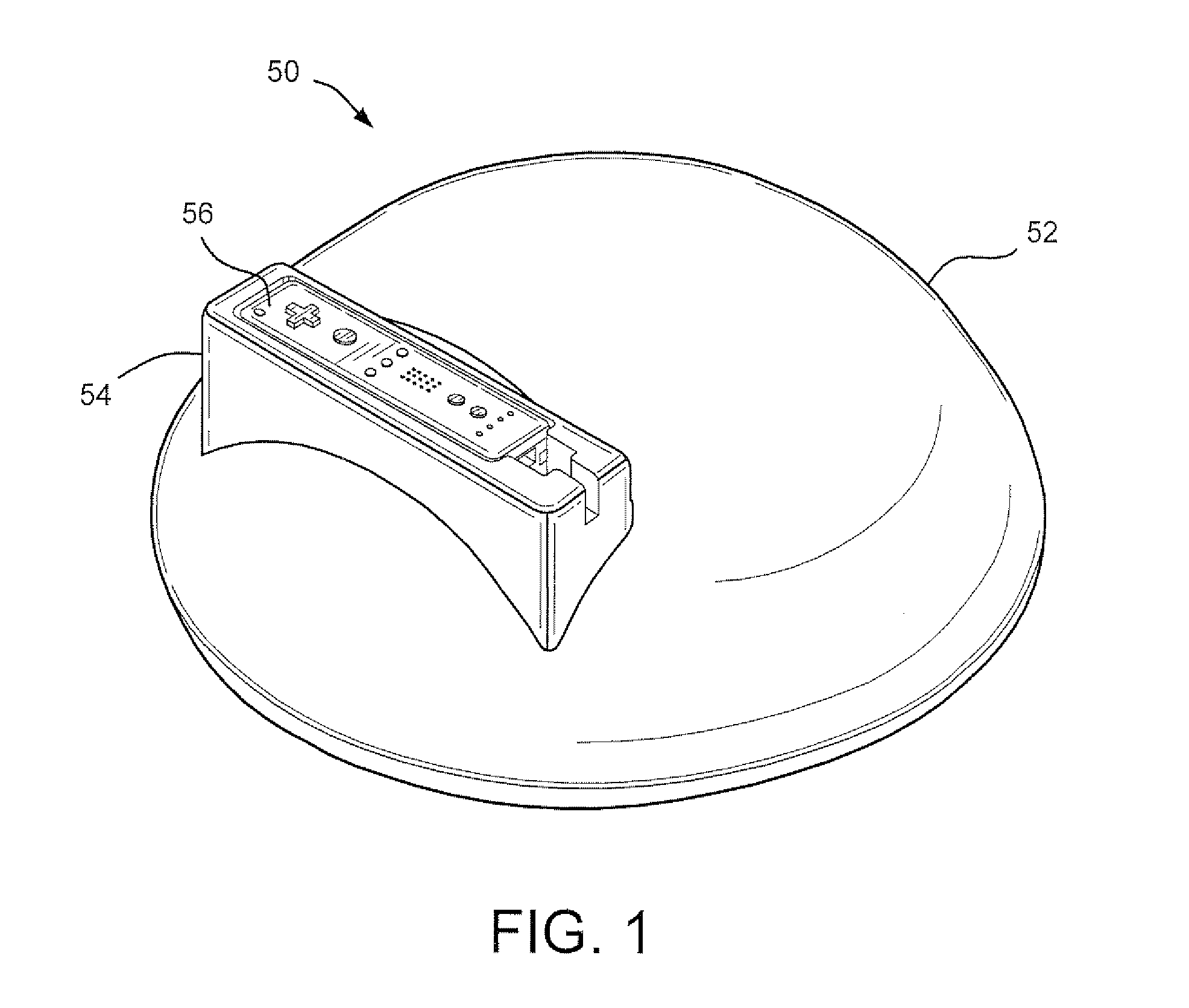

An inflatable air cushion or other type seat a person can sit on is instrumented with electronic input devices that can sense motion of the cushion and / or motion of the person's body. Such input devices provide inputs to a computer graphics system that dynamically generates a responsive scene on a real time display. The sensed motion can be used to generate a graphics simulation of horseback riding.

Owner:NINTENDO CO LTD

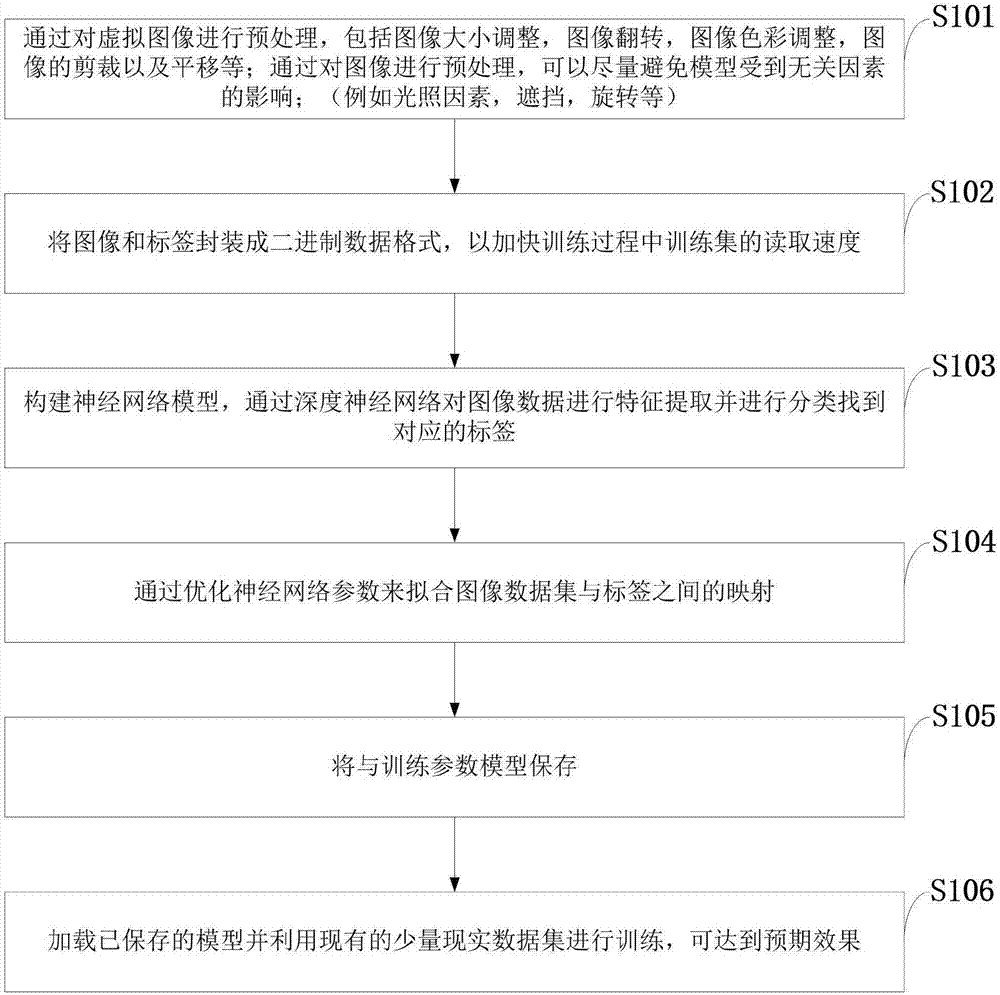

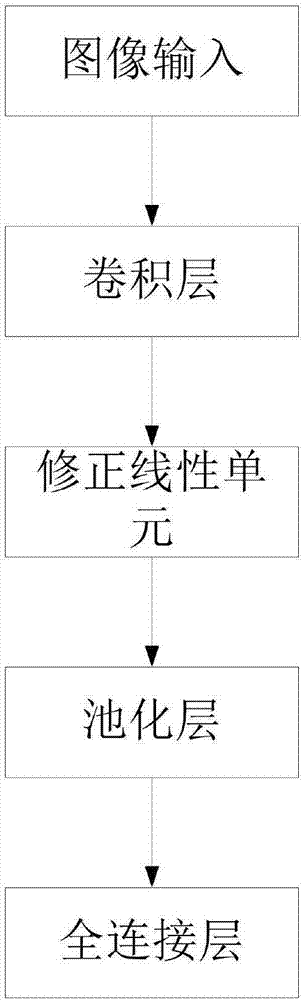

Neural network migration learning method based on virtual image dataset

InactiveCN107451661AAchieve practical application effectMachine learningNeural learning methodsPattern recognitionNerve network

The invention belongs to the field of machine learning technology and discloses a neural network migration learning method based on a virtual image dataset. The method comprises the steps that virtual image data is acquired through graphic simulation software, classified marking is performed on a virtual dataset, and an image dataset is obtained; a neural network is utilized to train a target recognition model through preprocessing of the virtual dataset, and a parameter model trained through the virtual dataset is saved; and migration learning is performed, and a new target dataset is utilized to train the saved pre-training model again. According to the method, a needed scene or target is collected through a virtual engine to construct a dataset based on the virtual image dataset, the pre-training model is obtained through training of the virtual dataset, and the migration learning method is utilized to achieve the practical application effect on a small quantity of datasets.

Owner:XIDIAN UNIV

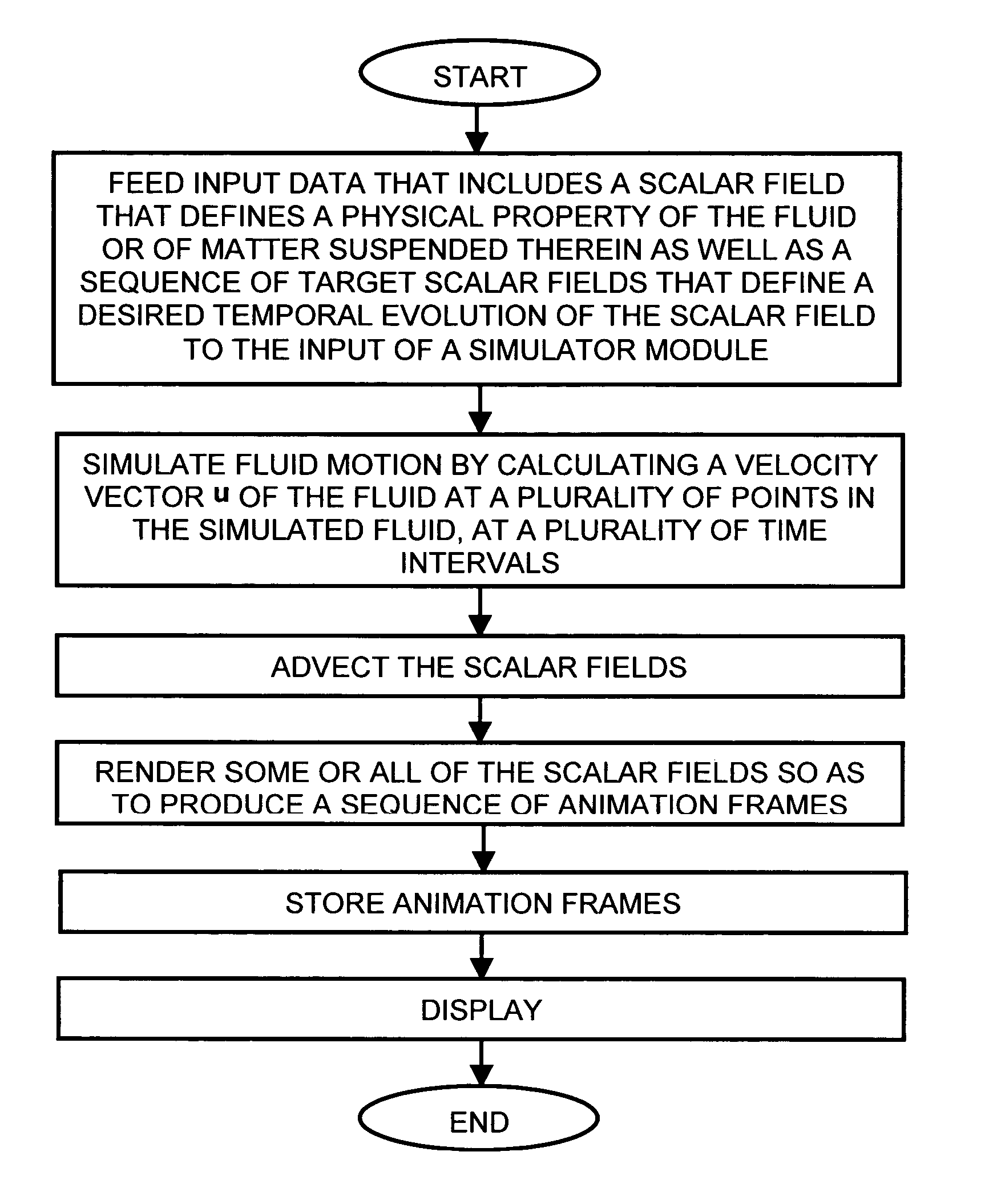

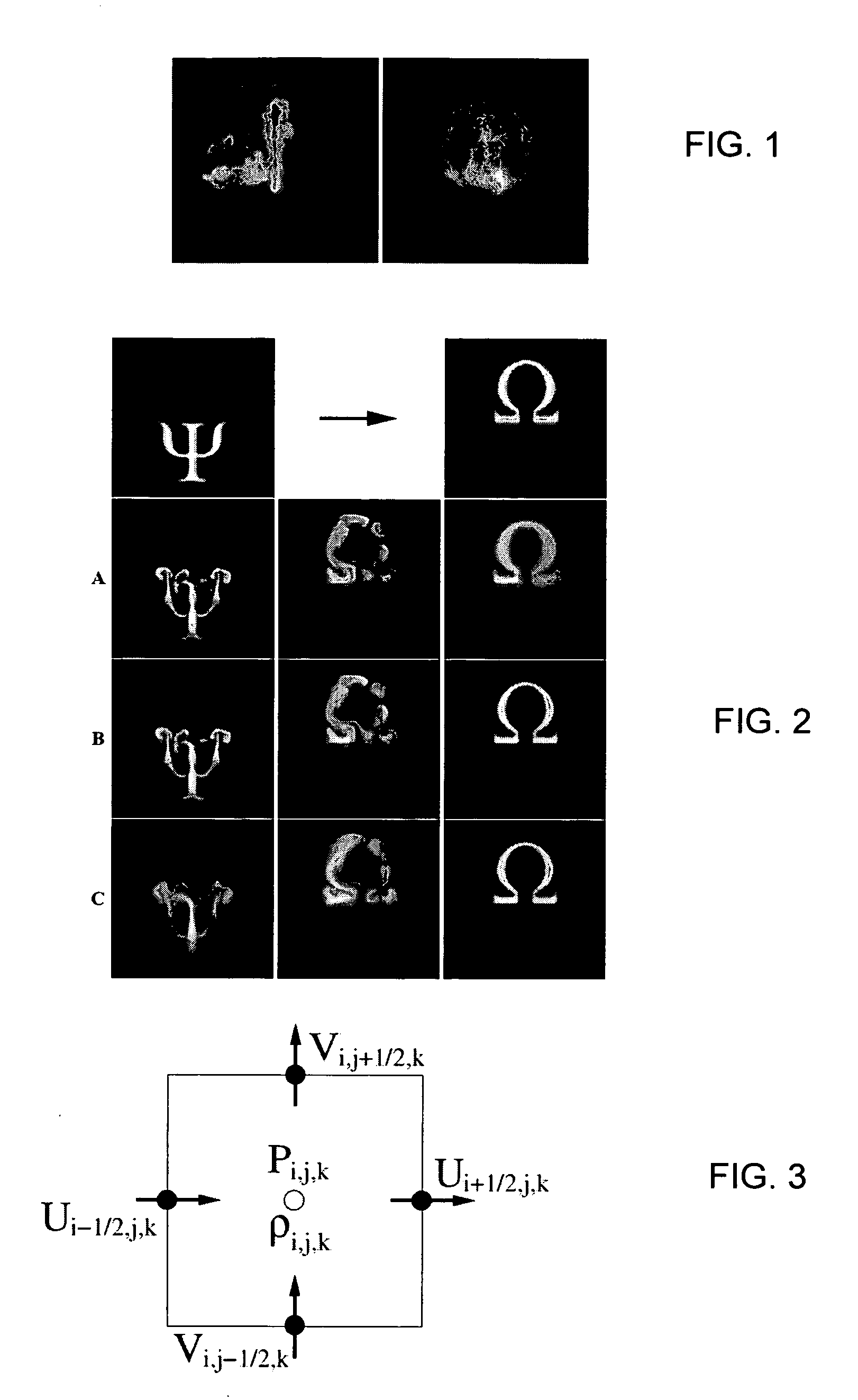

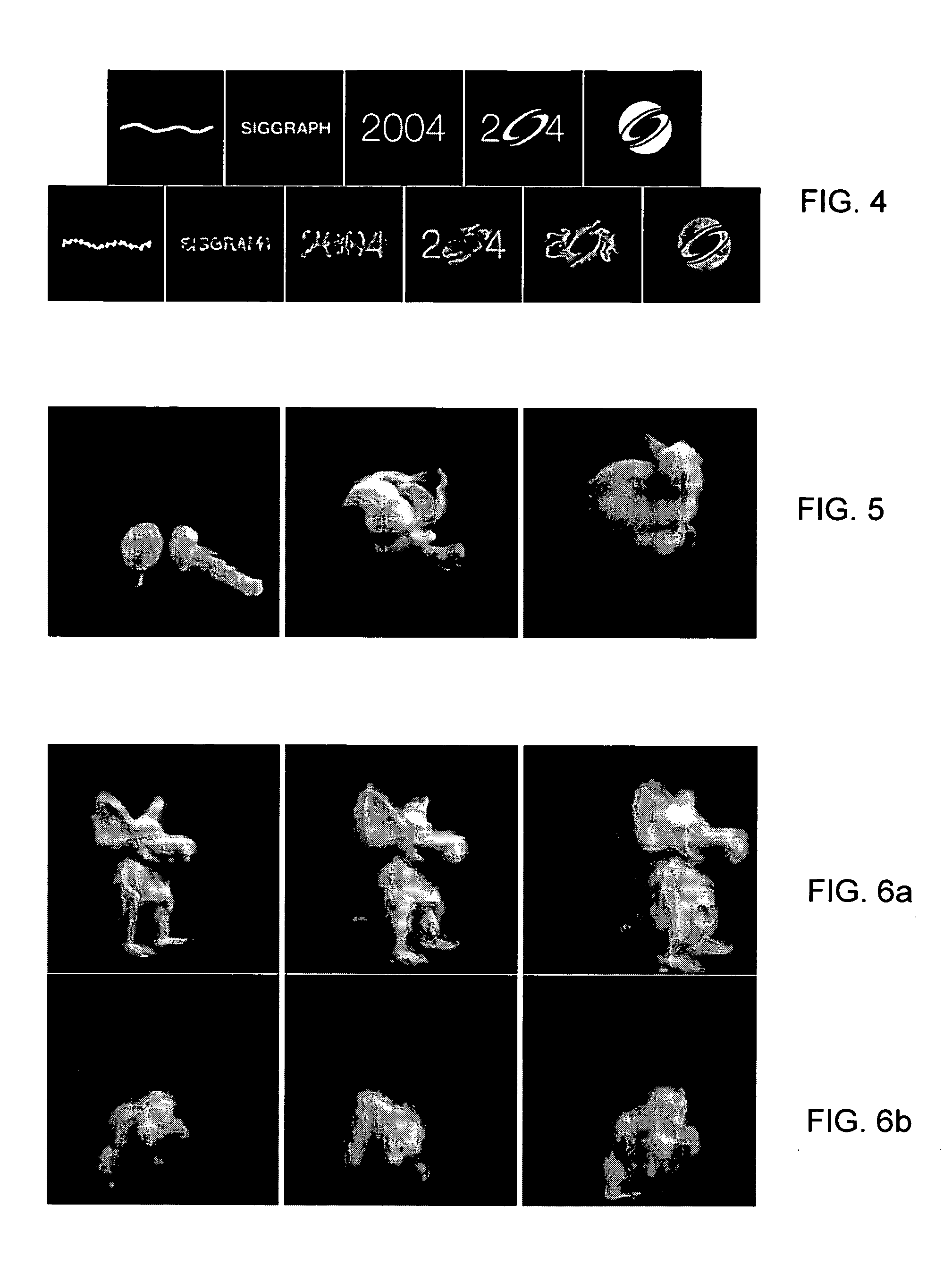

Method and system for performing computer graphic simulation of a fluid using target-driven control

InactiveUS20050253854A1Low additional costAvoid the needComputation using non-denominational number representationAnimationGraphicsAnimation

Method and system for efficiently controlling animated smoke which utilizes a sequence of target smoke states to generate a smoke simulation in which the smoke is driven towards each of these targets in turn, while exhibiting natural-looking interesting smoke-like behavior. This control is made possible by two new terms added to standard flow equations: (i) a driving force term that causes the fluid to carry the smoke towards a particular target, and (ii) a smoke gathering term that prevents the smoke from diffusing too much. These terms are explicitly defined by the instantaneous state of the system at each simulation time step. Thus, no expensive optimization is required, allowing complex smoke animations to be generated with very little additional cost compared to ordinary flow simulations. The invention is also applicable to animation of other fluid flow phenomena.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

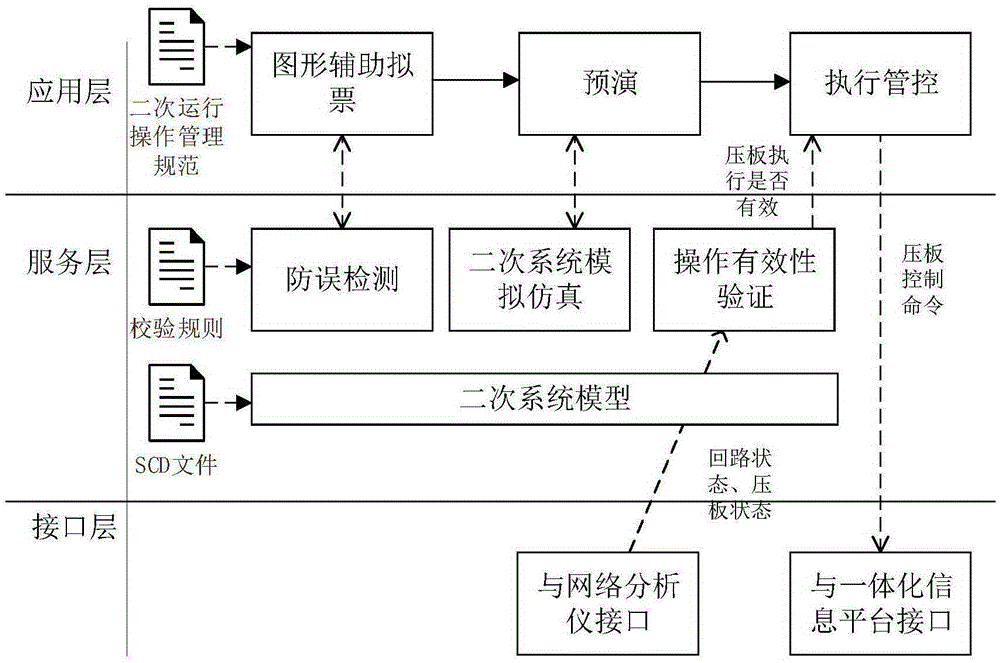

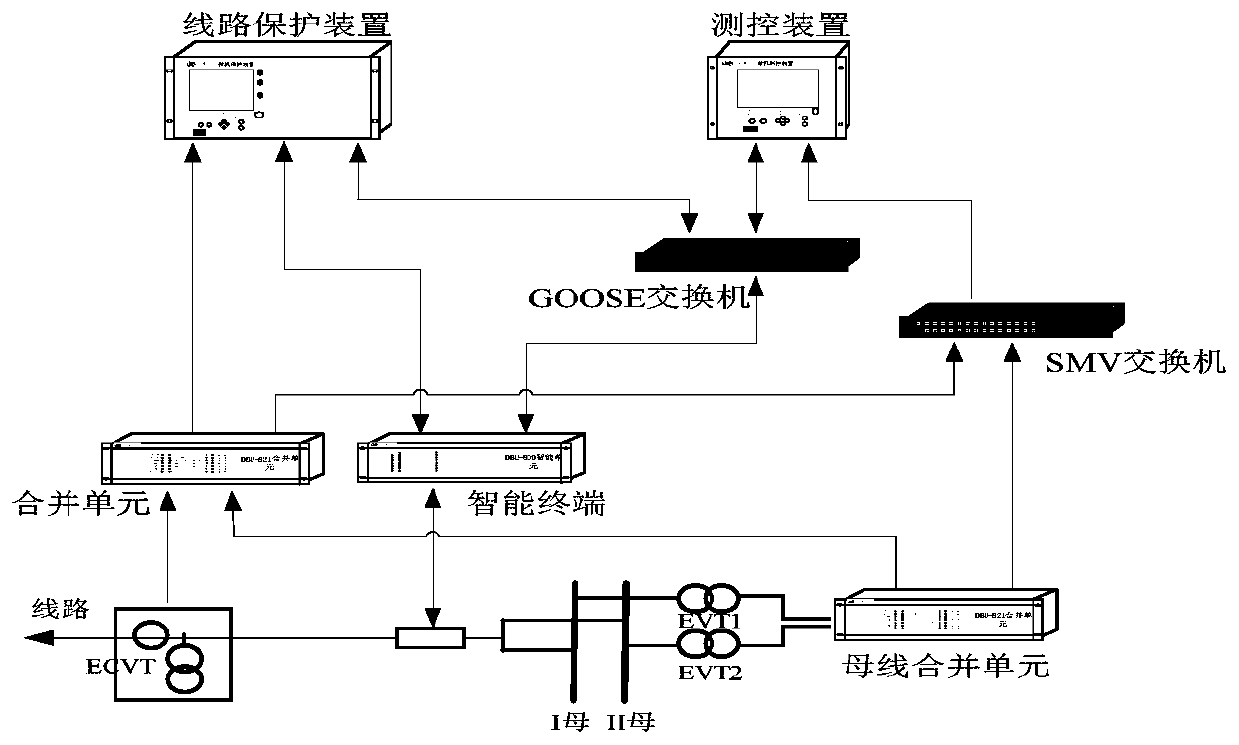

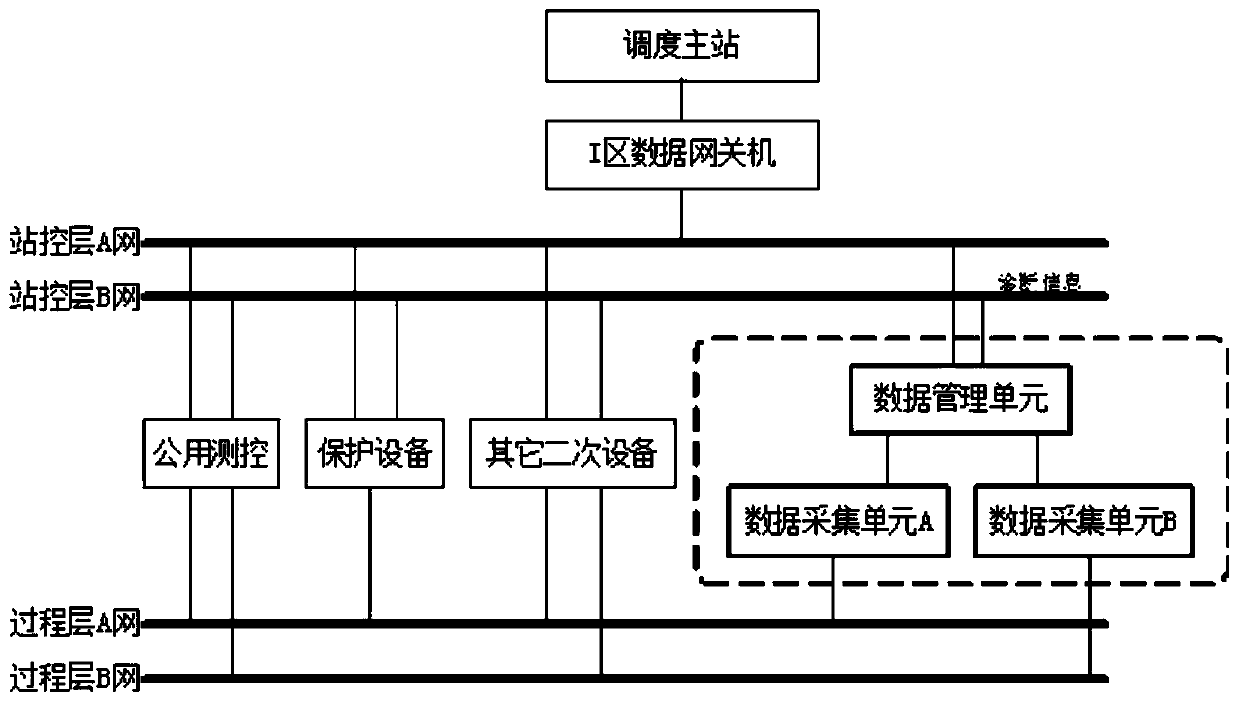

Secondary safety measure support system in operation and maintenance of intelligent substation and construction method

The invention discloses a secondary safety measure support system in operation and maintenance of an intelligent substation and a construction method. The system comprises an application layer, a service layer and an interface layer, wherein the application layer is used for generating a secondary safety measure in a graphic simulation process and finishing safety isolation of secondary devices and a secondary system; the service layer is used for establishing a secondary system model, simulating and rehearsing the secondary safety measure by utilizing the secondary system, detecting whether the secondary safety measure in the graphic simulation process violates a rule set in advance, and judging the effectiveness of the secondary safety measure; and the interface layer obtains board pressing and loop states from a network analyzer and converts board pressing operation sent by a board pressing state check module into operation information identifiable for an integrated information platform. According to the system, for secondary safety measure establishment, the board pressing and loop states are visually seen and the interoperation relationship of the secondary devices in the whole secondary system can assist operating personnel to establish the secondary safety measure.

Owner:STATE GRID NINGXIA ELECTRIC POWER +1

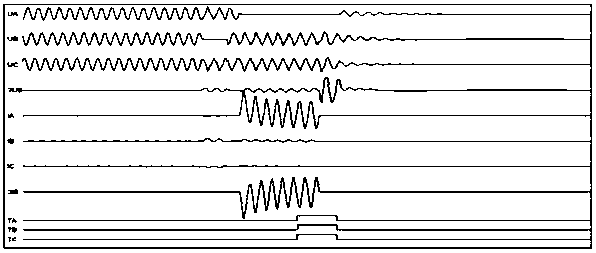

Electromagnetic transient simulation platform-based secondary device modeling method

The invention provides an electromagnetic transient simulation platform-based secondary device modeling method. Based on an existing mature power grid primary device electromagnetic transient simulation (DDRTS) technology, digital models of various relay protection devices in a power grid are built by adopting a graphic simulation support platform system; protection setting values of all levels inthe power grid are input to the digital relay protection device models; and by performing various electromagnetic transient process simulation on the power grid, action conditions of the relay protection devices are observed, so that the correctness of the relay protection setting values of all the levels in the power grid is checked.

Owner:SKILL TRAINING CENT OF STATE GRID JIANGSU ELECTRIC POWER CO LTD +1

Injection mold manufacturing method based on CAD/CAE/CAM and products

The invention relates to an injection mold manufacturing method based on CAD / CAE / CAM. The method includes the steps of a, designing a mold, to be more specific, using three-dimensional software to build 3D models of the structural parts of the mold, and manufacturing the general assembly drawing of the mold; b, manufacturing the engineering drawing of each part and setting a mold tolerance standard; c, manufacturing the injection mold, to be more specific, CAM tool path programming and importing a CNC manufacturing process, an EEM manufacturing process, a WEEM manufacturing process and a grinding process; d, soaking the mold in special plant oil for more than 24 hours; e, detecting the mold. The method has the advantages that a mold prototype drawing CAD design link can avoid problems in actual machining according to graphic simulation analysis, overall mold design is further optimized, and subsequent processes can be implemented reliably; due to the fact that the mold is soaked in the plant oil for more than 24 hours, the precision of the mold can be increased evidently, the service life of the mold is prolonged evidently, and the yield of injection molding products is increased evidently.

Owner:DONGGUAN KONKA MOLD PLASTIC

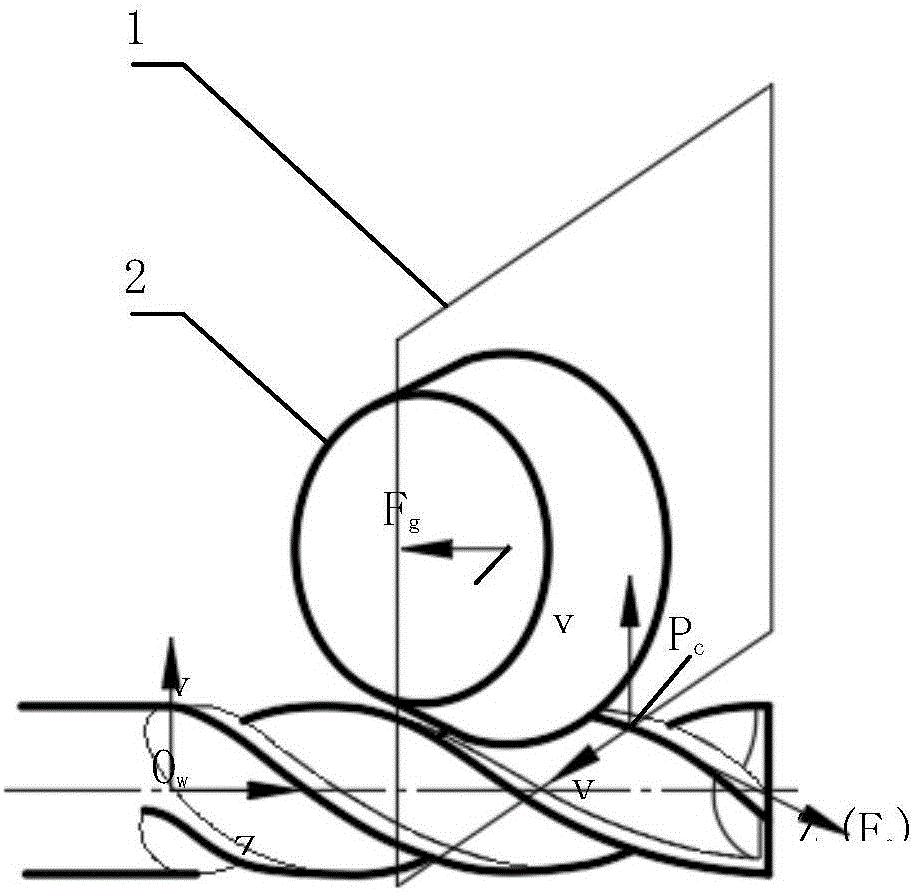

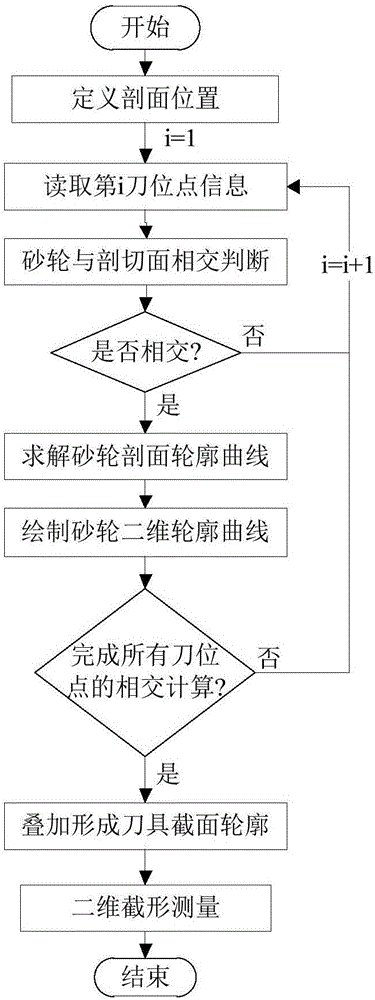

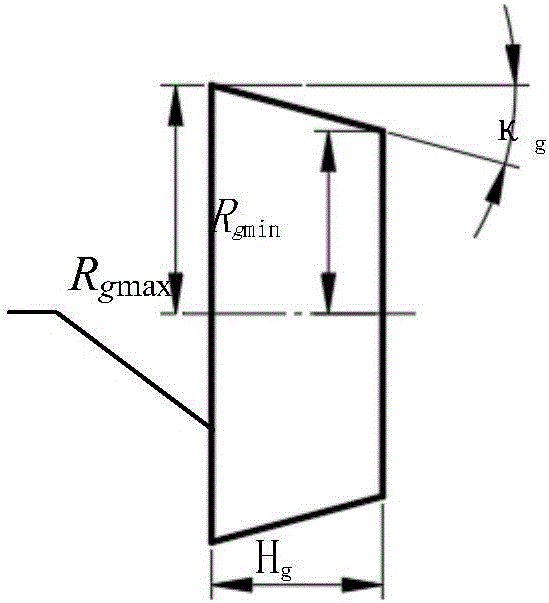

Two dimensional graphics simulation method of end mill grinding process

ActiveCN106826417AEasy to measureQuick fixMilling cuttersDesign optimisation/simulationGraphicsDimensional simulation

The invention discloses a two-dimensional graphics simulation method of an end mill grinding process, belonging to the technical field of two-dimensional simulation. The two-dimensional graphics simulation method solves the problem that it is difficult for the cutter grinding software in the prior art to find a normal section and an end section in the cutter grinding three-dimensional model, and further difficult to measure the cutter. The two-dimensional graphics simulation method comprises that firstly cutter position track data of a grinding wheel is read and a section cutting plane of the end milling is specified, relative position between the grinding wheel and the section cutting plane is analyzed and whether the grinding wheel corresponding to a cutter site intersects the section cutting plane is judged; if so, an intersecting contour curve of each cutter site corresponding to the grinding wheel and the specified section cutting plane is solved in order and the section cutting plane of all the grinding wheels is obtained; the section cutter planes of all the grinding wheel are superimposed to obtain a two-dimensional truncate section of a cutter slot; the two-dimensional section of the cutter slot is measured to determine whether the two-dimensional truncate section of the simulated cutter slot satisfies the machining precision; if not, a grinding process is modified. The invention is used to simulate the two-dimensional truncate of the cutter slot.

Owner:成都天佑创软科技有限公司

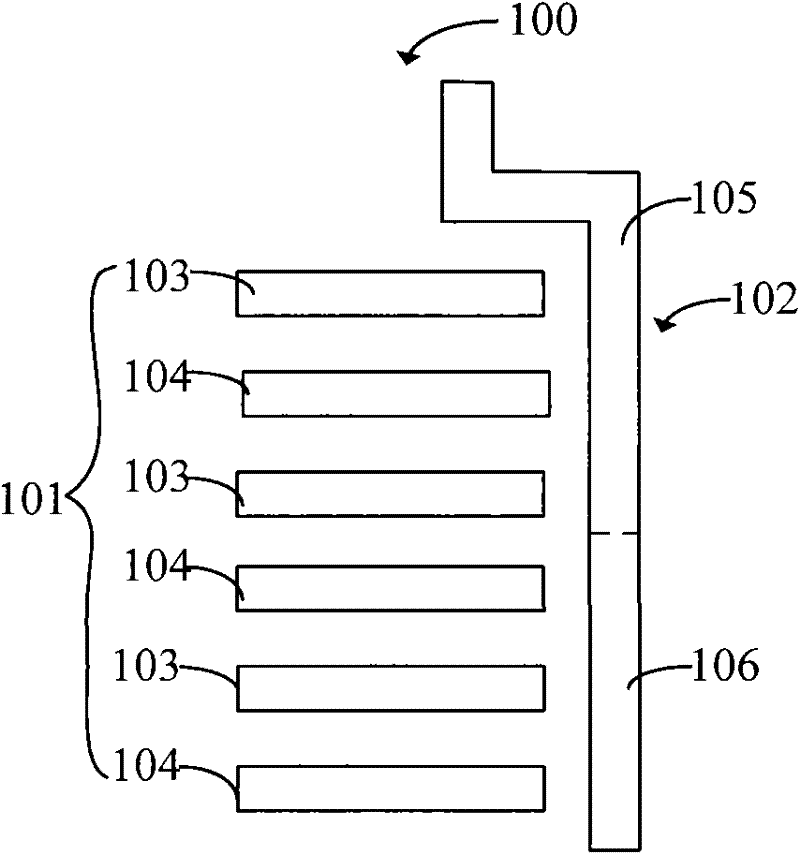

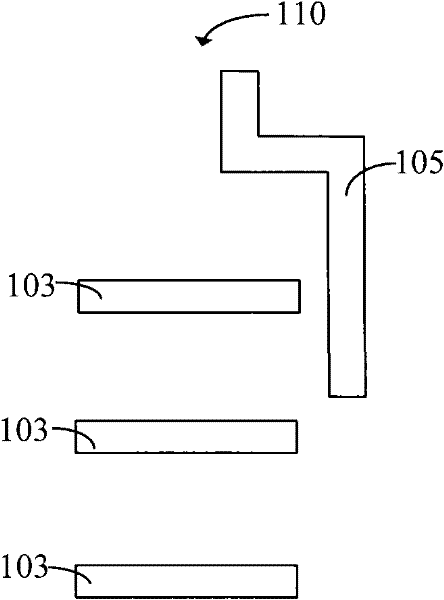

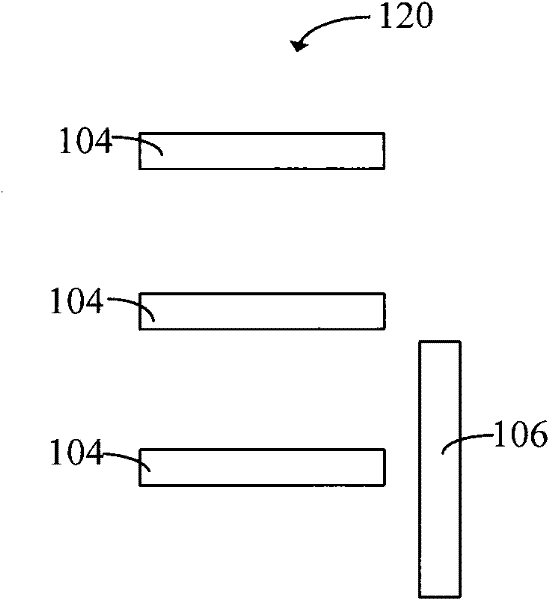

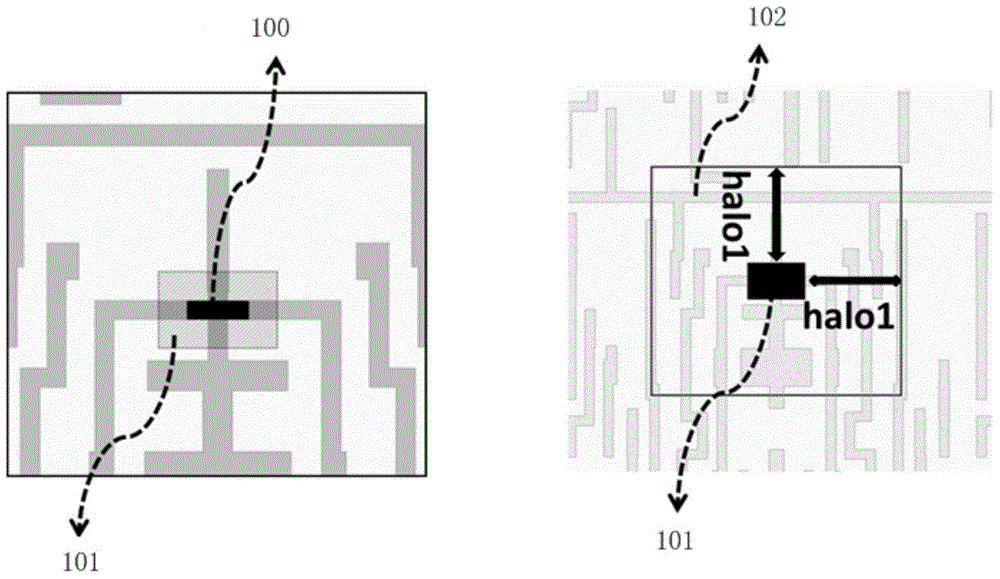

Method for making mask, method for performing optical proximity correction on layout pattern

The invention relates to a method for producing masks, and an optical proximity correction method for layout patterns. The mask production method comprises steps that: a layout pattern is provided; the layout pattern is segmented into a first layout pattern and a second layout pattern; a first extension segment is formed at a segmentation position of the first layout pattern; a second extension segment is formed at a segmentation position of the second layout pattern; optical proximity correction is carried out upon the first layout pattern and the first extension segment such that a first corrected pattern is obtained, an area of the second extension segment is encircled by the first corrected pattern after graphic simulation; optical proximity correction is carried out upon the second layout pattern and the second extension segment such that a second corrected pattern is obtained, an area of the first extension segment is encircled by the second corrected pattern after graphic simulation; the first corrected pattern is wrote into a first mask; and the second corrected pattern is wrote into a second mask. During graphicalization, at an overlaying position, a pattern width is equal to a target width, and at least a difference between the pattern width and the target pattern width is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

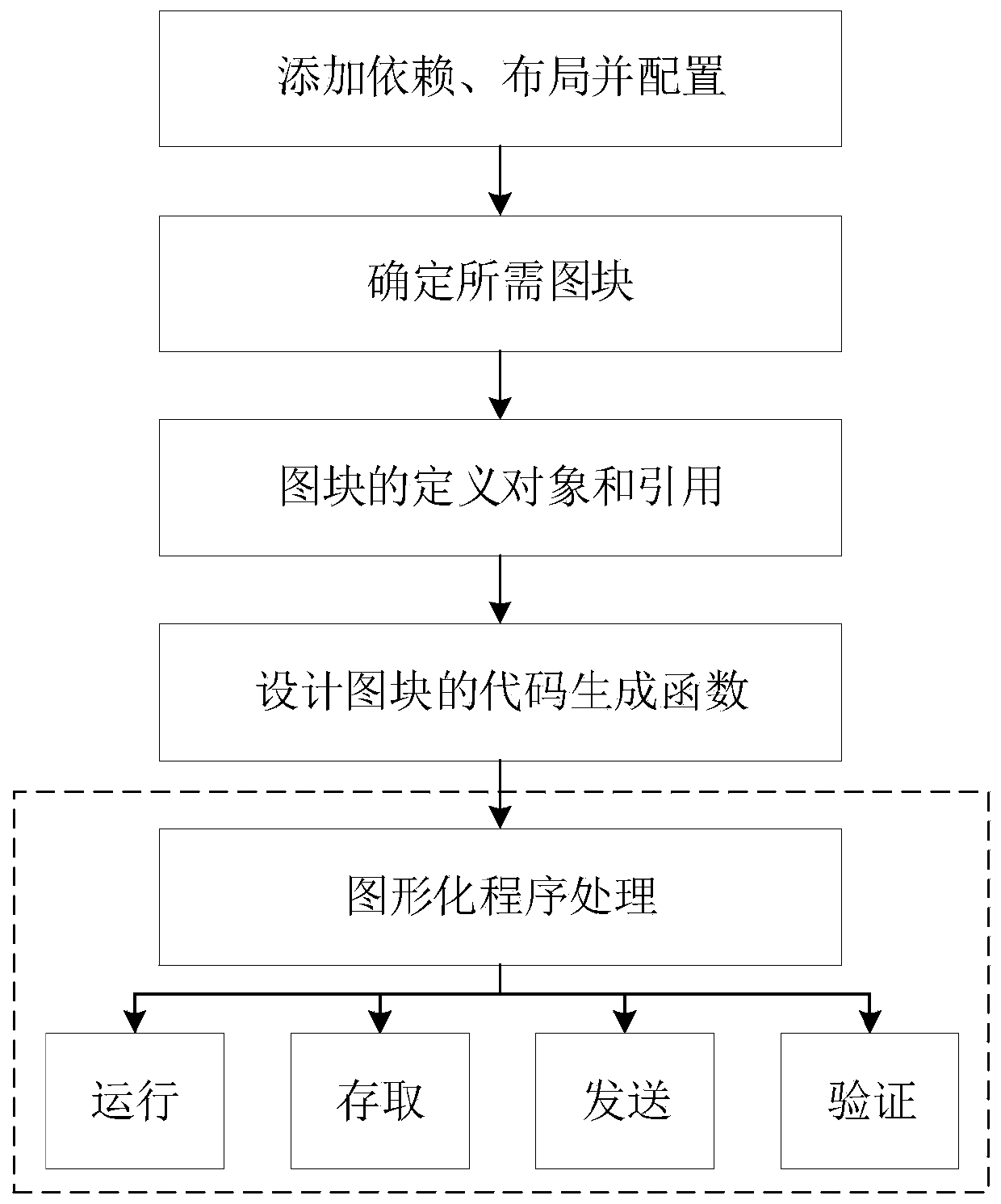

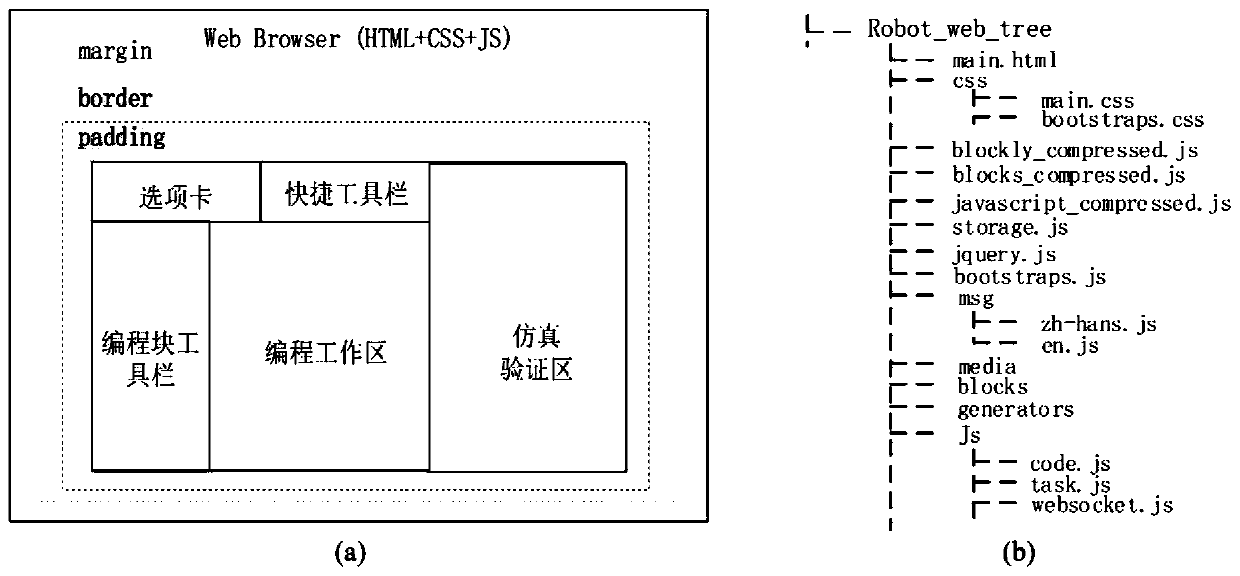

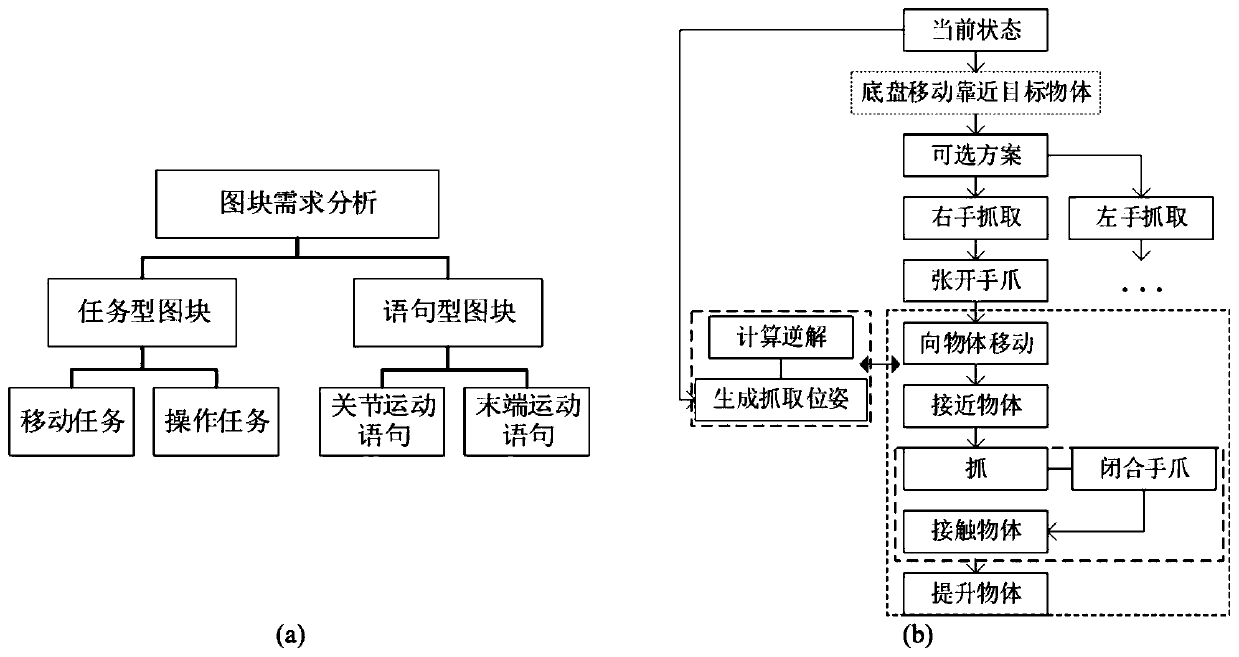

Graphical programming method for robot interaction based on tiles

ActiveCN111475155AImprove readabilityHelps to verifyVisual/graphical programmingTotal factory controlCode generationGraphics

The invention relates to a graphical programming method for robot interaction based on tiles. The method comprises the following steps: adding a Blockly dependent library into a webpage source code, and carrying out page layout and configuration; performing task requirement analysis according to the moving operation type of the robot, determining needed image blocks, wherein the needed image blocks comprise task type image blocks and statement type image blocks; determining a data interface of a required graph block according to the task, designing a custom graph block object and quoting, anddesigning the shape and connection characteristics of the graph block; designing a code generation function according to the self-defined image block object and the self-defined image block function;and performing graphical program processing, including program running, storing, taking, sending and verifying, and achieving control over the real robot. According to the method, graphic simulation is included, verification of a user program is facilitated, and therefore errors of a real robot are minimized.

Owner:HARBIN INST OF TECH

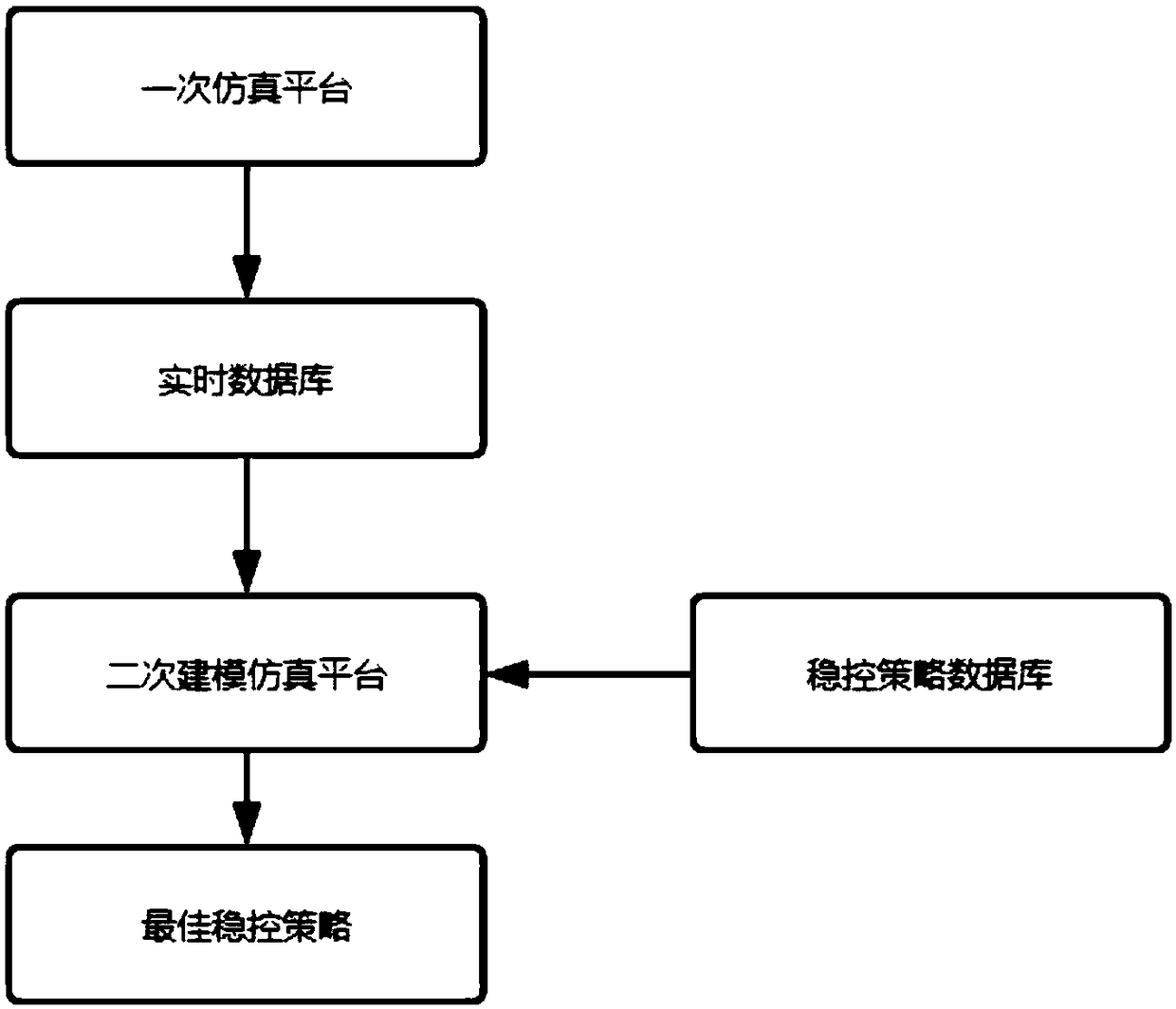

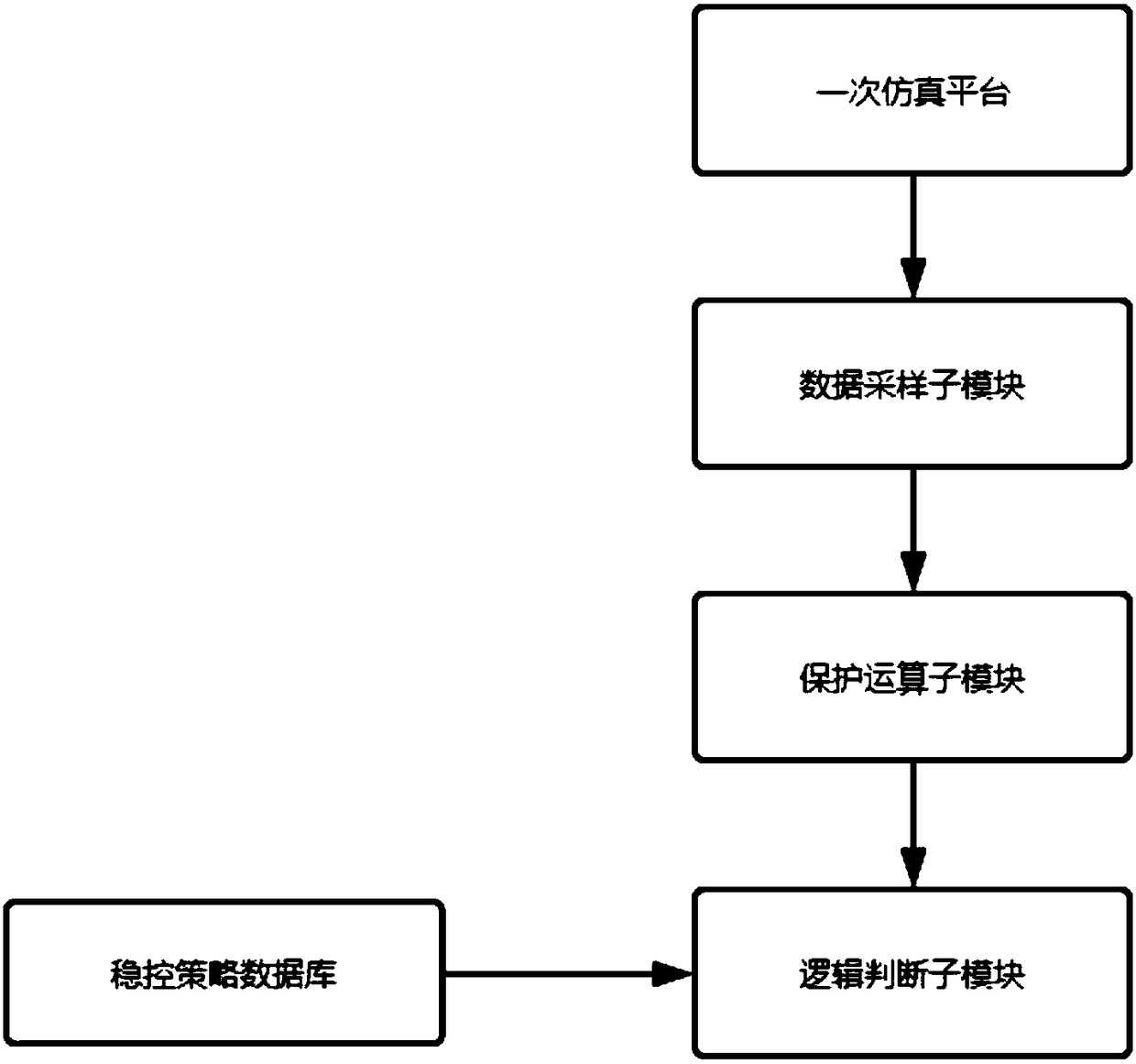

Electric power stability control strategy simulation system

The invention provides an electric power stability control strategy simulation system. The system comprises a primary simulation platform, a secondary modeling simulation platform, a real-time database and a stability control strategy database, the establishment and operation of the primary simulation platform can be realized by employing an electromechanical-electromagnetic transient hybrid simulation platform, the establishment and operation of the secondary modeling simulation platform can be realized by employing a graphic simulation support system, the primary simulation platform and thesecondary modeling simulation platform realize data exchange and mutual instruction control through the databases, the stability control strategy database stores stability control strategies, and thesecondary modeling simulation platform is connected with the stability control strategy database in a signal manner. According to the system, online simulation of a primary system and a secondary system of a power grid can be realized, the optimal stability control strategy of an electric power system is obtained, weak links in the power grid are analyzed, and optimization and improvement suggestions and measures are proposed.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST

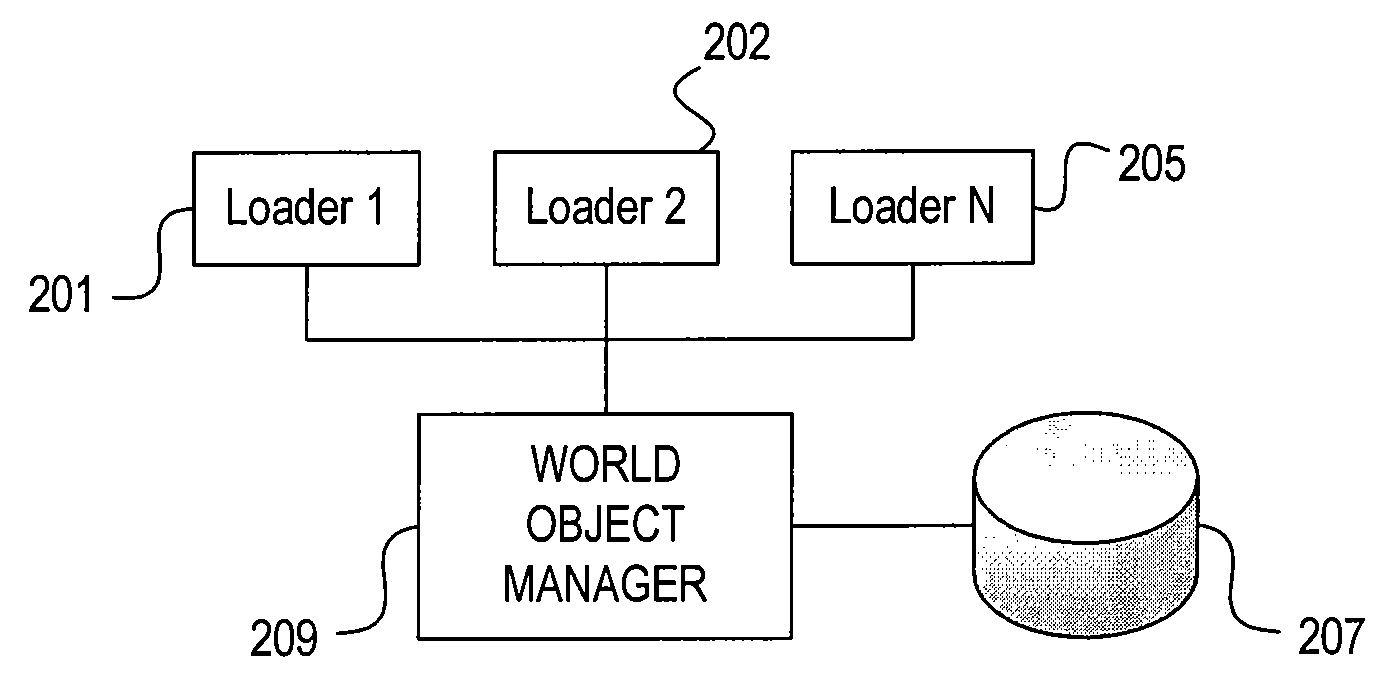

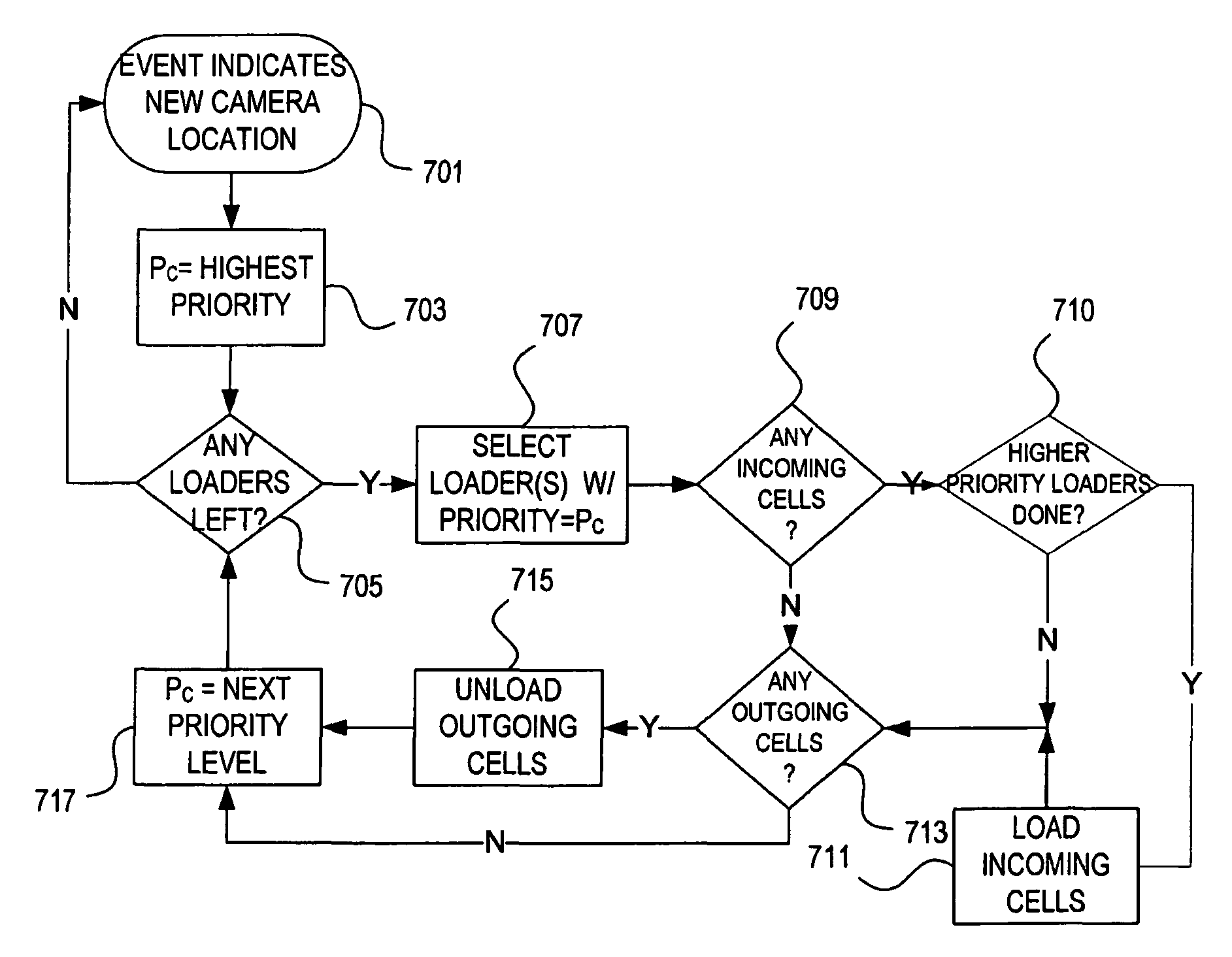

Object loading and unloading system

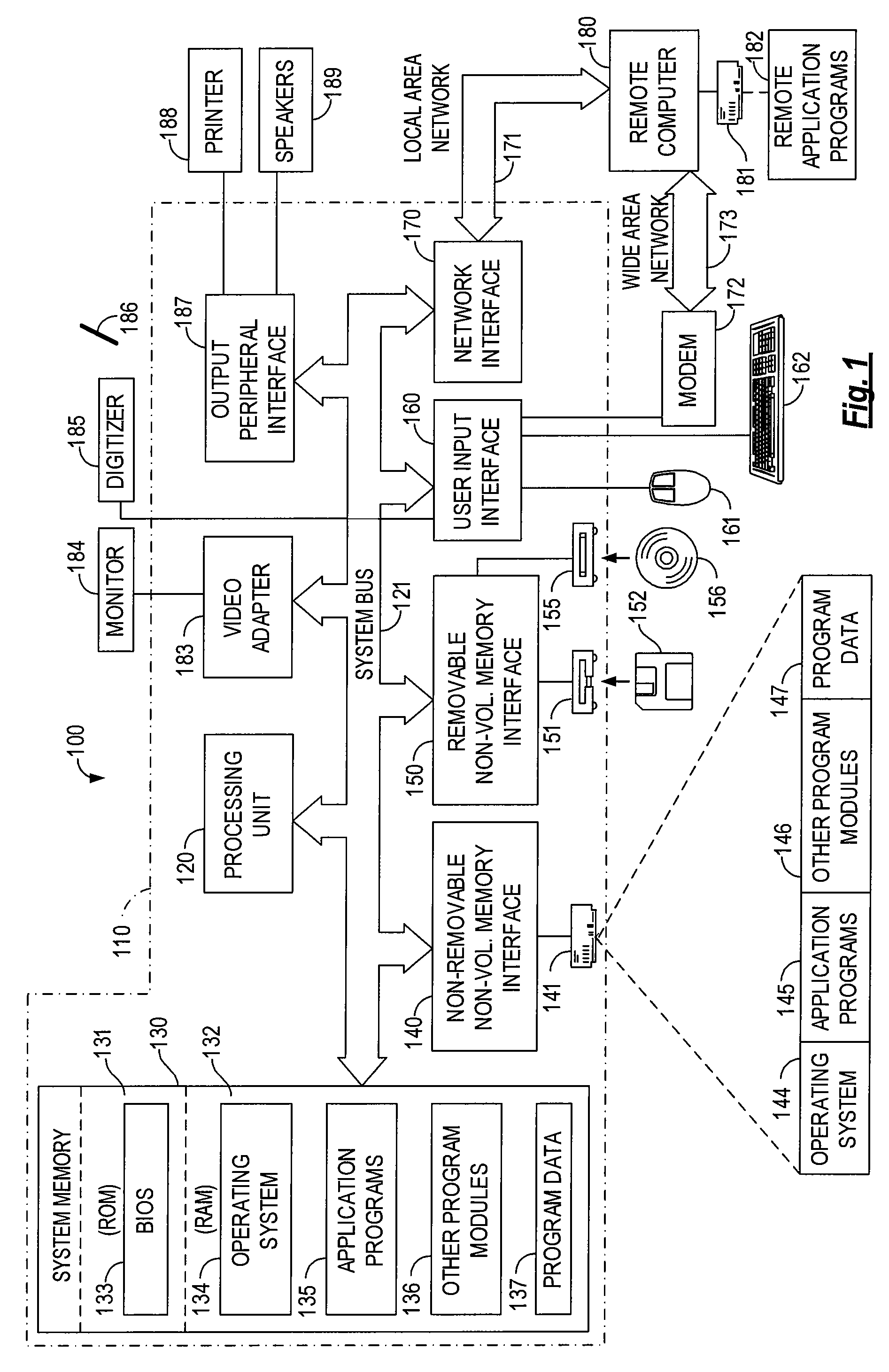

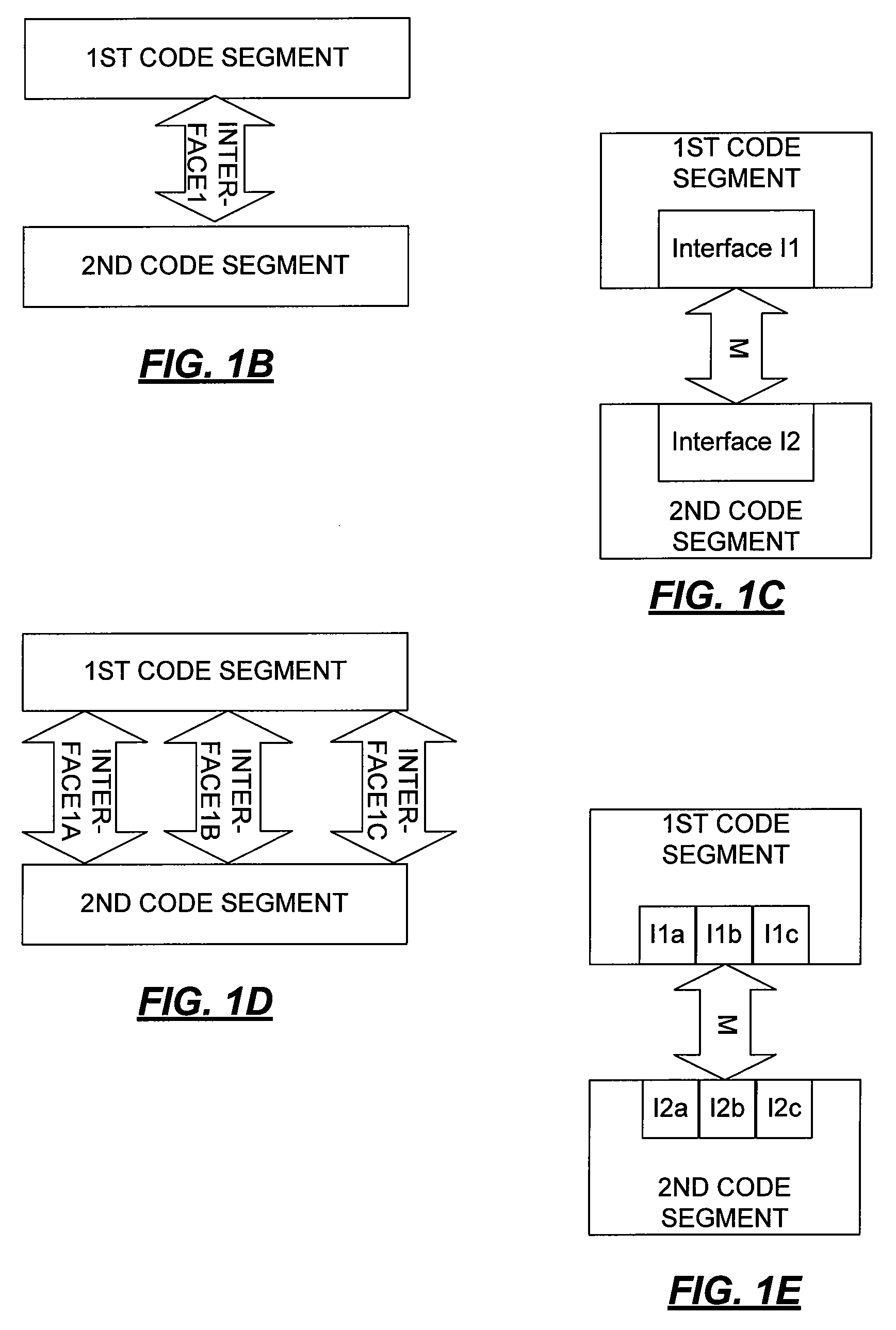

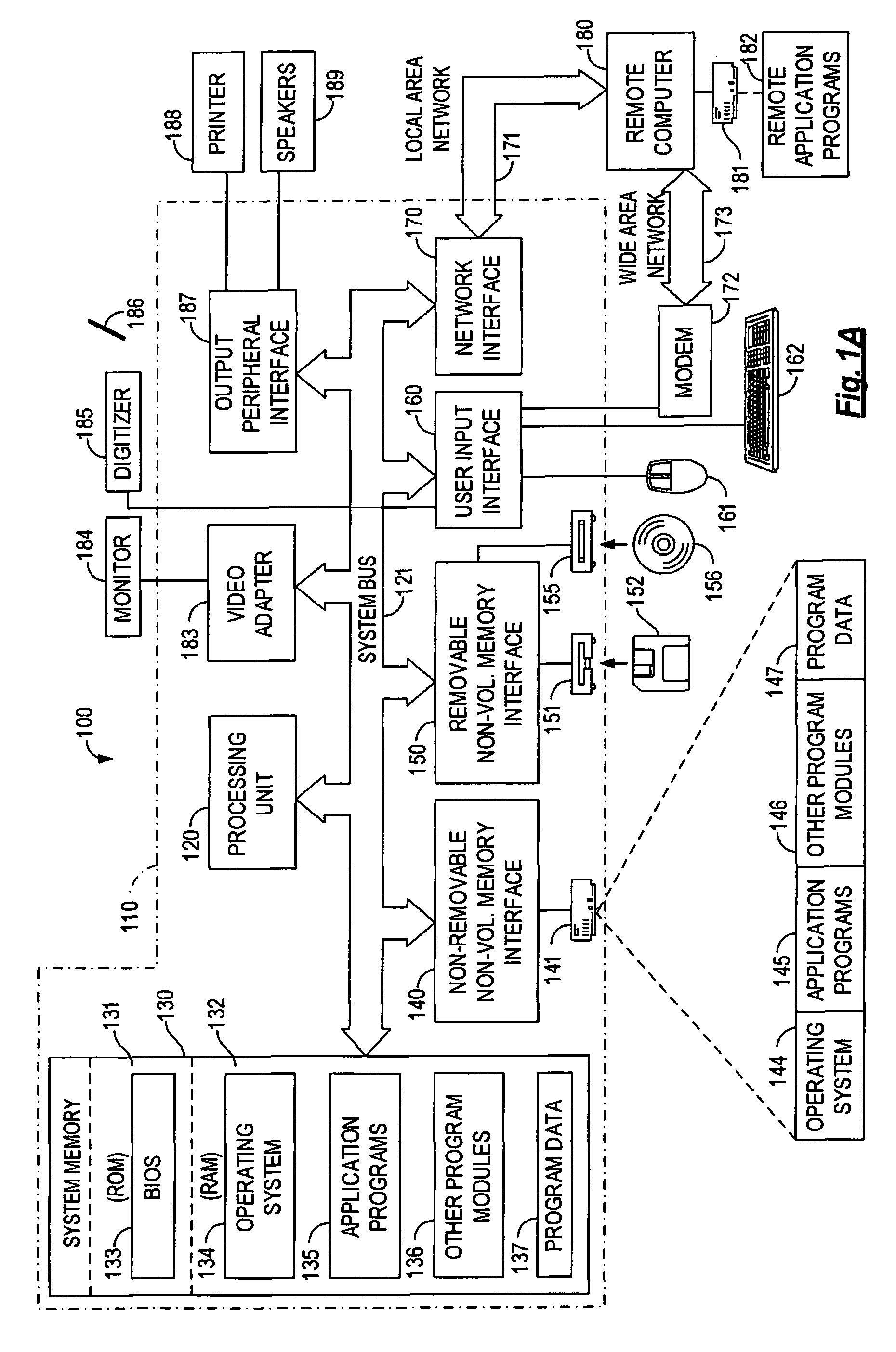

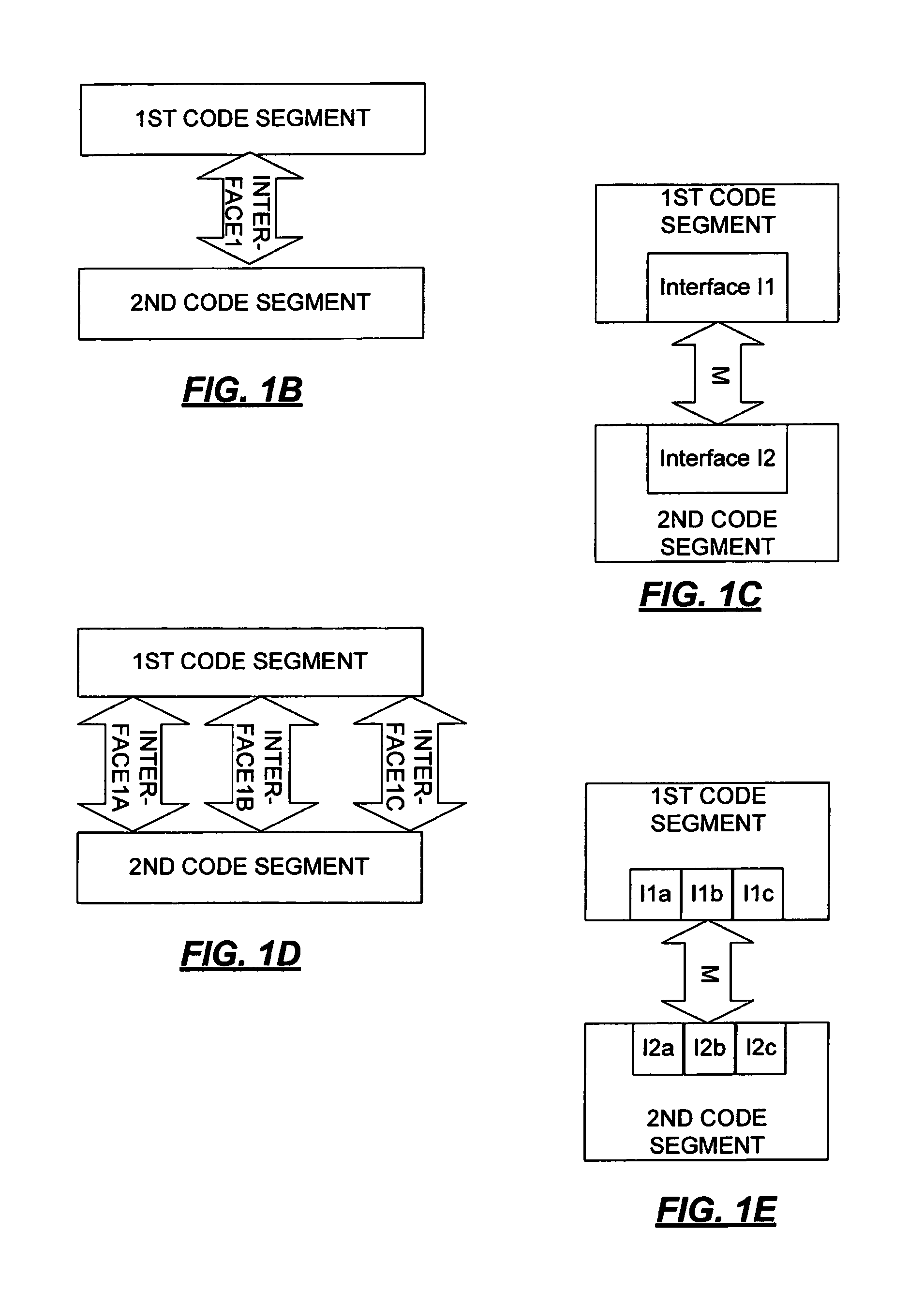

An object loading and unloading system for loading and unloading objects in a graphically simulated virtual environment, or virtual world, is described. A world object manager manages multiple object loaders to load and unload objects as geographic cells move within and out of a loading radius of each loader based on a position of a camera or view within the virtual world. Each object loader has an associated priority level, and the world object manager notifies a loader to load its corresponding objects in a cell only after all loaders having higher priority levels, which also have that cell in their respective loading radii, have already loaded their corresponding objects in that cell. The world object manager may expose various programming interfaces to provide an extensible object loading system whereby third parties can define new loaders to be incorporated into the hierarchical spatial object loading system.

Owner:MICROSOFT TECH LICENSING LLC

Horseback riding simulation

An inflatable air cushion or other type seat a person can sit on is instrumented with electronic input devices that can sense motion of the cushion and / or motion of the person's body. Such input devices provide inputs to a computer graphics system that dynamically generates a responsive scene on a real time display. The sensed motion can be used to generate a graphics simulation of horseback riding.

Owner:NINTENDO CO LTD

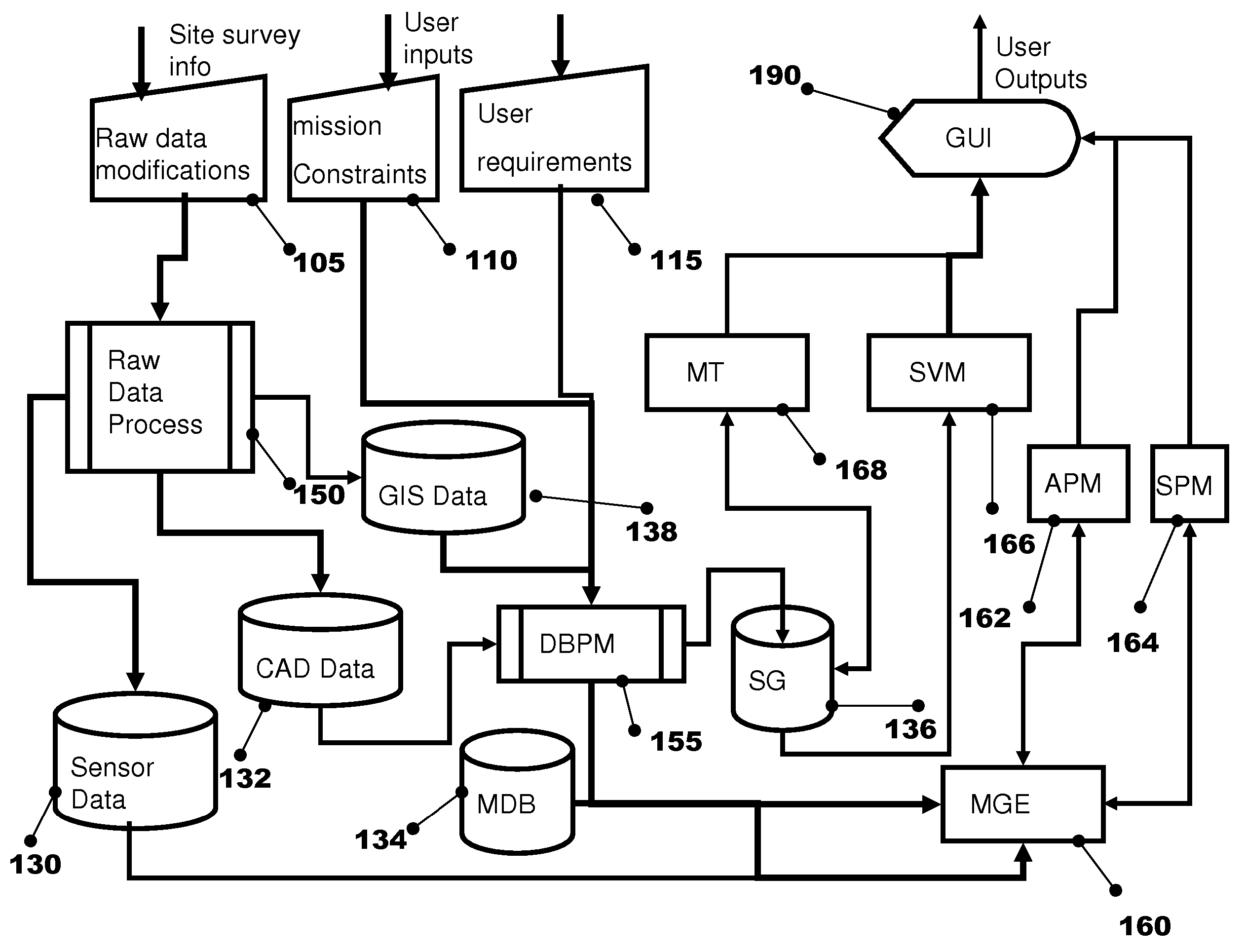

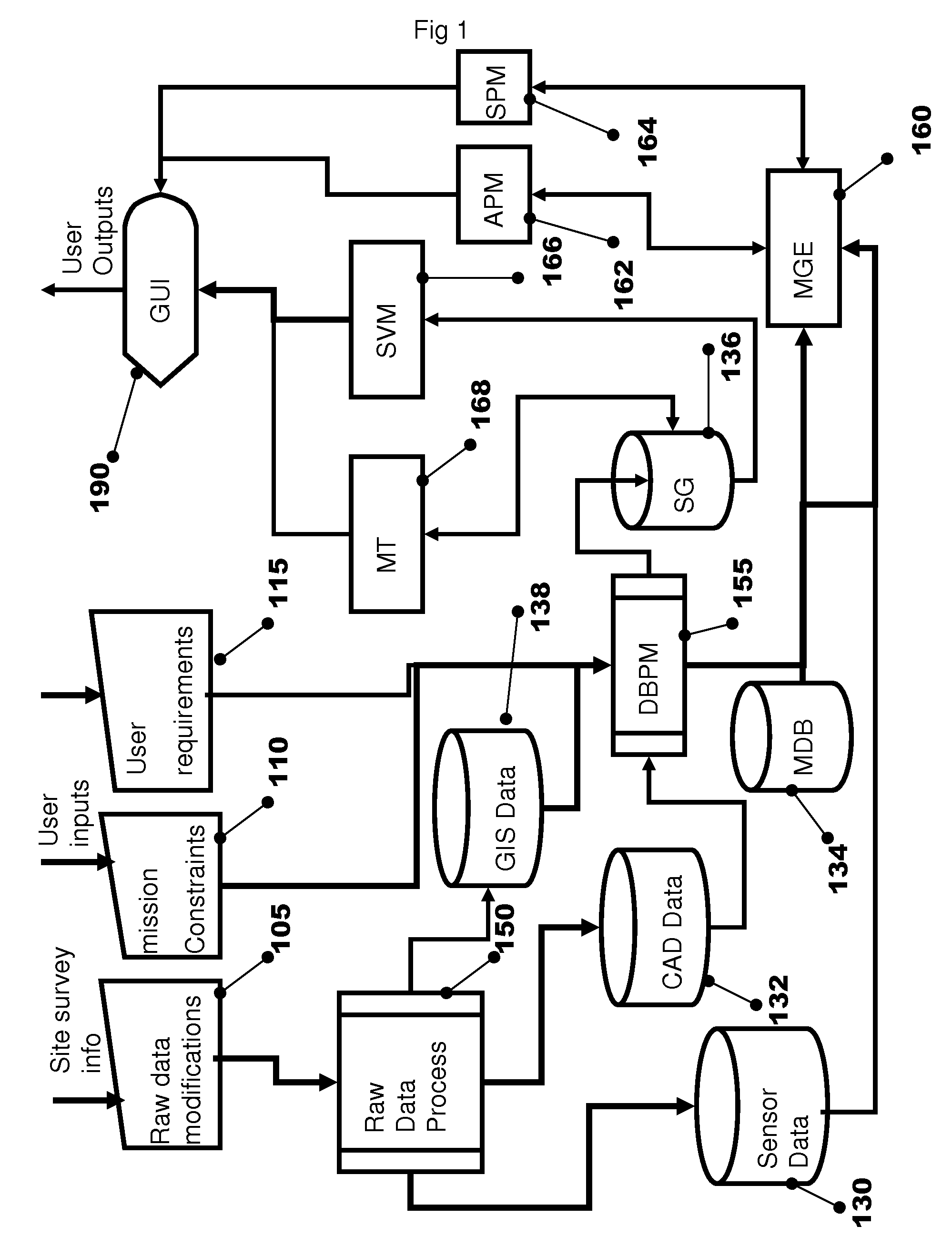

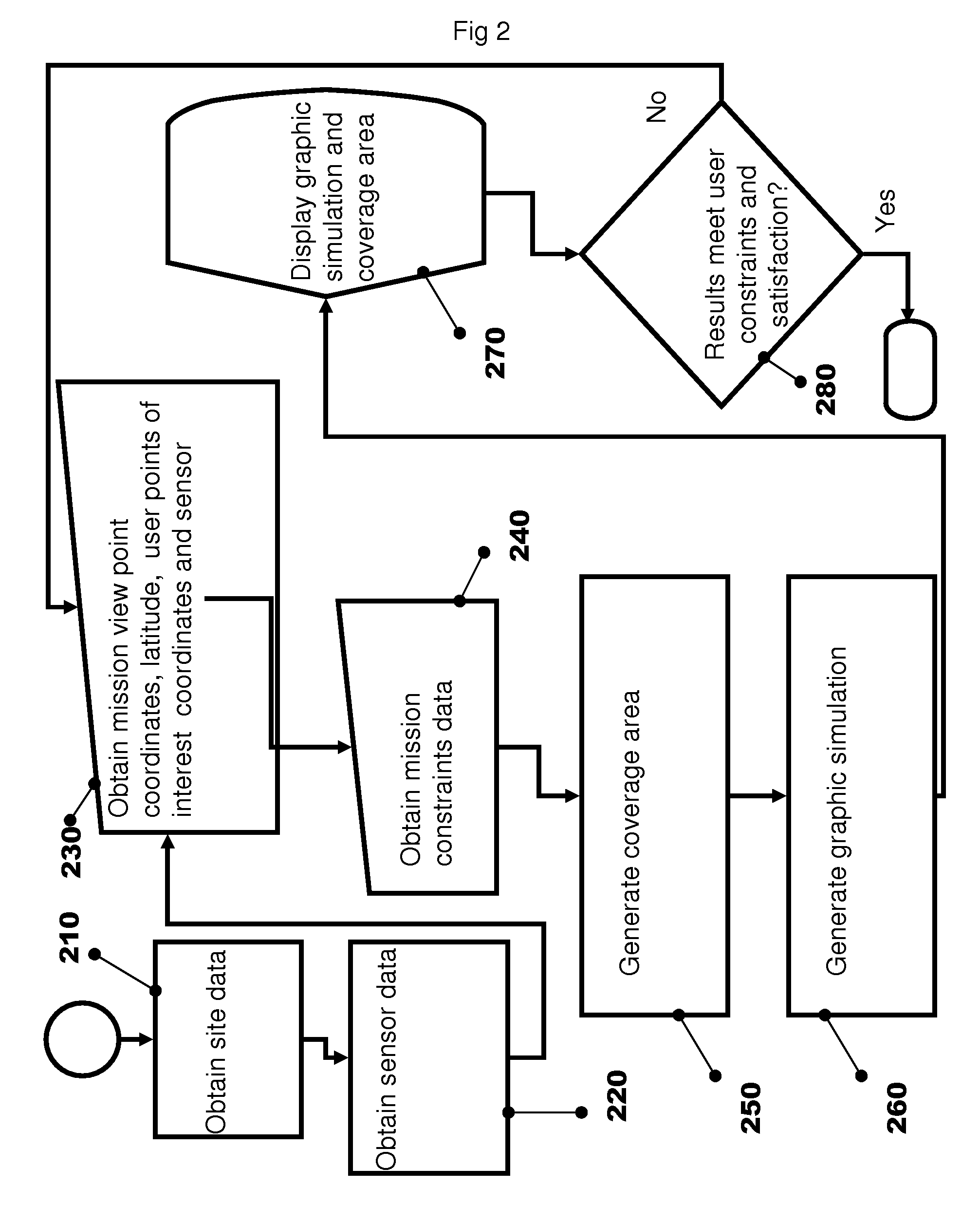

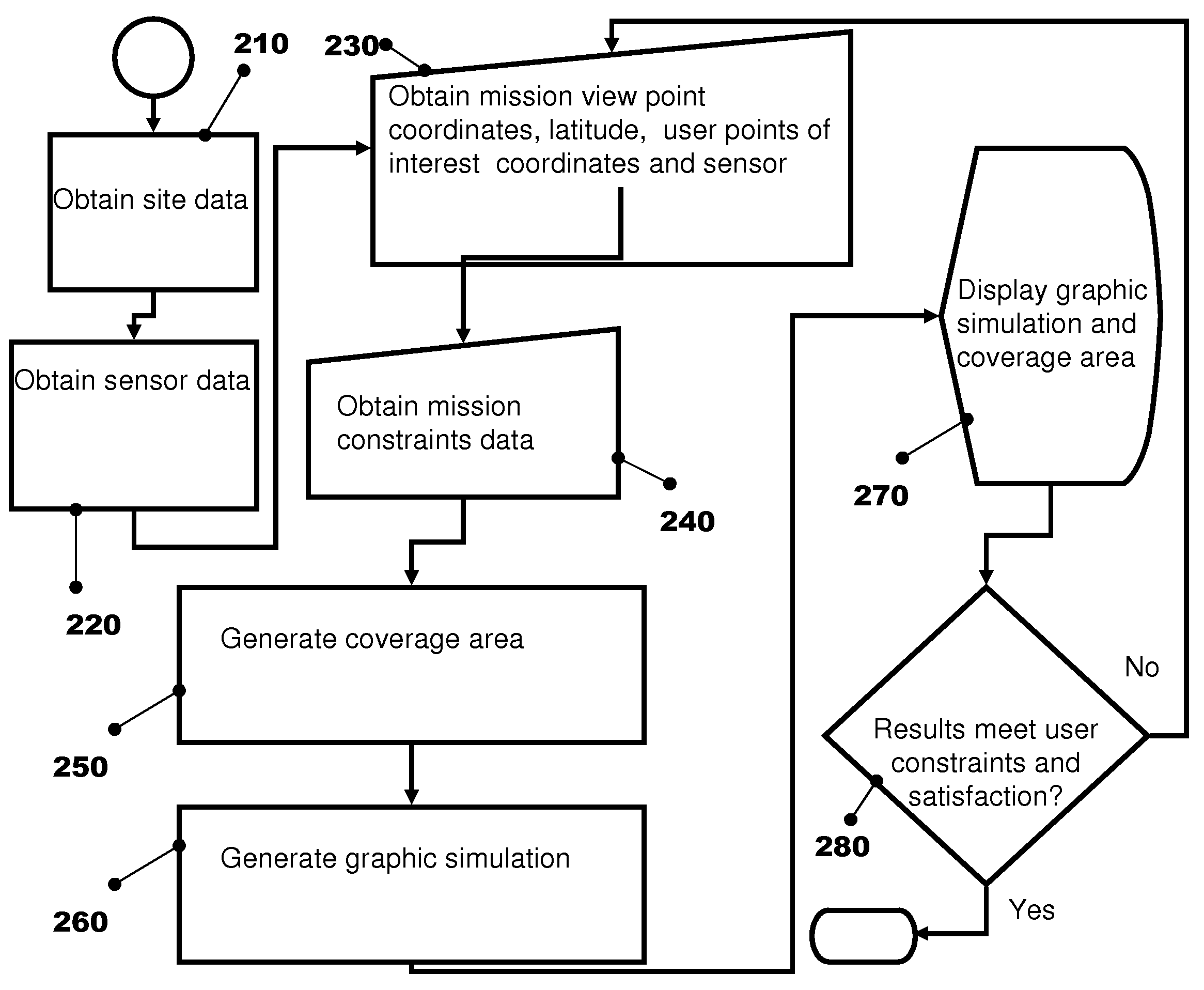

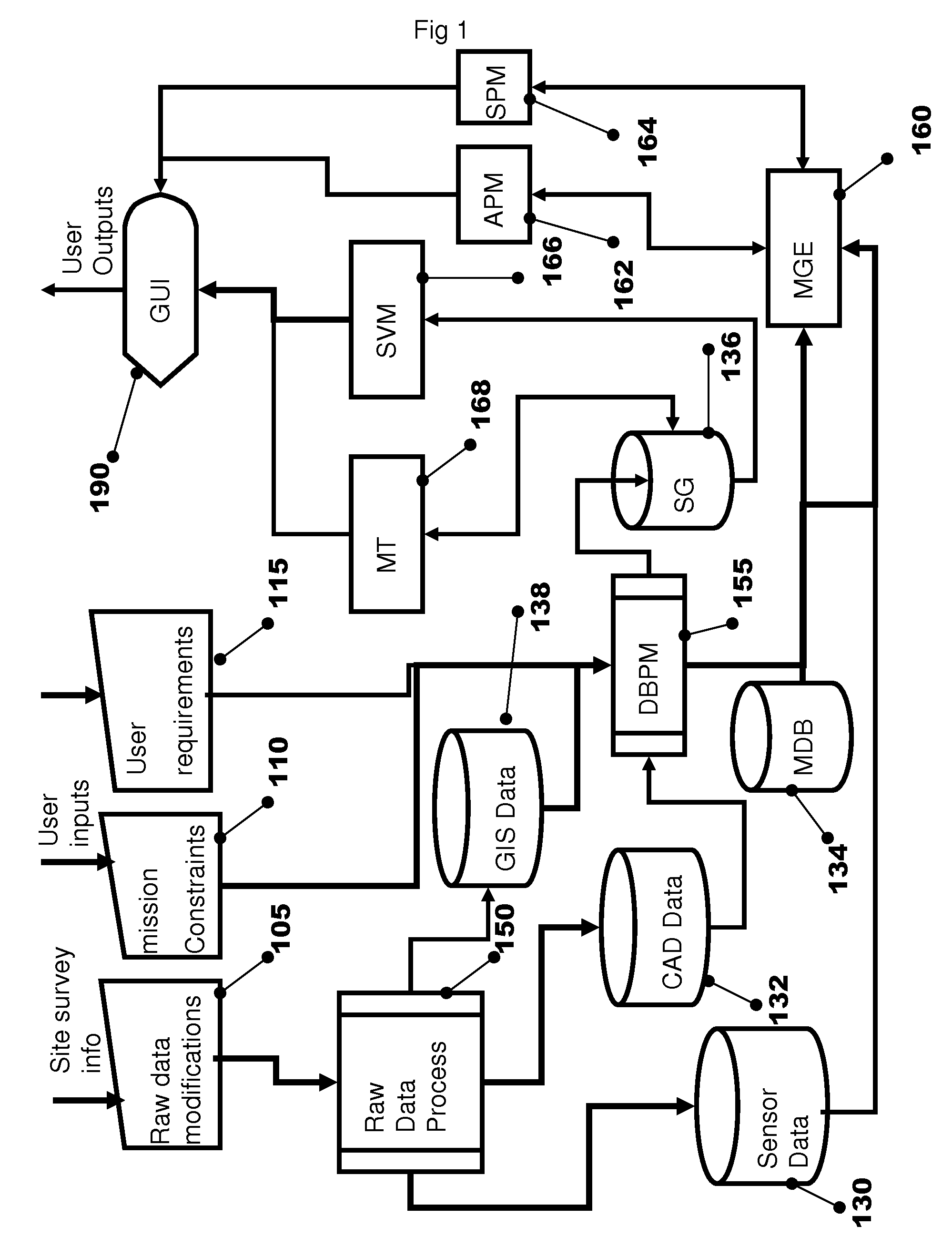

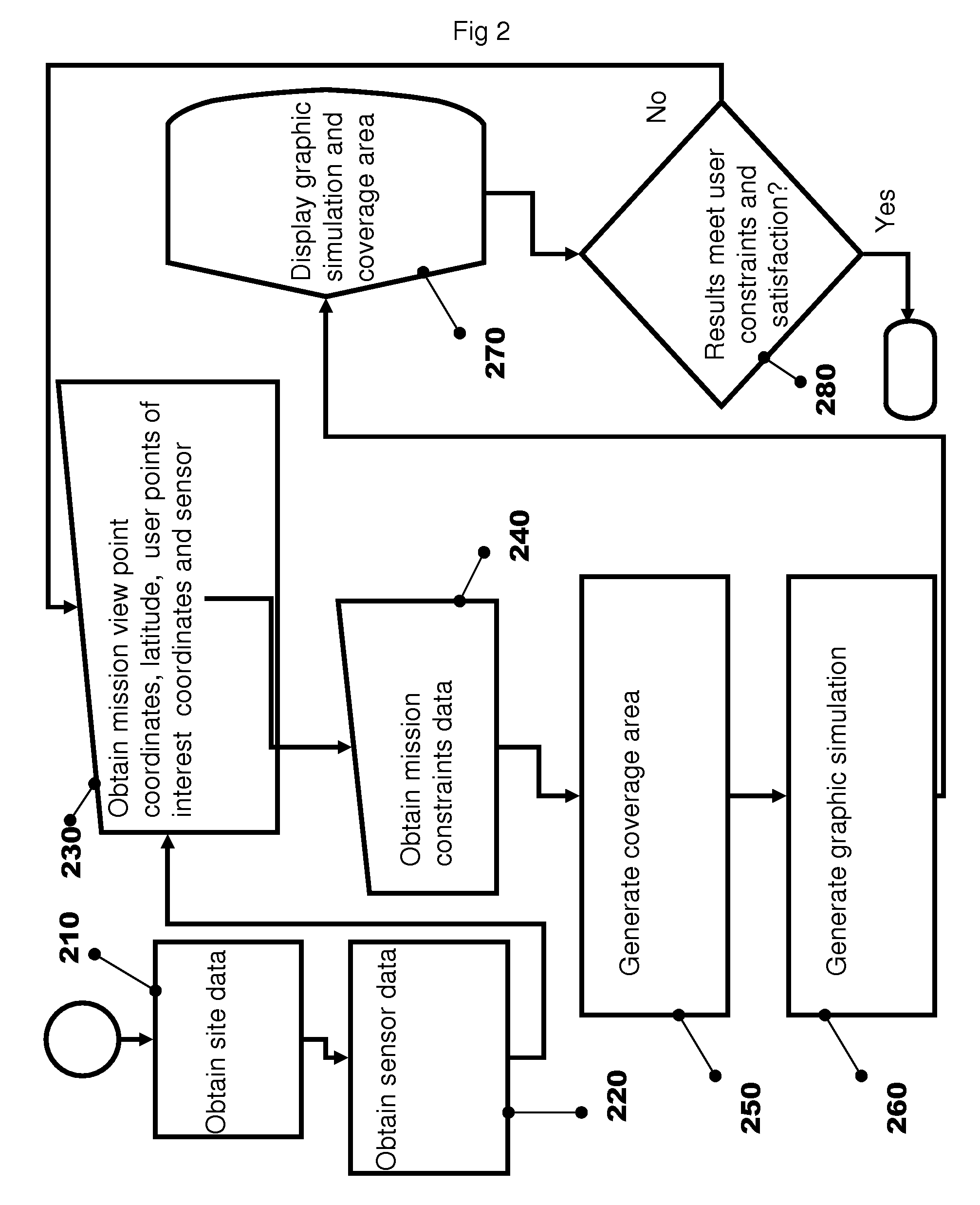

Method For Planning A Security Array Of Sensor Units

Methods for planning a security array of sensor units are provided. In one embodiment, the method provides an optimized security planning for at least one entity. The method includes the steps of: receiving design data (for instance, geographically-referenced information) indicative of the geographic location; receiving data indicative of the sensors attributes (for instance sensor type, cost, weight, range); receiving data indicative of the preferred coverage area; receiving scenario constraints (for instance specific points of interest); conducting a graphic simulation of the proposed solution; generating multiple alternatives for the proposed solution.

Owner:DEFENSOFT

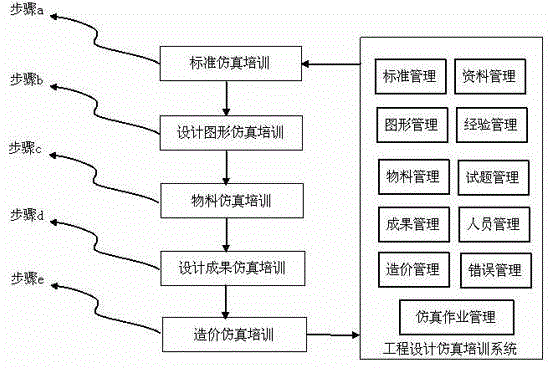

System and method for simulation training of power distribution network engineering design

InactiveCN103605866ADoes not affect the actual engineering design qualityEasy to operateElectrical appliancesSpecial data processing applicationsMaterial DesignSimulation training

The invention provides a system and method for simulation training of power distribution network engineering design. The system comprises a standard design management module, a graphic design management module, a material design management module, an achievement design management module, a manufacturing cost design management module, a data training management module, an experience training management module, a test training management module, a personnel training management module, an error training management module and a simulation operation management module. The method comprises the steps of standard simulation training, design graphic simulation training, material simulation training, design achievement simulation training and manufacturing cost simulation training. The system and method for the simulation training of the power distribution network engineering design are creatively provided, a vivid training environment is provided for power distribution network engineering design personnel, the training process and the design simulation process are completely fused to achieve the aims of not influencing practical engineering design quality and training engineering designers, the system is simple and practical, the operation is convenient, training cost can be effectively lowered, the method is strong in pertinence, systematicness is achieved, and the training effect is good.

Owner:STATE GRID CORP OF CHINA +1

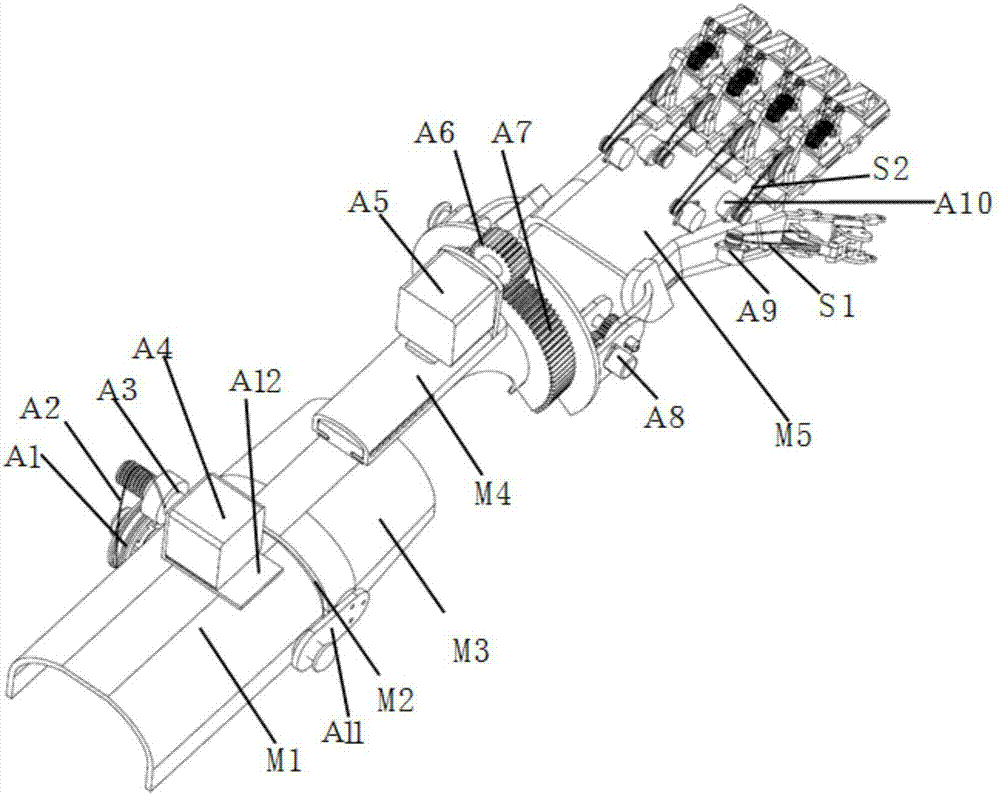

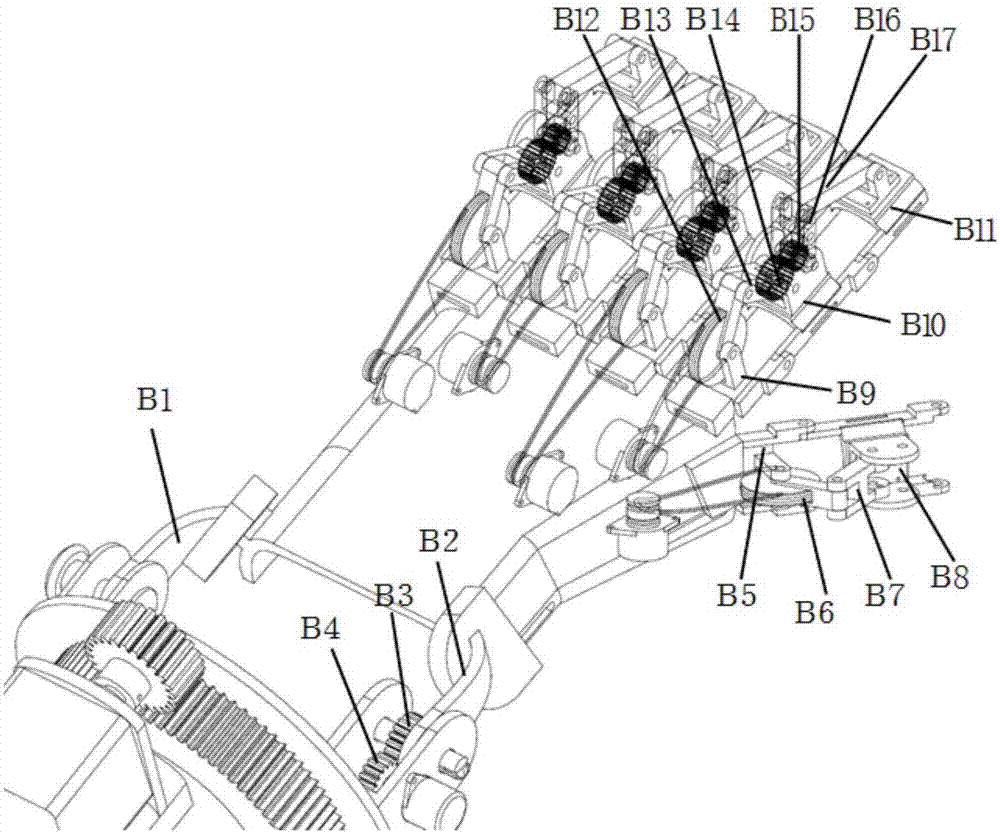

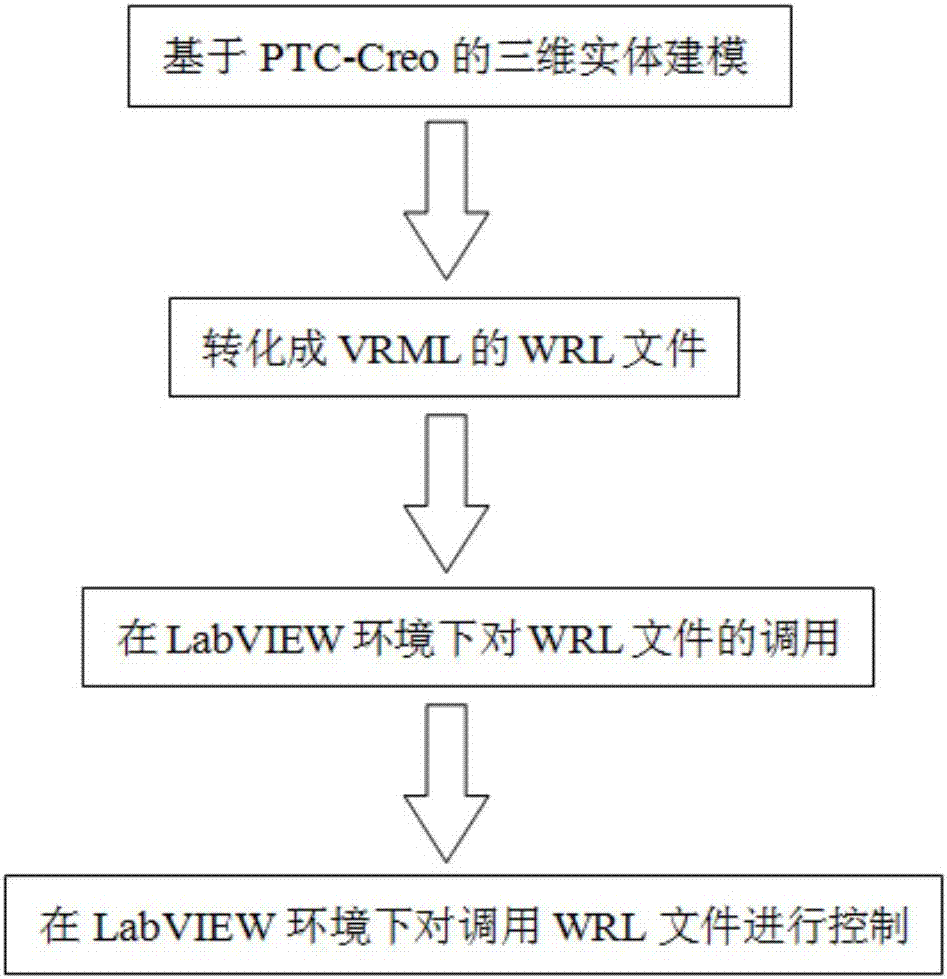

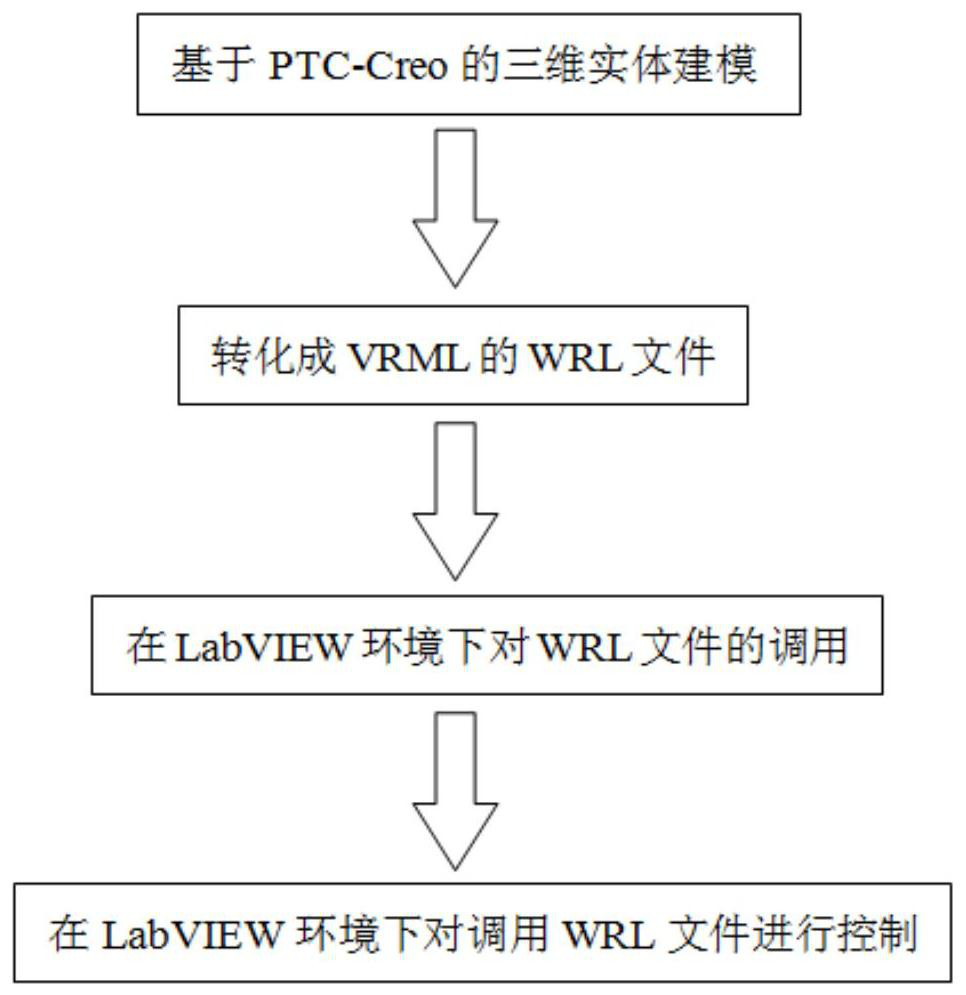

Portable upper limb rehabilitation robot and digital simulation realization method based on LabVIEW

The invention provides a portable upper limb rehabilitation robot and a digital simulation realization method based on LabVIEW. The portable upper limb rehabilitation robot is novel in structure and high in integration degree, can realize auxiliary rehabilitation training on 17 joints including the upper limbs and fingers at the same time, and is attractive in appearance; the three-dimensional visual graphic simulation is realized by utilizing LabVIEW and the PTC-Creo engine technology, the operation is simple, the virtual movement of the rehabilitation robot can be simulated, and an operator can clearly and visually observe the rotating angle of each joint in the simulation process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

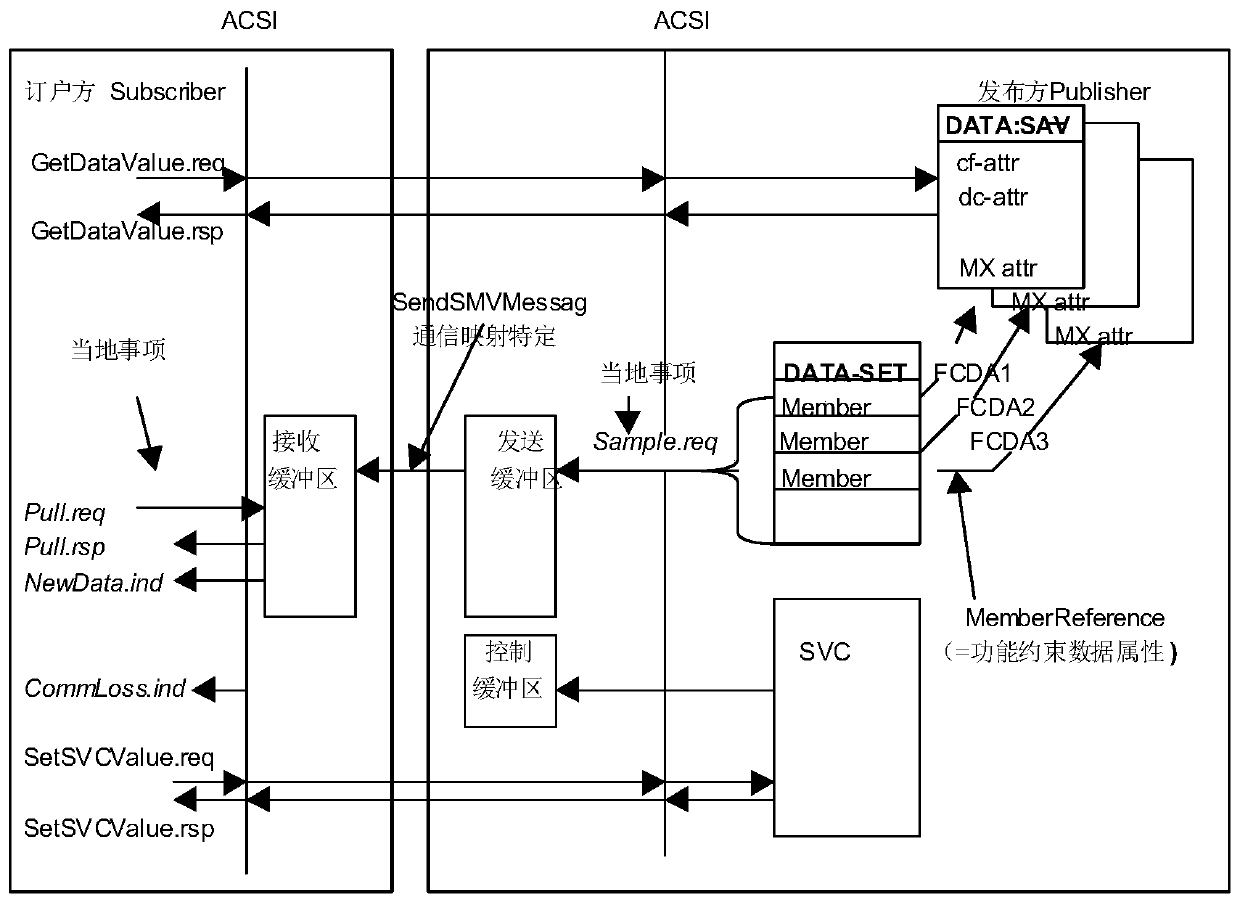

Intelligent substation test simulation system based on SCD

PendingCN110991037AImprove understandingIncrease awarenessCircuit arrangementsDesign optimisation/simulationSoftware systemIntelligent equipment

The invention discloses an intelligent substation test simulation system based on an SCD. The system comprises a GOOSE graphic simulation module, a whole-station MMS simulation module and an SCD graphic analysis and comparison module. And the GOOSE image simulation module is constructed based on an SCD mode and is used for carrying out simulation configuration on different intelligent devices. Constructing a GOOSE graphical simulation module, a whole-station MMS simulation module, an SCD graphical analysis module, a comparison module and the like based on the SCD; an intelligent substation debugging expert system is established, debugging and analysis testing of MMS conventional functions of different intelligent devices of different manufacturers are achieved, an intelligent substation portable debugging and analysis software system with multiple application modes is developed, and the production efficiency of debugging, operation and maintenance of an intelligent substation secondarysystem is improved. The fault processing efficiency of the intelligent substation is effectively improved, the operation and maintenance cost is reduced, and powerful guarantee and technical supportare provided for secondary operation, maintenance and debugging.

Owner:GUIZHOU POWER GRID CO LTD

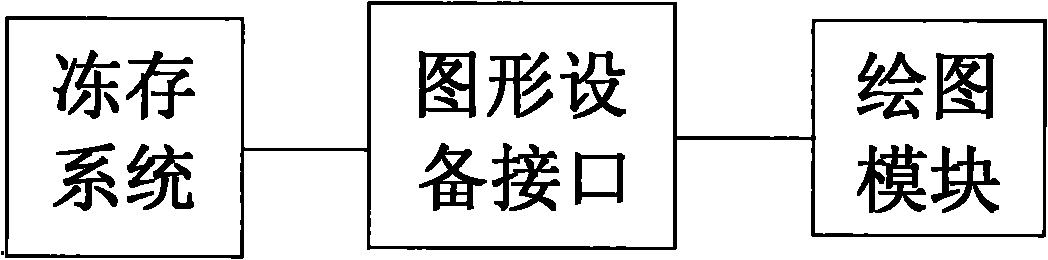

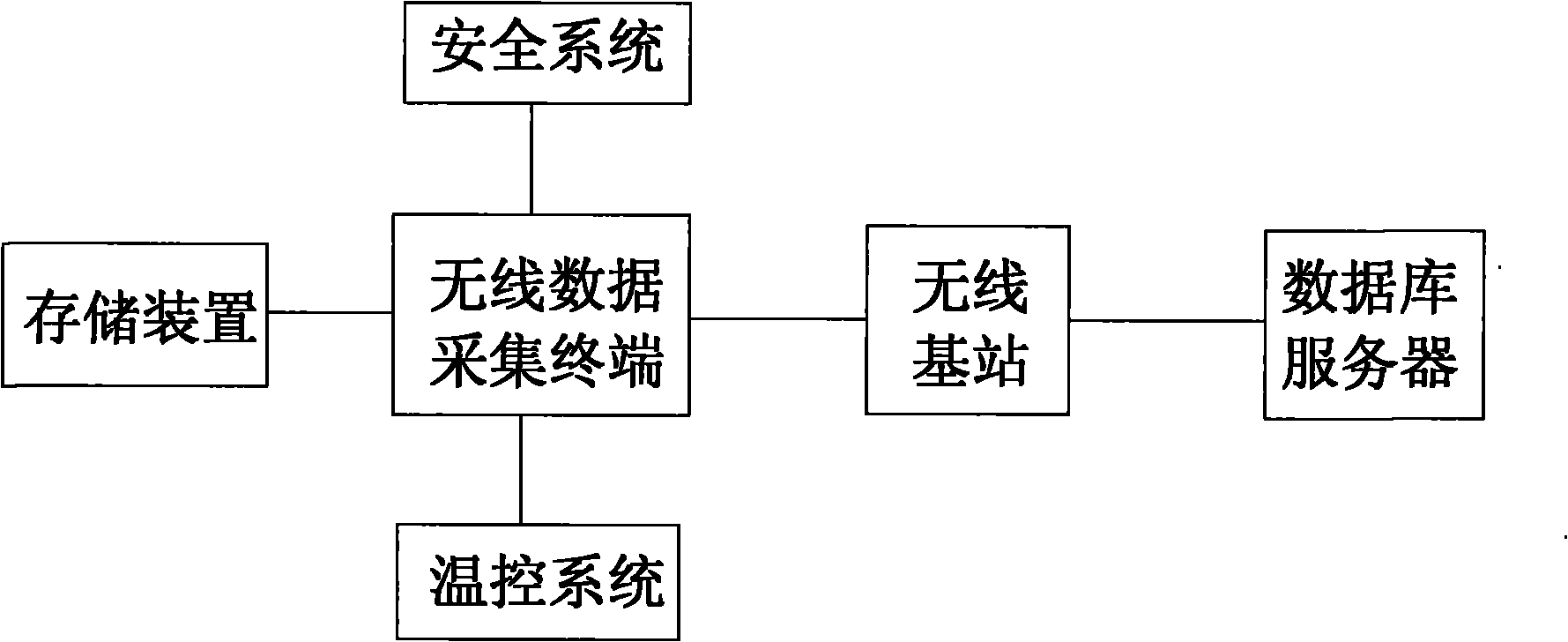

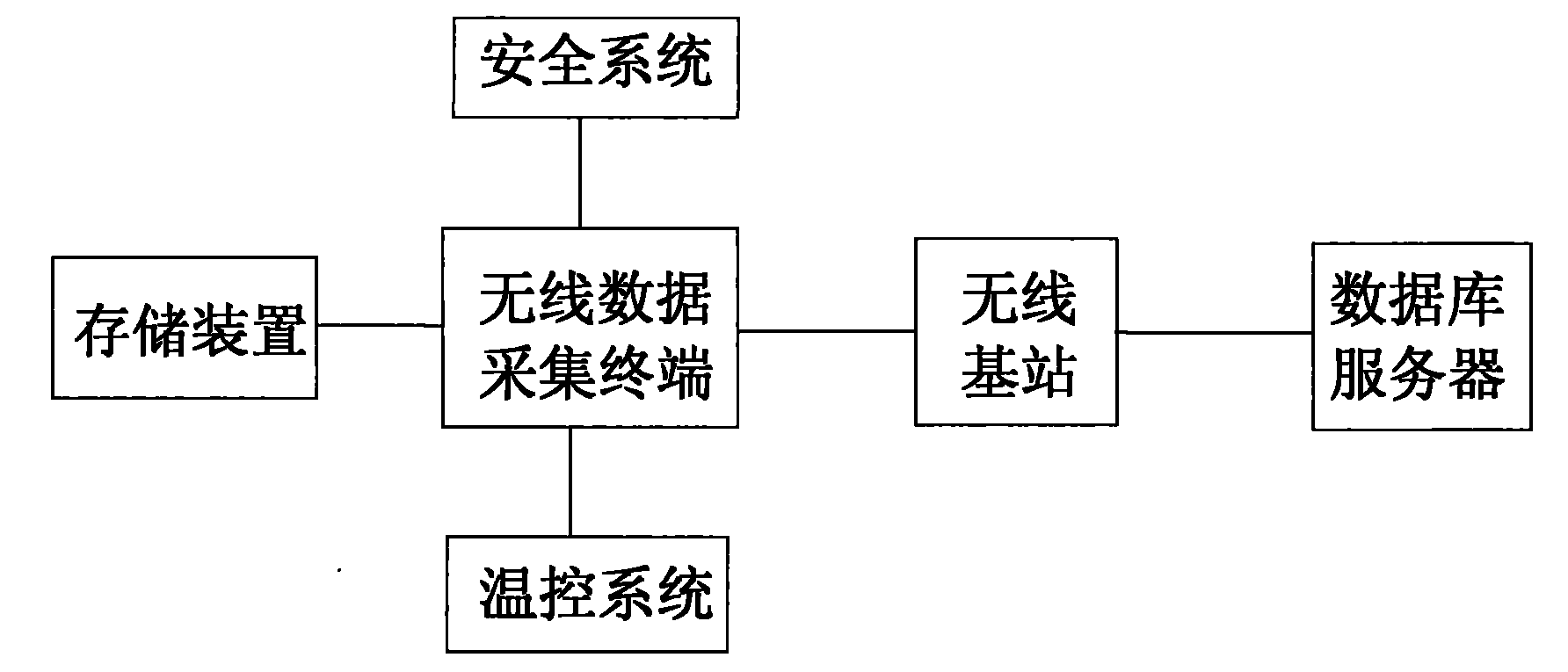

Graphic management system for freezing and storing samples

InactiveCN102116568AImprove work efficiencyImprove accuracyLighting and heating apparatusSensing record carriersGraphicsRefrigerated temperature

The invention relates to a management technology for freezing and storing samples, in particular to a graphic management system for freezing and storing samples in a biomedical refrigerator, comprising a freezing and storing system, a graphic device interface and a drawing module, and the freezing and storing system is communicated with the drawing module by the graphic device interface. In the system, by adopting graphic simulation, the graphic configuration of the equipment, and visual operation of storage, transportation, recovery, re-storage and other daily working of the samples can be realized.

Owner:QINGDAO PENGHAI SOFT CO LTD

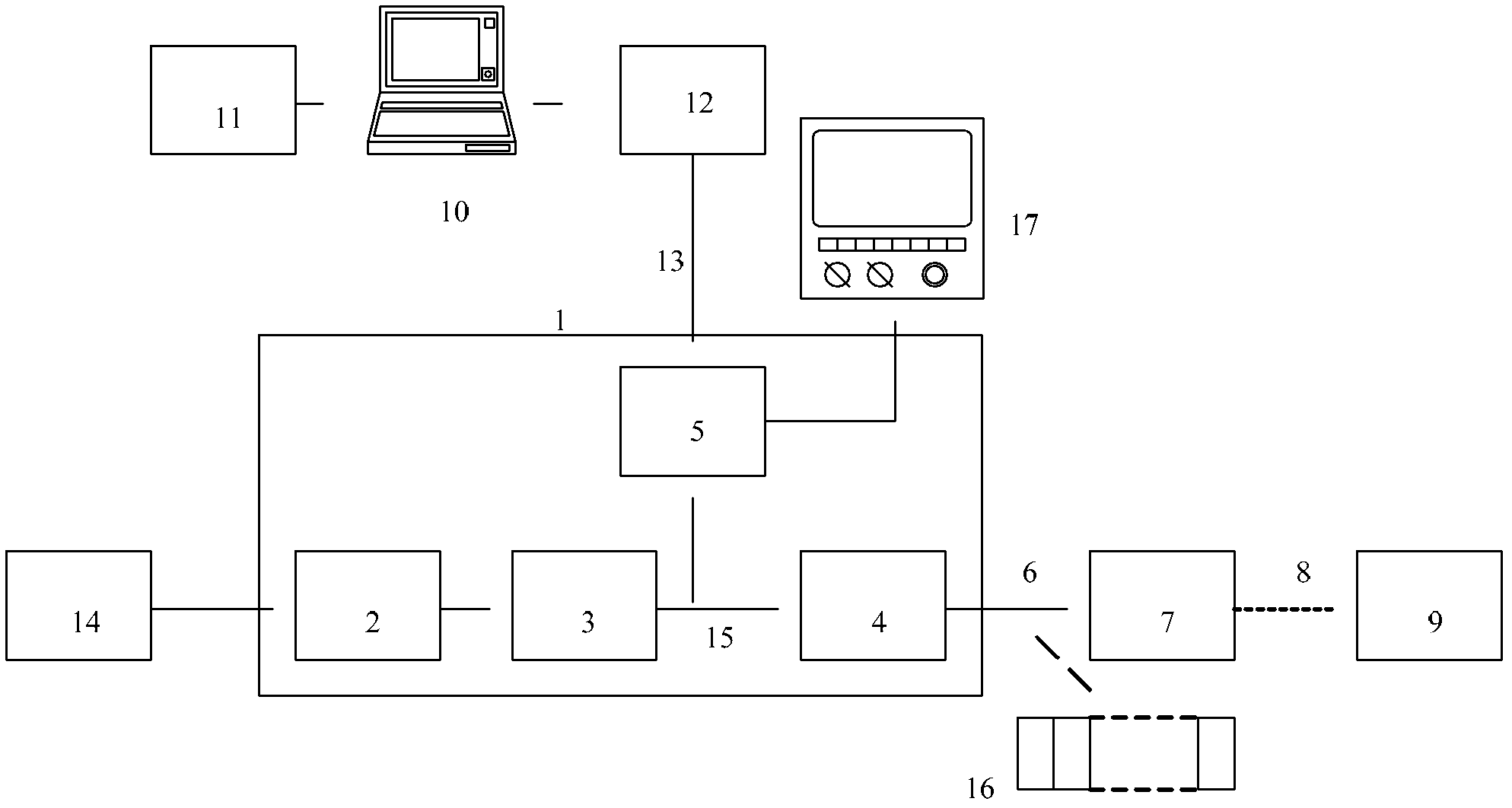

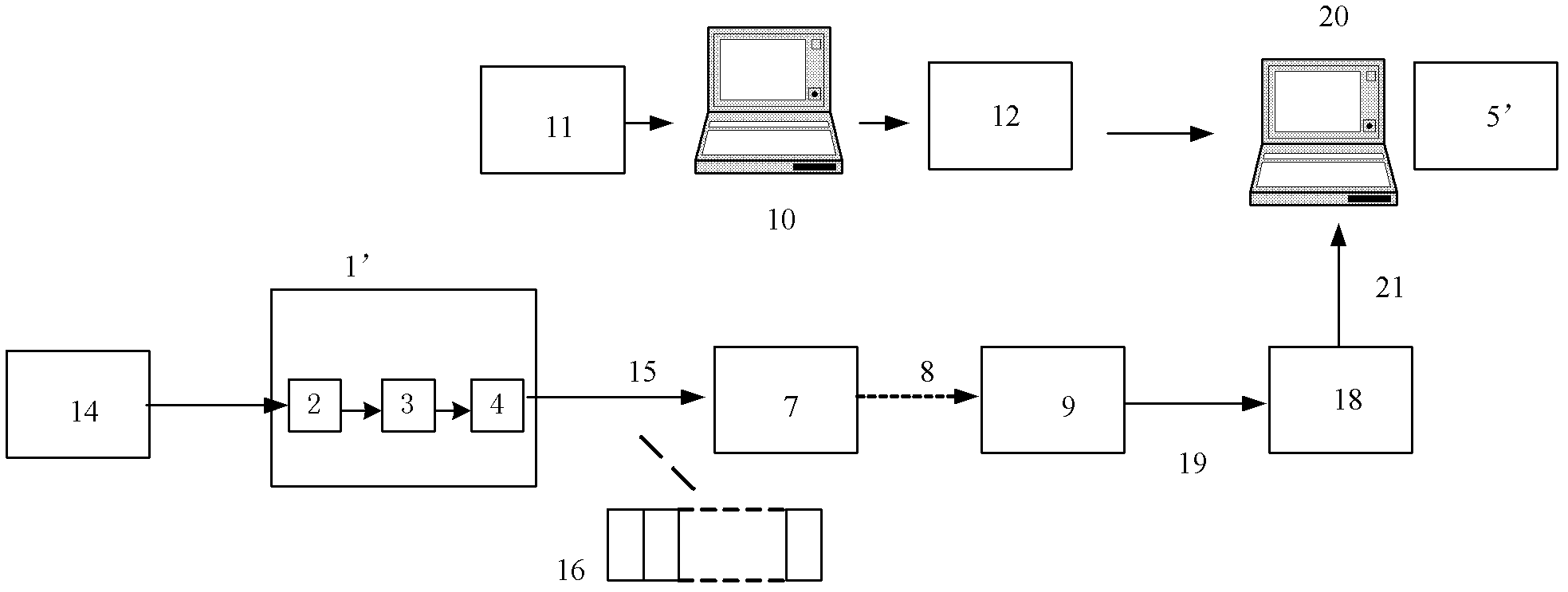

Machine tool motion dynamic graphic simulation system using service filed bus to communicate

InactiveCN102339020AShorten the timeSimple structureSimulator controlMotion dynamicsSoftware development

The invention discloses a construction method of a machine tool motion dynamic graphic simulation system and the machine tool motion dynamic graphic simulation system established on the method. The simulation system comprises a numerical control system, a servo device, a field bus, a bus data receiver, a simulation PC (Personal Computer) and a CAD (Computer Aided Design) modeling system. A machine tool layout structure and part modeling data which are provided by the CAD system are used by the PC; when the numerical control operates, a data frame is transmitted by the servo field bus during each cycle; a position instruction data frame is received by the simulation system through the bus data receiver and is transmitted to a simulation computer through Ethernet; and the simulation system can be used for generating three-dimensional virtual motion of a machine tool part according to the machine tool modeling data and each servo position. By adopting the construction method of the machine tool motion dynamic graphic simulation system, a software structure of the numerical control system is simplified and the simulation and operation time of the numerical control system is reduced; and a general numerical control machine tool motion simulation system is formed without occupying a system operation display interface, and thus development expense of software is reduced.

Owner:BEIHANG UNIV

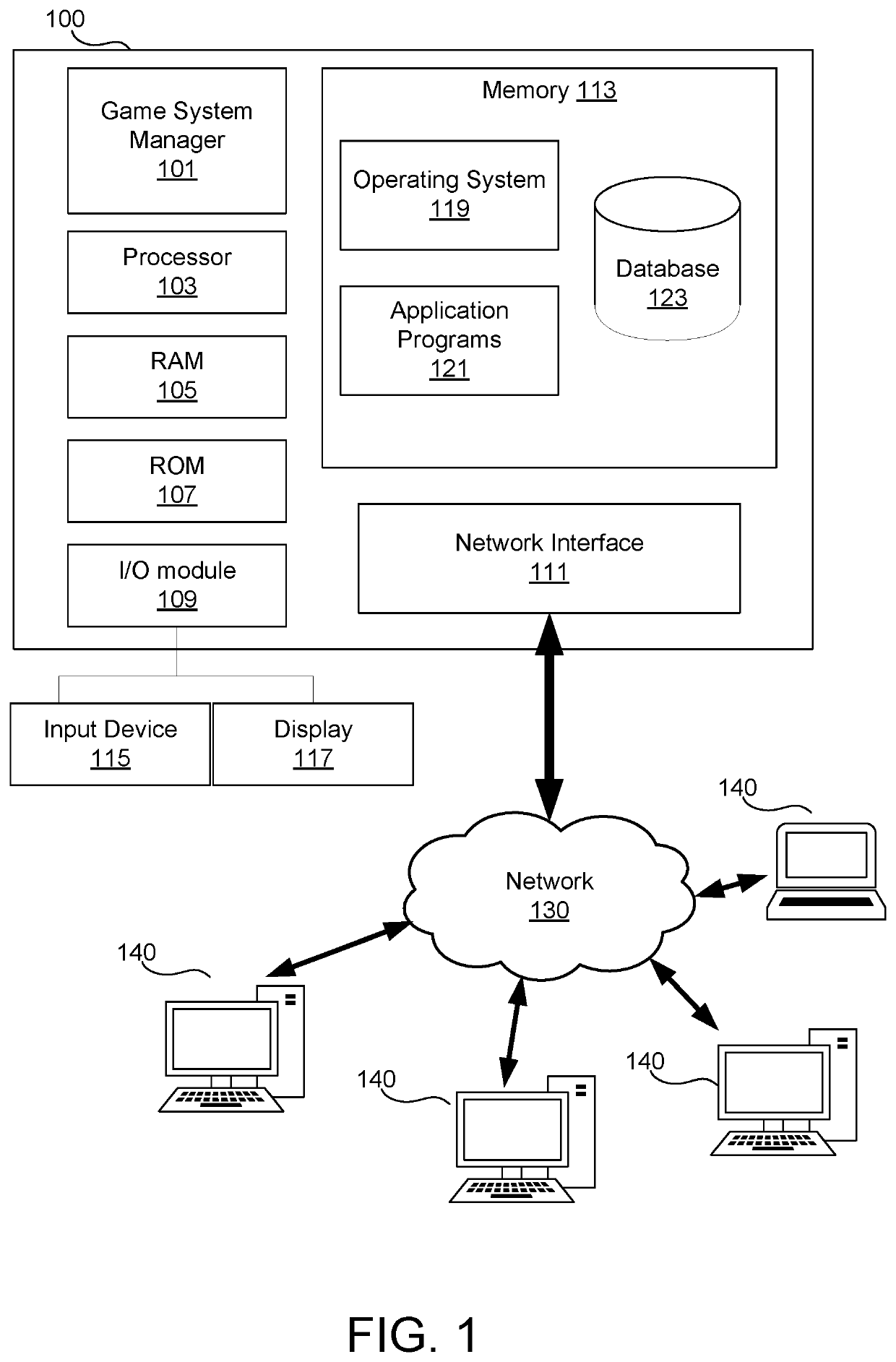

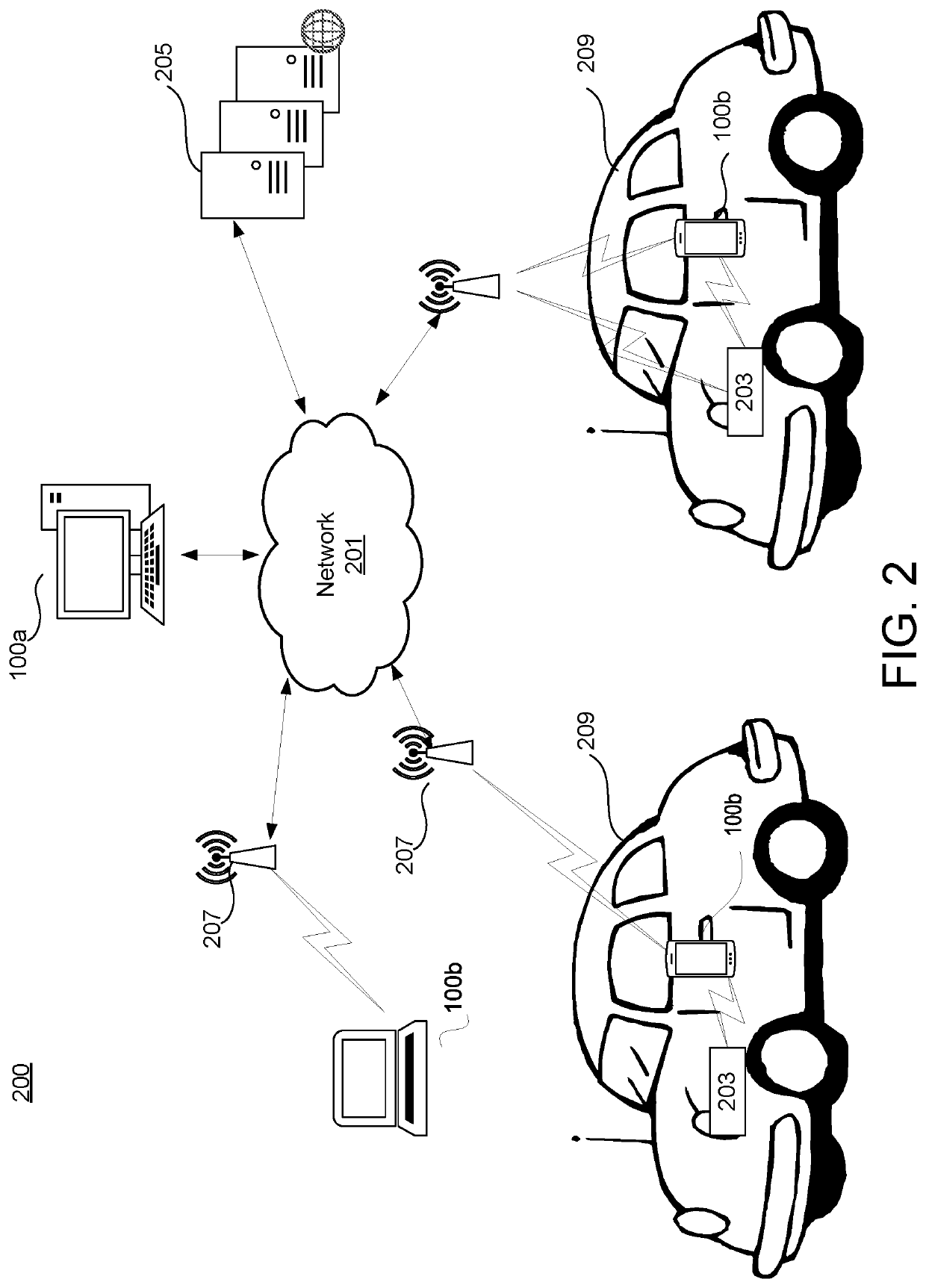

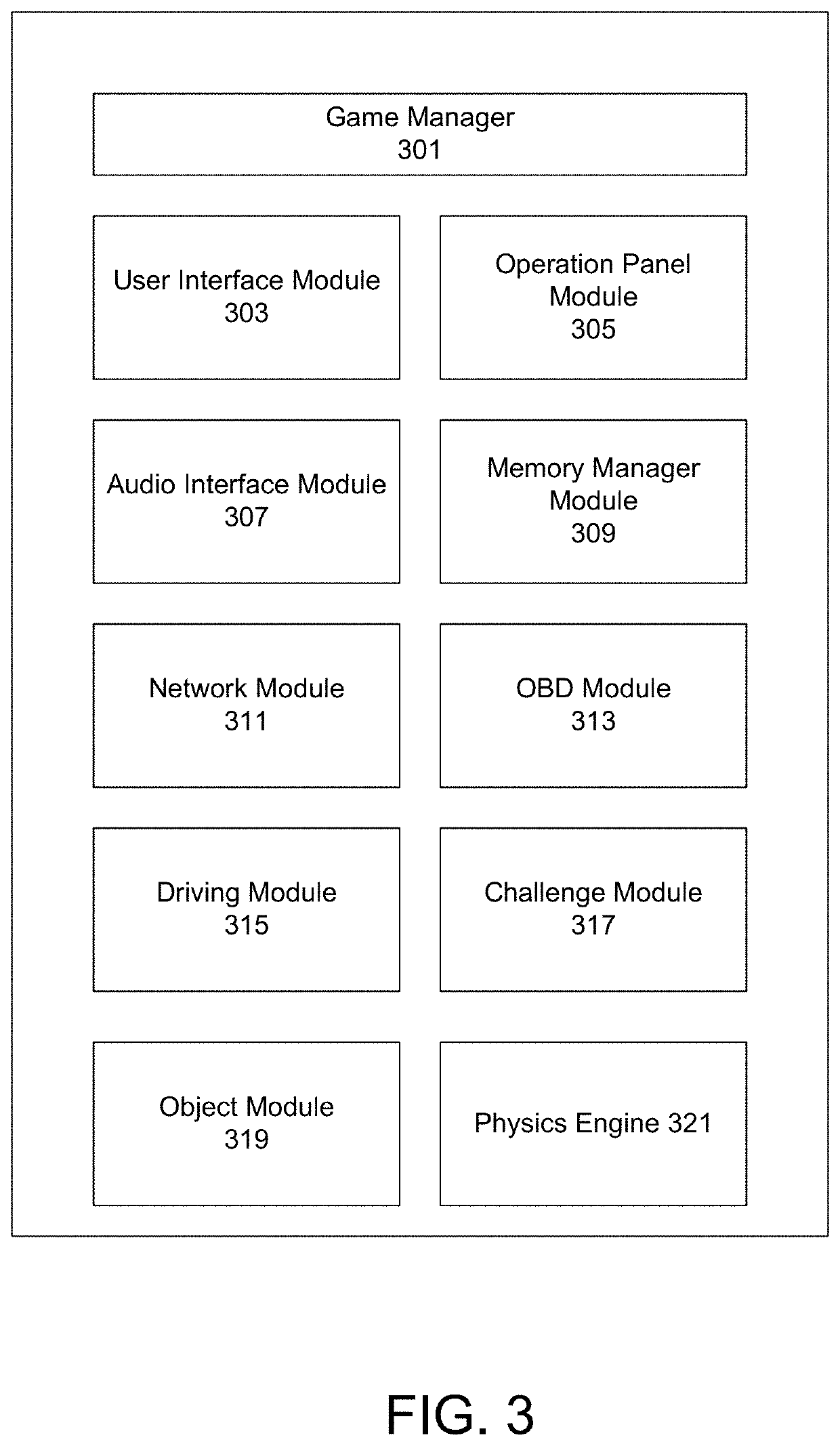

Interactive driver development

Owner:ALLSTATE INSURANCE

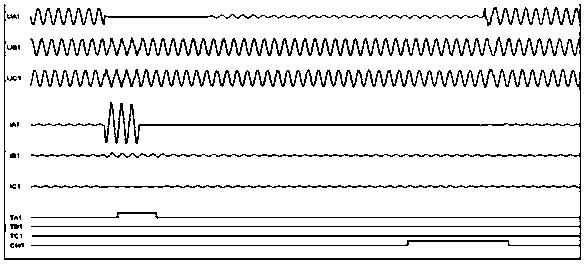

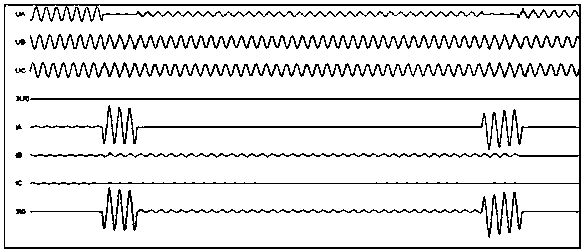

Experimental device for simulating microseismic monitoring fracturing effect and experimental method for experimental device

InactiveCN104656143AImprove accuracyReduce measurement errorFluid removalSeismology for water-loggingObservational errorExperimental methods

The invention relates to an experimental device for simulating a microseismic monitoring fracturing effect and an experimental method for the experimental device. The experimental device for simulating the microseismic monitoring fracturing effect comprises a central control system, a dynamic monitoring assembly, a static monitoring assembly and a display screen, wherein the dynamic monitoring assembly, the static monitoring assembly and the display screen are respectively connected with the central control system; the dynamic monitoring assembly comprises a laser doppler vibrometer; the static monitoring assembly comprises an ultrasonic transmitter and an ultrasonic receiver; the ultrasonic transmitter and the ultrasonic receiver are connected with the central control system through an oscilloscope via a signal; and the experimental method for simulating the microseismic monitoring fracturing effect comprises the following steps: model building, dynamic monitoring, static monitoring, data calculation and graphic simulation. According to the experimental device and the experimental method for simulating the microseismic monitoring fracturing effect, a microseismic event is monitored in dynamic and static manners, so that the measurement error is reduced; the data monitoring accuracy is improved; the monitoring effect is improved; and the experimental device and the experimental method are suitable for popularization.

Owner:SOUTHWEST PETROLEUM UNIV

Method for planning a security array of sensor units

Methods for planning a security array of sensor units are provided. In one embodiment, the method provides an optimized security planning for at least one entity. The method includes the steps of: receiving design data (for instance, geographically-referenced information) indicative of the geographic location; receiving data indicative of the sensors attributes (for instance sensor type, cost, weight, range); receiving data indicative of the preferred coverage area; receiving scenario constraints (for instance specific points of interest); conducting a graphic simulation of the proposed solution; generating multiple alternatives for the proposed solution.

Owner:DEFENSOFT

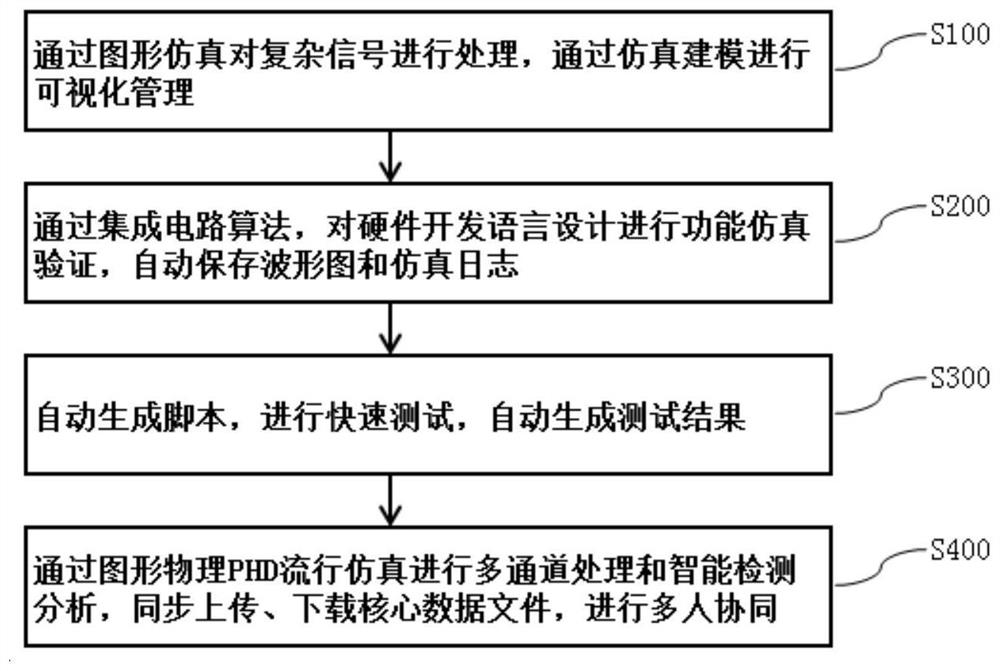

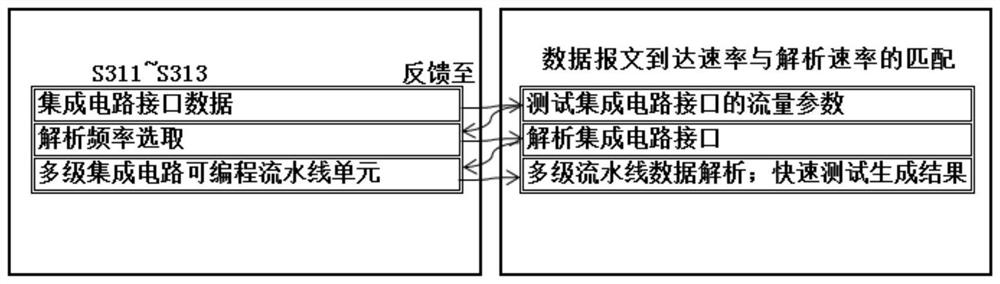

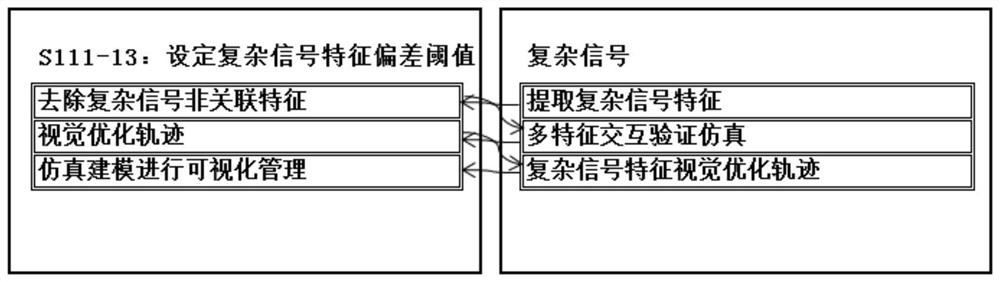

Graph physical PHD popular simulation implementation method

ActiveCN113987980AEasy to handleImprove reliabilityCAD circuit designSpecial data processing applicationsGraphicsModelSim

The invention discloses a graphic physical PHD popular simulation implementation method, which comprises the following steps of: processing a complex signal through graphic simulation, and carrying out visual management through simulation modeling; performing function simulation verification on hardware development language design through an integrated circuit algorithm, and automatically storing an oscillogram and a simulation log; generating a script automatically, performing rapid testing to automatically generate a testing result; making multi-channel processing and intelligent detection analysis by graphic physical PHD popular simulation, uploading and downloading core data files synchronously for multi-person cooperative work.

Owner:BEIJING CHERILEAD TECH

Object loading and unloading system

An object loading and unloading system for loading and unloading objects in a graphically simulated virtual environment, or virtual world, is described. A world object manager manages multiple object loaders to load and unload objects as geographic cells move within and out of a loading radius of each loader based on a position of a camera or view within the virtual world. Each object loader has an associated priority level, and the world object manager notifies a loader to load its corresponding objects in a cell only after all loaders having higher priority levels, which also have that cell in their respective loading radii, have already loaded their corresponding objects in that cell. The world object manager may expose various programming interfaces to provide an extensible object loading system whereby third parties can define new loaders to be incorporated into the hierarchical spatial object loading system.

Owner:MICROSOFT TECH LICENSING LLC

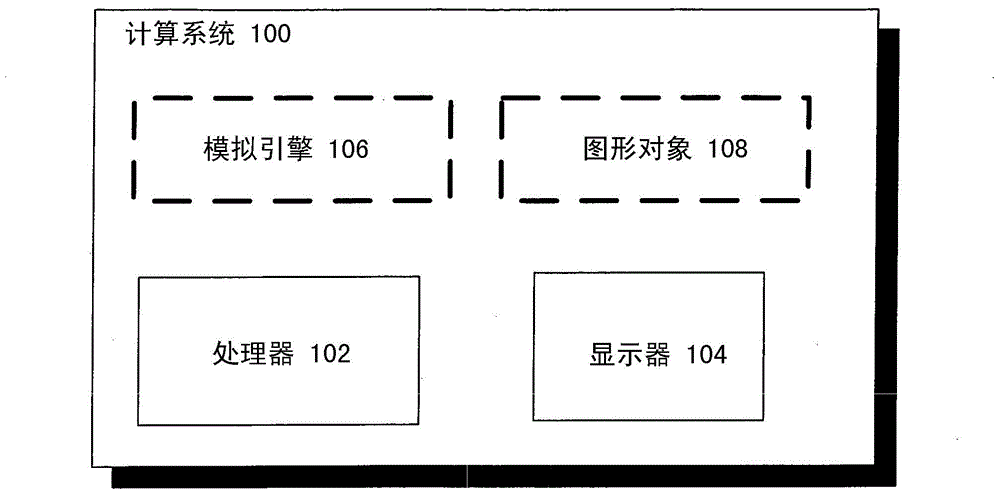

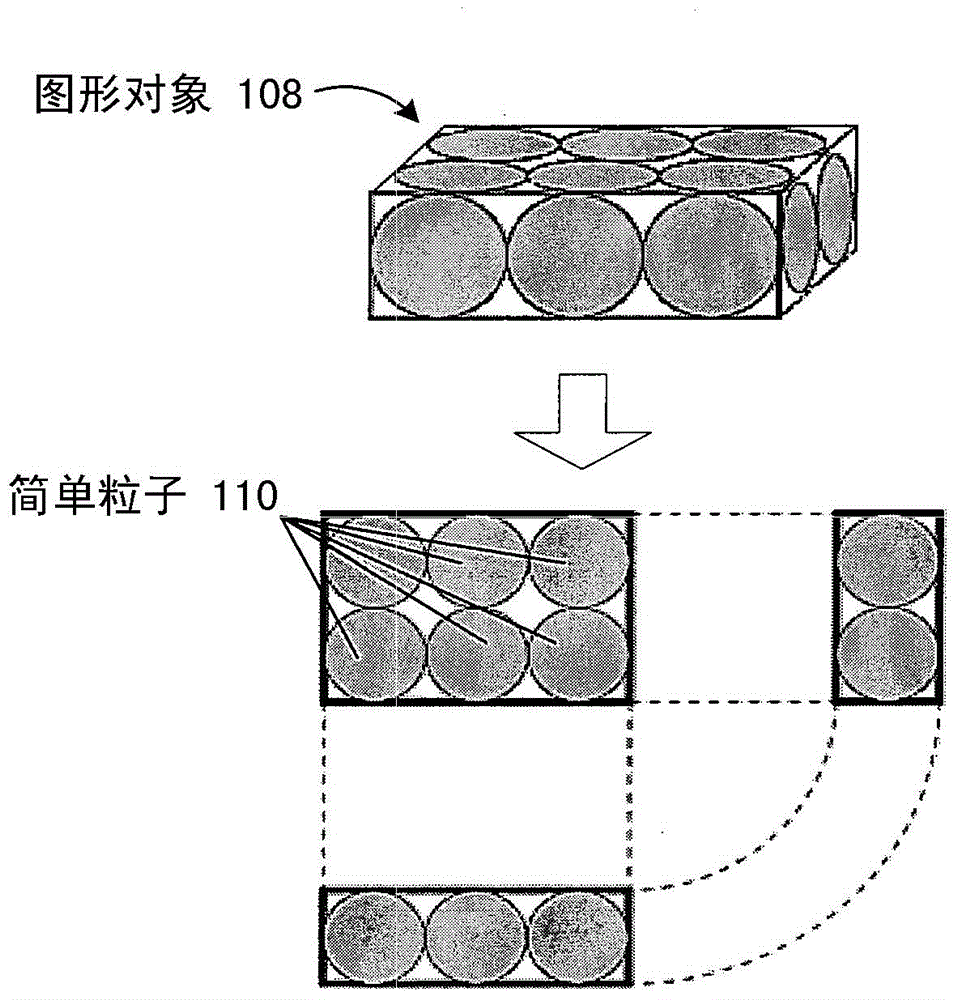

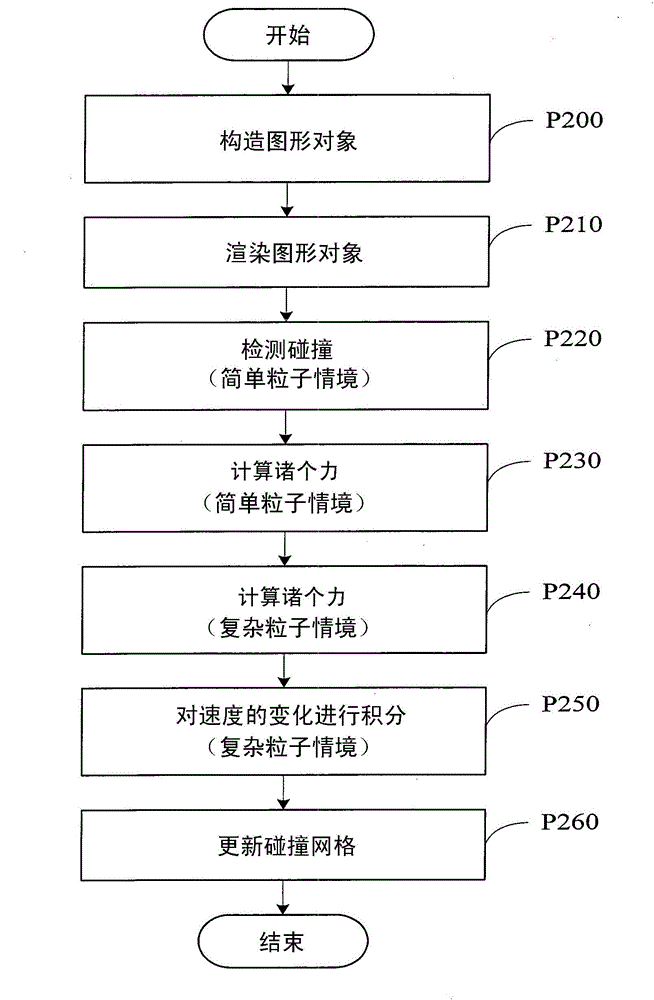

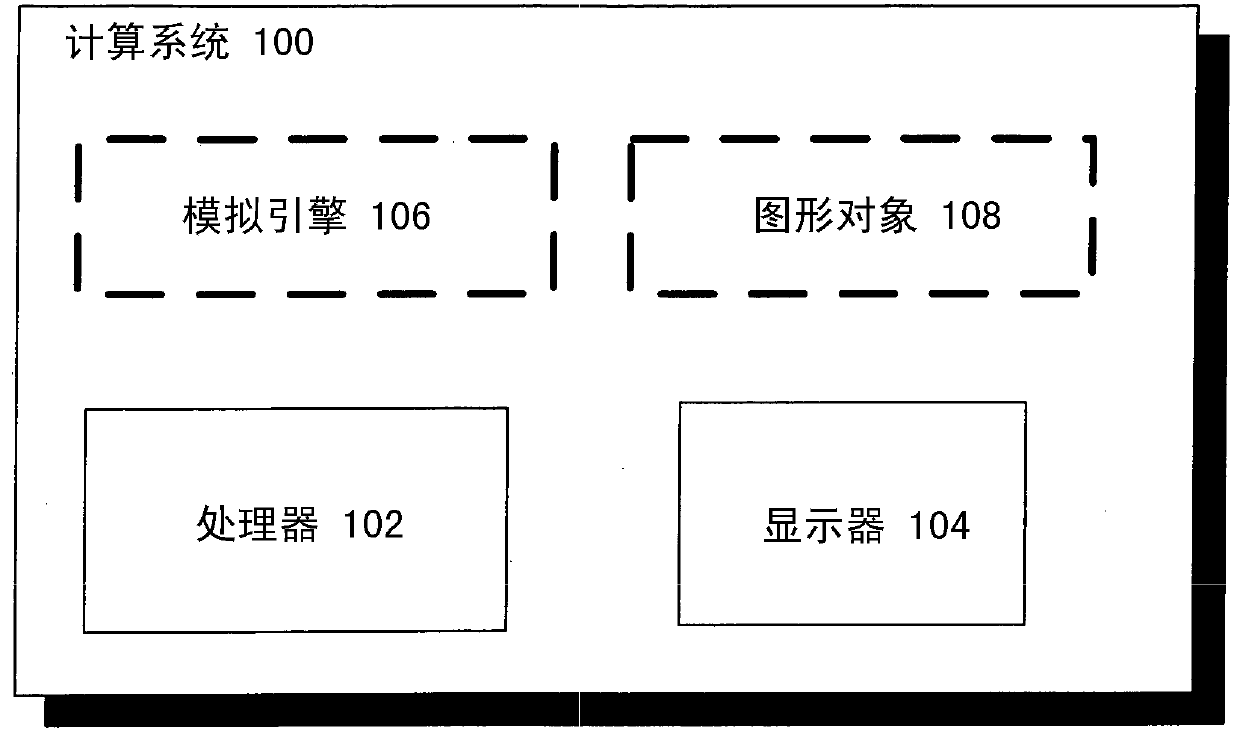

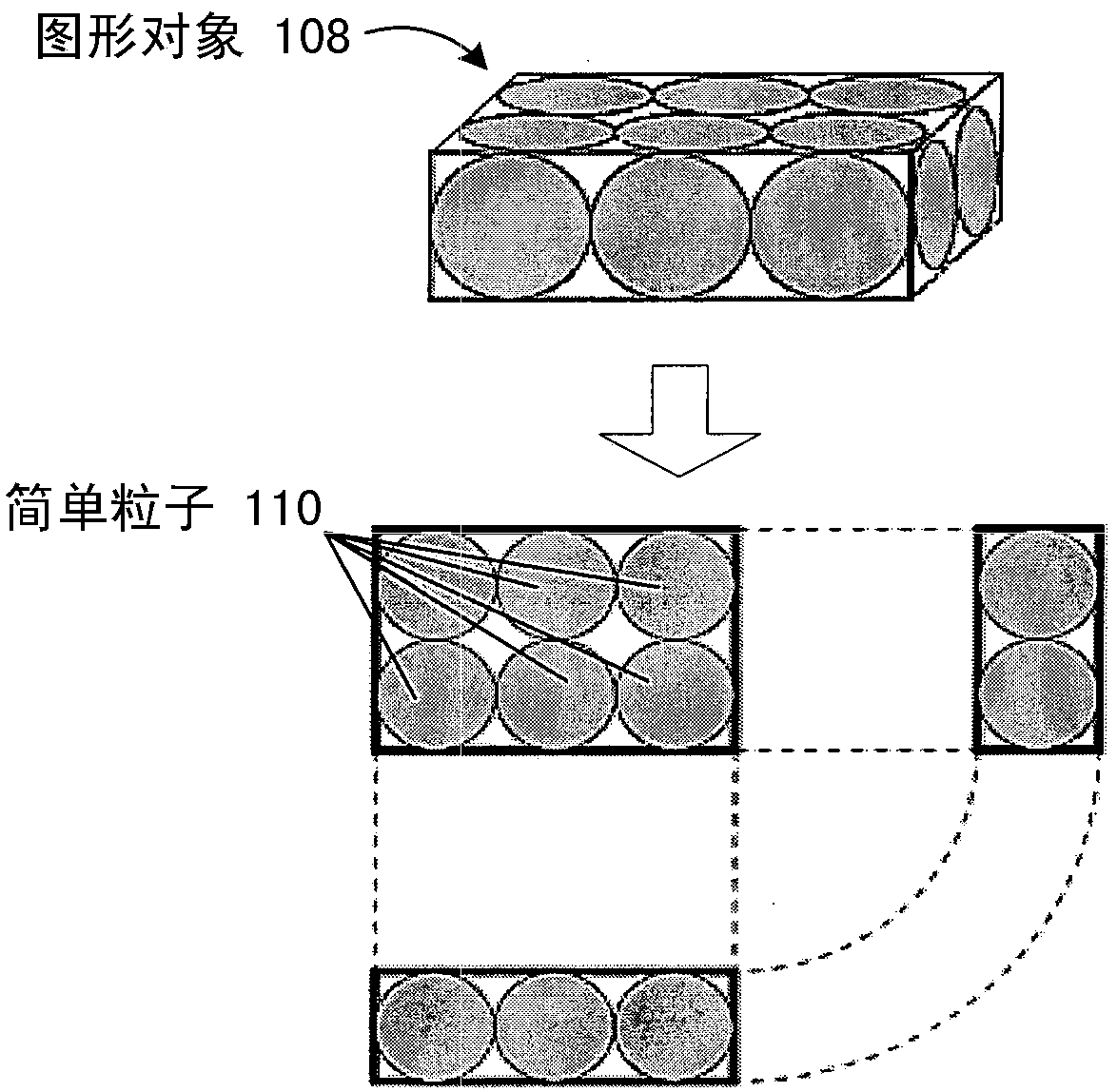

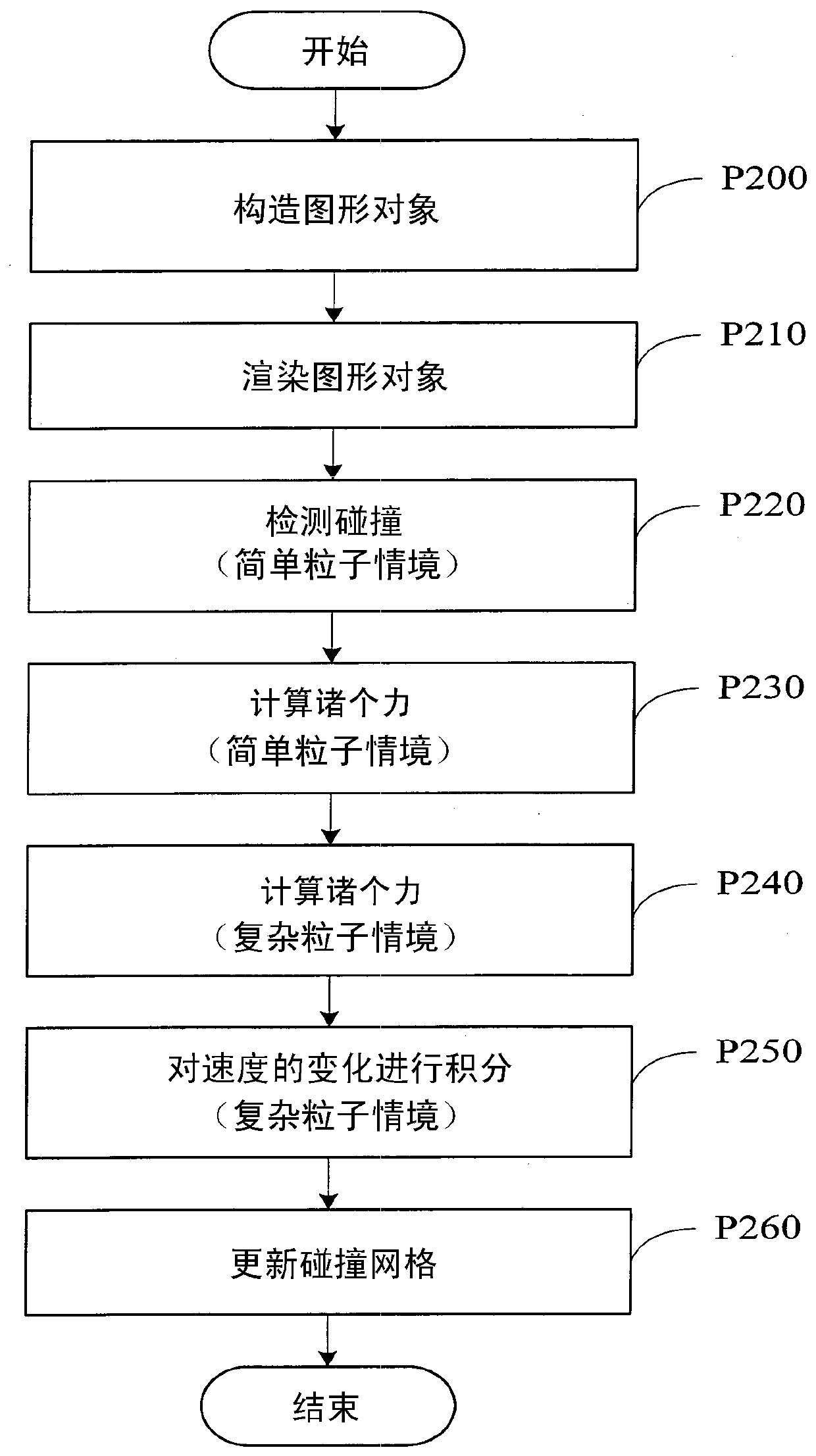

Graph simulation method for object in virtual environment

The invention provides a graph simulation method for an object in a virtual environment. The method comprises the following steps: monitoring an approximate distance between a first graph object and a second graph object, wherein the first graph object is provided with at least first particles and the second graph object is provided with at least second particles; detecting the collision (P220) between the first particles and the second particles; calculating a first group of force (P230) related to the first particles and the second particles and caused by the collision; calculating the first group of force in a first situation, wherein in the first situation, attributes of X types of particles related to the first particles and the second particles are considered; calculating a second group of force (P240) related to the first particles and the second particles and caused by the collision; and calculating the second group of force in a second situation, wherein in the second situation, the attributes of Y types of particles related to the first particles and the second particles are considered, and X is less than Y.

Owner:INTEL CORP

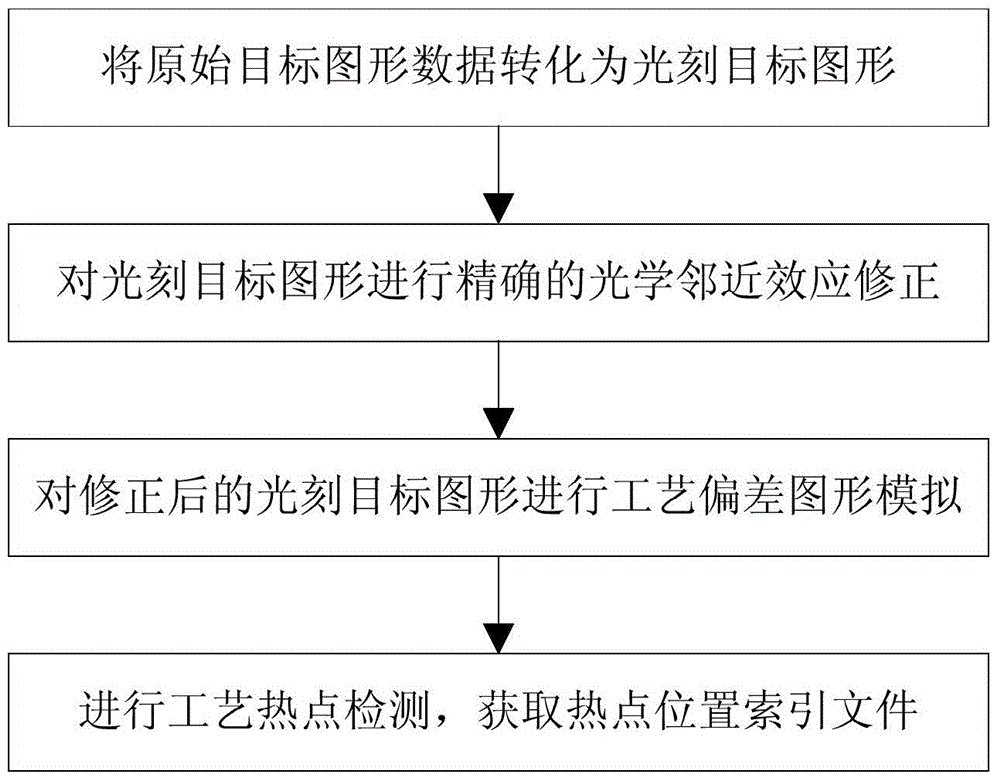

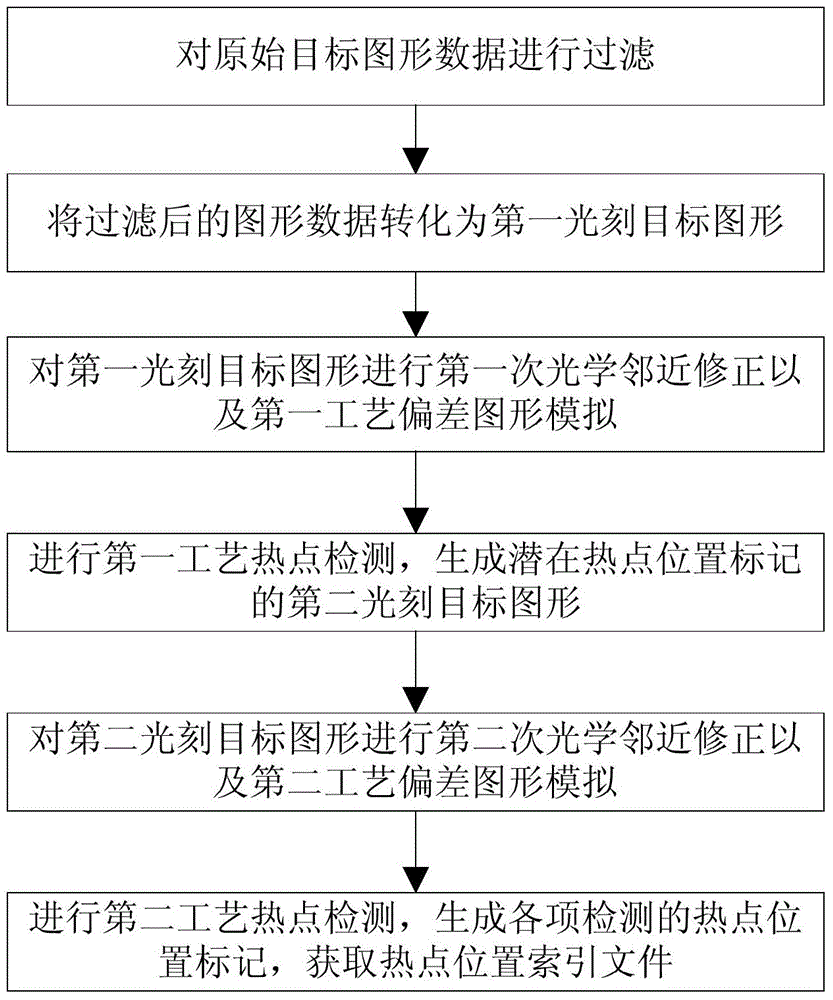

A detection method for layout design photolithography process friendliness

ActiveCN103645611BReduce computing timeReduce usage timePhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsDesign methods

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Graphical Simulation of Objects in Virtual Environments

The invention provides a graph simulation method for an object in a virtual environment. The method comprises the following steps: monitoring an approximate distance between a first graph object and a second graph object, wherein the first graph object is provided with at least first particles and the second graph object is provided with at least second particles; detecting the collision (P220) between the first particles and the second particles; calculating a first group of force (P230) related to the first particles and the second particles and caused by the collision; calculating the first group of force in a first situation, wherein in the first situation, attributes of X types of particles related to the first particles and the second particles are considered; calculating a second group of force (P240) related to the first particles and the second particles and caused by the collision; and calculating the second group of force in a second situation, wherein in the second situation, the attributes of Y types of particles related to the first particles and the second particles are considered, and X is less than Y.

Owner:INTEL CORP

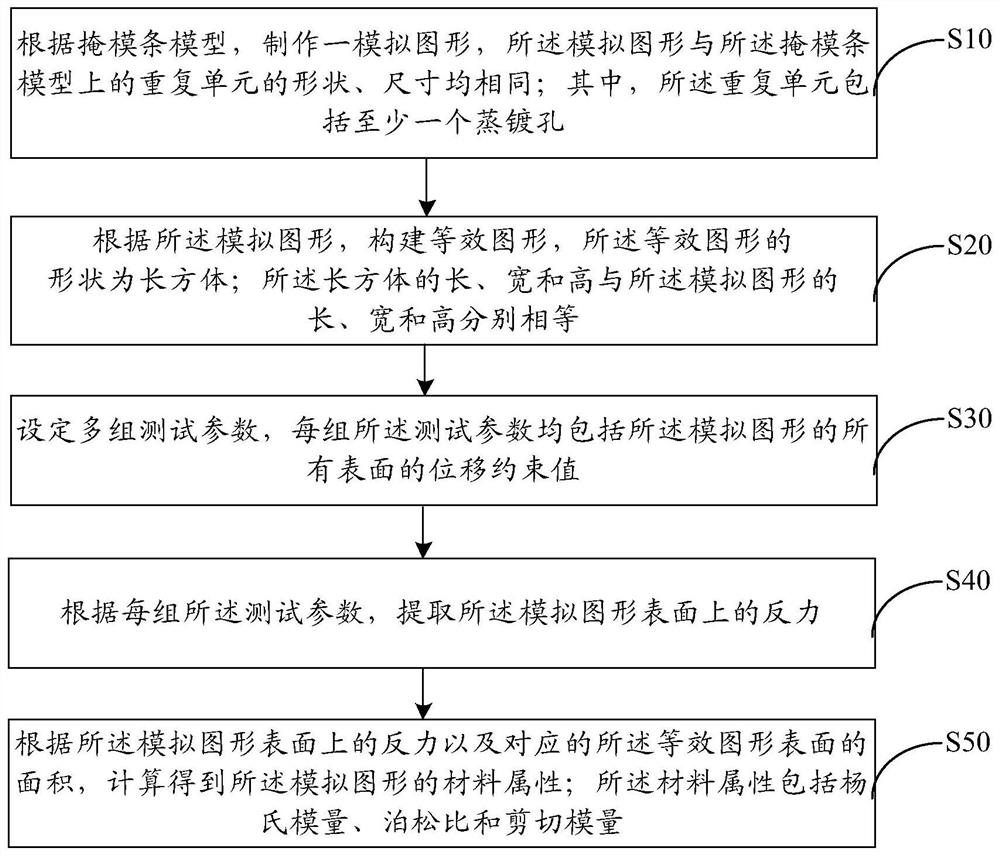

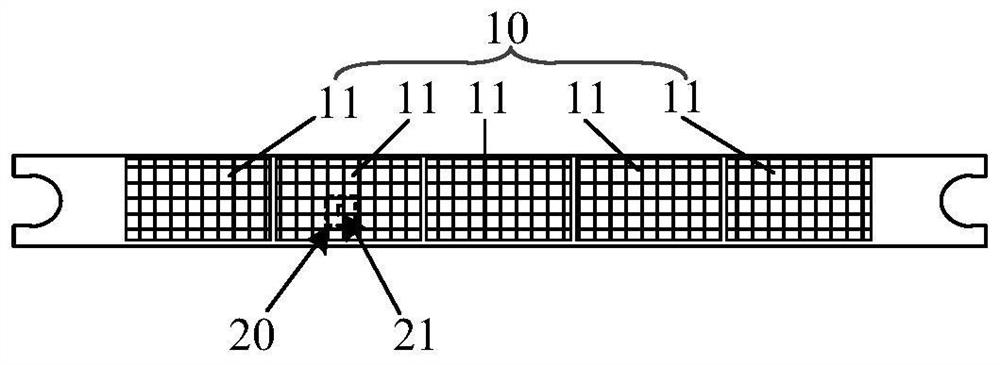

Method and device for obtaining material properties of mask strips and method for manufacturing mask plates

Owner:BOE TECH GRP CO LTD +1

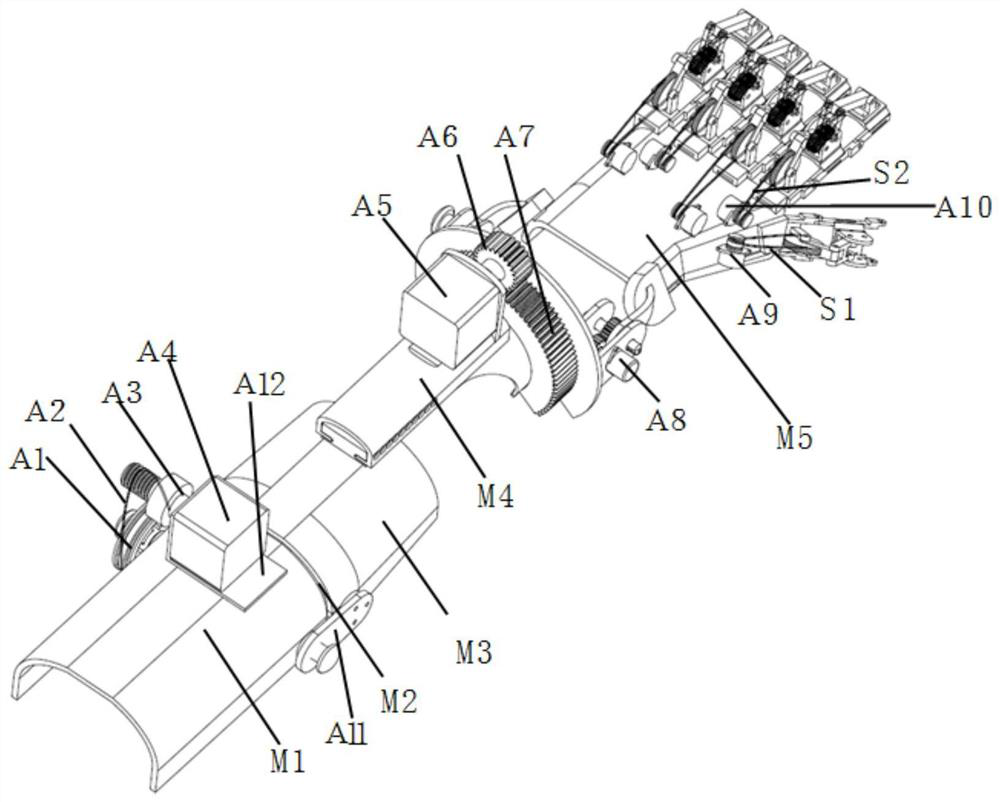

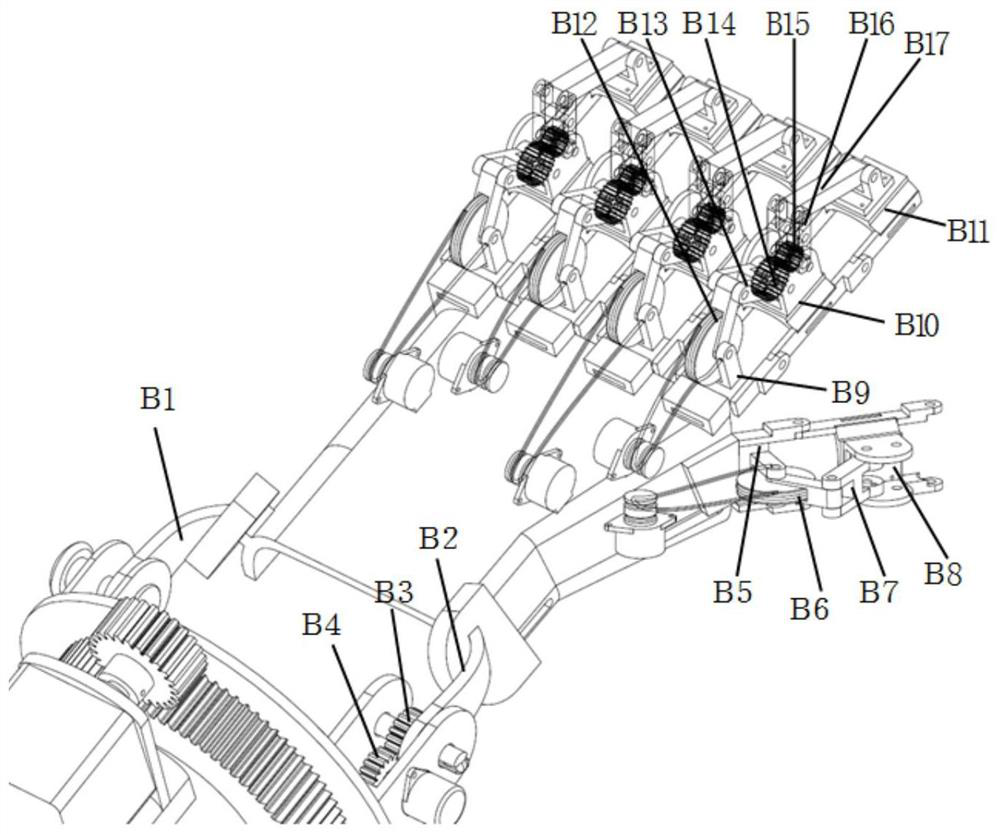

Portable upper limb rehabilitation robot and its digital simulation implementation method based on labview

ActiveCN107260487BEasy to useEasy to carryProgramme-controlled manipulatorChiropractic devicesVirtual locomotionGraphics

The invention provides a portable upper limb rehabilitation robot and a digital simulation realization method based on LabVIEW. The portable upper limb rehabilitation robot is novel in structure and high in integration degree, can realize auxiliary rehabilitation training on 17 joints including the upper limbs and fingers at the same time, and is attractive in appearance; the three-dimensional visual graphic simulation is realized by utilizing LabVIEW and the PTC-Creo engine technology, the operation is simple, the virtual movement of the rehabilitation robot can be simulated, and an operator can clearly and visually observe the rotating angle of each joint in the simulation process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

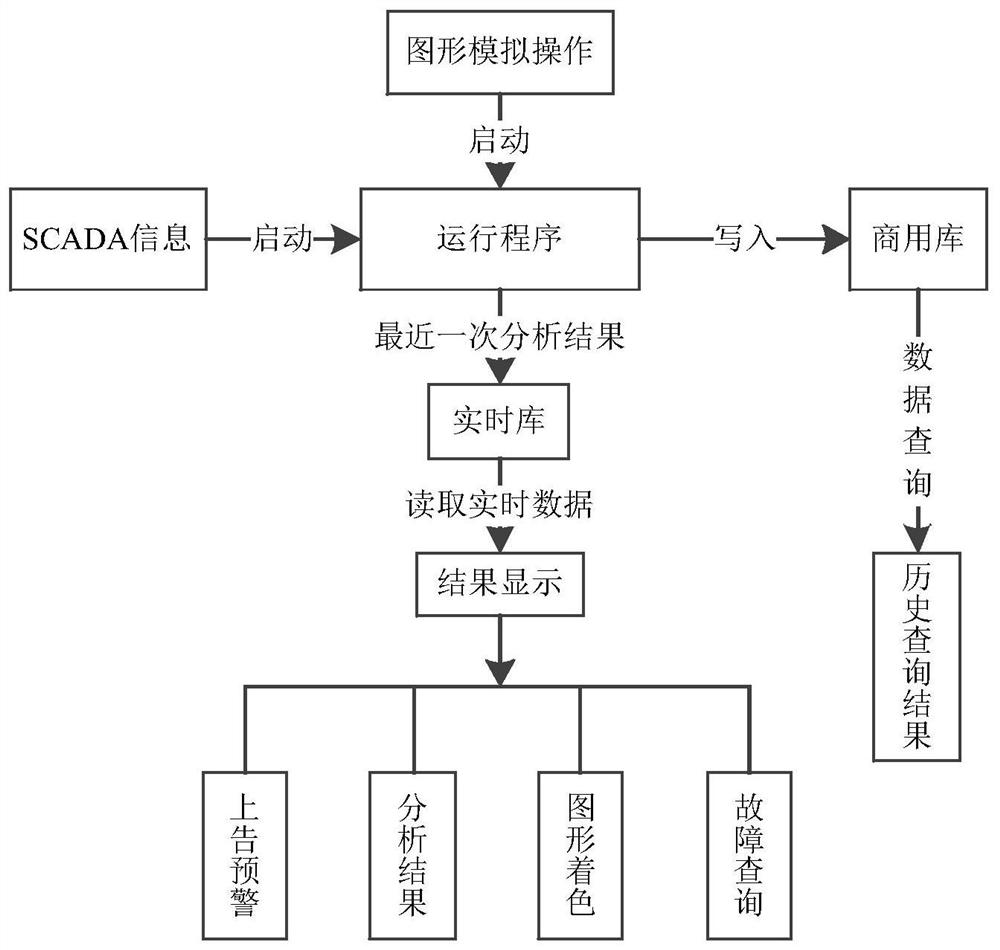

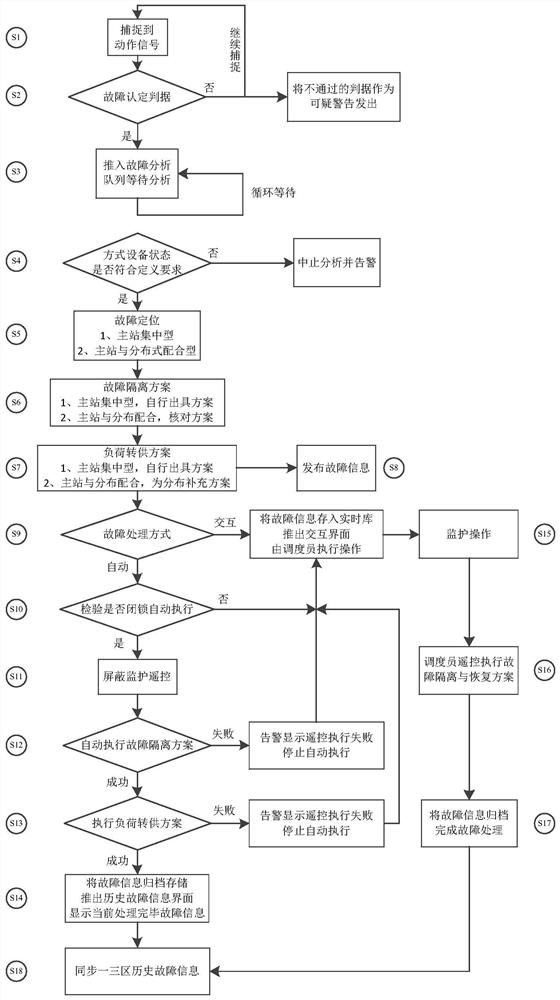

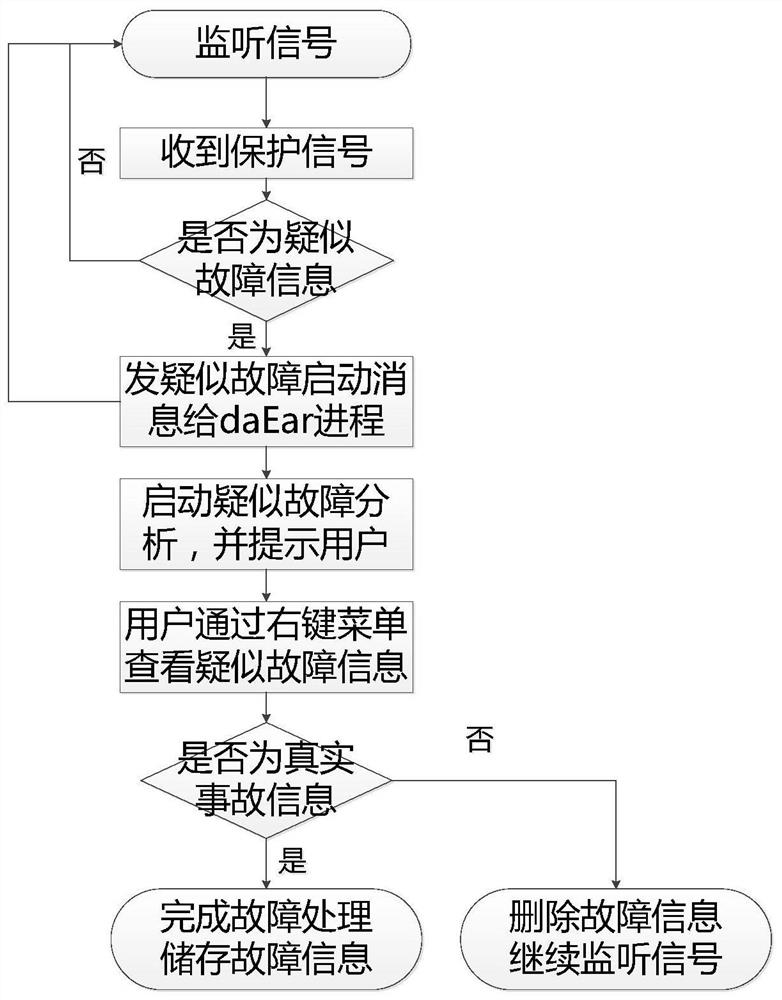

Feeder automation active fault processing system and method based on multi-dimensional information fusion, and readable storage medium

PendingCN113612228ASolve various problems of manual processing of faultsImprove accuracySustainable buildingsInformation technology support systemGraphicsSCADA

The invention discloses a feeder automation active fault processing system and method based on multi-dimensional information fusion and a readable storage medium. The system comprises an SCADA system, an operation controller and a network communication system, wherein the network communication system builds communication among the SCADA system, the operation controller, a power distribution terminal and a control assembly thereof; the SCADA system is used for reading a real-time action signal or a graphic simulation operation signal and starting the operation controller to execute an operation program; and the operation controller stores or calls an operation program, completes automatic active fault control processing of the feeder line based on the real-time action signal, and realizes positioning and isolation of a fault area and load transfer of a non-fault area. The system can also expand and set a real-time database and a commercial database.

Owner:STATE GRID HUNAN ELECTRIC POWER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com