Feeder automation active fault processing system and method based on multi-dimensional information fusion, and readable storage medium

A feeder automation and multi-dimensional information technology, applied in the field of feeder automation, can solve problems such as low efficiency of manual fault processing and inaccurate research and judgment, and achieve the effect of improving fault processing efficiency, improving accuracy and reducing manual workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

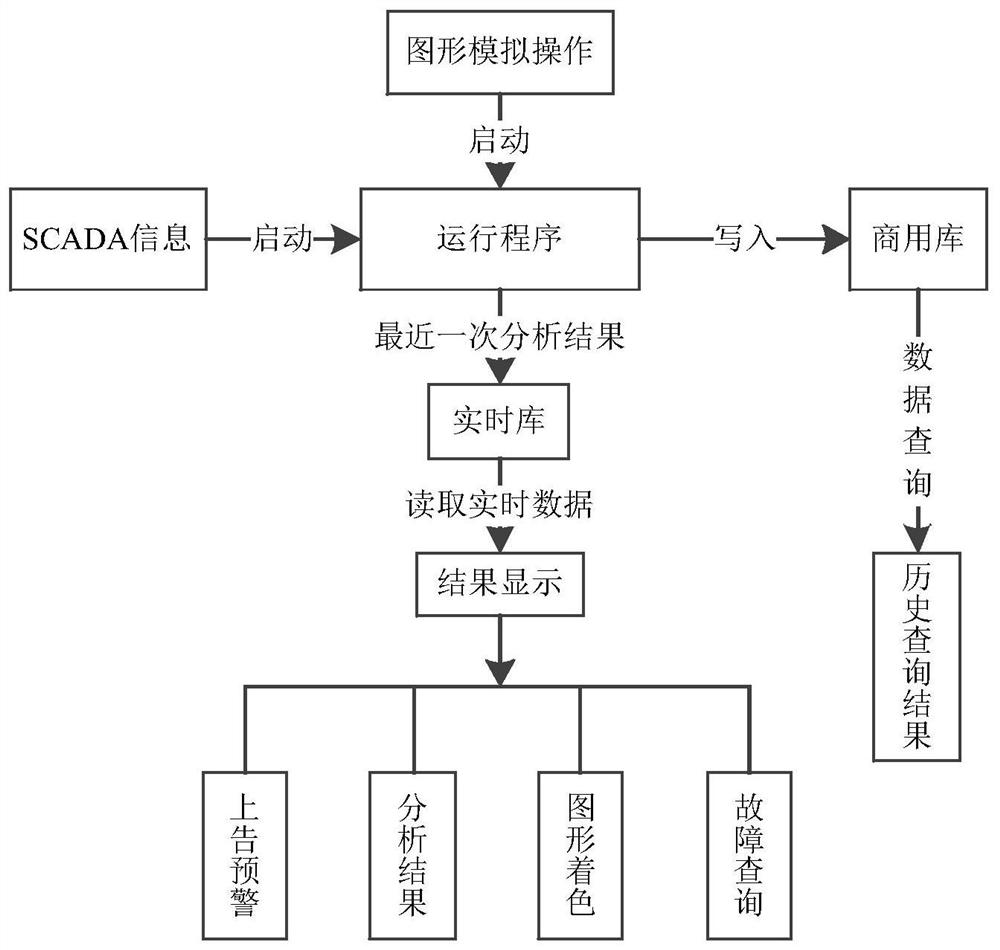

[0053] like figure 1 As shown, a feeder automatic active fault handling system based on multi-dimensional information fusion provided by this embodiment includes: SCADA system (data acquisition and monitoring control system), operation controller (loading or calling operation program), real-time library , commercial library and network communication system. Among them, the network communication system builds the SCADA system, the communication between the operation controller and the power distribution terminal and its control components, such as the communication between the SCADA system and the power distribution terminal, the communication between the operation controller and the switch on the feeder, and the power distribution terminal. Therefore, based on the network communication system, the collection of real-time action information and other fault information is realized.

[0054] The SCADA system is used to read real-time action signals or graphic simulation operatio...

Embodiment 2

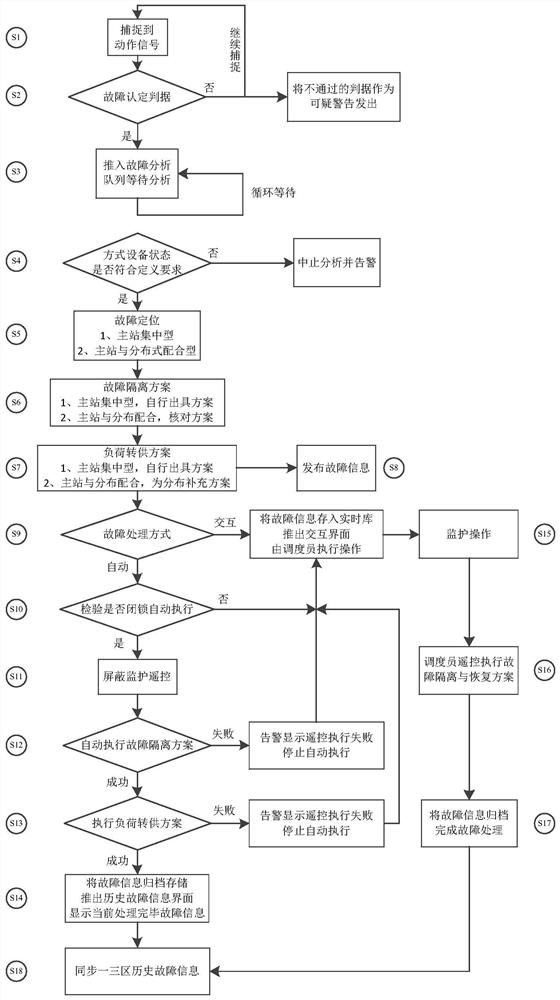

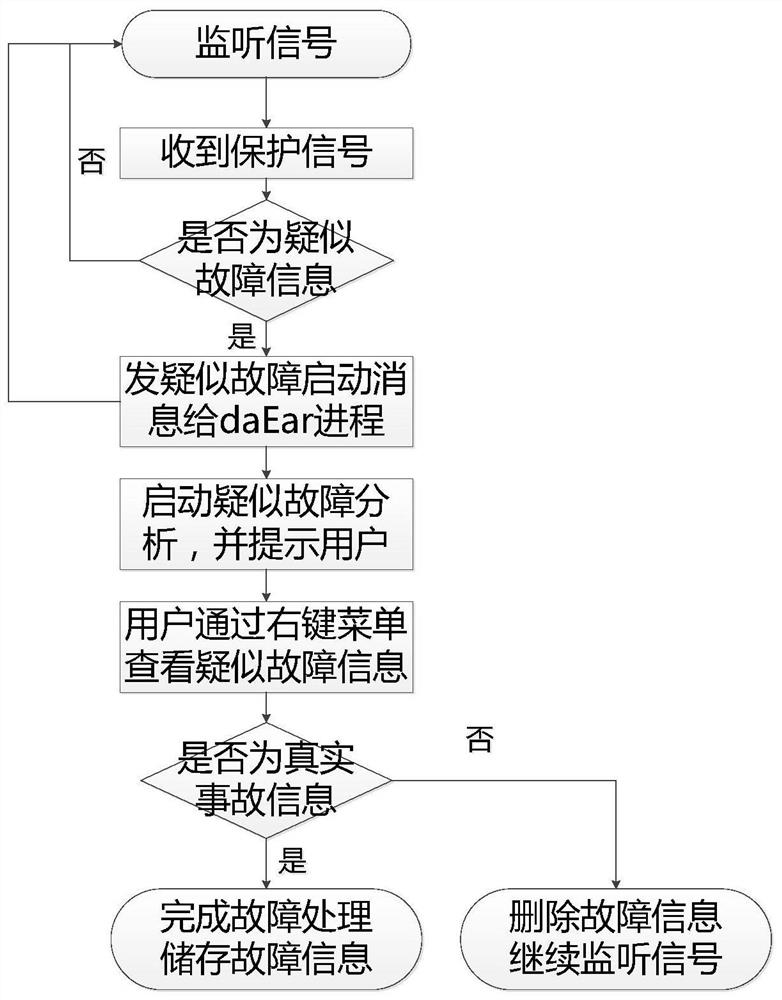

[0065] like figure 2 As shown, this embodiment provides a feeder automatic active fault handling method based on multi-dimensional information fusion, including the following steps:

[0066] Step S1: Acquire captured action signals, which generally include switch opening and closing signals, protection signals, and accident general signals, and go to step S2.

[0067] Among them, the action signal is captured by the SCADA system.

[0068] Step S2: Identify whether it is a fault based on the action signal and the fault identification criterion. If it is judged to be a fault, go to step S3. Otherwise, issue the failure criterion as a suspicious warning and continue to capture.

[0069] Among them, the fault identification criterion is essentially the fault start condition, which generally includes opening plus accident total, opening and closing, abnormal opening, and opening plus protection. For the situation on site, choose one of the four conditions, generally choose "open...

Embodiment 3

[0135] This embodiment provides a readable storage medium, which stores a running program, and the running program is invoked to execute:

[0136] The steps of a feeder automatic active fault handling method based on multi-dimensional information fusion. For the specific implementation process of the method, reference may be made to the description of the above-mentioned embodiment 2.

[0137] The readable storage medium is a computer-readable storage medium, which may be an internal storage unit of the controller described in any of the foregoing embodiments, such as a hard disk or memory of the controller. The readable storage medium can also be an external storage device of the controller, such as a plug-in hard disk equipped on the controller, a smart memory card (Smart Media Card, SMC), a secure digital (Secure Digital, SD) card, flash memory card (Flash Card), etc. Further, the readable storage medium may also include both an internal storage unit of the controller and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com