Patents

Literature

65results about How to "Save manufacturing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

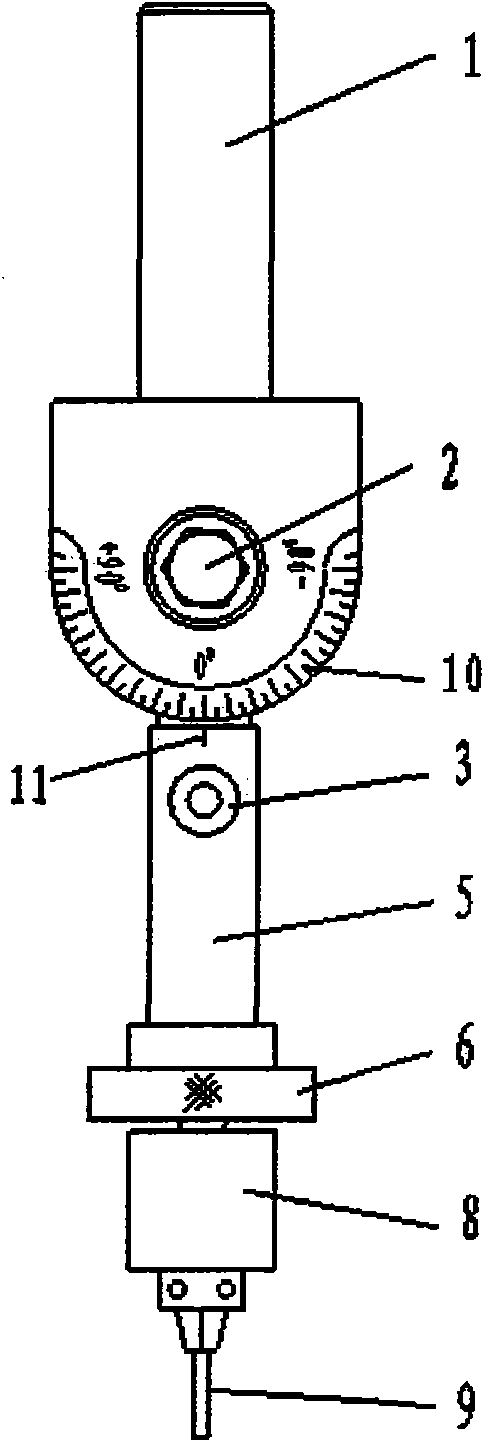

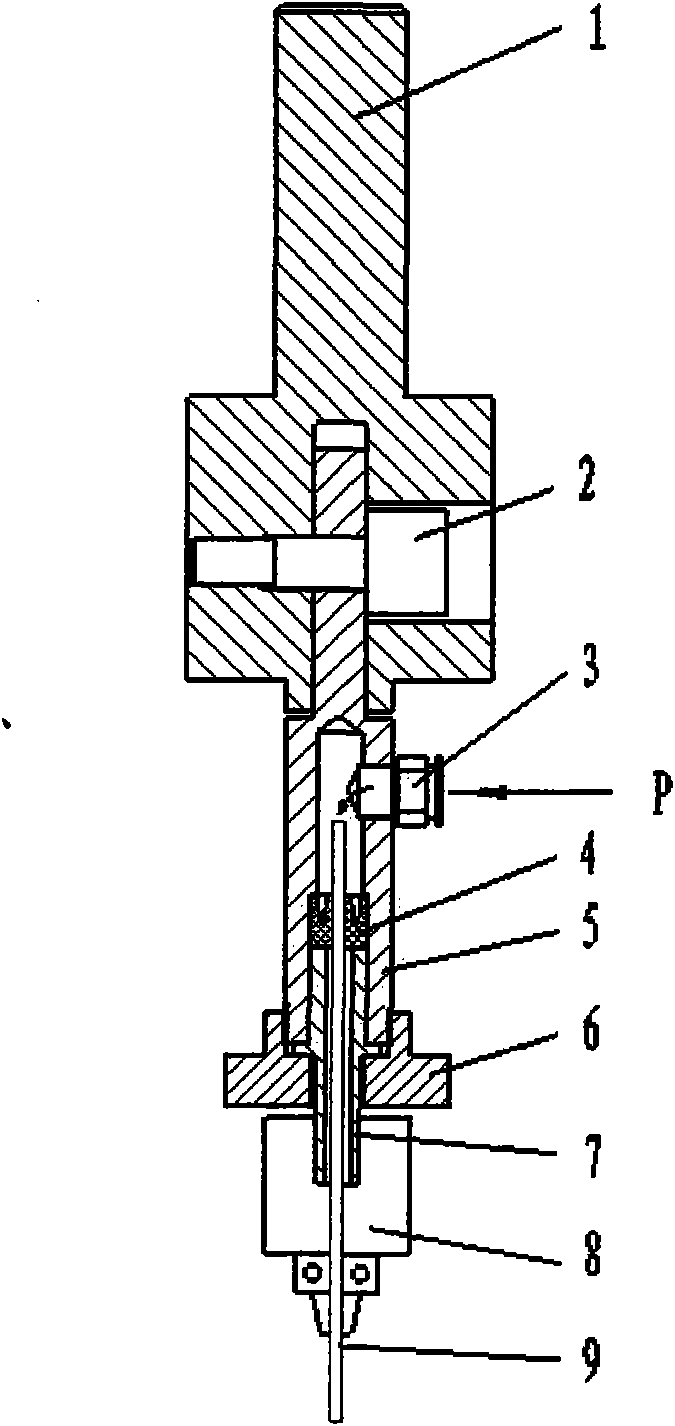

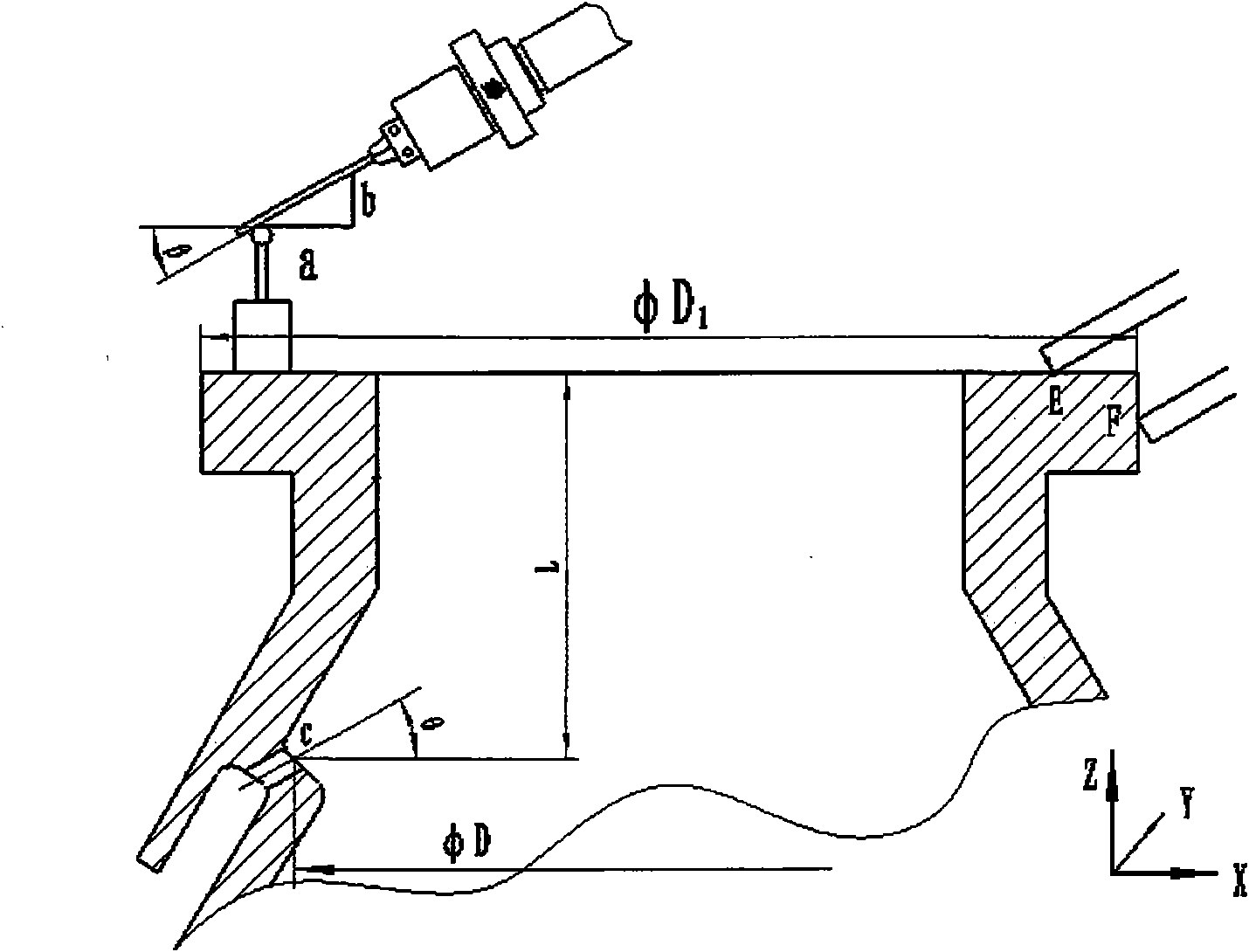

Inclined hole electrosparking processing device and method for adjusting position and angle of electrode

The invention relates to an inclined hole electrosparking processing device, comprising a joint body, an electrode deflection shaft, a positioning clamping screw, a tightening screw cap, a positioning shaft and a hollow small hole electrode. A connecting rod of the electrode deflection shaft is located in a rectangular slotted hole of the joint body; an equal-diameter end of a positioning shaft is located in a shaft hole of the electrode deflection shaft and is tightened up; a rubber sealing piece is located in the shaft hole of the electrode deflection shaft and the hollow small hole electrode penetrates through a drill chuck and is placed into the positioning shaft. In the invention, according to the inclined angle between the inclined hole and the X axis or Y axis and degree scale on the joint body, the inclined angle beta between the electrode and the X axis or the Y axis is initially adjusted, and the electrode is moved along the negative direction of Z axis or the positive direction of the X axis to obtain the actual inclined angle beta between the electrode and the X axis or the Z axis. In addition, the corresponding position of the inclined hole electrode and the inclined hole center C is identified to obtain coordinates of the Z axis and X axis of a machine tool, so that the problems of the existing small hole electrosparking processing device such as high cost, long cycle, difficult positioning of the electrode and low positional precision of processing holes and the like are solved and 0-90-degree inclined hole electrosparking processing is realized.

Owner:NANTONG ZHONGLING INSULATION MATERIALS +1

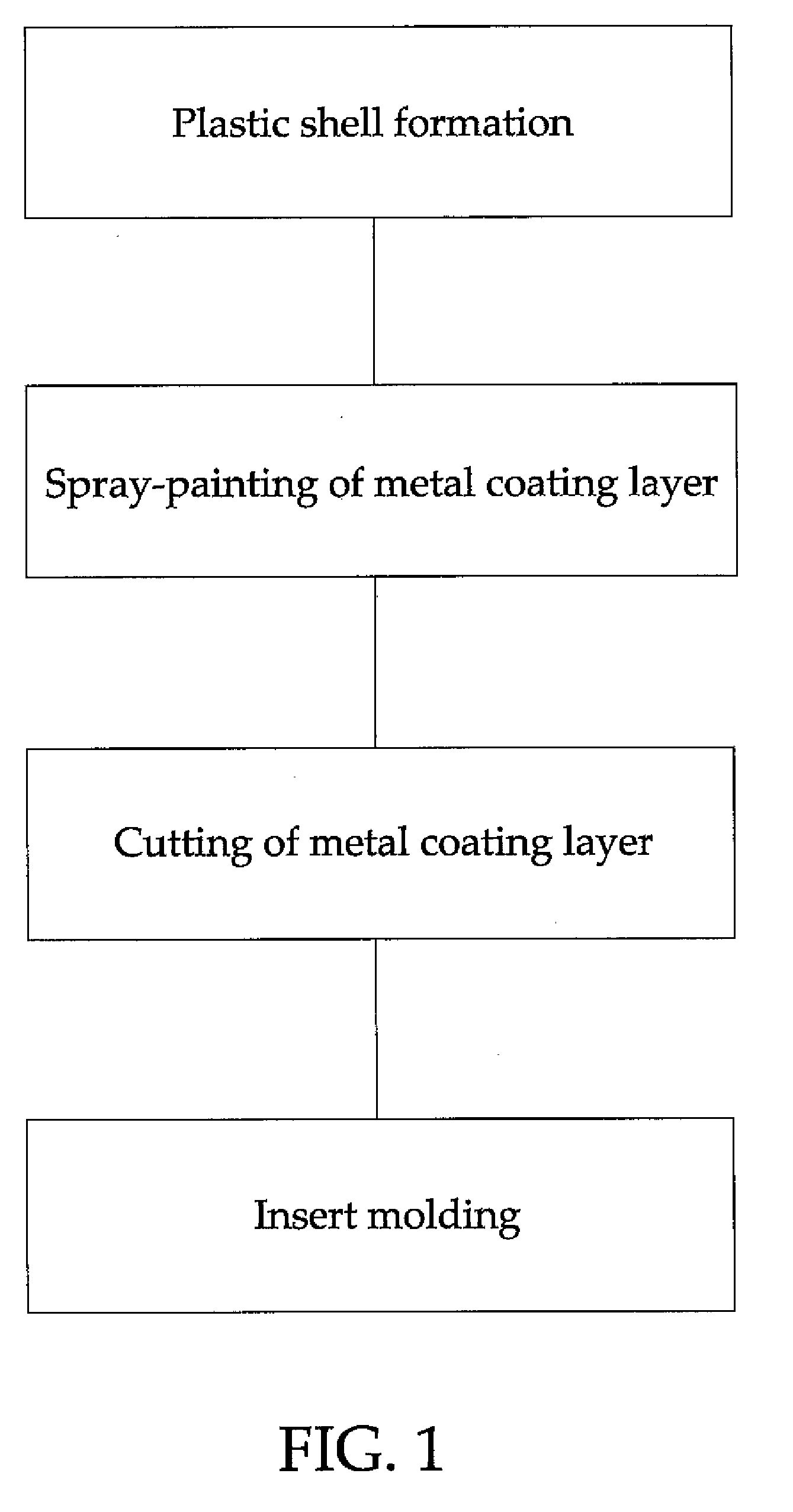

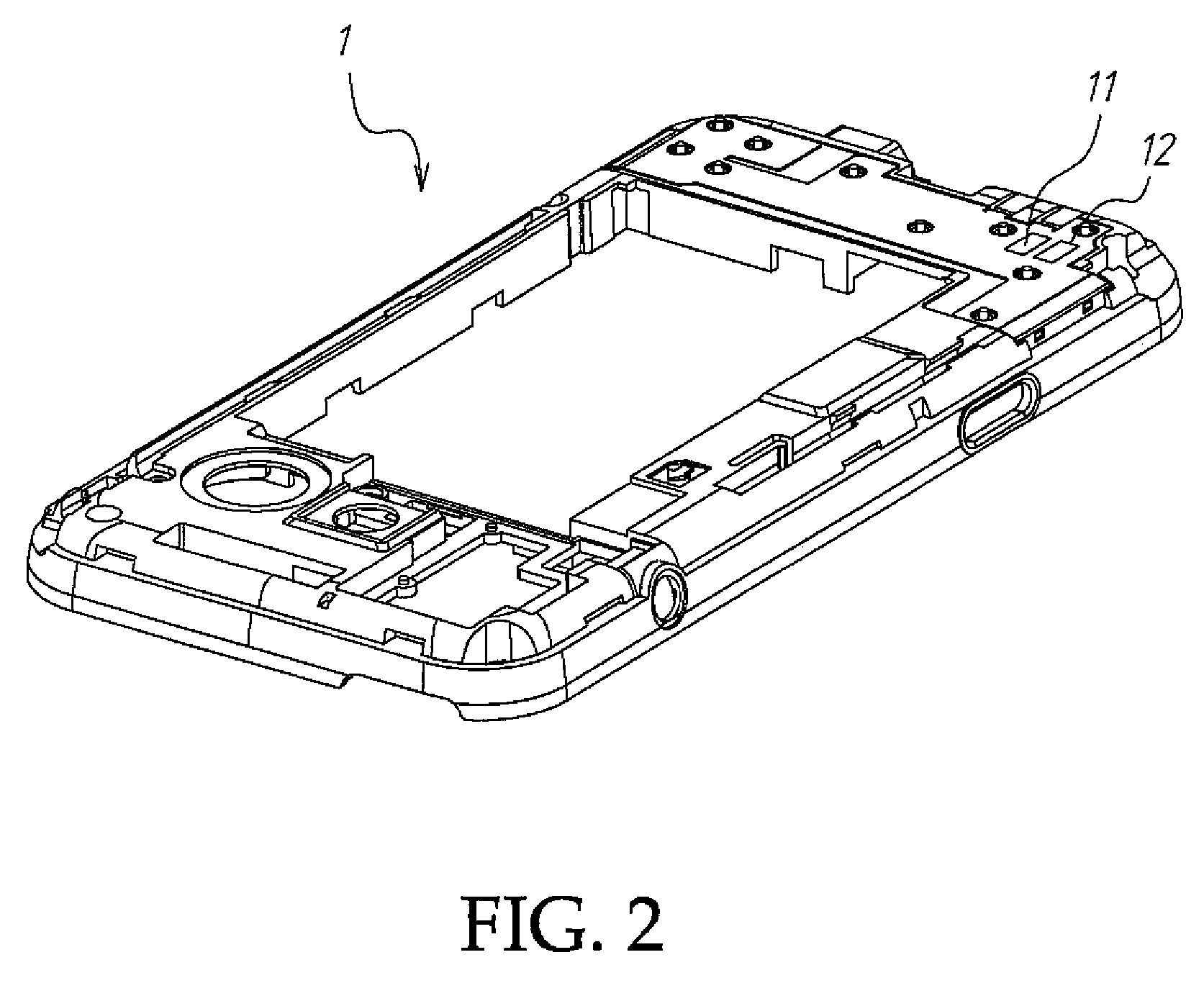

Spray non-contact cutting type antenna and its fabrication method

InactiveUS20100033400A1Save manufacturing timeLower defect rateRadiating elements structural formsProtective material radiating elementsEngineeringElectrical and Electronics engineering

A spray non-contact cutting type antenna fabrication method is disclosed to have an antenna radiator be formed on a plastic shell by means of spray-painting a metallic spray paint on the surface of the plastic shell and then cutting the metallic coating into shape, and then to cover the plastic shell with a cover layer by means of an insert molding or spray paining technique to have the antenna radiator be enveloped in the cover layer.

Owner:AUDEN TECHNO

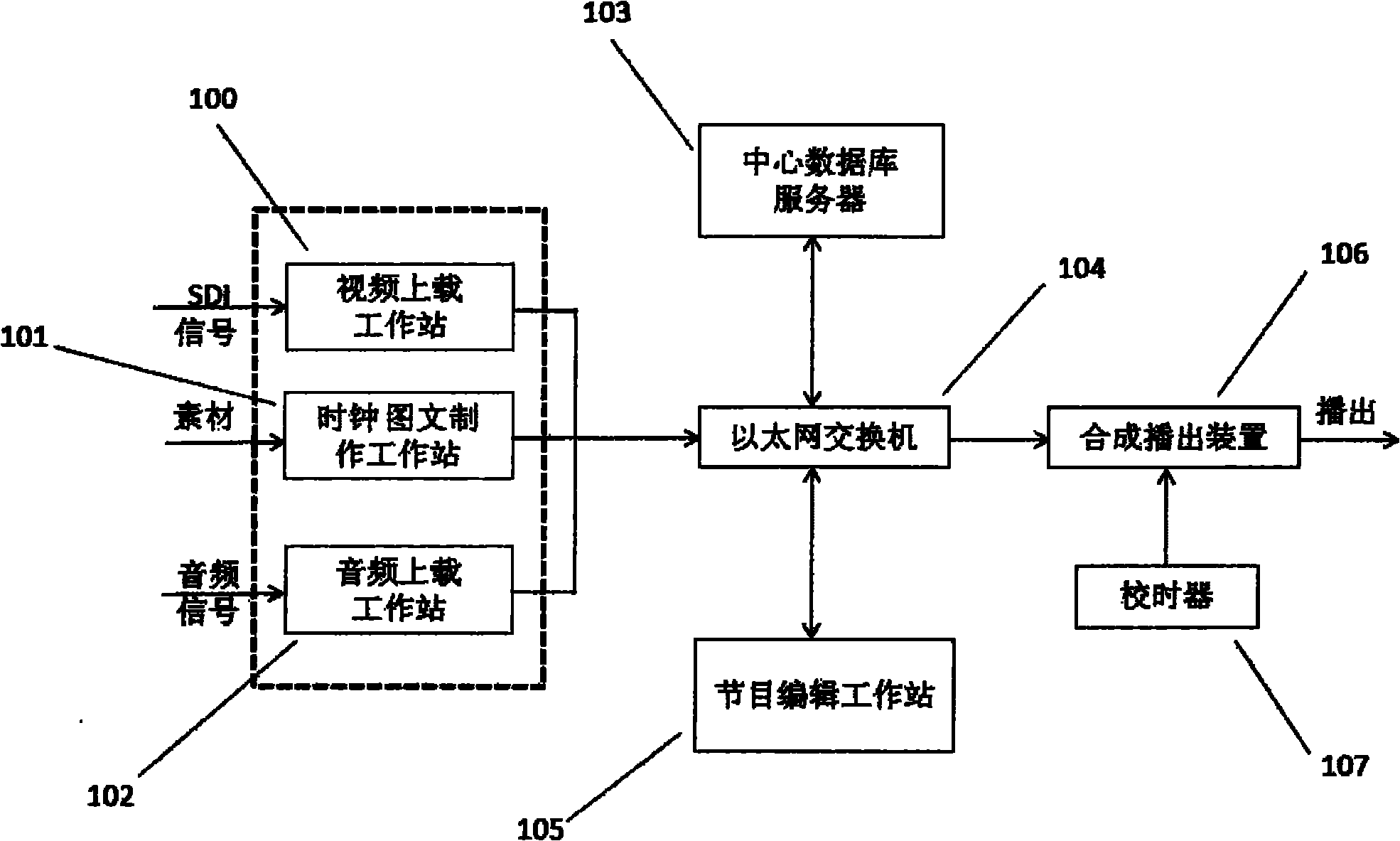

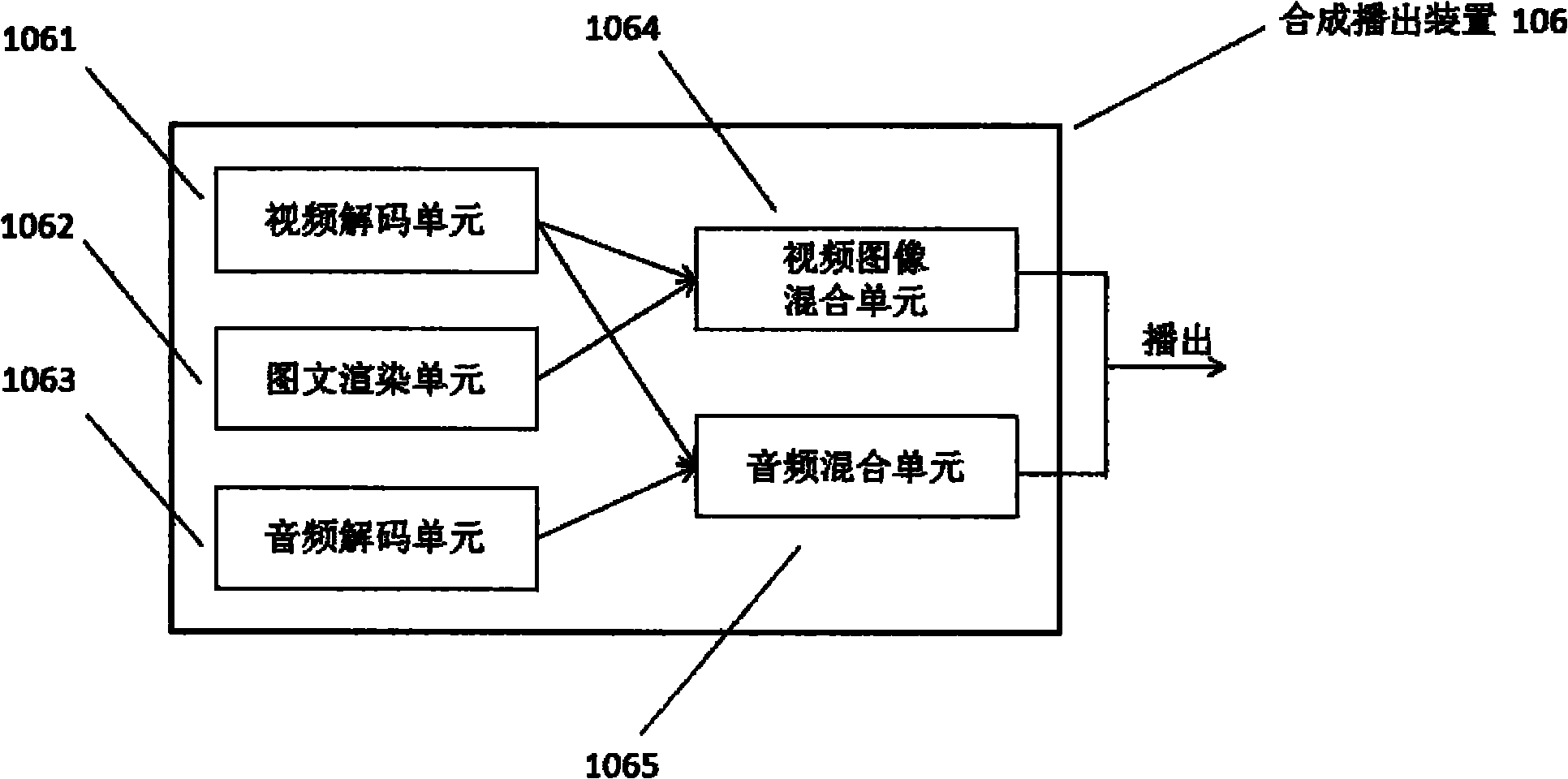

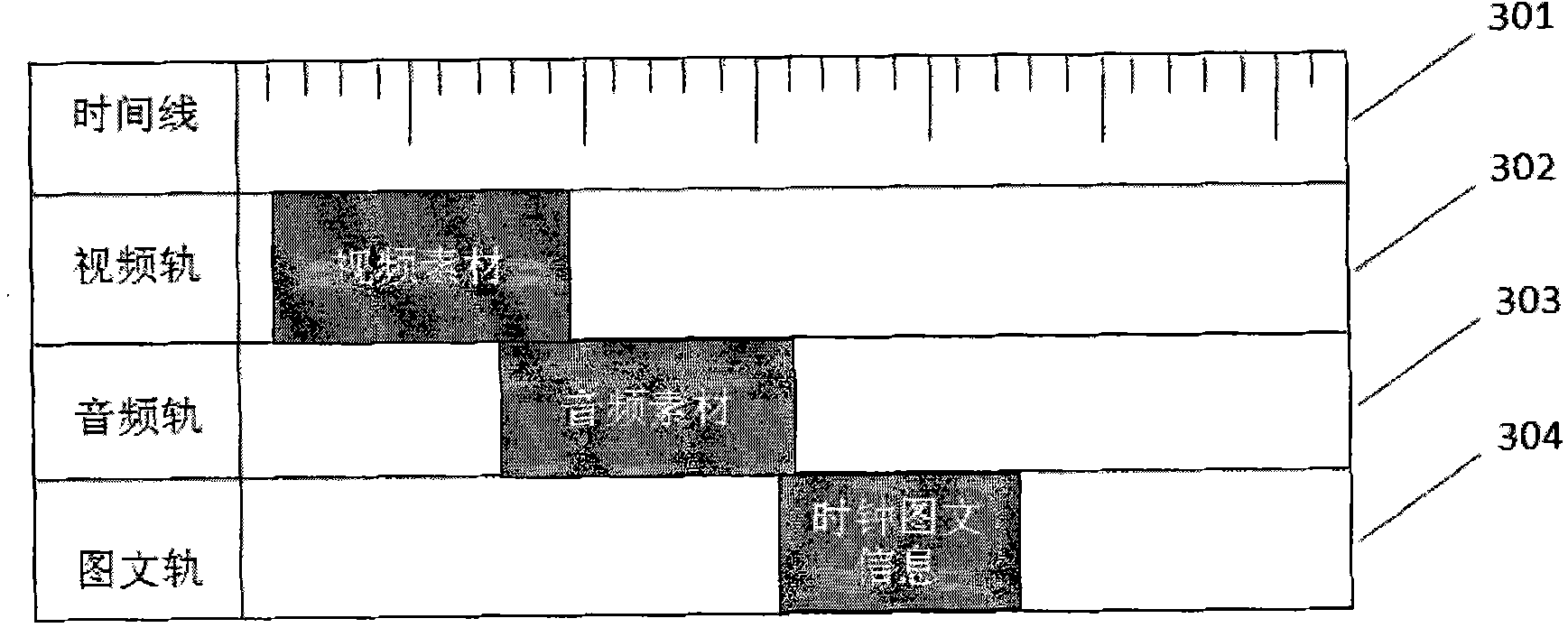

Timing system of on line advertisement for television station and method thereof

ActiveCN101867762ASave manufacturing timeSave resourcesTelevision system detailsSynchronous motors for clocksFir systemTelevision station

The invention provides a timing system of on line advertisement for a television station and a method thereof. The system comprises a video upload workstation for collecting and processing initial advertisement video files, a clock image-text making workstation for making clock image-text information, an audio upload workstation for collecting initial audio files, an ethernet switch for transmitting the video files, the clock image-text information and the audio files, a program editing workstation for performing the EDL code edit to the received video files, the received clock image-text information and the received audio files, packaging and generating the template material, a central data base for receiving and saving the video files, the clock image-text information and the audio files, and receiving and saving the template material, a combining and broadcasting device for combining and broadcasting the template material, and a timing device for synchronous timing of the system time and the standard time. By using the system and the method, the making and the broadcasting of the timing program are more flexible and convenient, and the material can be edited again for use, thereby saving plenty of time and resource.

Owner:IDEAPOOL CULTURE & TECH CO LTD

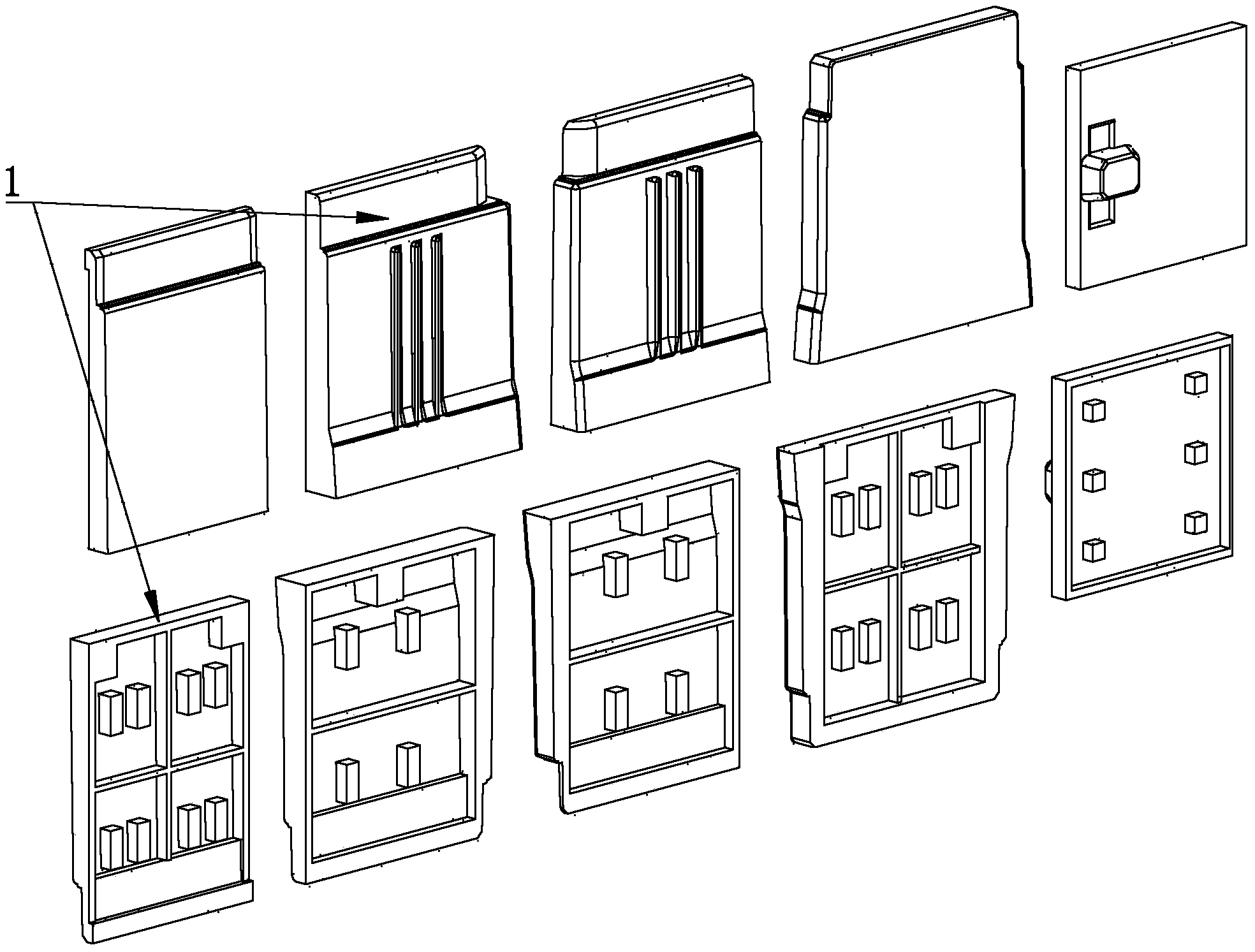

V-method mold for casting electronic appliance mold casting blank

ActiveCN103658525APrecise and stable billet sizeReserved machining allowance is smallFoundry mouldsFoundry coresUltimate tensile strengthRefrigerated temperature

The invention discloses a V-method mold for casting an electronic appliance mold casting blank, and relates to the technical field of aluminum alloy casting. The V-method mold comprises a V-method mold body, wherein the mold body consists of independent combined mold blocks; each combined mold block is subjected to three-dimensional forming and design according to mold drawing requirements; the combined mold blocks are adhered to both sides so as to form the mold body; a plurality of vent holes for vacuuming are formed in the combined mold blocks. The mold casting blank of an inner container of a refrigerator is produced by using a V-method casting process, not only is the energy saved, is the consumption reduced, and is the working intensity alleviated, but also the factory environment is improved, and the V-method is an economic, environment-friendly and green project.

Owner:CHUZHOU JINNUO INDAL

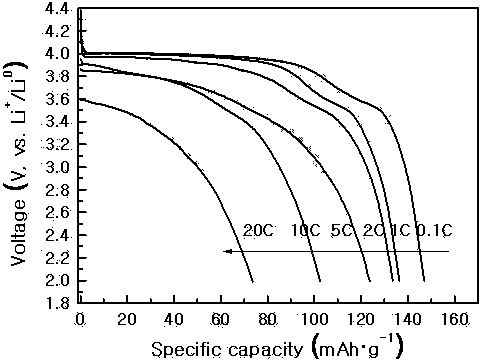

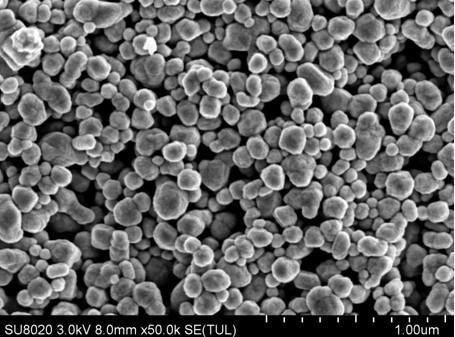

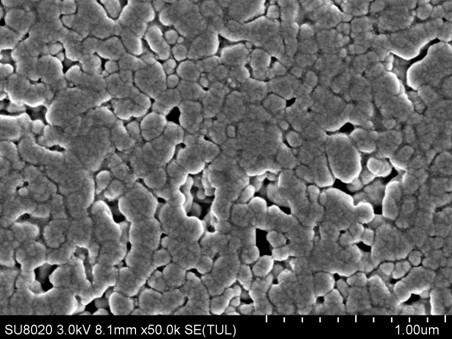

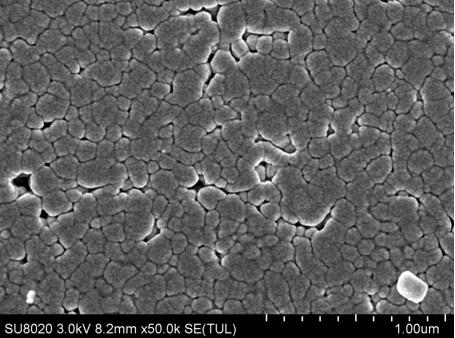

Preparation method for positive electrode material of iron, lithium and manganese phosphate battery

InactiveCN103985871AIncrease profitWith ultra-microporous structureCell electrodesSecondary cellsShielding gasManganese

The invention provides a method for synthesizing a positive electrode material of a nano-level iron, lithium and manganese phosphate battery (Li(FeyMn1-y)XzPO4 / C) which is high in energy density, is provided with a high-discharge-voltage platform and is excellent in conductivity by combining a sol-gel method with a microwave drying method. The method comprises the following steps of a, adding a lithium source, an iron source, a manganese source and metal X salt into ethyl alcohol to prepare sol A; b, adding citric acid into a phosphorus source-containing ethyl alcohol aqueous solution, and adding a carbon source into the phosphorus source-containing ethyl alcohol aqueous solution to obtain a solution B, wherein the carbon source added into the solution B contains 1-5 percent of carbon elements by mass; c, mixing and heating the sol A and the solution B, and adjusting the pH to form gel C; d, performing microwave drying on the gel C to obtain a precursor; e, preparing powder from the precursor, and pre-burning, sintering and screening the powder under protection gas to obtain the positive electrode material of the iron, lithium and manganese phosphate battery.

Owner:宁波艾能锂电材料科技股份有限公司

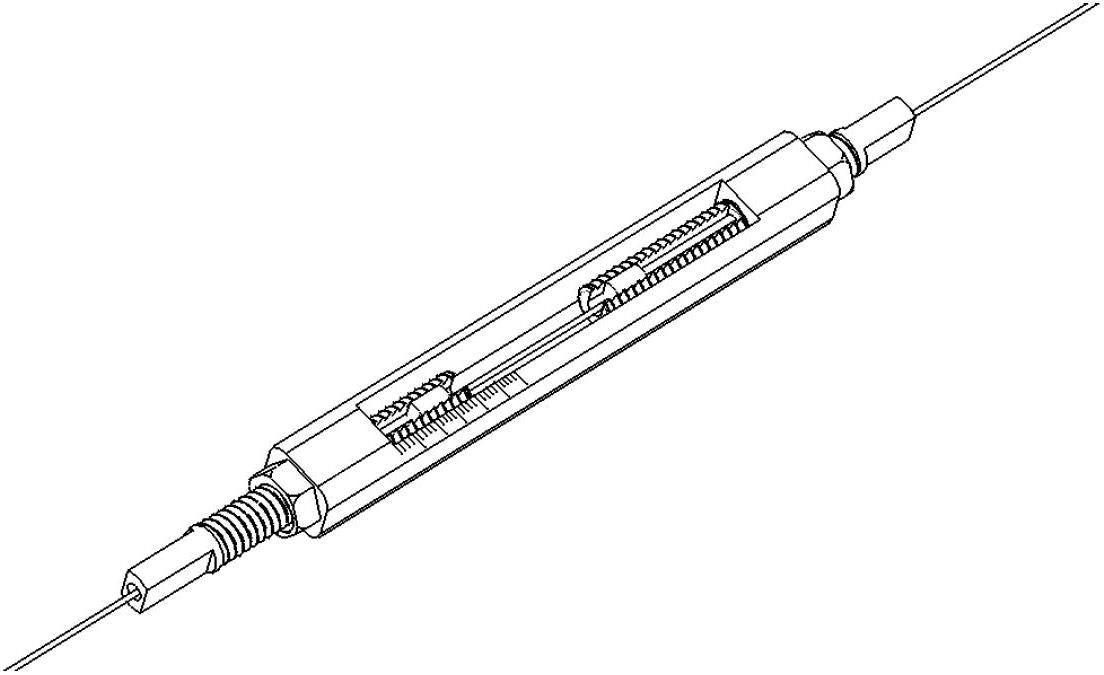

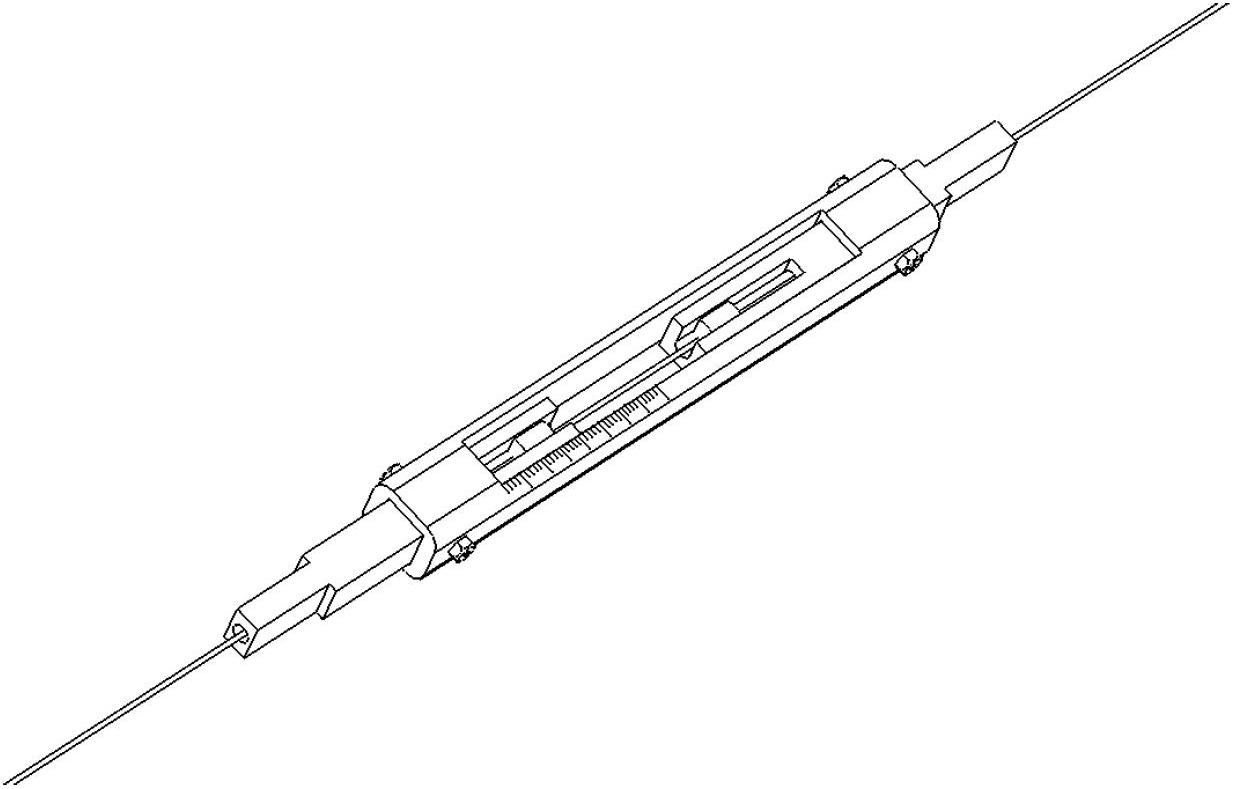

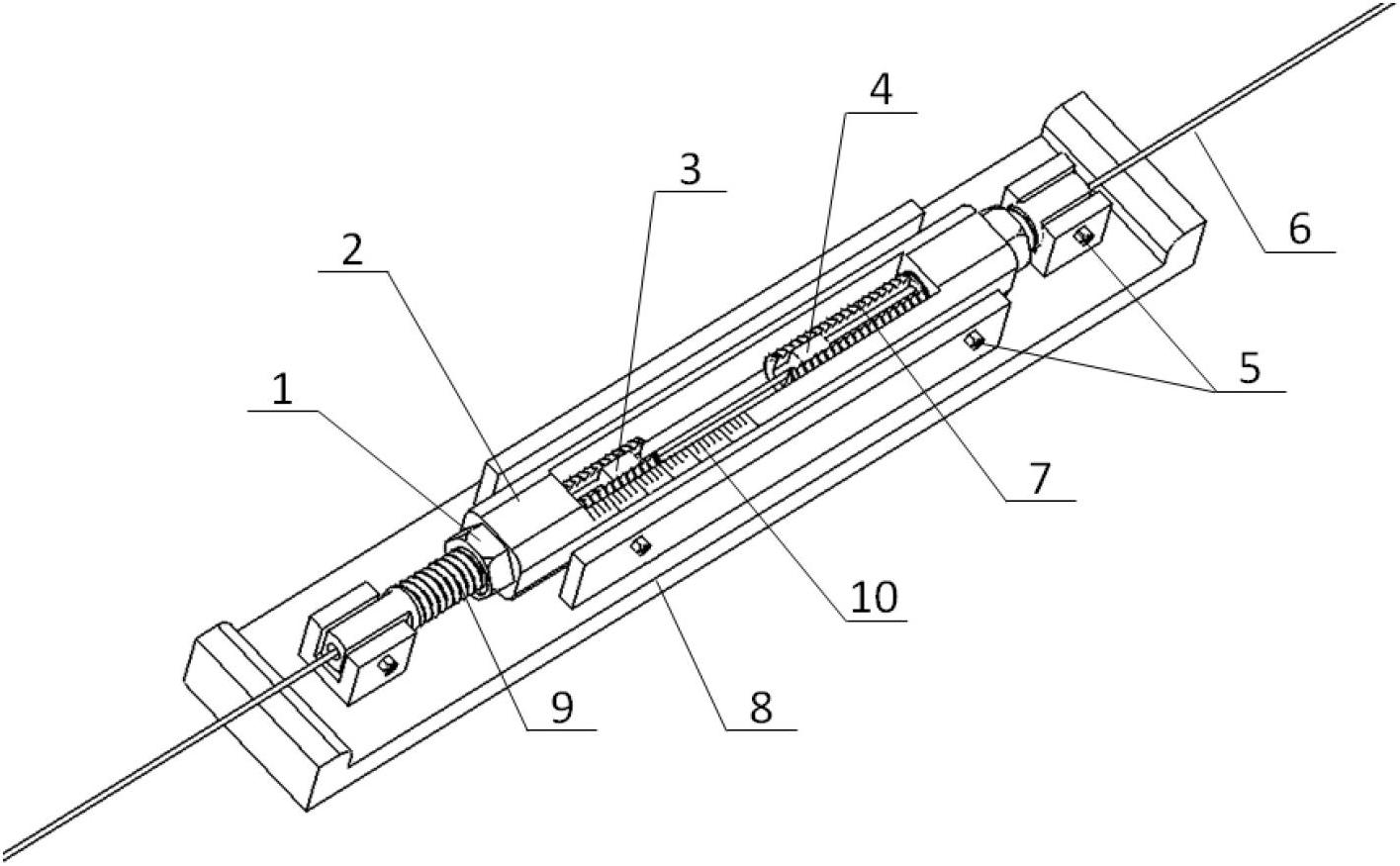

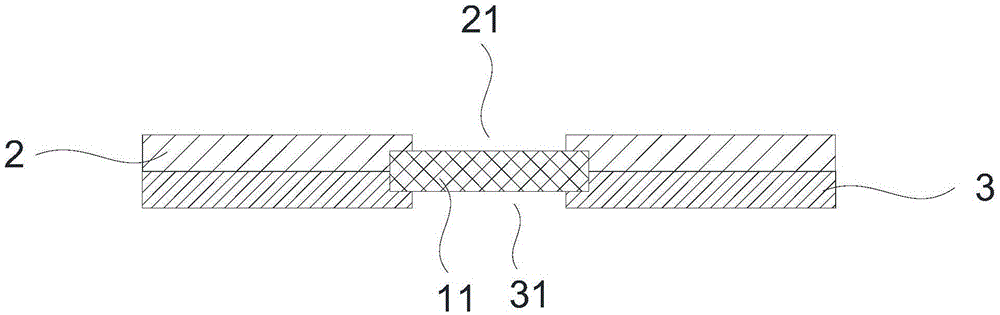

Package method and device for fiber bragg grating with adjustable central wavelength and adjustable temperature coefficient

InactiveCN102636838ASave manufacturing timeSave manufacturing costCladded optical fibreOptical waveguide light guideFiberEngineering

The invention discloses a package method and device for a fiber bragg grating with adjustable central wavelength and an adjustable temperature coefficient. Two ends of a sleeve pipe (the middle section of which is provided with a cavity) are respectively connected with two adapting rods with a low thermal expansion coefficient and a high thermal expansion coefficient through a thread or a slidingrod structure; each adapting rod partially protrudes into the cavity of the sleeve pipe; two tail fibers of the fiber bragg grating are respectively fixed on the adapting rods at the two ends; the two adapting rods as compensation elements change the positions of two fixed points at the tail of the fiber bragg grating along with the changes of the temperature, and further prestress applied to thefiber bragg grating is changed, and thus the temperature compensation is realized; and through regulating the adapting rods at two sides internally or externally at the same time, the central wavelength of the fiber bragg grating can be regulated, and the temperature coefficient of the fiber bragg grating is regulated through rotating or moving the sleeve pipe to regulate the lengths of the two adapting rods protruding into the cavity in the sleeve pipe.

Owner:杭州联光电子有限公司

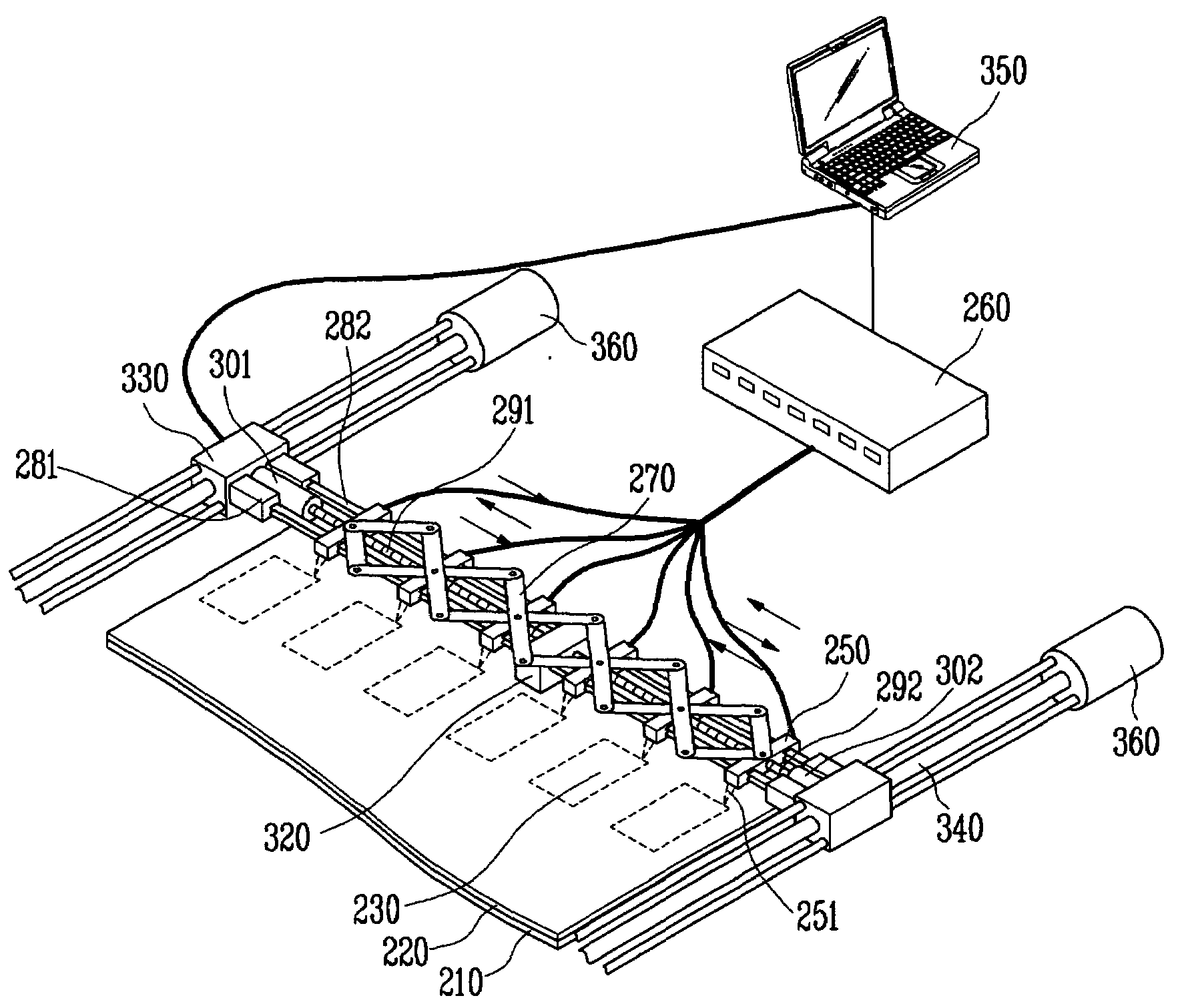

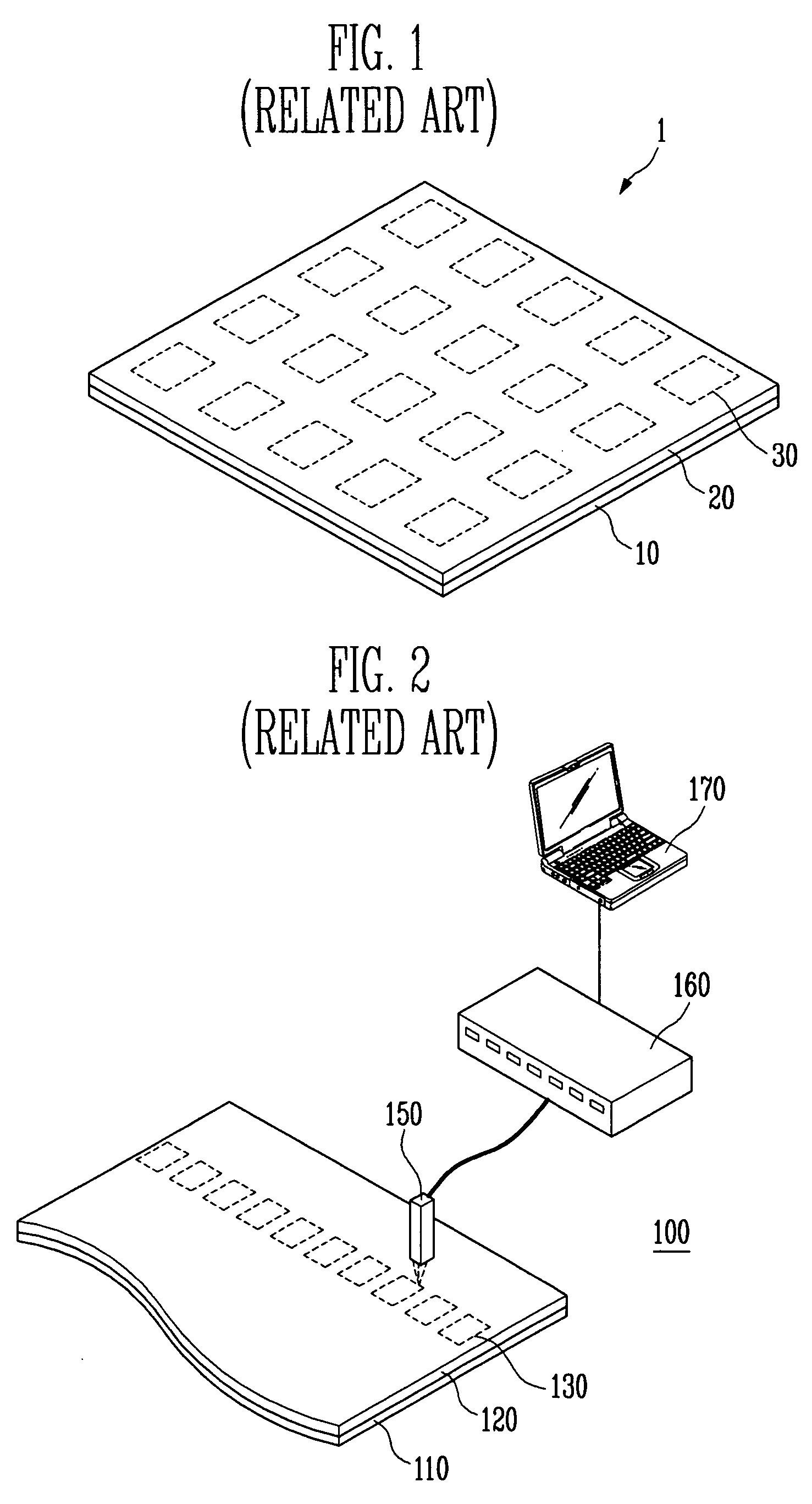

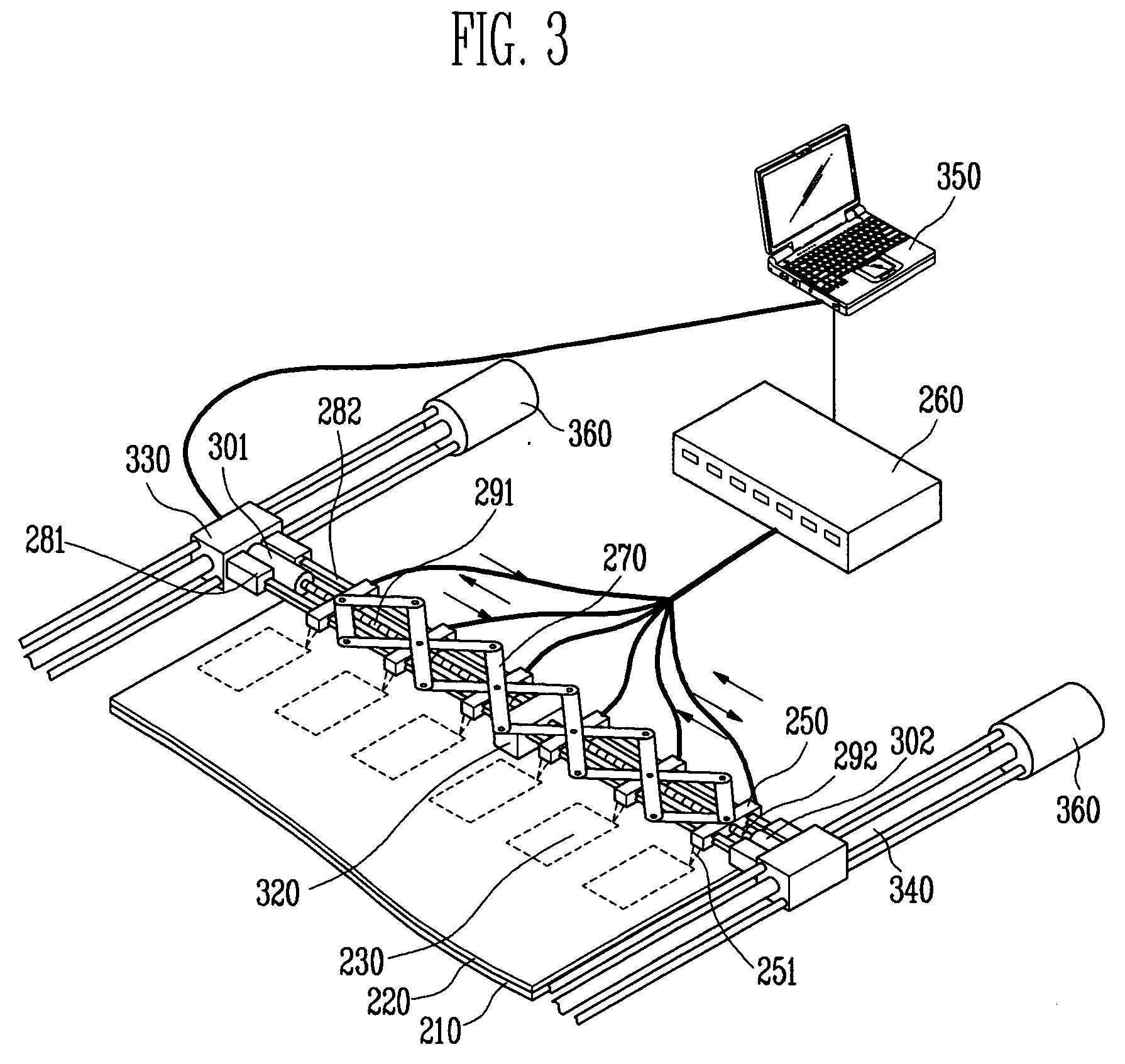

Laser irradiation apparatus

ActiveUS20070211323A1Save manufacturing timeEliminate requirementWindow/door framesLaser beam welding apparatusIrradiation laserOptoelectronics

A laser irradiation apparatus includes a plurality of laser heads from which a laser is irradiated, can adjust arranged intervals of the laser heads, and moves freely to irradiate the laser along a shape of a subject. A laser oscillator oscillates a laser. A plurality of laser heads linearly irradiate the laser oscillated by the laser oscillator. A first driving means adjusts arranged intervals of the laser heads, and moves the laser heads in an X direction. A second driving means moves the laser heads in a Y direction different from the X direction.

Owner:SAMSUNG DISPLAY CO LTD

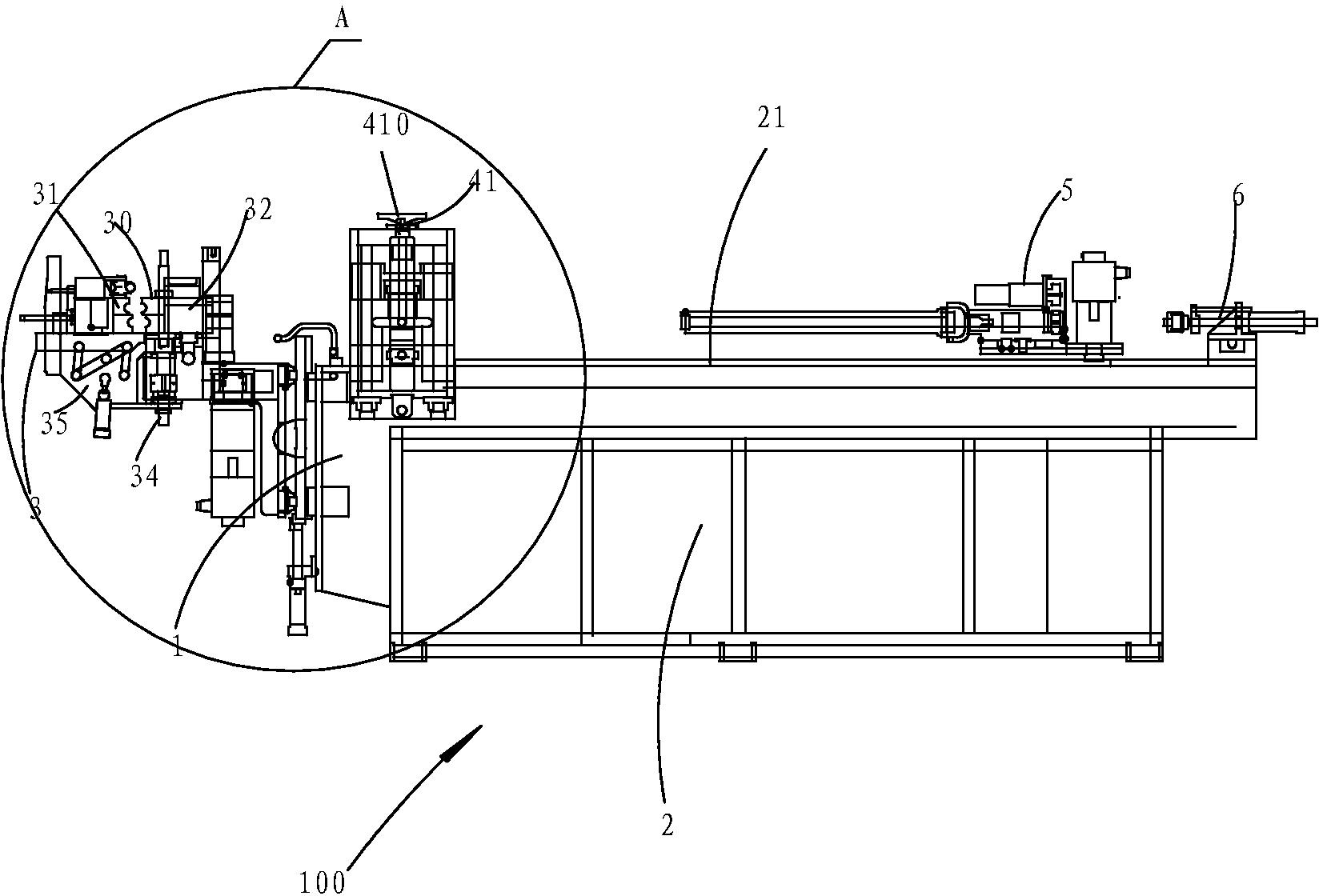

Punching and bending integrated machine

The invention discloses a punching and bending integrated machine which comprises a machine head, a machine body, a pipe bending mechanism, an avoidance machine base, a feeding device and a core-pulling device, wherein the pipe bending mechanism is installed on the machine head; the avoidance machine base is installed on the machine body; the avoidance machine base is provided with a die installation seat and a die regulation device; a punching mechanism is installed on the die installation seat and comprises an upper punching die, a lower punching die, a punching core die, an avoidance clamping oil cylinder and a punching oil cylinder; the punching core die is arranged on the end surface of a piston rod of the punching oil cylinder and fixedly connected with the piston rod; the pipe bending mechanism consists of a pipe bending die, a clamping die, a jacking die, a pipe bending oil cylinder, a pipe bending spindle and a pipe bending arm fixed on the pipe bending spindle; the machine body is provided with a first guide rail and a second guide rail; the avoidance machine base moves on the first guide rail of the machine body through a servo motor and a ball screw; and the feeding device moves on the second guide rail of the machine body. By using the punching and bending integrated machine, die cost can be reduced, and debugging time and manufacturing time can be shortened.

Owner:ZHANGJIAGANG MINGHUA MACHINERY MFG

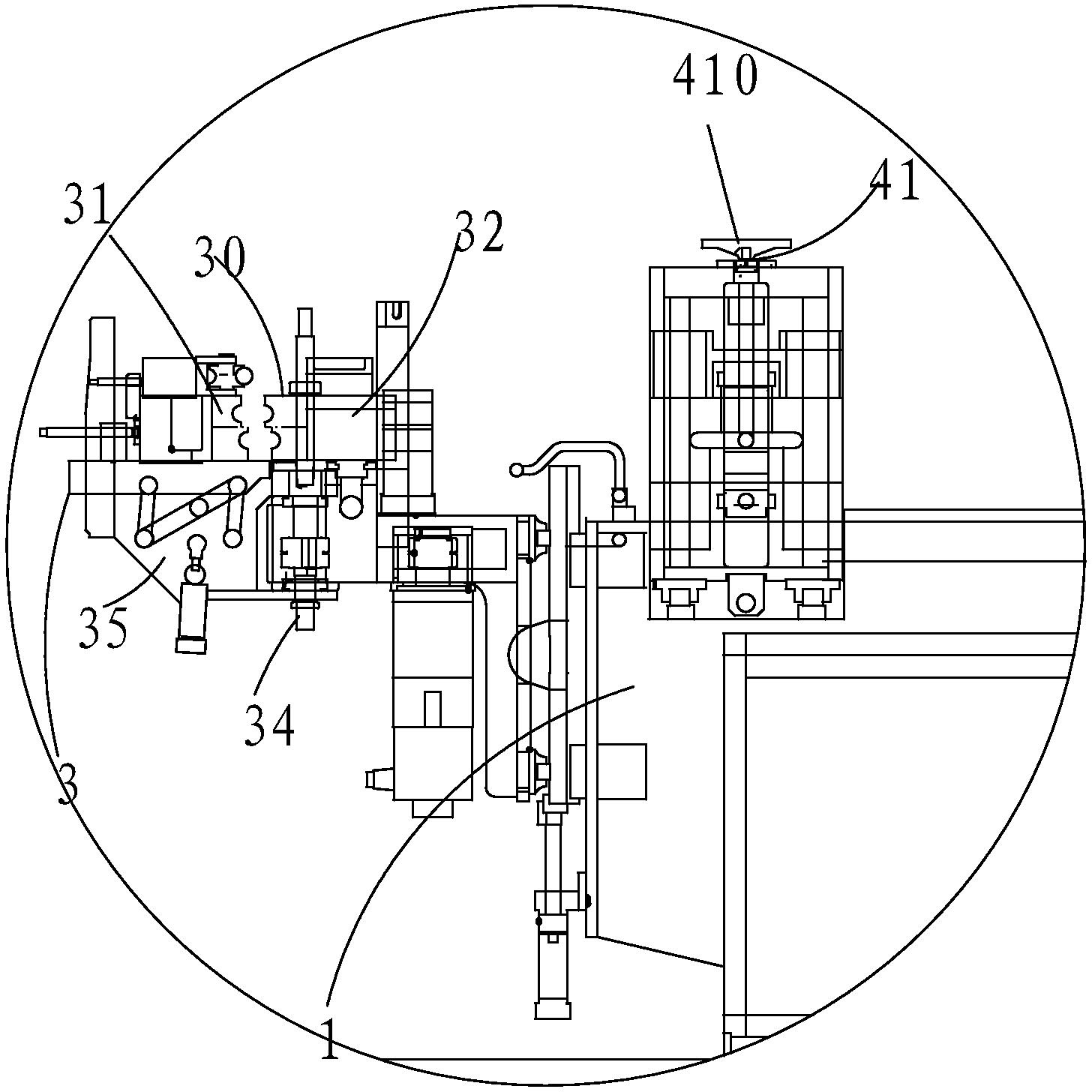

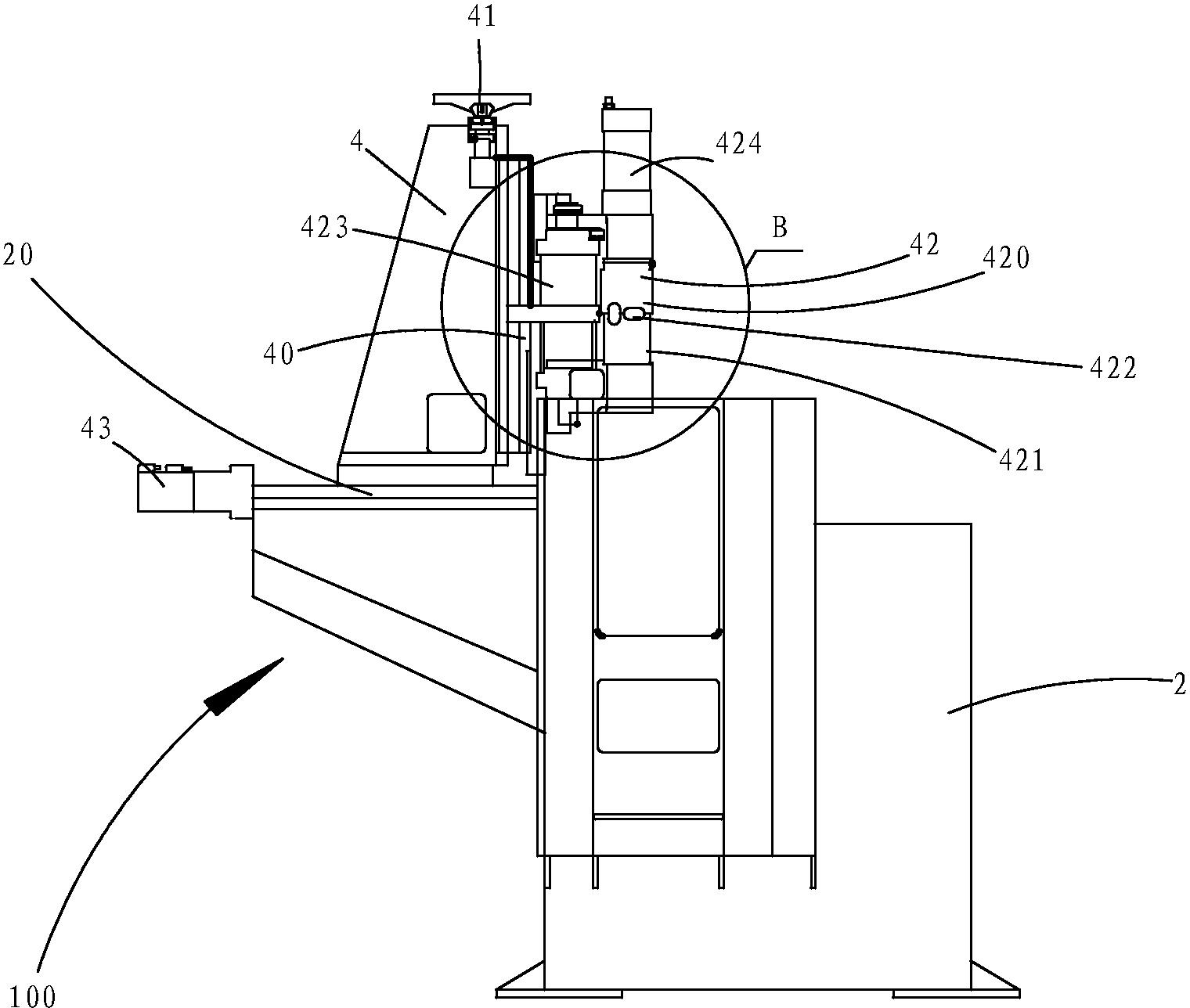

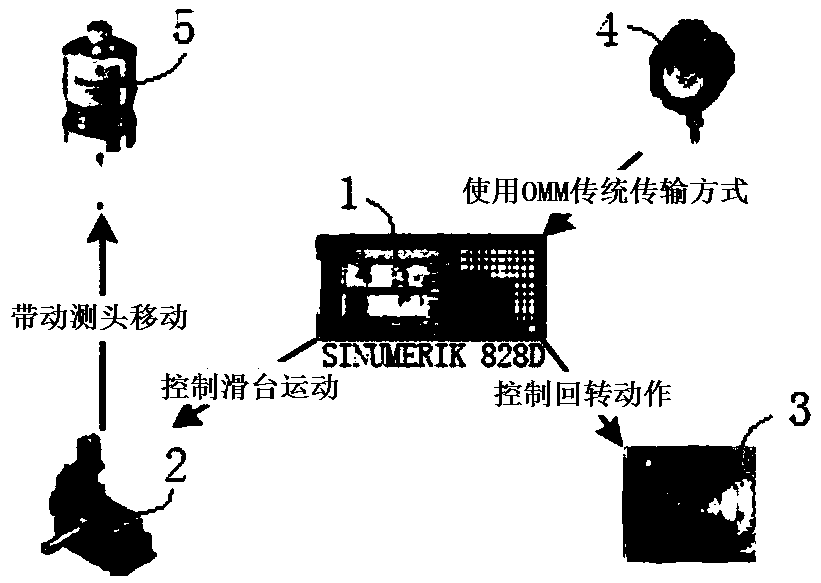

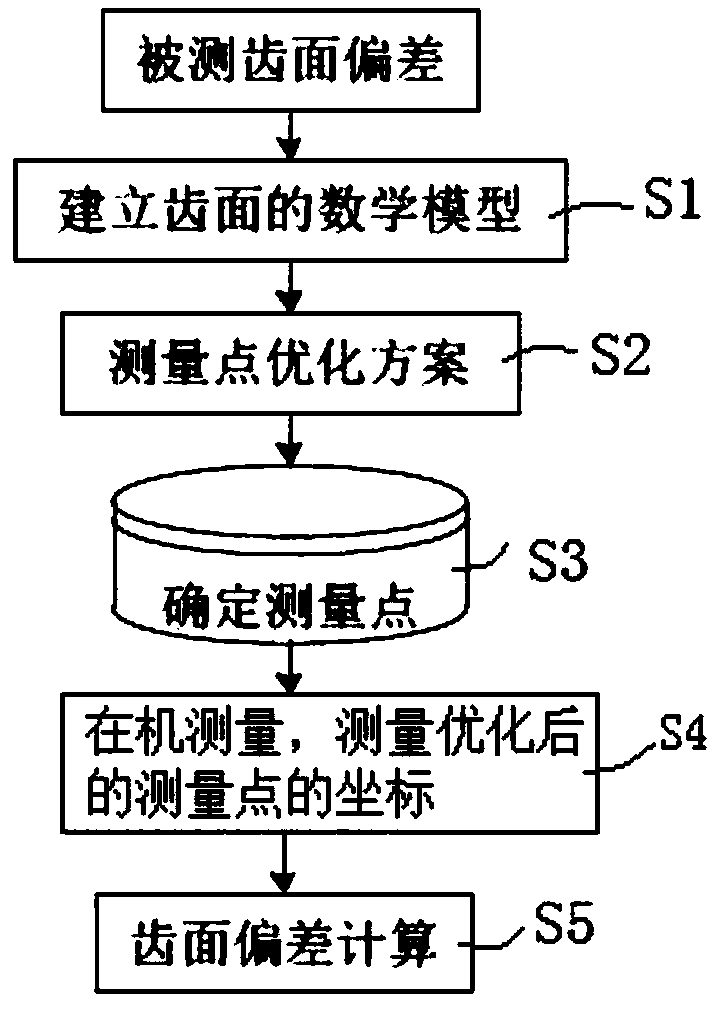

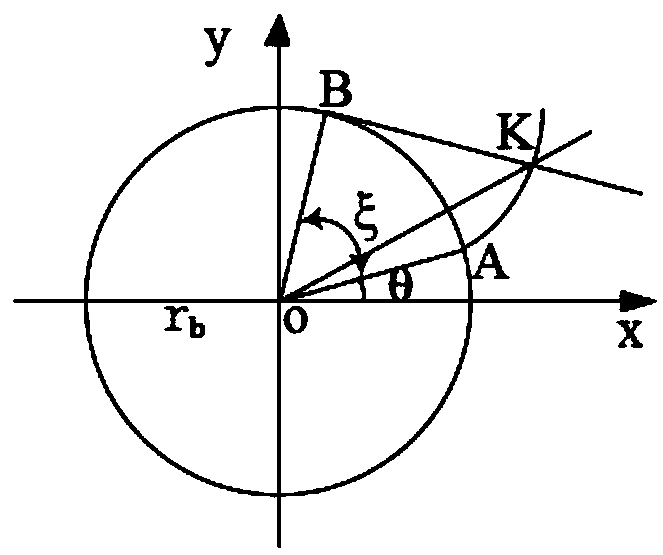

On-machine measurement method for tooth surface deviation of spur gear

InactiveCN108645301AImprove measurement efficiencySave manufacturing timeMeasuring wheelsNumerical controlMeasurement testing

The invention discloses an on-machine measurement method for a tooth surface deviation of a spur gear. The method comprises the following steps that a) a gear tooth surface measuring model is established, and a gear tooth surface point K equation is derived according to a point K equation in an involute tooth profile; and b) measurement points in the on-machine measurement point of the tooth surface deviation are planned, and an optimization scheme is provided for the measurement points selected in the on-machine measurement process according to the established gear tooth surface measuring model. After that a measurement area in the tooth surface is determined, a measurement point number plan based on the normal curvature radius and a measurement point distribution plan based on a Hammersley sequence are provided. According to the method, an on-machine measurement testing stand is formed by adding a Renishaw probe system to a present structure based on a numerical control gear grindingmachine, and on-machine measurement is realized. A gear to be measured is measured in the on-machine measurement gear testing stand, and a measuring result of the tooth surface deviation of the gearis obtained.

Owner:NANJING INST OF TECH

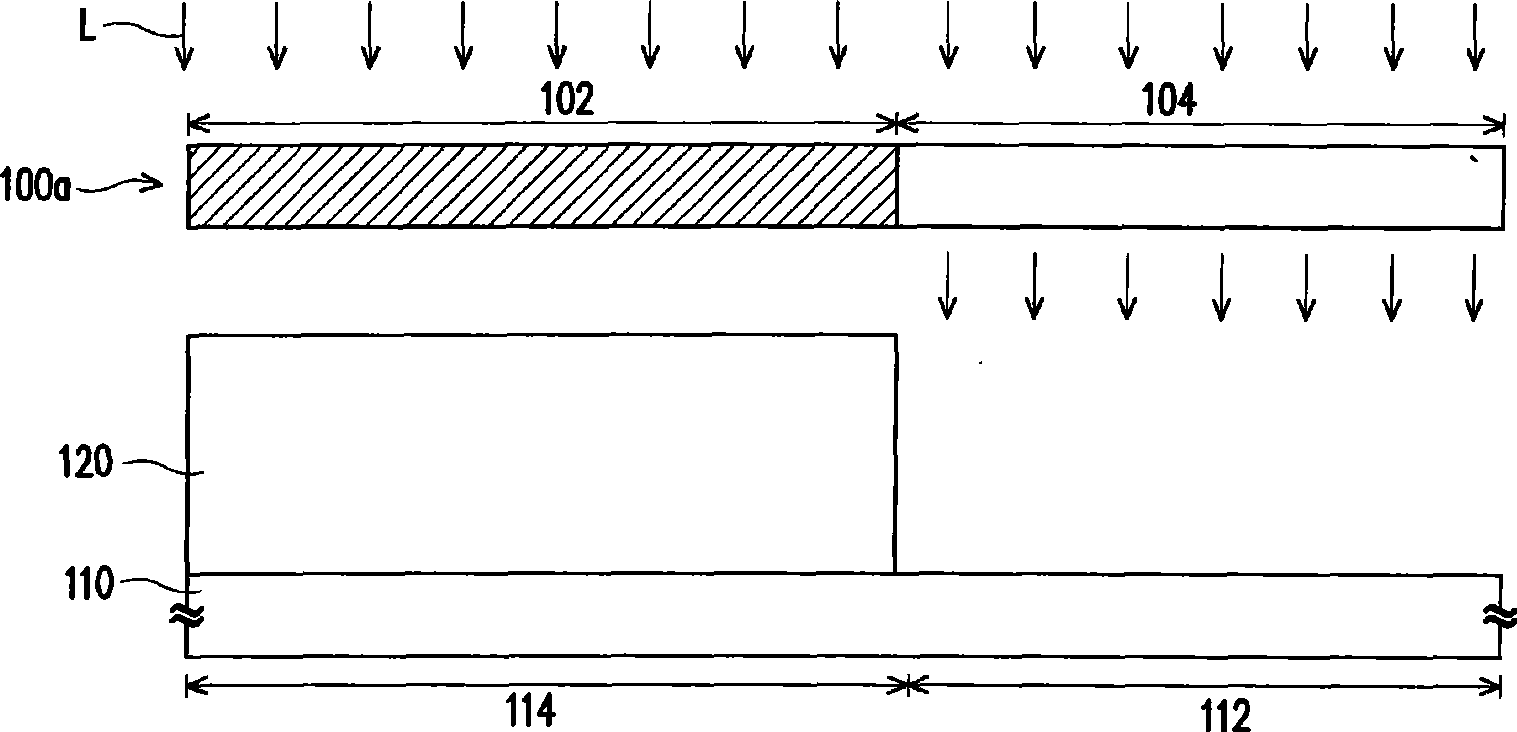

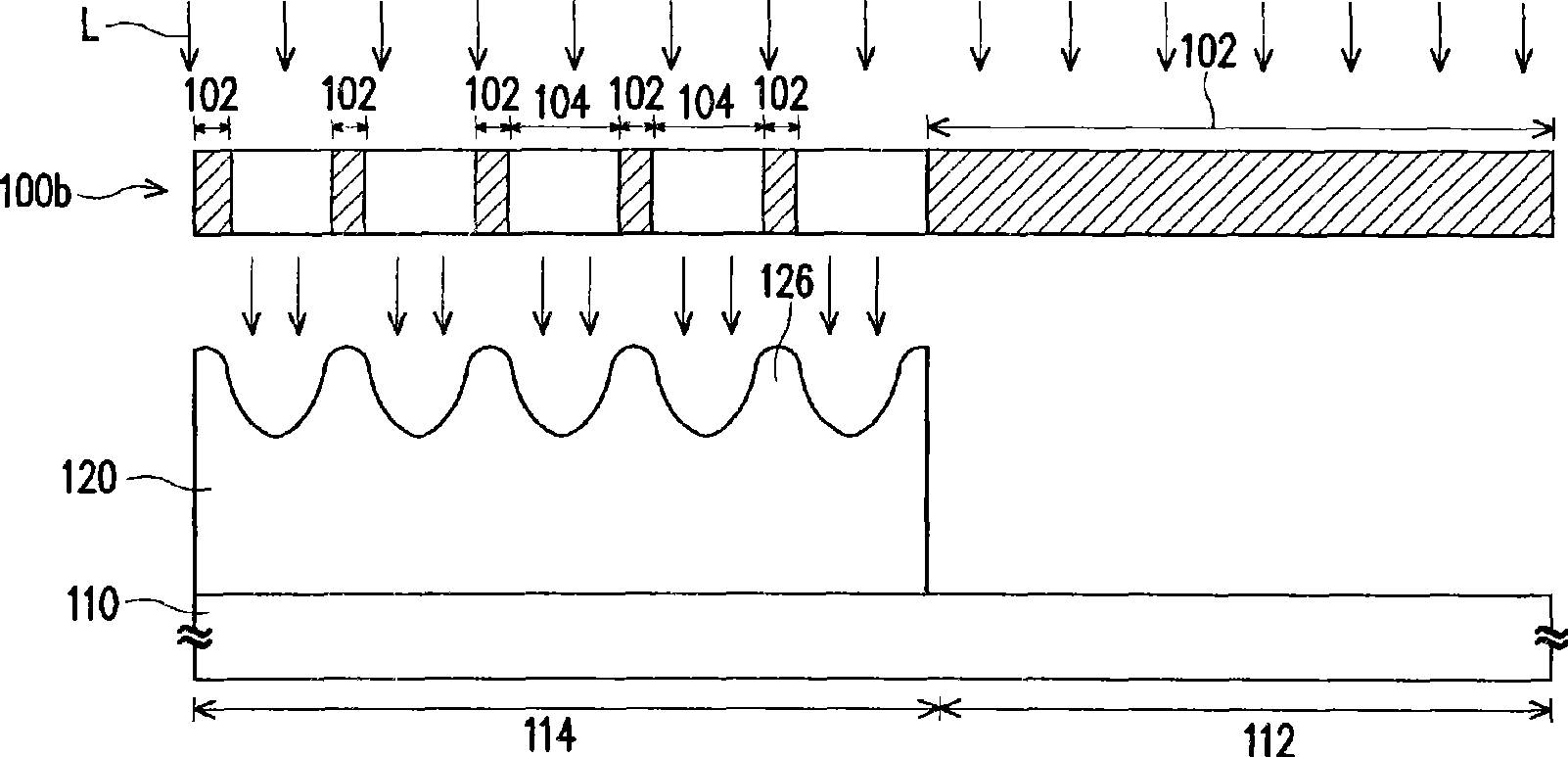

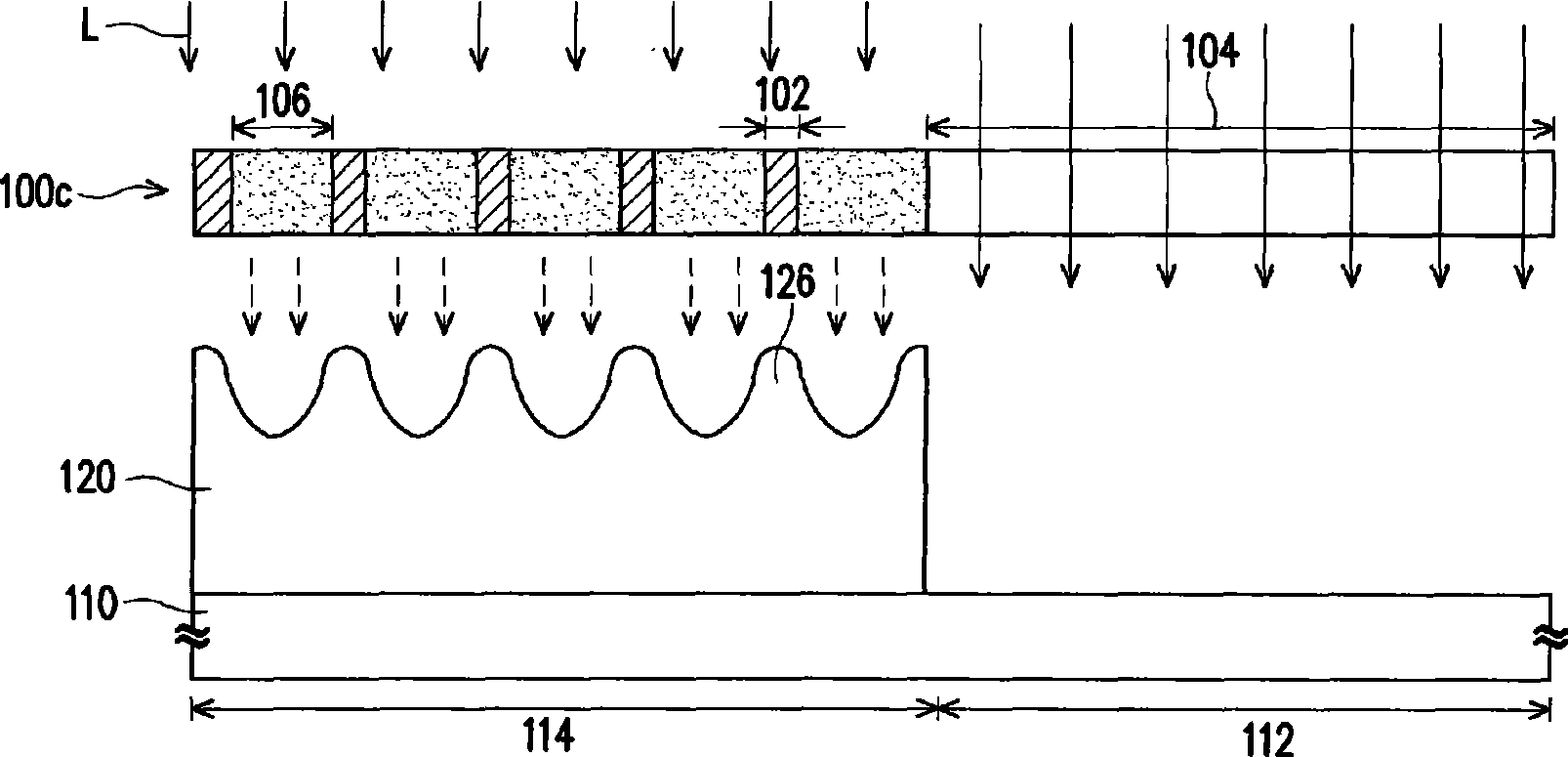

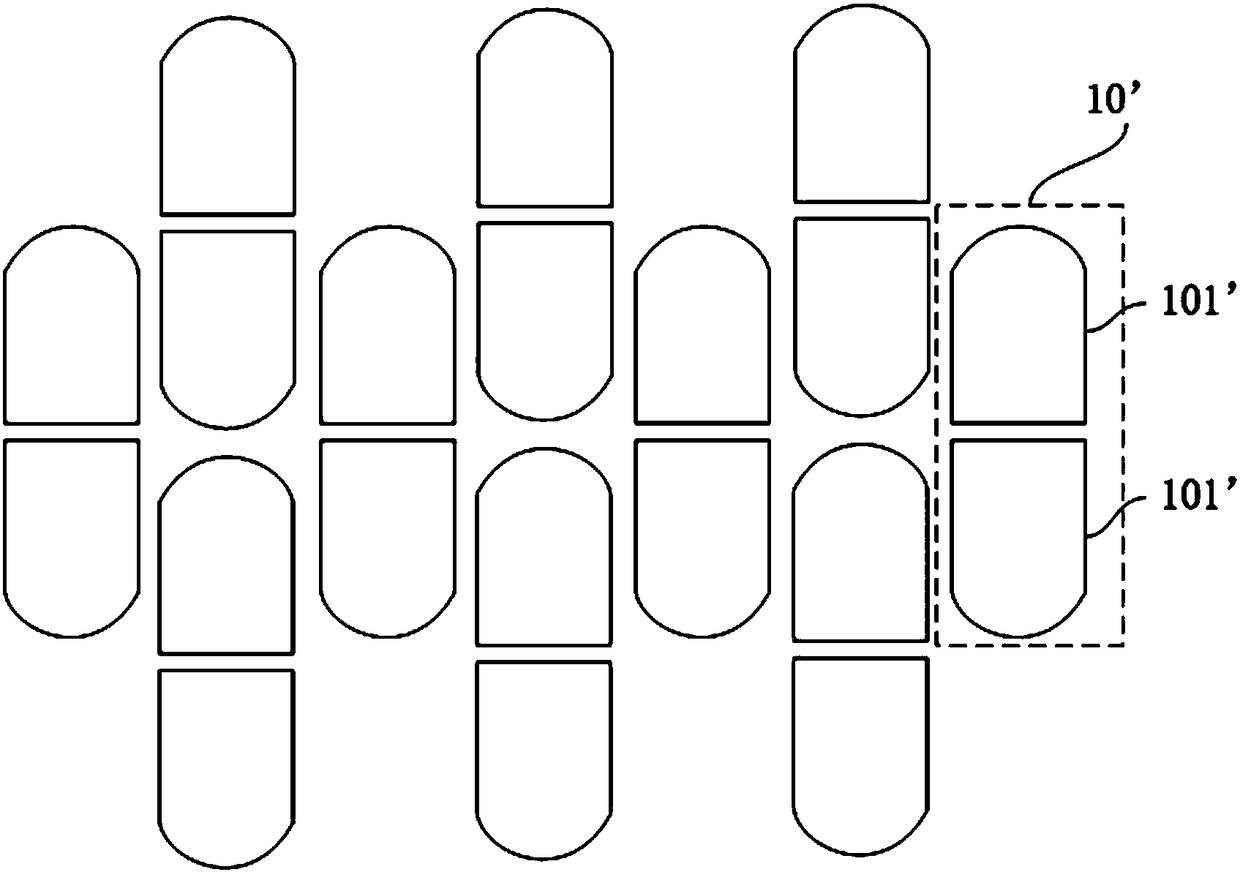

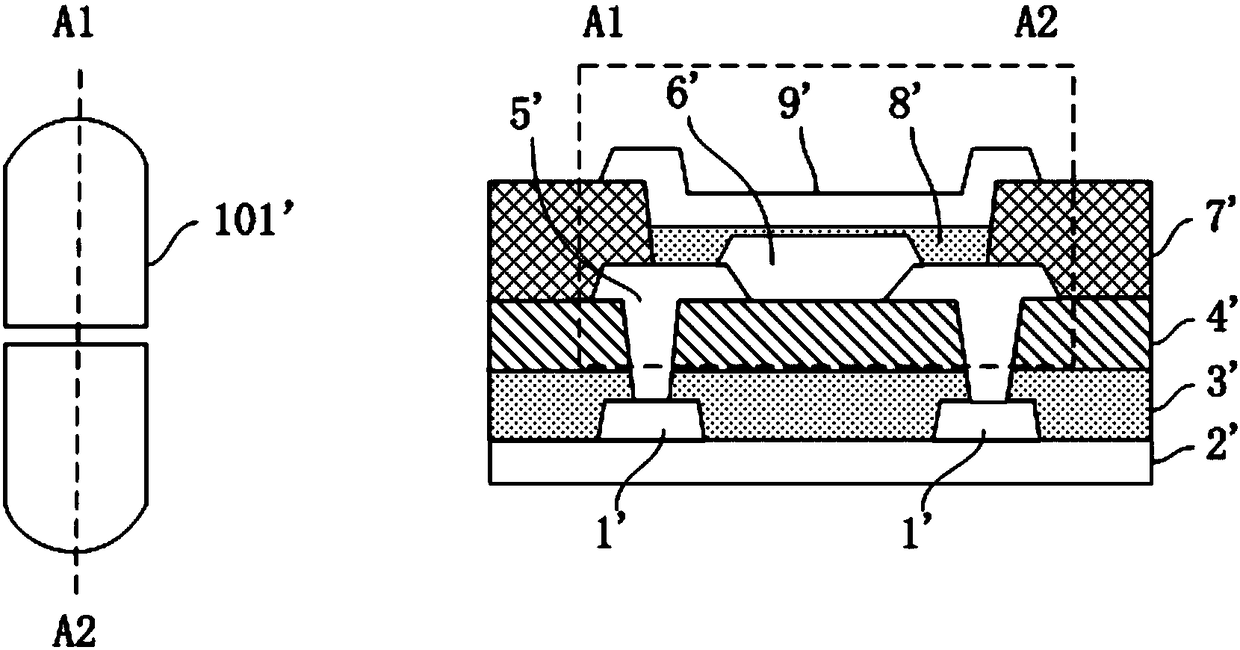

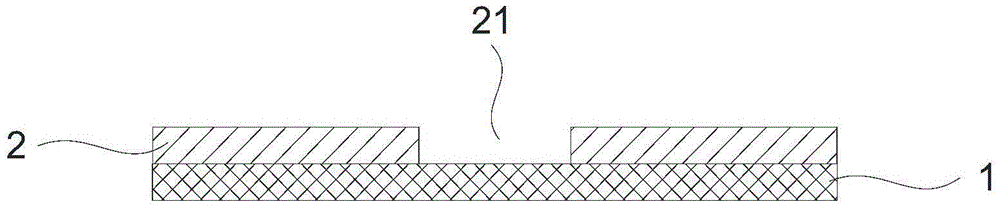

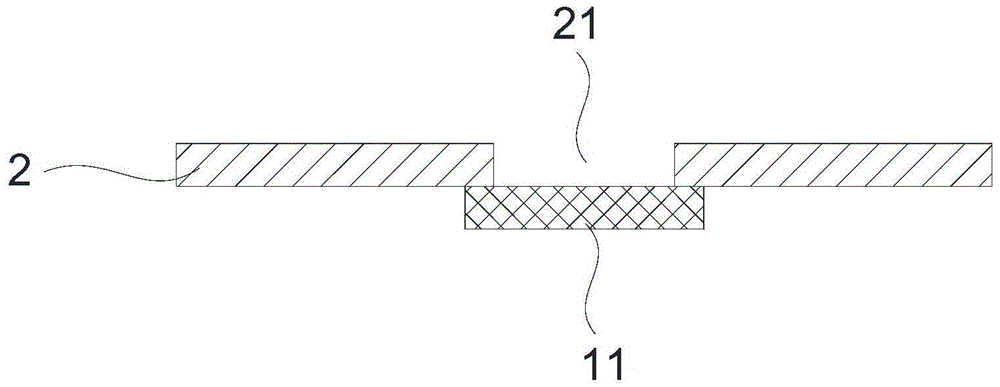

Production method for asymmetric prominence and picture element structure

InactiveCN101499414AUniform heightSave manufacturing timeSemiconductor/solid-state device manufacturingNon-linear opticsNon symmetricOptoelectronics

Owner:CHUNGHWA PICTURE TUBES LTD

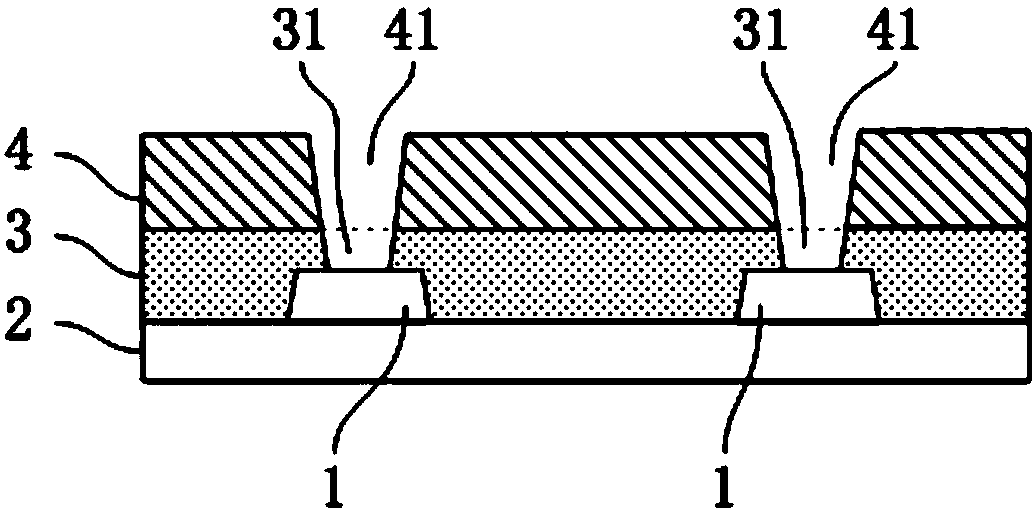

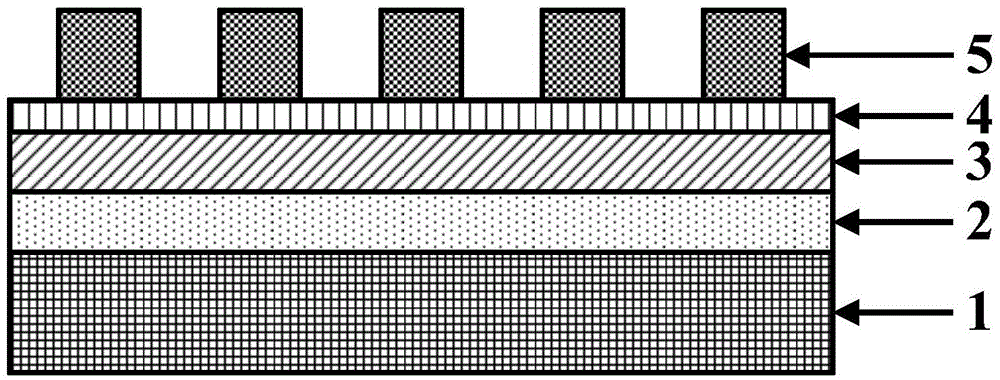

Inkjet printing OLED display panel and preparation method thereof

ActiveCN108565357ALower the altitudeSave manufacturing timeSolid-state devicesSemiconductor/solid-state device manufacturingGraphicsEngineering

The invention provides an inkjet printing OLED display panel and a preparation method thereof. The method comprises the steps that a passivation layer and a flat layer are successively formed on a glass substrate on which at least one pair of thin film transistors are prepared, and the passivation layer covers at least one pair of thin film transistors; at least one pair of via holes are formed onthe passivation layer and the flat layer; at least one pair of anodes are prepared on the flat layer, and the anodes are electrically connected with the thin film transistors through the via holes arranged on the flat layer and the passivation layer; a pixel defining layer is deposited on the flat layer to cover the anodes; the pattern of the pixel defining layer is defined by using a halftone photomask so that the region arranged on the anodes of the pixel defining layer is enabled to form a notch, and the height of the pixel defining layer between the anodes is reduced; and a light-emittinglayer is prepared in the notch by using the inkjet printing technology. A photomask can be saved, the performance of the thin film transistors in the inkjet printing OLED display panel can be improved without reducing the mobility of the thin film transistors, and threshold voltage drift can also be effectively suppressed.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

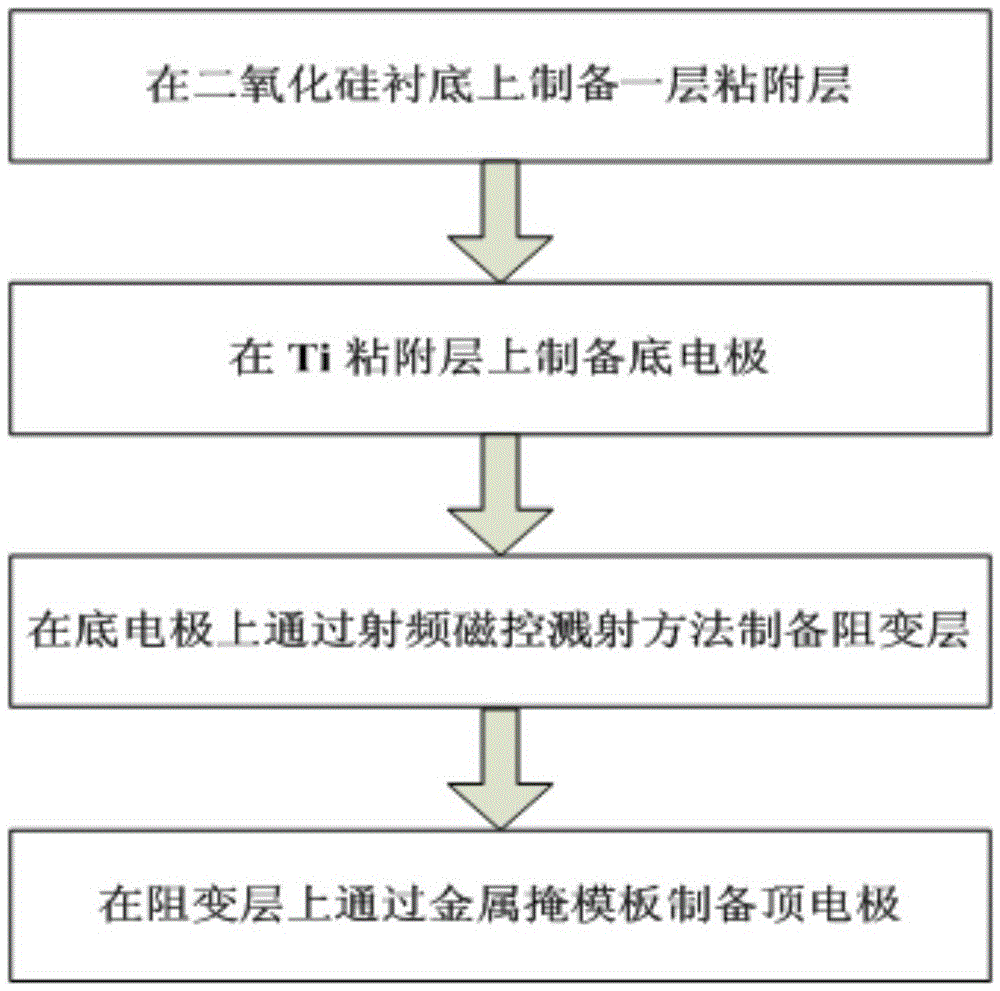

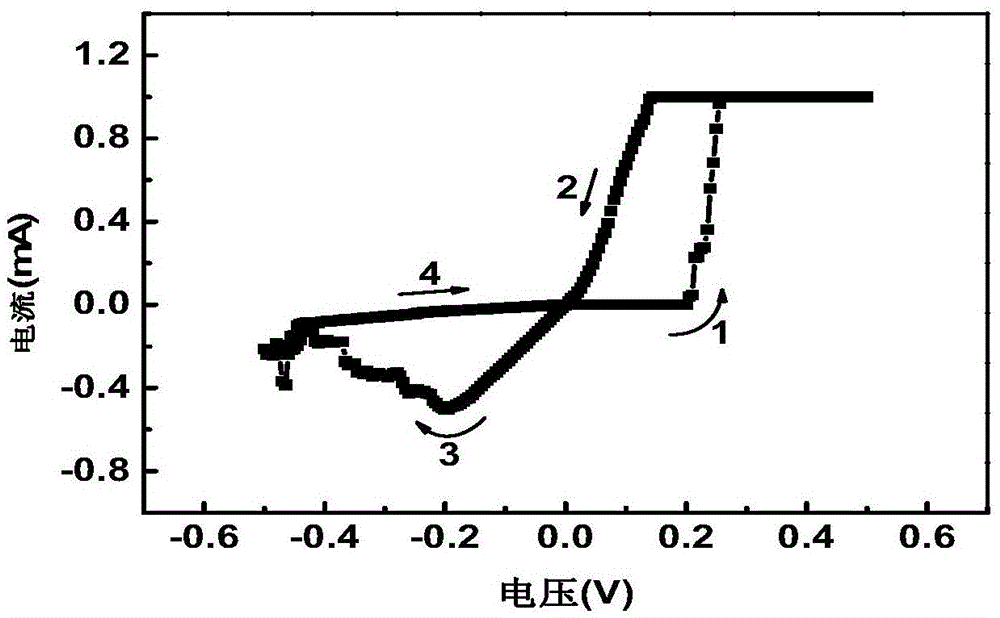

Silicon oxide thin film based low power consumption resistive random access memory and preparation method therefor

InactiveCN105552220ALow powerReduce power consumptionElectrical apparatusStatic random-access memoryRadio frequency magnetron sputtering

The invention discloses a silicon oxide thin film based low power consumption resistive random access memory. The low power consumption resistive random access memory comprises a substrate, a Ti adhesion layer, a bottom electrode, a resistance variable layer and a top electrode that are overlaid in sequence; the resistance variable layer is the silicon oxide thin film with a loose structure; the preparation method for the resistive random access memory comprises the following steps of preparing the Ti adhesion layer on the substrate; preparing a Pt bottom electrode on the Ti adhesion layer; and preparing the silicon oxide thin film resistance variable layer on the Pt bottom electrode through a radio frequency magnetron sputtering method, wherein the process conditions of the radio frequency magnetron sputtering are as follows: a silicon oxide target is taken as the sputtering target material; the cavity pressure is less than 5*10<-6>Torr; the sputtering temperature, sputtering pressure, sputtering power, argon flow and volume fraction of oxygen are properly controlled; and preparing a point-like metal Ag thin film on the resistance variable layer through a direct current magnetron sputtering method on the resistance variable layer to be used as the top electrode to obtain the resistive random access memory. The resistive random access memory has the advantages of low preparation temperature, and low operating voltage.

Owner:NAT UNIV OF DEFENSE TECH

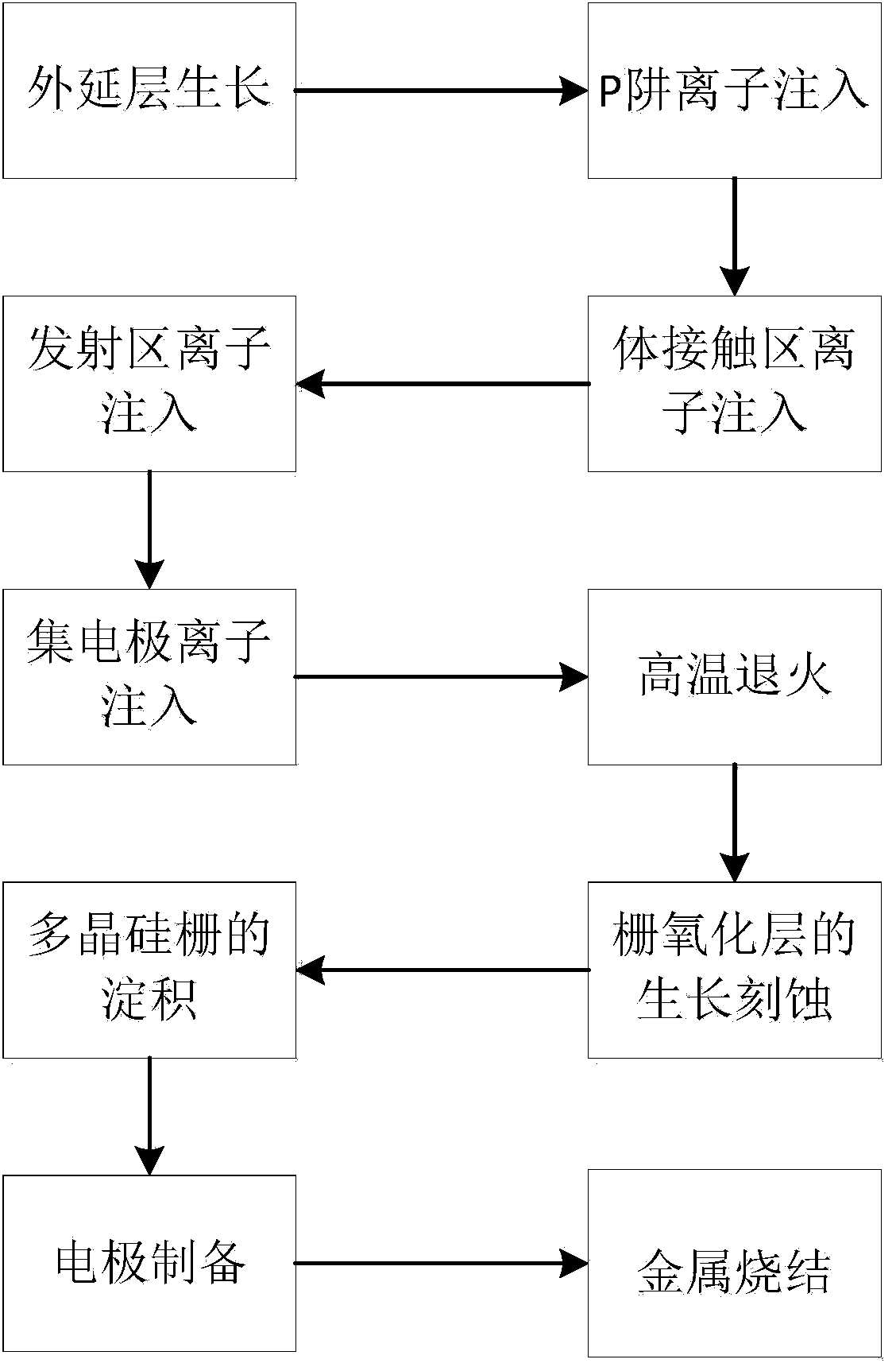

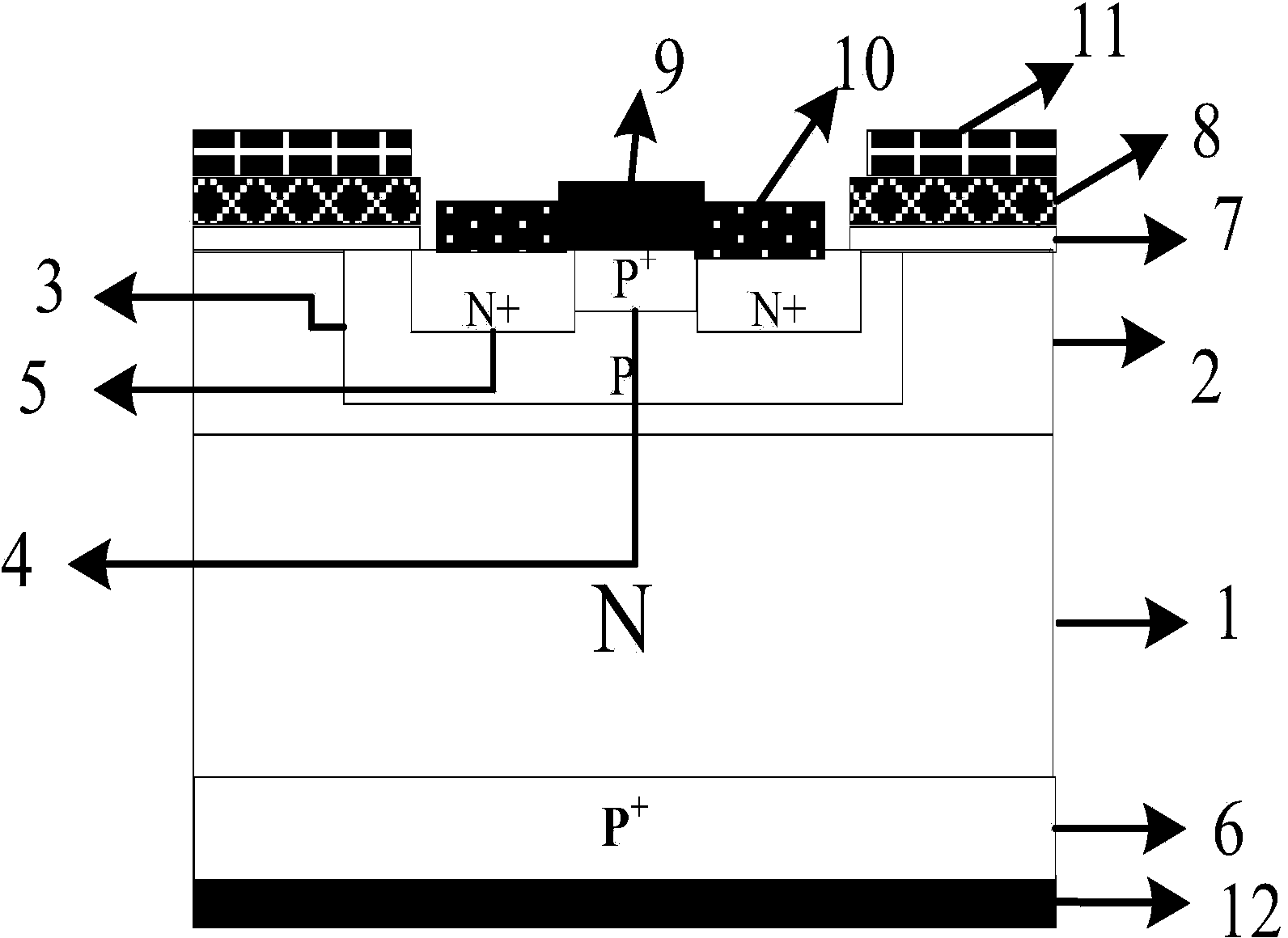

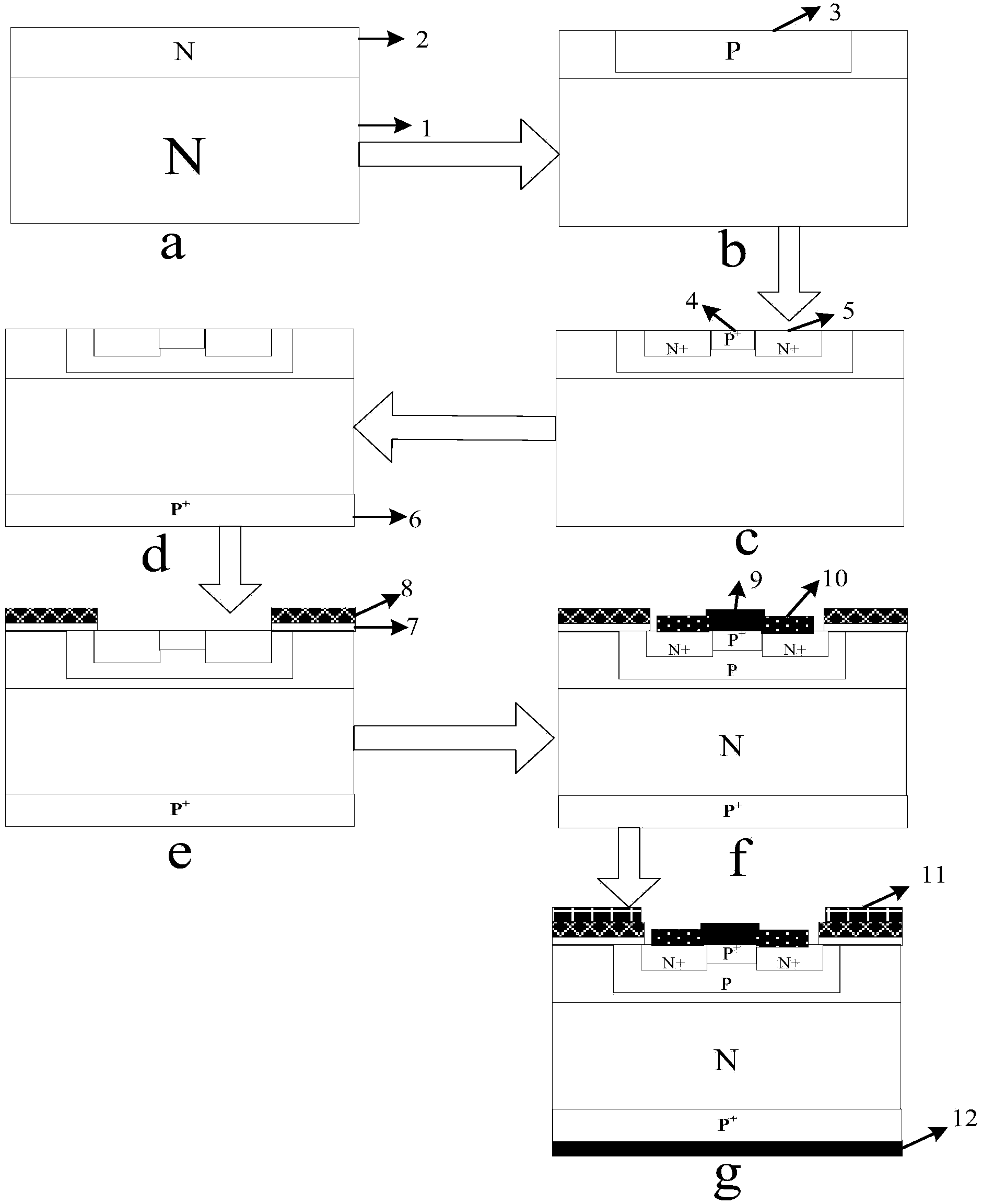

Method for manufacturing N-channel silicon carbide insulated gate bipolar transistor

ActiveCN103928309AEliminate the epitaxial processReduce manufacturing difficultySemiconductor/solid-state device manufacturingSemiconductor devicesBody contactParasitic bipolar transistor

The invention discloses a method for manufacturing an N-channel punch-through silicon carbide insulated gate bipolar transistor. The method mainly solves the problem that currently, the manufacturing cost of the silicon carbide insulated gate bipolar transistor is too high. The method includes the implementation steps that first, an N-type silicon carbide substrate with excellent structural performance is selected, and an N-type epitaxial layer is grown on the front face of the substrate in an epitaxial mode; second, a P well region, a P+ body contact region and an N+ emitter region are sequentially formed on the epitaxial layer of the substrate through ion implantation; third, ion implantation of a P+ collector region and high-temperature annealing are performed on the back face of the substrate, and implanted impurities are activated; fourth, an etching gate oxide layer is grown on the front face of the substrate, and a polysilicon gate is deposited; fifth, metal is deposited on the front face and the back face of the substrate respectively, and electrodes are led out. Compared with an existing method, the method for manufacturing the N-channel silicon carbide insulated gate bipolar transistor has the advantages that an over-thick voltage resisting layer does not need to be grown in an epitaxial mode, a large amount of production cost is saved, the technological steps are simplified, and the transistor can be used for an inverter, a switch power supply and a lighting circuit.

Owner:XIDIAN UNIV

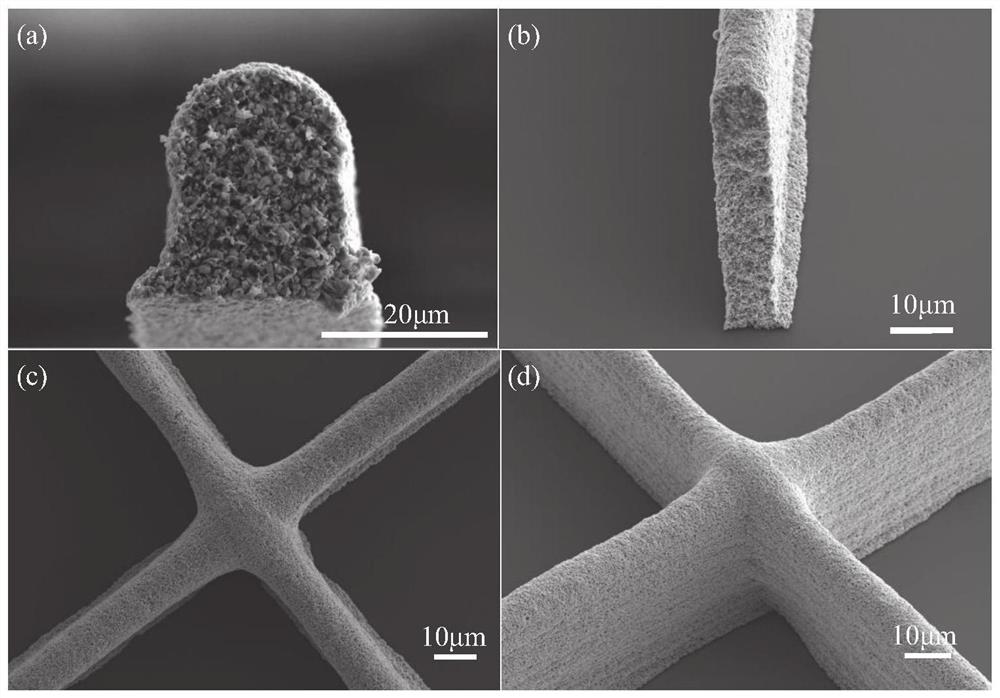

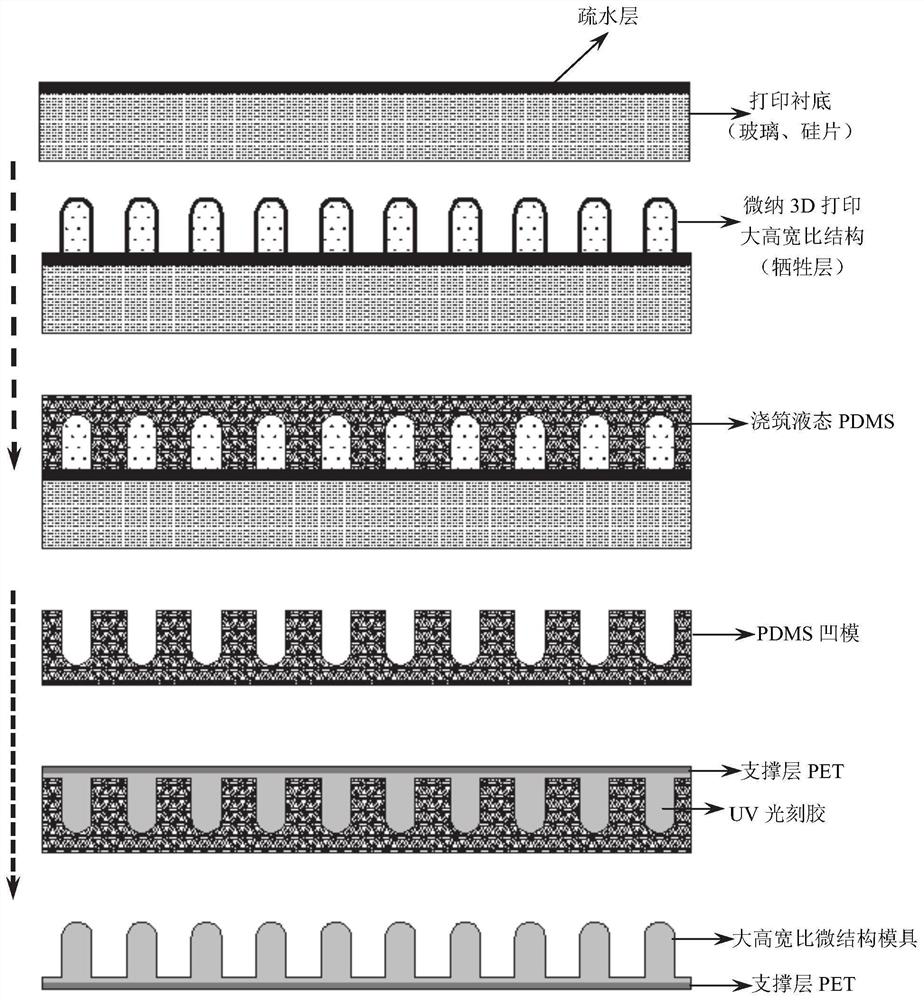

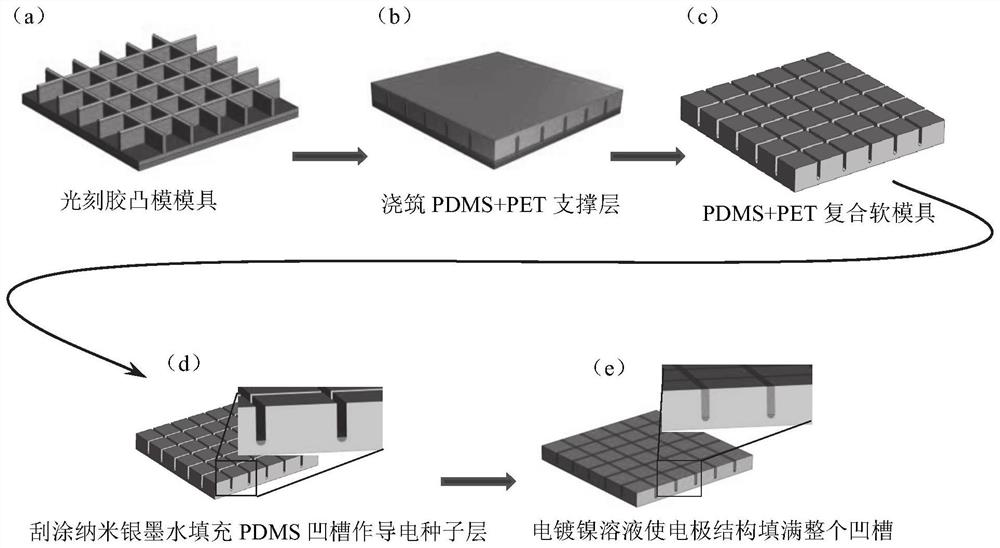

High-performance large-area flexible transparent electrode, preparation method and application thereof

ActiveCN112927862AHigh light transmittanceReduce square resistanceConductive layers on insulating-supportsCable/conductor manufacturePhotoresistMicrostructure fabrication

The invention relates to a high-performance large-area flexible transparent electrode, a preparation method and application thereof. The method comprises the following specific steps of: 1) printing a metal patterned structure on a printing substrate in a micro-nano 3D multi-layer printing manner by using an electric field driven jet micro-nano 3D printing technology and taking metal nano slurry as a printing material, and then curing and sintering the metal patterned structure; 2) conducting transfer printing of a PDMS female die; (3) conducting transfer printing of a UV photoresist male die; (4) preparing a composite soft mold; and 5) preparing an embedded flexible transparent conductive film. The manufacturing of a microstructure with a diameter size of 10-15 microns and a height-width ratio of 0.5-4.0 is realized, and a transparent electrode structure with high light transmittance and low square resistance can be manufactured.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for preparing high-concentration nano-silver particle conductive ink through two-step method and conductive ink

InactiveCN109370316AImprove production efficiencyGood Performance GuaranteedInksHigh concentrationMicrowave

The invention discloses a method for preparing high-concentration nano-silver particle conductive ink through a two-step method and the conductive ink. The method comprises the following steps: (1) completely dissolving 1 part by mass of silver nitrate in 30 parts by mass of glycol, and completely dissolving 1 part by mass of polyvinylpyrrolidone in a glycol solution, so as to prepare a conductiveink precursor; and (2) carrying out microwave heating on the glycol solution containing silver nitrate and polyvinylpyrrolidone for 90 seconds, cooling the heated mixed liquid to the room temperature, carrying out centrifugal concentration, and removing supernate, so as to obtain the conductive ink containing high-concentration nano-silver particles. The preparation steps in a traditional three-step method are replaced with the two steps of microwave heating and centrifugal concentration for preparing the conductive ink, so that the process steps are reduced, the preparation time and cost aresaved, and the preparation efficiency is improved; and a nano-silver lead prepared by virtue of the method preserves good electrical properties, and the preparation efficiency of the conductive ink is improved.

Owner:JIAXING UNIV

Method for preparing non-evaporable thin film getter

ActiveCN106835024ASave manufacturing costSave manufacturing timeOther chemical processesVacuum evaporation coatingGetterMetal

The invention discloses a method for preparing a non-evaporable thin film getter. The method comprises the steps that a plurality of gettering metals are placed in a plurality of evaporation boats of a coating machine in a one-to-one correspondence mode to serve as target materials, the kind of the gettering metals is at least two, the working parameters of each evaporation boat are separate and controllable, and film thickness monitors are arranged on all the evaporation boats in a one-to-one correspondence mode so that the evaporation rates of the gettering metals in the corresponding evaporation boats can be monitored; substrates and the evaporation boats are put into a vacuum cavity of the coating machine; the interior of the vacuum cavity is vacuumized; the gettering metals are pre-molten, and the working parameters of all the evaporation boats are controlled, so that all the gettering metals are evaporated at the same time; and the working parameters of the evaporation boats are adjusted according to the feedback value of the film thickness monitors so that the evaporation rates of all the gettering metals can be adjusted into the preset ratio. According to the method for preparing the non-evaporable thin film getter, the various gettering metals can be evaporated at the same time, and alloy does not need to be manufactured additionally, so that the preparation cost of the getter is beneficially reduced, and the preparation time is beneficially saved; and meanwhile, the components of the getter can be precisely controlled by controlling the evaporation rates of all the gettering metals.

Owner:苏州厚朴传感科技有限公司

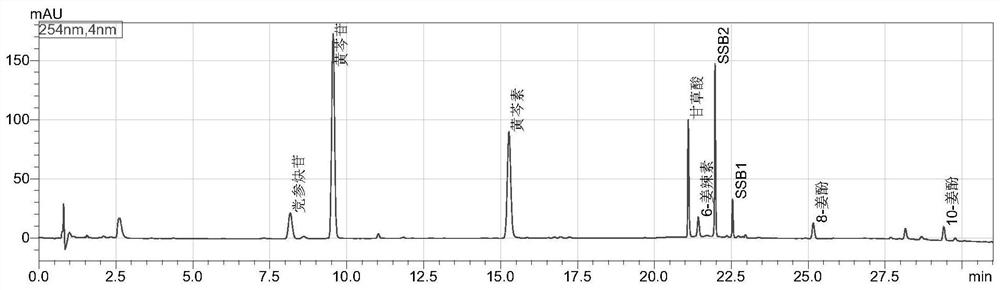

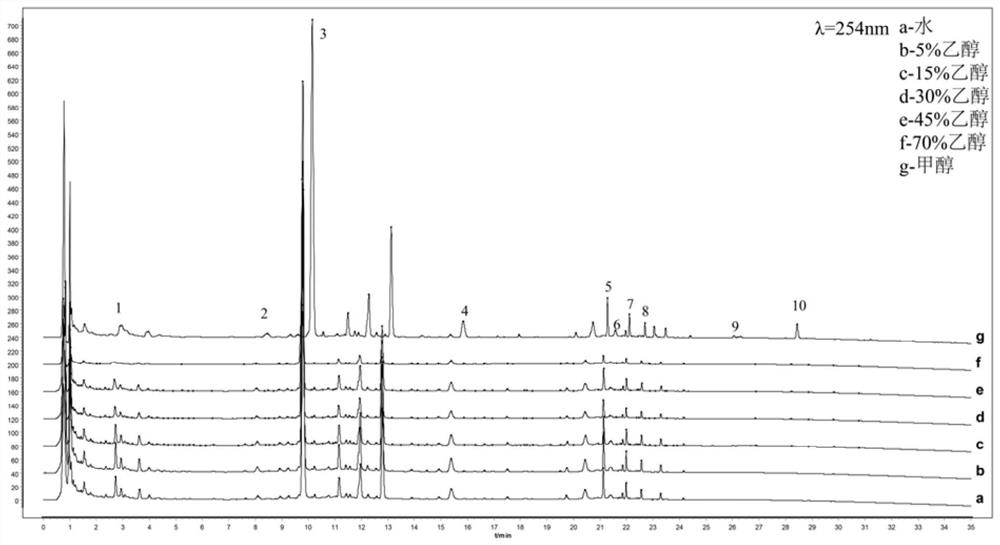

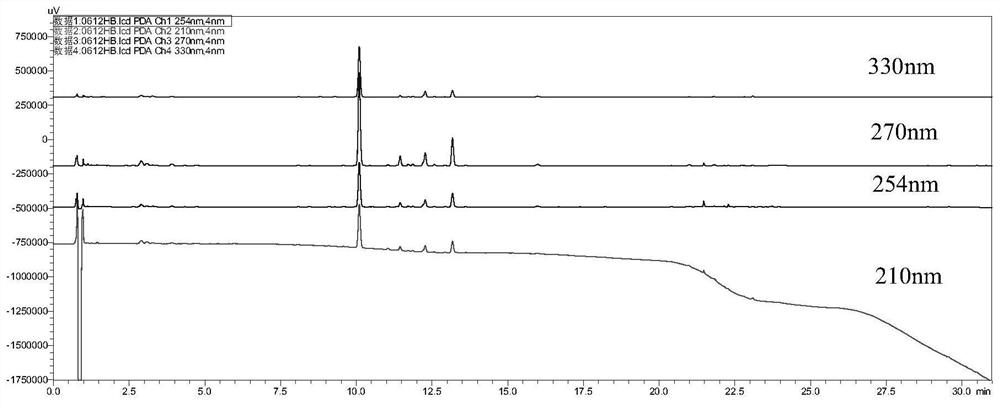

Fingerprint spectrum of xiaocaihu compound preparation, construction method of fingerprint spectrum and content determination method of xiaocaihu compound preparation

ActiveCN113138239ATotal Quality InspectionClear quality inspectionComponent separationGradient elutionOctadecane

The invention belongs to the technical field of quality detection of traditional Chinese medicine preparations, and particularly provides a fingerprint spectruma of a xiaocaihu compound preparation, a construction method of the fingerprint spectrum and a content determination method of the xiaocaihu compound preparation, and the construction method of the xiaocaihu compound preparation fingerprint spectrum comprises the following steps: (1) preparing a xiaocaihu compound preparation test solution; and (2) taking a test solution of the xiaocaihu compound preparation, performing detecting by adopting a high performance liquid chromatography, carrying out gradient elution by taking octadecylsilane chemically bonded silica as a filler and formic acid aqueous solution-acetonitrile as a mobile phase, and carrying out repeated tests to obtain an elution procedure. Under the elution condition, the number of common peaks is obviously increased, the separation degree of common characteristic peaks is obviously improved, the detection time is greatly shortened, and the common peaks are good in peak shape and free of interference, so that the quality of the Under the elution condition, the number of common peaks is obviously increased;xiaocaihu compound preparation can be detected more comprehensively, clearly and effectively.

Owner:CHINA RESOURCES SANJIU MEDICAL & PHARMA

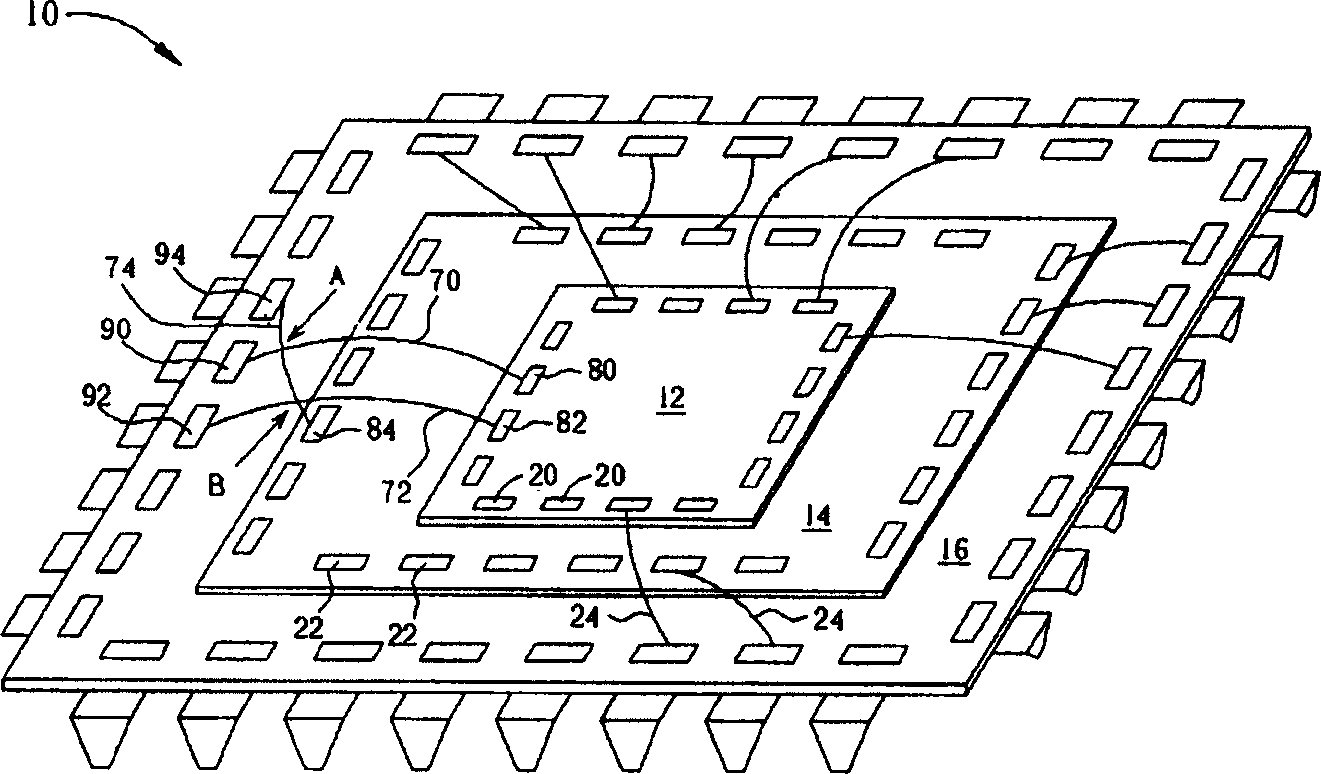

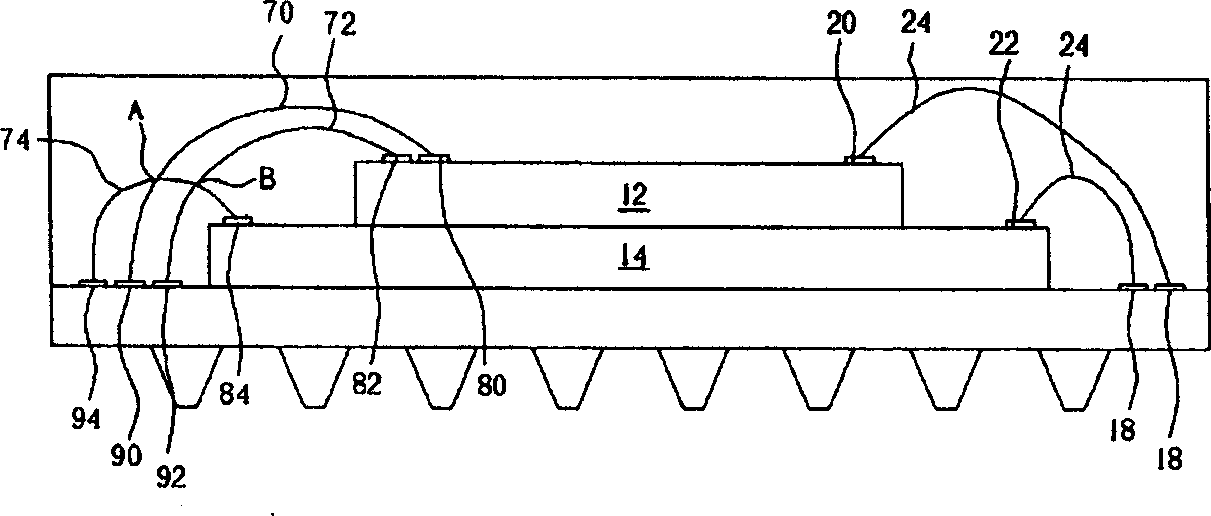

Wire bonding packaging body

ActiveCN1641869AMeet the requirements for real-time listingSituations to Avoid Coupling EffectsSemiconductor/solid-state device detailsSolid-state devicesIngested foodWire bonding

The invention provides a throwing jointing packaging body. It includes one shell body with many foot, one circuit board set in the shell body, no less than one crystal grain set on the circuit board, no less than welding cushion connected to the crystal grain, and joint lead wire on the circuit board. The joint leas wire can make the welding cushion on the crystal grain electronically connect to the food of the shell body.

Owner:ALICORP

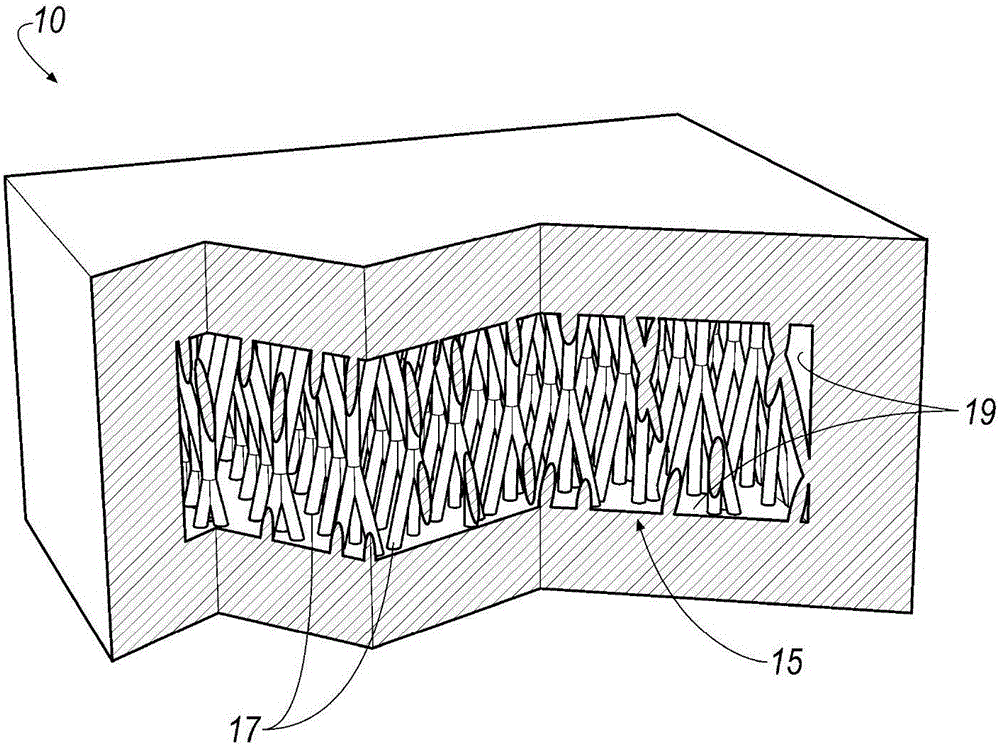

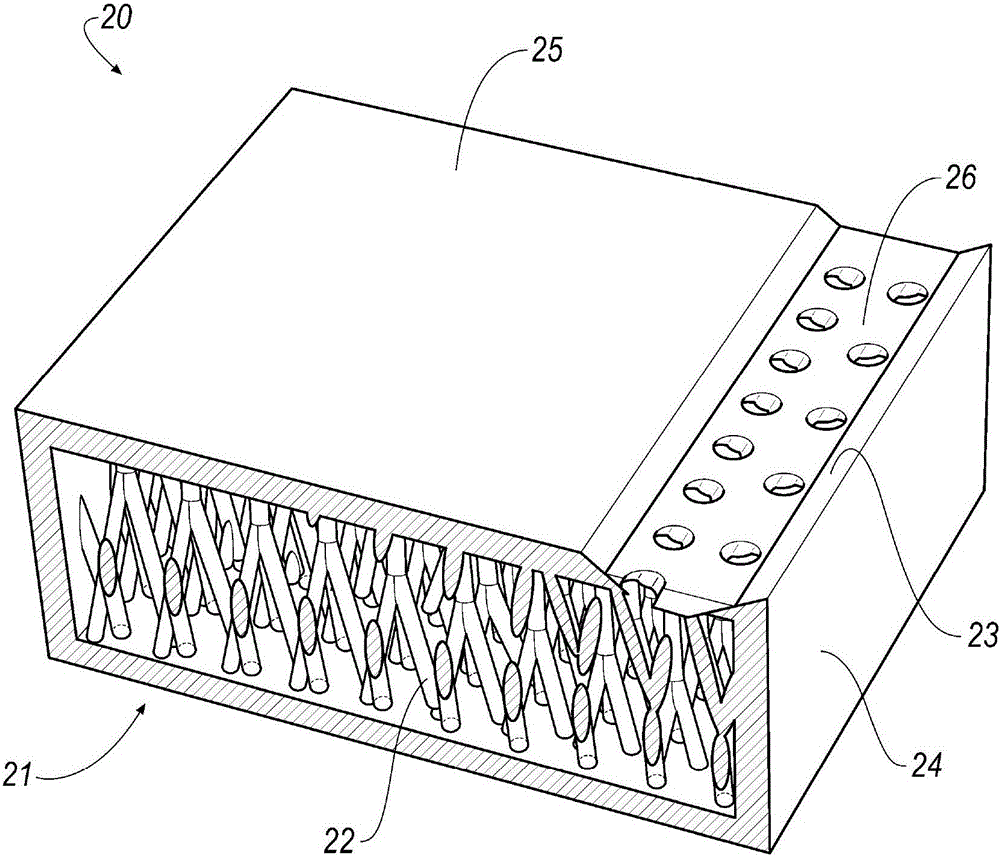

Cutting Tool Made By Additive Manufacturing

ActiveCN106141180AImprove mechanical propertiesImprove wear resistanceAdditive manufacturing apparatusMilling cuttersEngineeringHoneycomb structure

A cutting tool made by an additive manufacturing process is disclosed. The cutting tool has an exterior surface and an enclosed interior cavity defined by one or more inwardly facing surfaces. The interior cavity may have internal supports such as a lattice or a honeycomb structure. The cutting tool may be an insert, drill or endmill with coolant holes.

Owner:KENNAMETAL INC

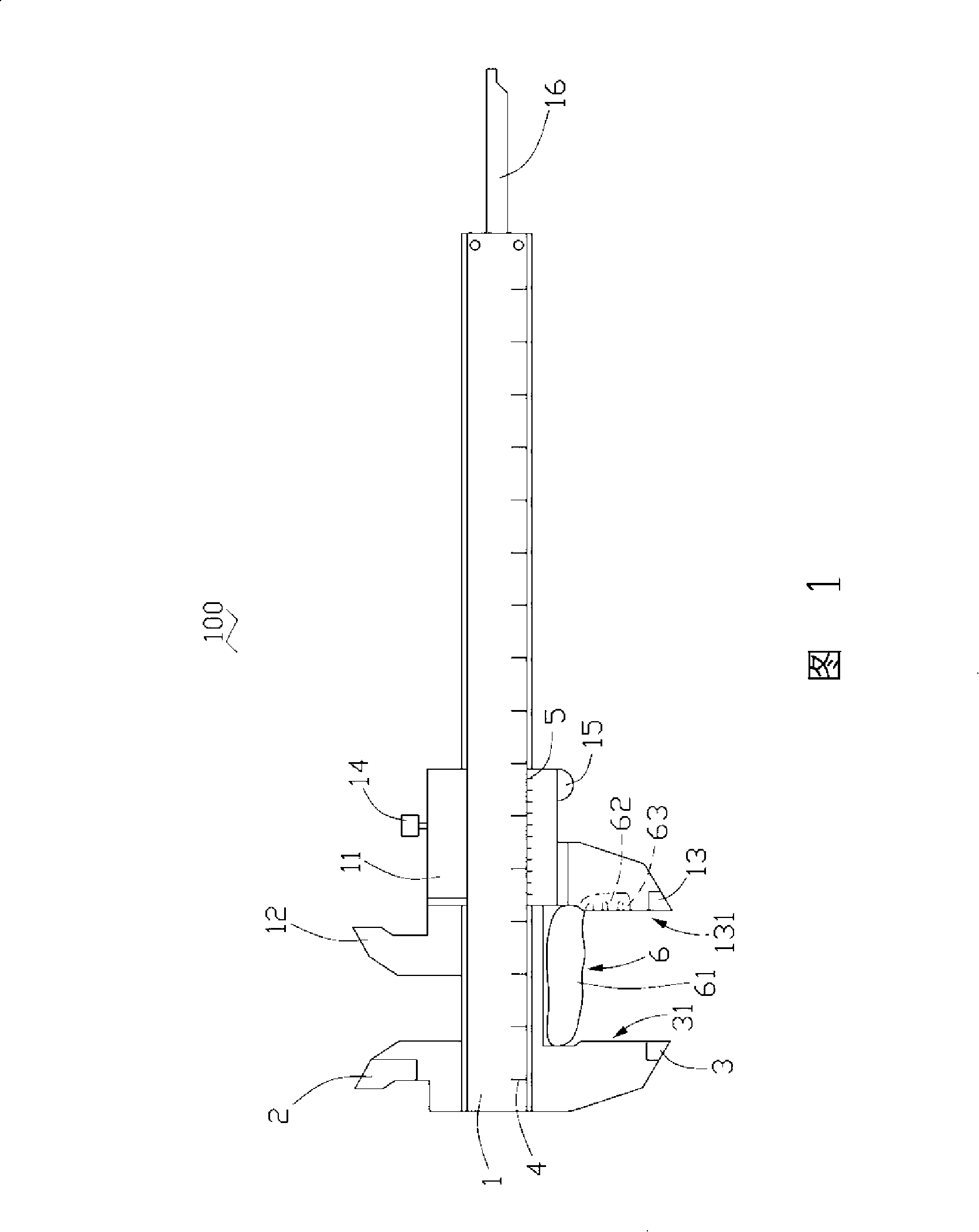

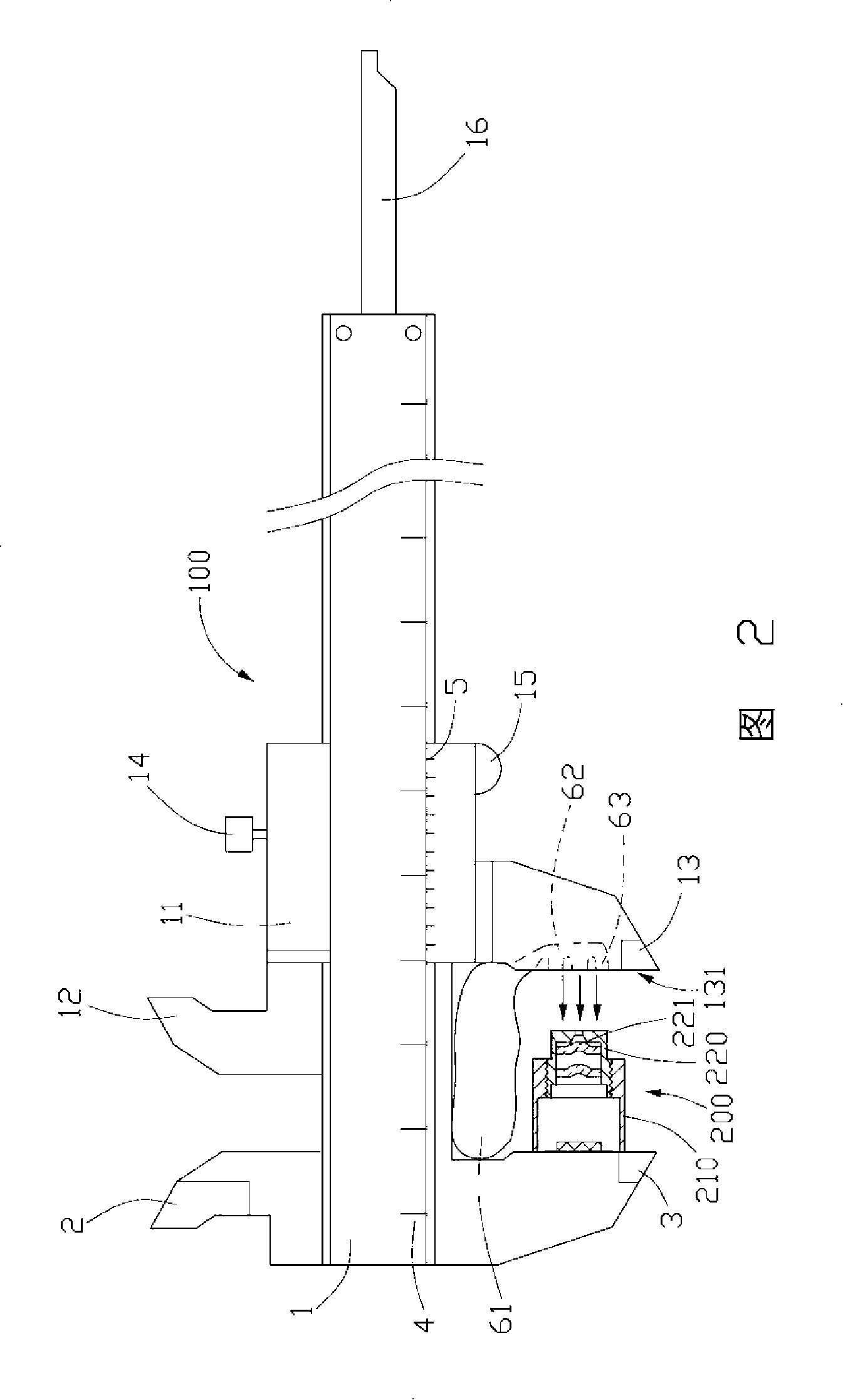

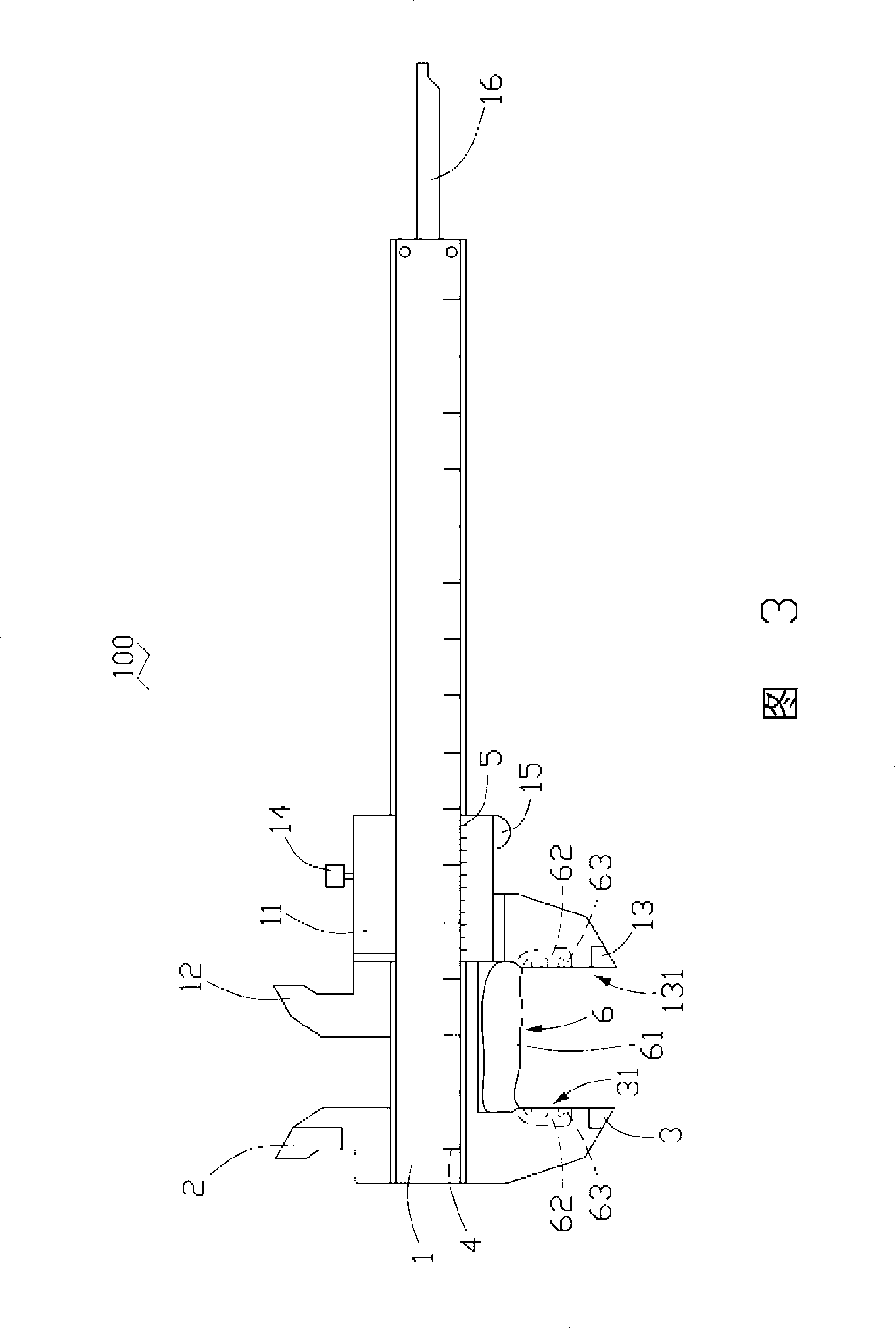

Vernier caliper

The invention relates to a vernier caliper which comprises a main ruler with a first outside-measuring claw, and a slipper with a second outside-measuring claw engaged with the first outside-measuring claw. The vernier caliper further comprises a blowing device which comprises at least one air sac positioned between the first outside-measuring claw and the second outside-measuring claw, at least one air passage communicated with the relevant air sac, and at least one blowing hole provided on the at least one air passage to provide air to the surface of an object to be measured. The vernier caliper can measure the object to be measured and simultaneously blow dust off the surface of the measured object, and has short production cycle and low cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

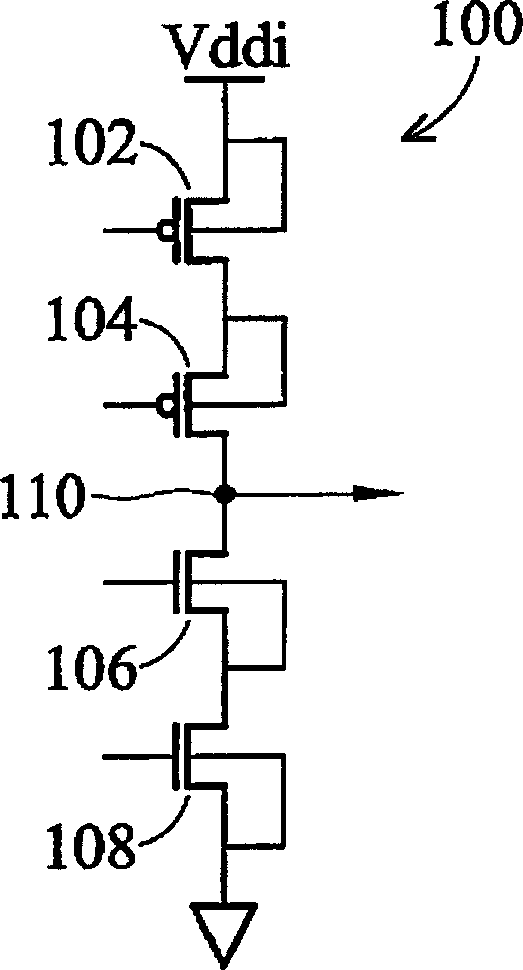

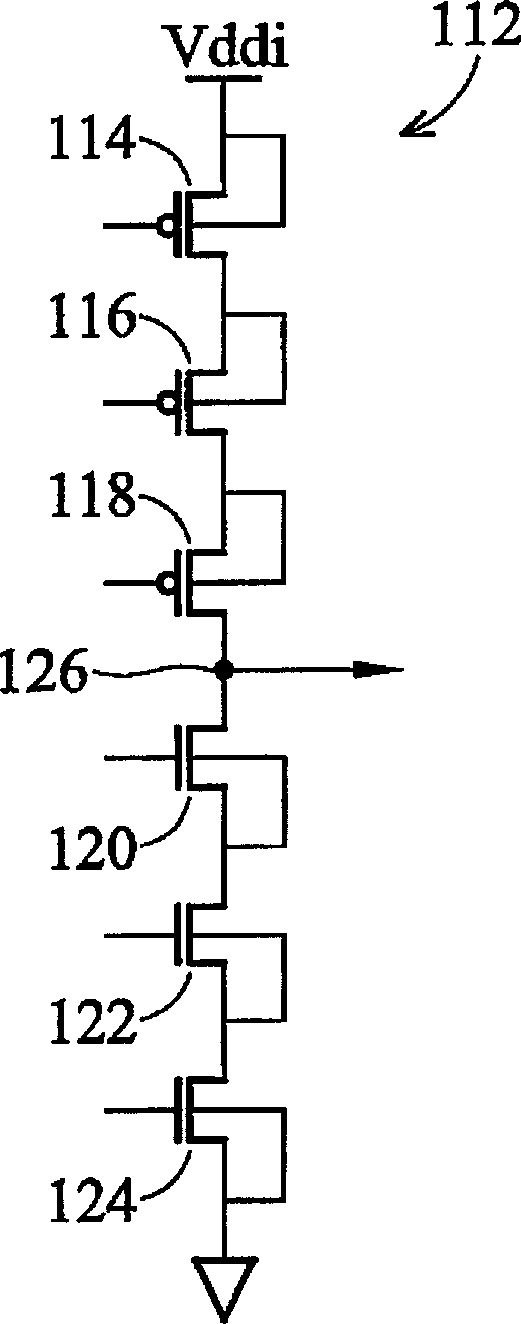

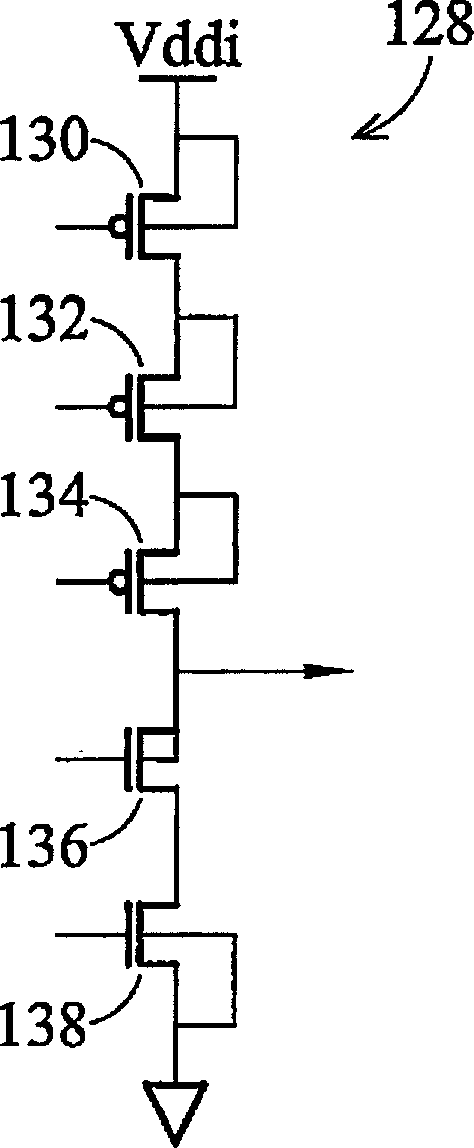

Thin-oxide devices for high voltage i/o drivers

ActiveCN1862967ACut costsSave manufacturing timeLogic circuits coupling/interface using field-effect transistorsThin oxideSemiconductor

An I / O driver includes a pull-down module and pull-up module. The pull-down module has one or more NMOS transistors serially coupled between ground and an output node. The pull-up module has one or more PMOS transistors serially coupled between a first voltage and the output node. The gates of the PMOS and NMOS transistors are controlled by a set of differential biases for selectively pulling the output node to the first voltage or ground. The differential biases are separately set for each of the transistors so that a voltage difference across each of the transistors does not exceed a predetermined value, thereby preventing the same from damage.

Owner:TAIWAN SEMICON MFG CO LTD

Manufacturing method of one-sided double-contact flexible circuit board

InactiveCN105430914AAvoid damageSave manufacturing costPrinted element electric connection formationFlexible circuitsCopper foil

The present invention discloses a manufacturing method of a one-sided double-contact flexible circuit board, and relates to the technical field of circuit board production. The manufacturing method comprises the following steps: S1, press-fitting a front side cover film provided with a window on a surface of pure copper foil; S2, by making a circuit pattern, etching the pure copper foil to form a copper circuit, wherein the pure copper foil, at a position corresponding to the window in step S1, of the copper circuit is kept, to form a pad; and S3, press-fitting a back side cover film provided with a window on a side, opposite to the front side cover film, of the pure copper foil, wherein a position of the window of the back side surface cover film corresponds to a position of the pad in the step S2. According to the manufacturing method of the one-sided double-contact flexible circuit board provided by the present invention; the cover films are press-fit on two sides of the pure copper foil; the windows are disposed in the cover films before the cover films are press-fit; and the cover films on the two sides are press-fit respectively before and after the circuit pattern is made. Copper surface adhesive residue and copper surface damage caused by using a laser to make a window on a back side pad in the existing method are avoided. Moreover, the process of using a laser to make a window on the back side of the pad is eliminated, thereby significantly reducing the manufacturing cost and the manufacturing time.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

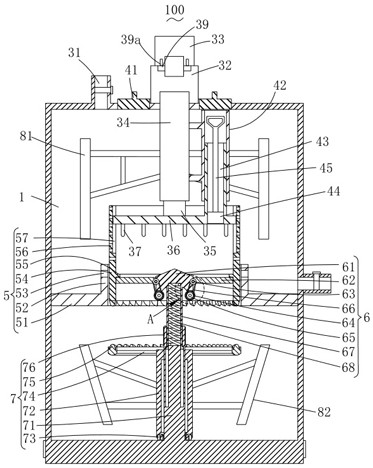

Scuticociliatid ciliate resistant pharmaceutical composition and preparation method thereof

ActiveCN111603493AReduce infection rateAntibacterial and anti-inflammatoryOrganic active ingredientsPharmaceutical delivery mechanismBiotechnologyAlcohol ethyl

The invention provides a scuticociliatid ciliate resistant pharmaceutical composition and a preparation method thereof. The pharmaceutical composition is prepared from the following raw materials in parts by weight: 2-3 parts of sundew, 20-30 parts of food-grade ethanol with a concentration of 95%, and 0.3-0.6 part of fatty alcohol polyoxyethylene ether sodium sulfate. The preparation method comprises the following steps: taking 2-3 parts by weight of sundew, crushing sundew, putting crushed sundew into the upper part of a reaction kettle, adding 20-30 parts by weight of food-grade ethanol with a concentration of 95%, stirring and extracting the raw materials for 5 hours to obtain an extract, adding 0.3-0.6 part by weight of fatty alcohol polyoxyethylene ether sodium sulfate into the extract obtained in S1, uniformly mixing to obtain a mixed solution; adding 1000 parts of a turbot feed into the lower part of the reaction kettle, mixing the sundew residues obtained after extraction in S1 with a turbot feed, and fully stirring for 0.5 h. The pharmaceutical composition has the advantages that the toxicity to turbots is small, the pharmaceutical composition is environmentally friendly,the scuticociliatid ciliate infection rate is effectively reduced, and the extract and a mixed feed can be produced at the same time.

Owner:BEIJING CENT BIOLOGY

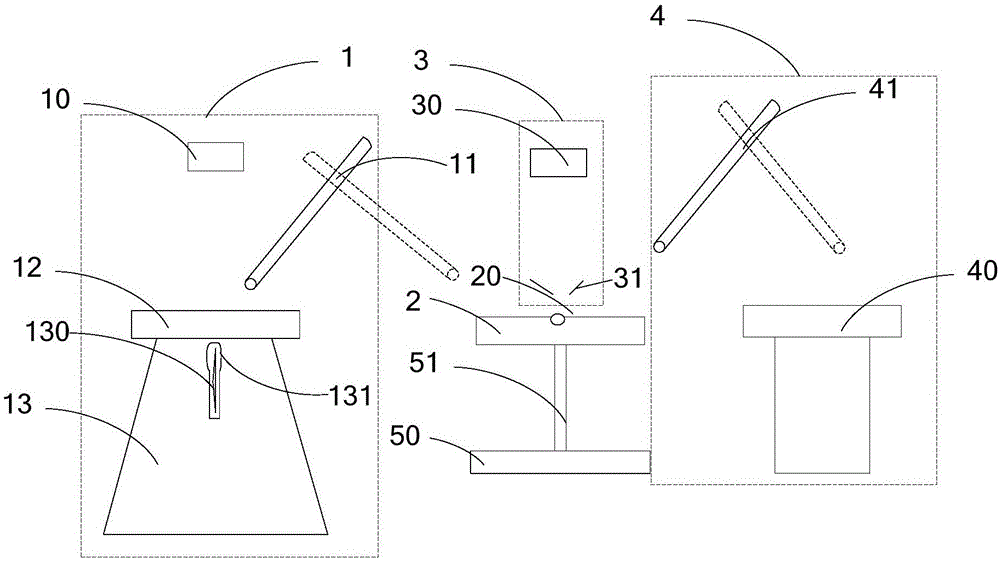

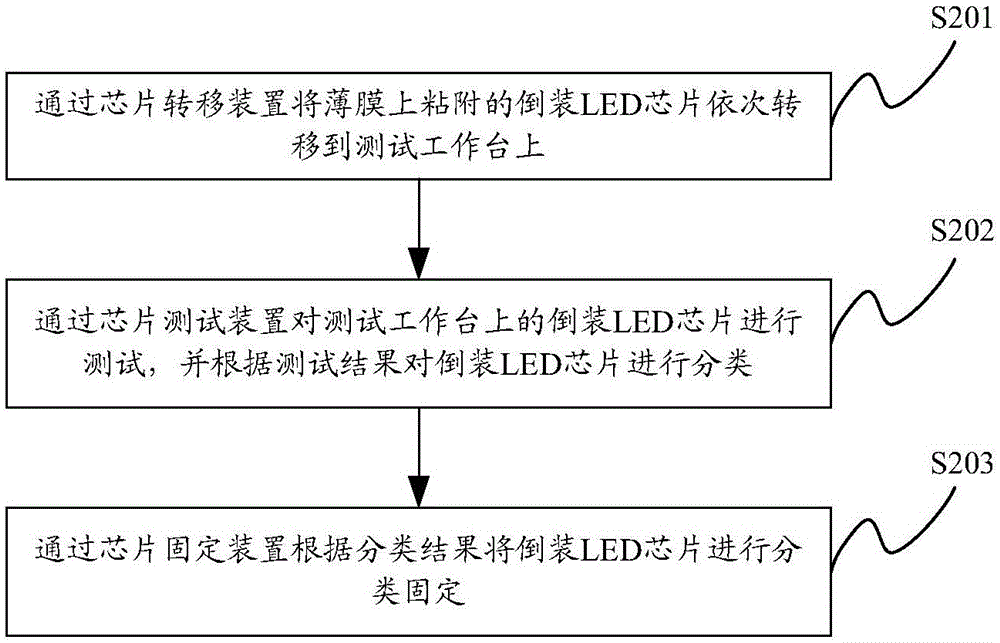

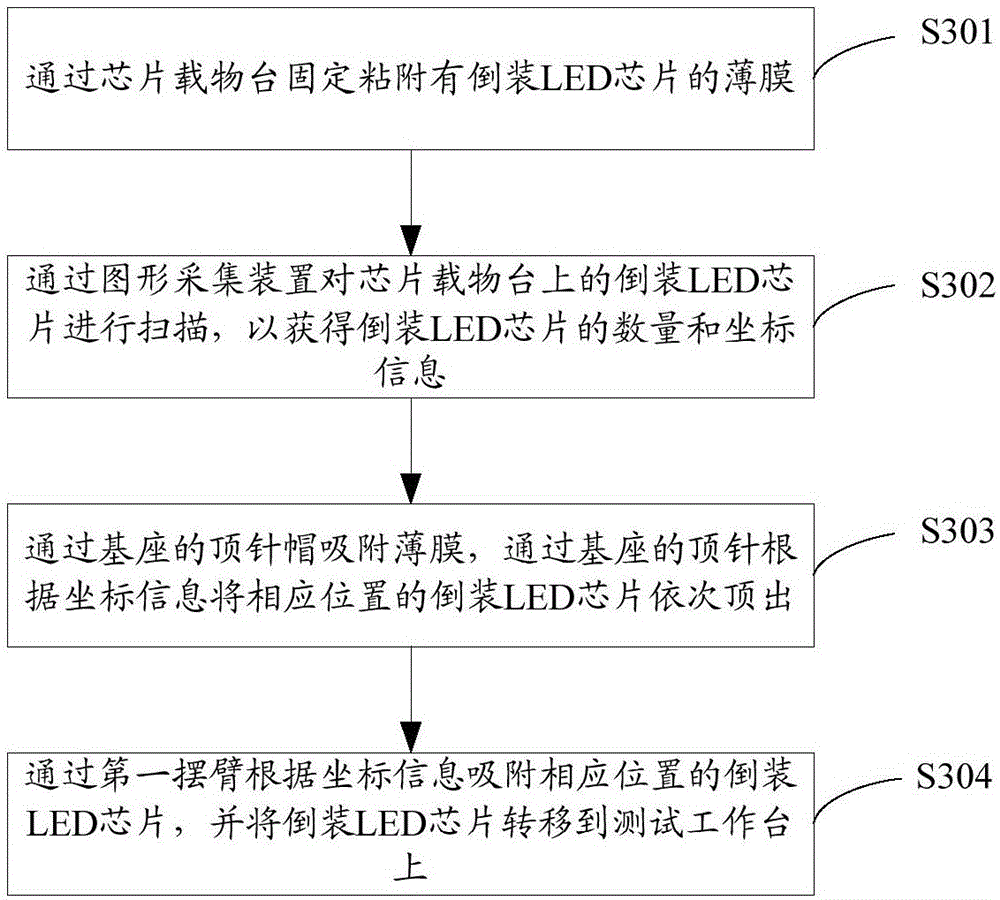

Inverted LED chip test equipment and test method thereof

The invention provides inverted LED chip test equipment and a test method thereof. The inverted LED chip test equipment comprises a chip transferring device, a test worktable, a chip testing device and a chip fixing device, wherein the test worktable is made of transparent materials; the chip transferring device is used for transferring inverted LED chips adhering to a film to the test worktable in sequence; the chip test device is used for testing the inverted LED chips on the test worktable and classifying the inverted LED chips according to the test result; the chip fixing device is used for fixing the inverted LED chips in a classifying mode according to the classification result. According to the inverted LED chip test equipment and the test method thereof, the inverted LED chips adhering to the film are transferred to the test worktable through the chip transferring device to be tested; as the test worktable is made of the transparent materials, errors of the optical test result of the inverted LED chips can be reduced, and a relatively accurate test result is obtained; moreover, the workload for subsequent treatment of the inverted LED chips can be lightened, the manufacturing cost is reduced, and the manufacturing time is shortened.

Owner:FOSHAN NATIONSTAR SEMICON

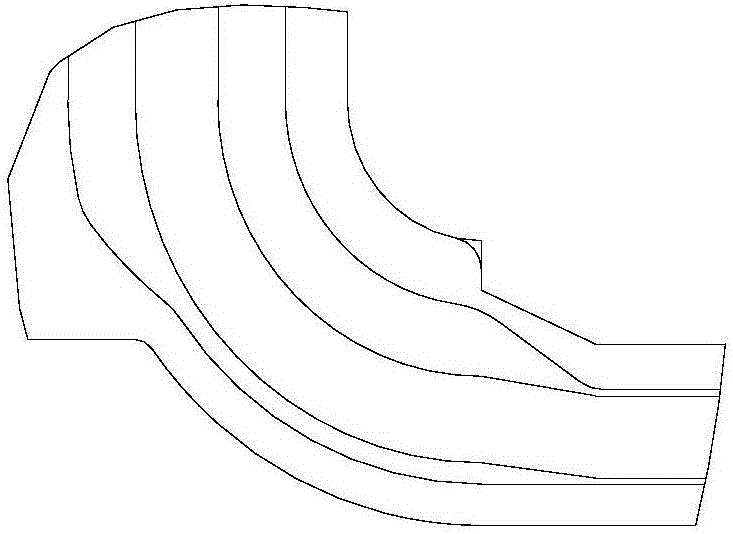

Machining method for large high-strength stamping part with inner hole

The invention relates to a machining method for a large high-strength stamping part with an inner hole. According to the specific method, sample putting and spreading, blank part size determining, blank part cutting, stamping, inner hole cutting, external straight side shearing, external curve side cutting and leveling are sequentially carried out according to the material performance, the plate thickness, the part shape, the size and related technical requirements of the large high-strength stamping part with the inner hole. Thus, the machining method has the following beneficial effects that equipment with the cut fracture surface quality being relatively high is adopted to machine the size of the inner hole and the size of an outer hole of a stamped blank part, and it can be ensured that no pull crack phenomenon or an extremely small number of pull crack phenomena of the part appear during profiling; and by means of the machining manners of manufacturing an explorator for manual cutting and manufacturing a shearing sample plate for shearing a straight side, the cost of manufacturing a large number of dies can be saved, the die manufacturing time and the die testing and repairing time can be saved, the production cost can be greatly reduced, and timeliness of production is guaranteed.

Owner:CRRC YANGTZE CO LTD

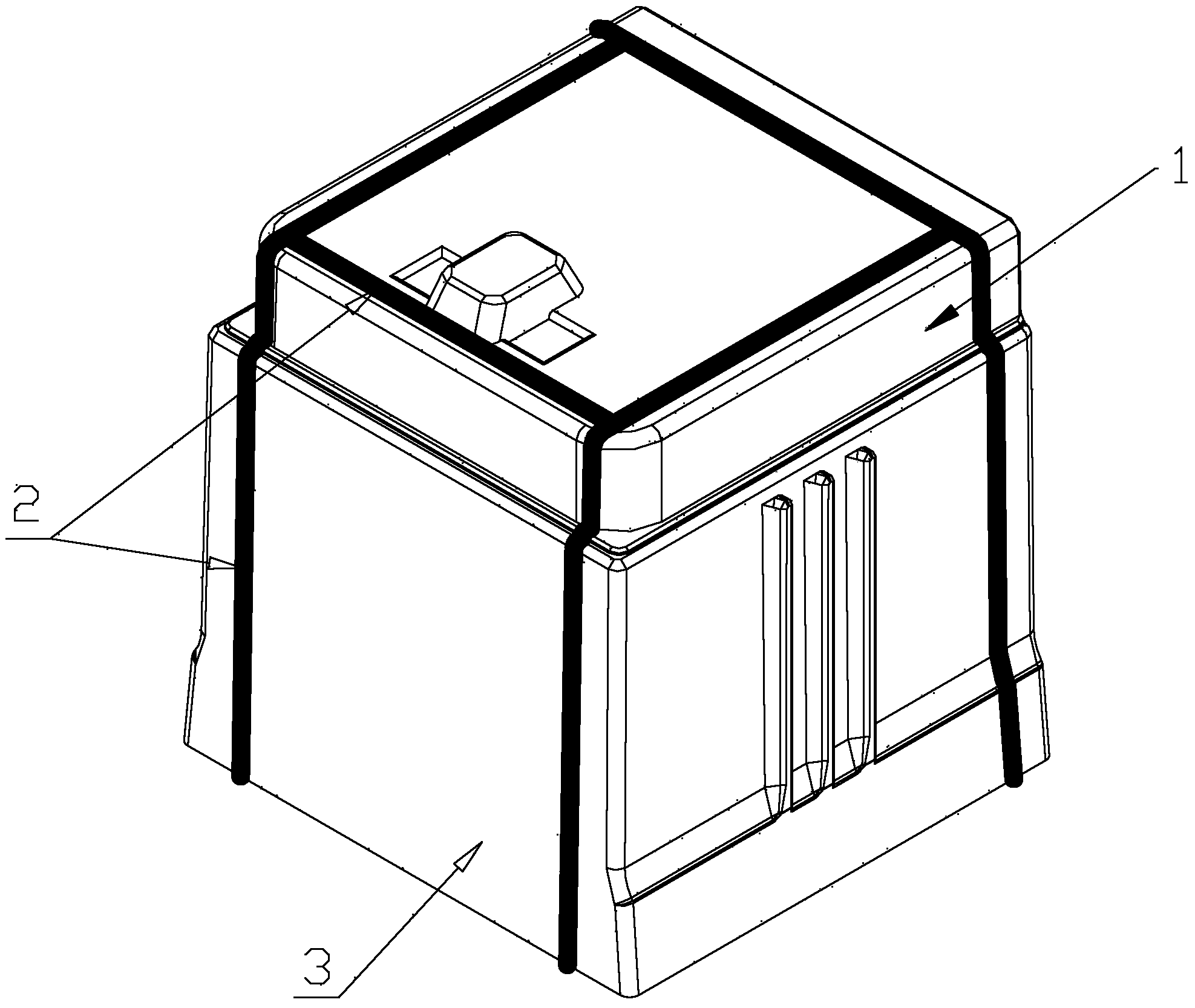

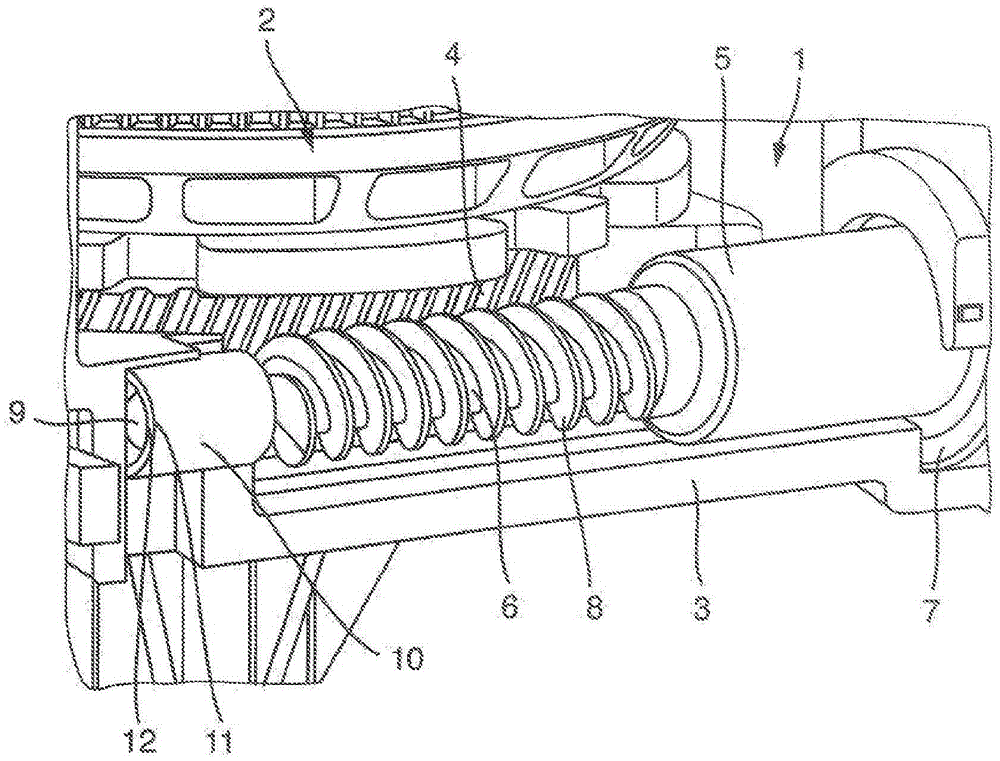

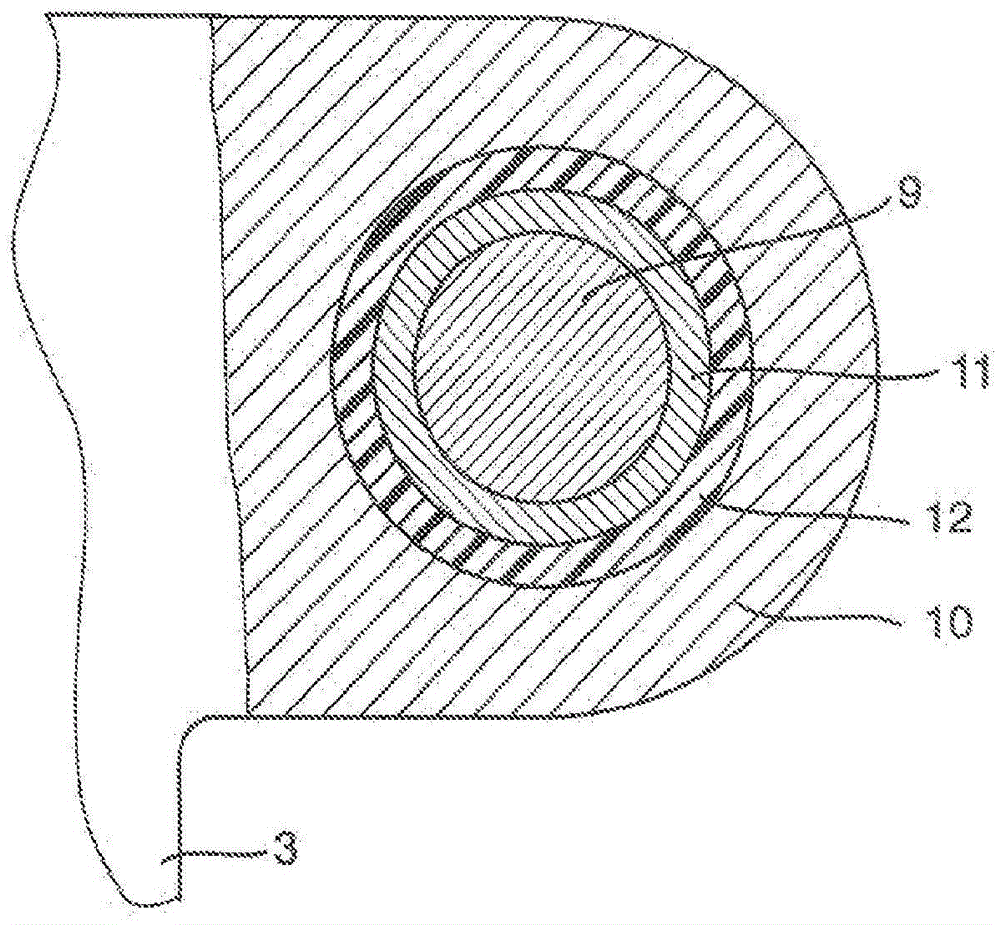

Adjusting unit for motor vehicle

ActiveCN105593571AHas shock-absorbing/vibration-damping propertiesCutting costsShaftsToothed gearingsElastomerEngineering

The invention concerns an adjusting unit for automotive applications, in particular motor vehicle door closures or locking systems (1). The adjusting unit is provided with a housing (3); a drive (2) disposed in the housing (3), in particular a worm gear,; an actuator which can be acted upon by the drive; and at least one sliding bearing (11) for accommodating a bearing point (10) of the drive (2), in particular a worm (6) of the worm gear. According to the adjusting unit, the adjusting unit comprises at least one sliding bearing (11) which is provided in sections with an elastomer covering (12).

Owner:KIEKERT AG

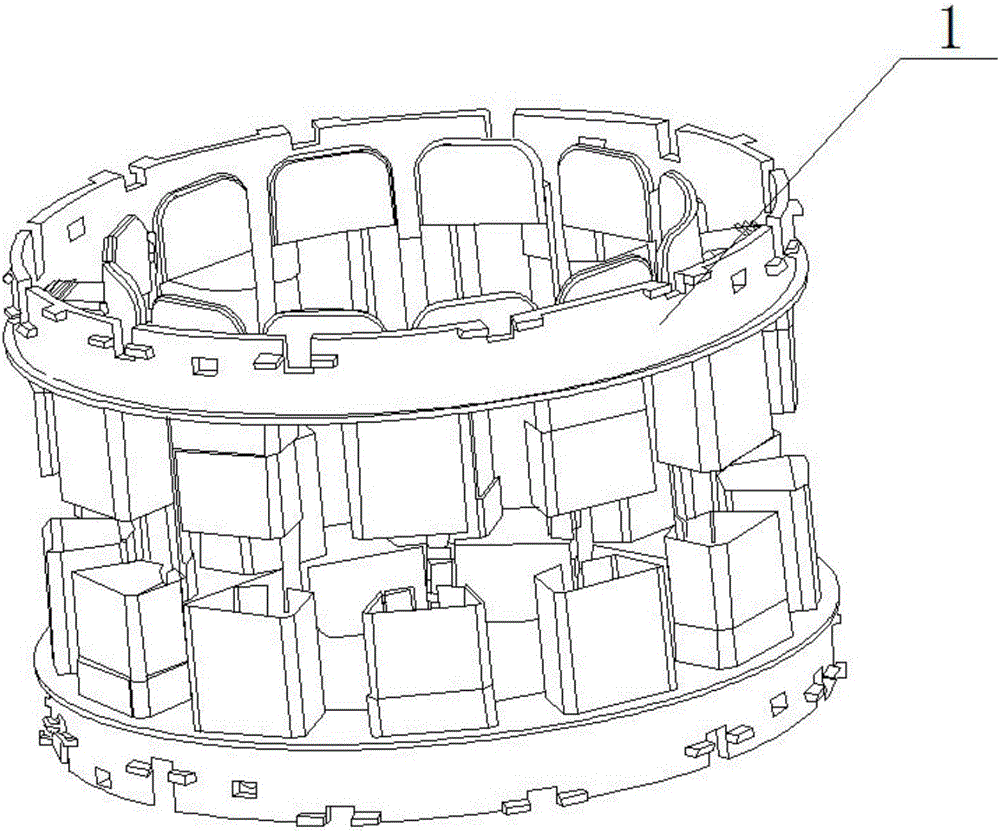

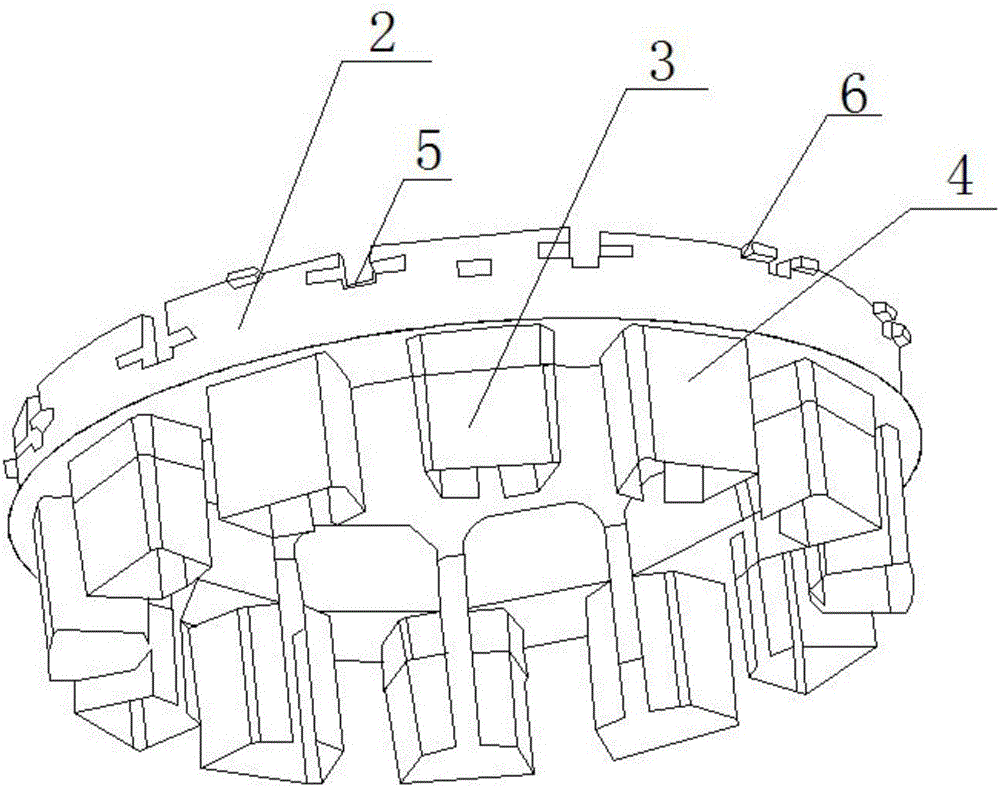

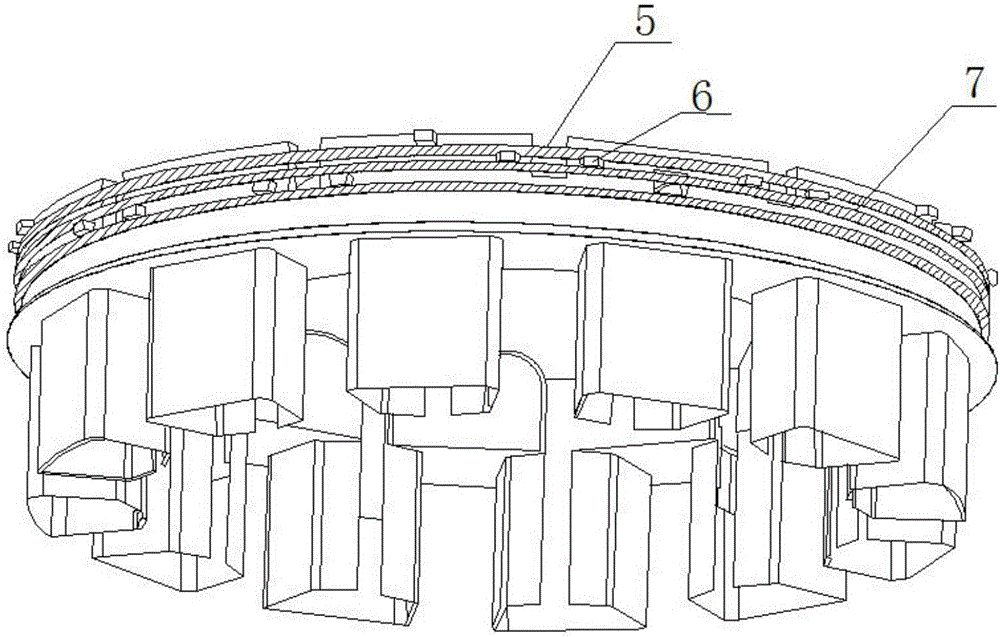

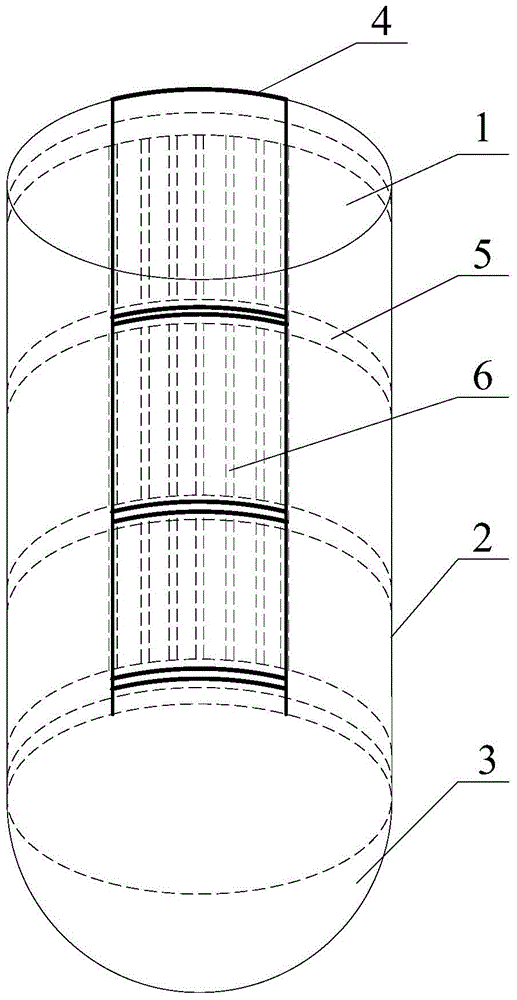

Motor stator insulation framework

InactiveCN105703513ALow input costShorten production timeWindings insulation shape/form/constructionTransition lineEngineering

The invention proposes a motor stator insulation frame, which includes two frame bodies. The frame body includes an end ring, an inner ring groove and an outer ring groove. The end ring, the inner ring groove and the outer ring groove are arranged in a staggered manner. The end ring, the inner ring groove and the outer ring groove are integrally formed by injection molding. There are several insulation gaps with different depths on the outside of the end ring, and there are wire retaining protrusions on the outside of the insulation gap rise. This structure only needs one injection mold to complete the injection molding of the insulation frame of the motor stator, which reduces the investment cost of the mold, saves production time, and improves production efficiency; through the cooperation of the insulation gap and the protrusion of the retaining line, the transition line can be Naturally separated to a reliable insulation distance, no need for further insulation treatment, saving preparation time and materials.

Owner:DIBAISHI MOTOR TECH SUZHOU CO LTD

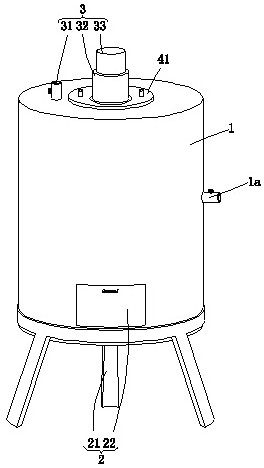

Polymerizer for producing polyacrylamide

InactiveCN104558310AEasy to manufactureSave manufacturing costProductsReagentsPolyacrylamideManufacturing engineering

The invention discloses a polymerizer for producing polyacrylamide. According to the polymerizer disclosed by the invention, a layer of lining is arranged on the inner side of a polymerizer wall and consists of a plurality of lining plates, the plurality of lining plates are fixedly adhered to the inner side of the polymerizer wall by virtue of connecting parts, and the edges of the two adjacent lining plates are welded in a sealing mode. When the lining of the polymerizer is manufactured, the polymerizer is not needed to be disassembled, and a worker only needs to enter the polymerizer to fixedly mount each lining plate. Compared with the prior art, the technical scheme is capable of greatly simplifying the manufacturing process of the polymerizer, saving the manufacturing cost and time and thus improving the production efficiency.

Owner:SICHUAN GUANGYA POLYMER CHEM

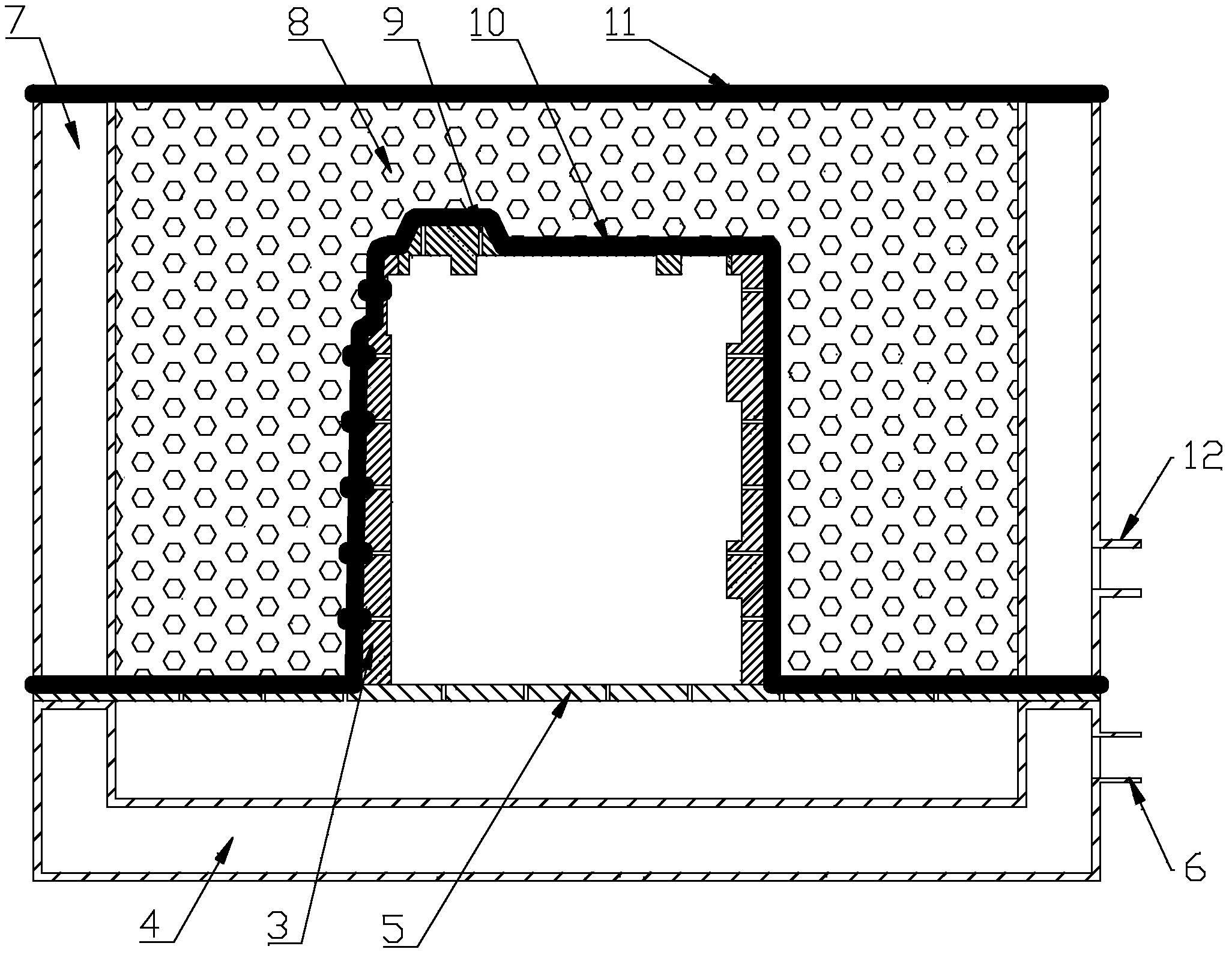

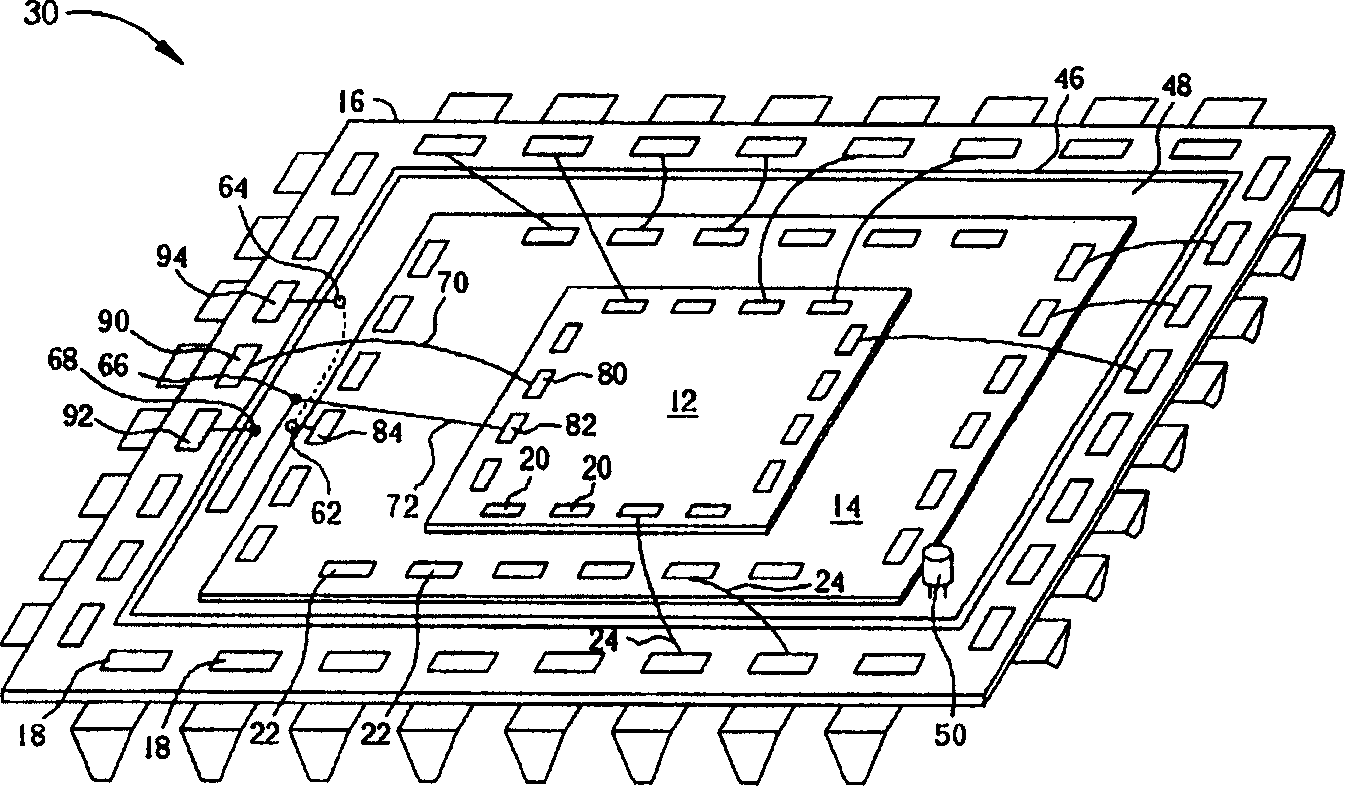

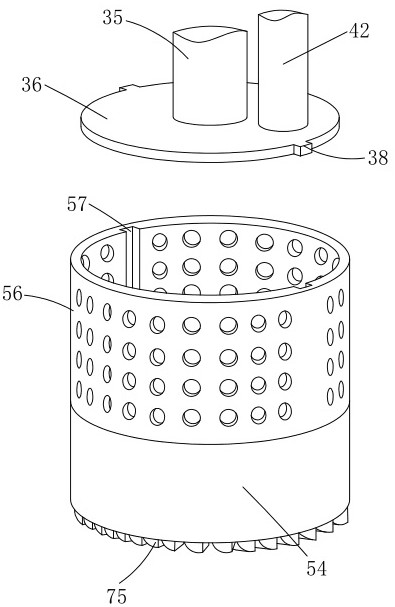

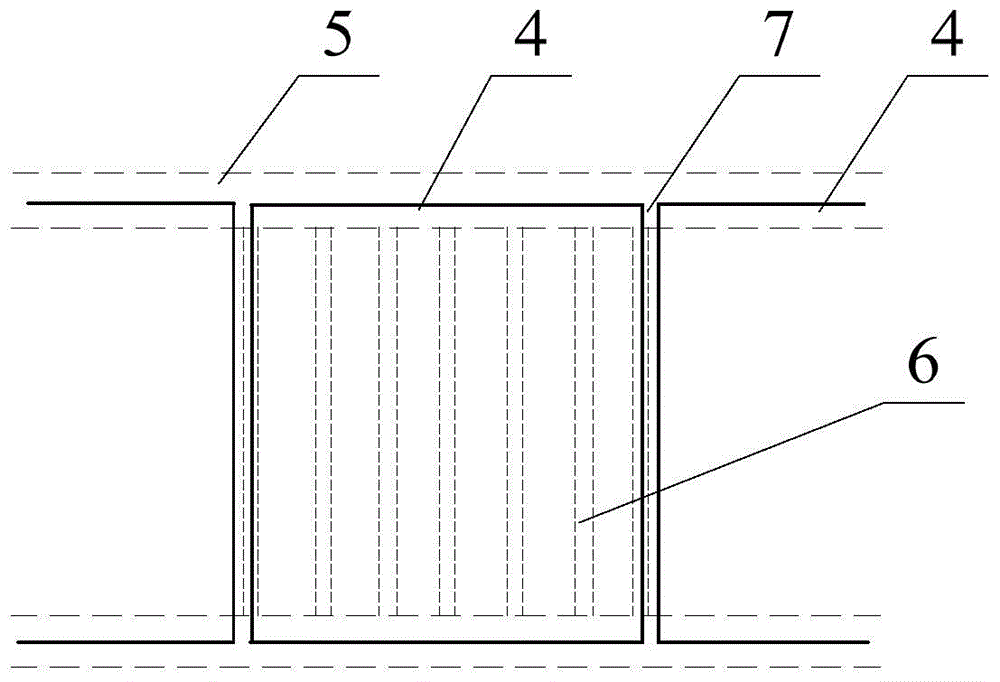

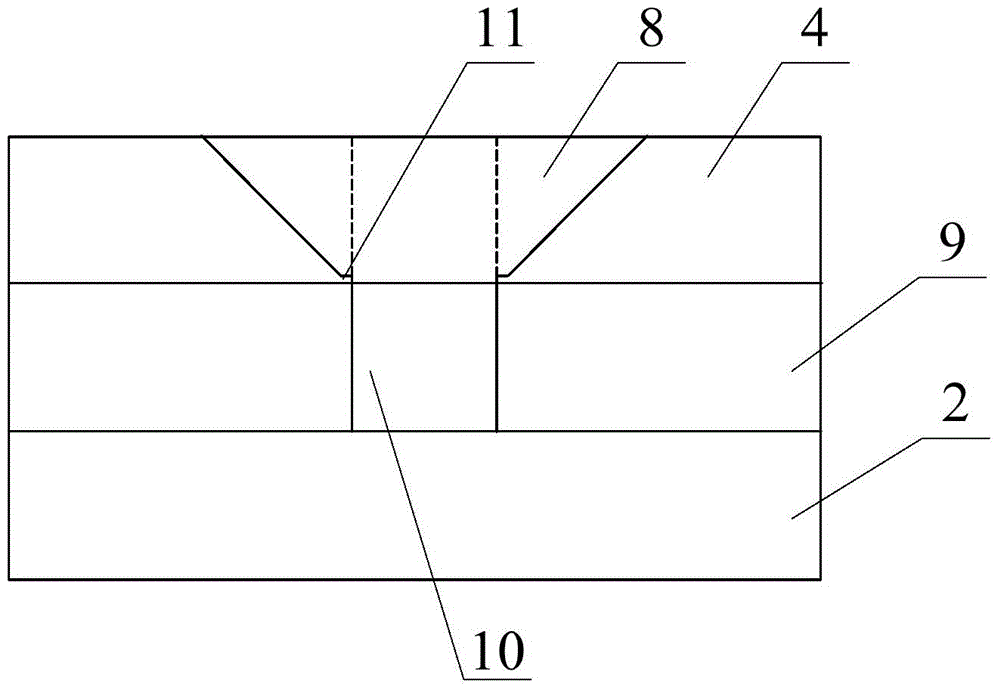

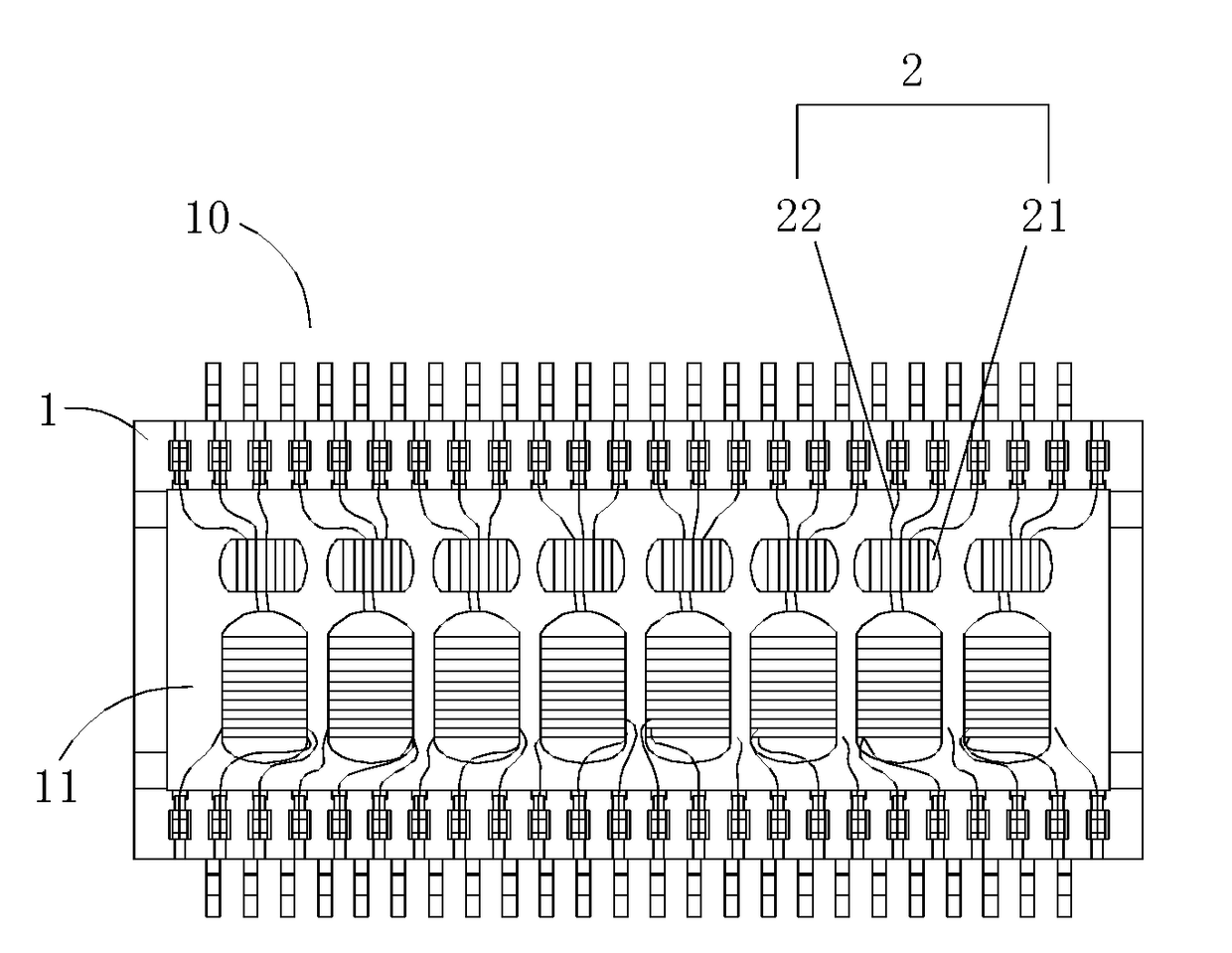

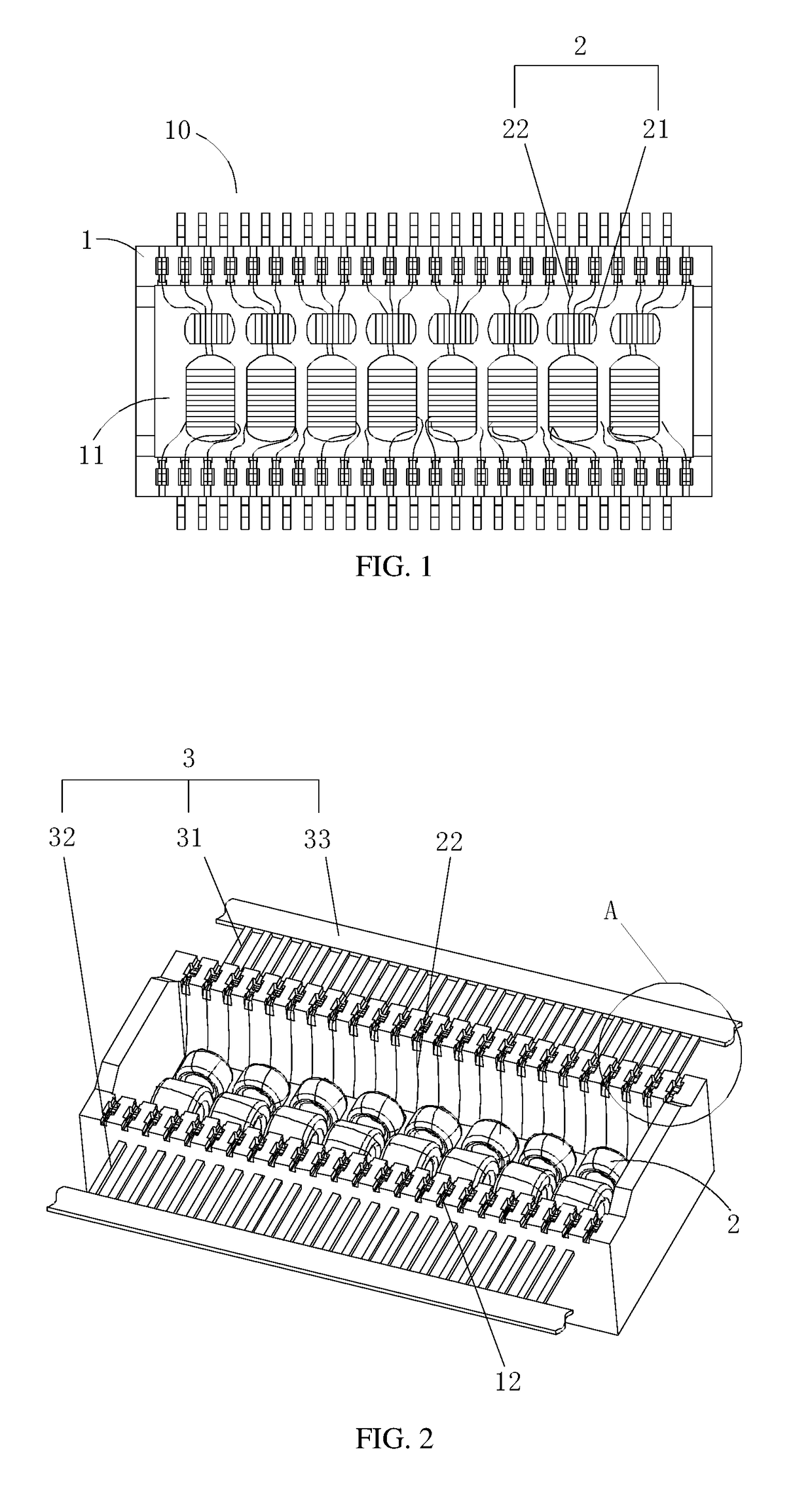

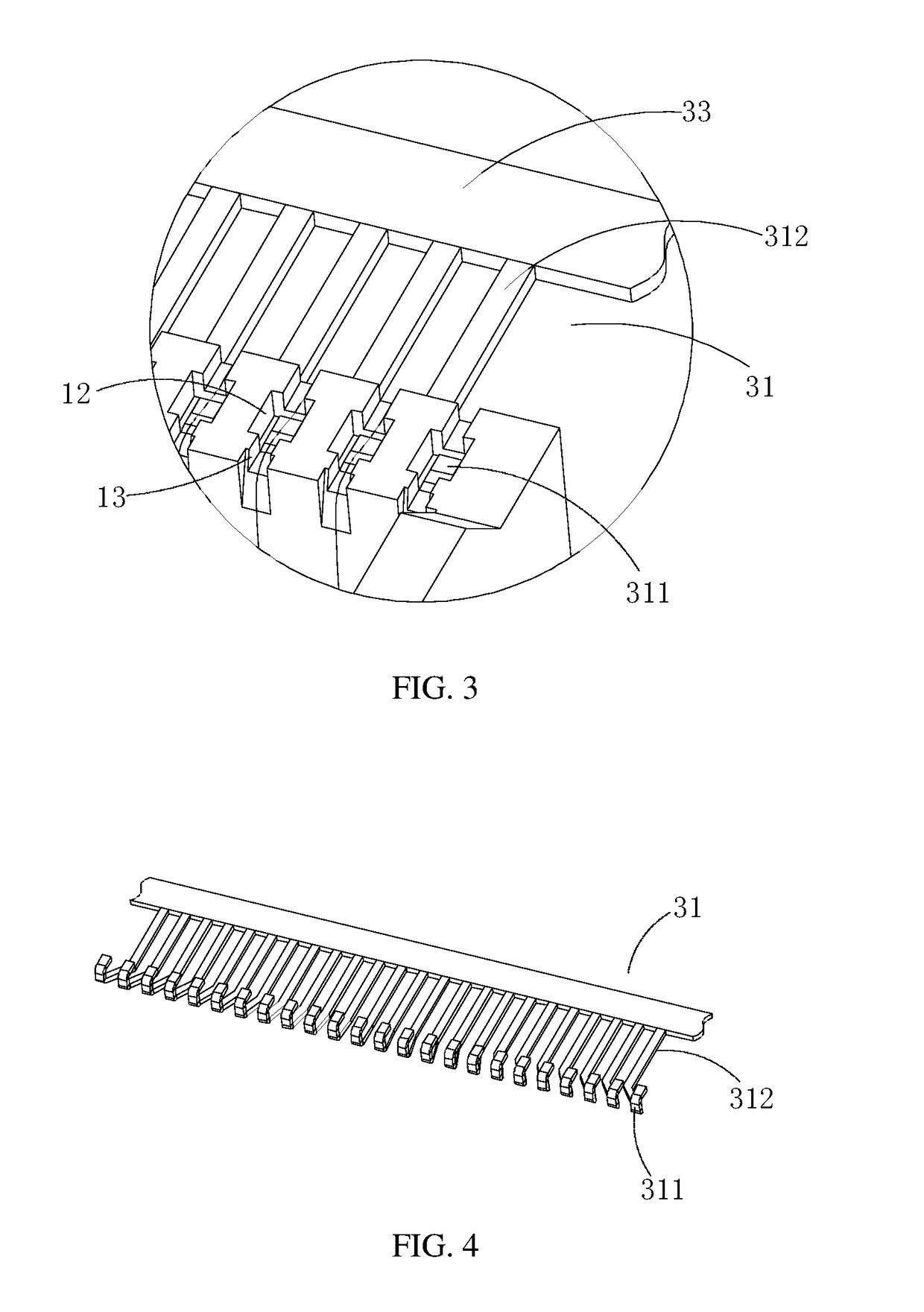

Filter Structure, Welding Fixture, and Manufacturing Method of the Filter Structure

ActiveUS20180247756A1Simplify processSave manufacturing timeTransformers/inductances coils/windings/connectionsWelding/cutting auxillary devicesEngineeringElectrical and Electronics engineering

Disclosed are a filter structure, a welding fixture, and a manufacturing method of the filter structure. The filter structure includes: a box having a cavity; coil components installed in the cavity; and wiring components, each having a positive wiring pin and a negative wiring pin fixed to the box. The conductive wire has conductive wires coupled to both ends of the coil component and welded with the positive and negative wiring pins respectively. After a wiring section of the pins is embedded into a side of a wire latch slot, the conductive wire of the coil is latched into the wire latch slot and welded with the pins by spot welding without the need of manually winding the conductive wire and the pins, so as to reduce labor, expedite assembling, improve production efficiency and save material cost of the conductive wire.

Owner:GUANGDONG MISUN TECH CO LTD

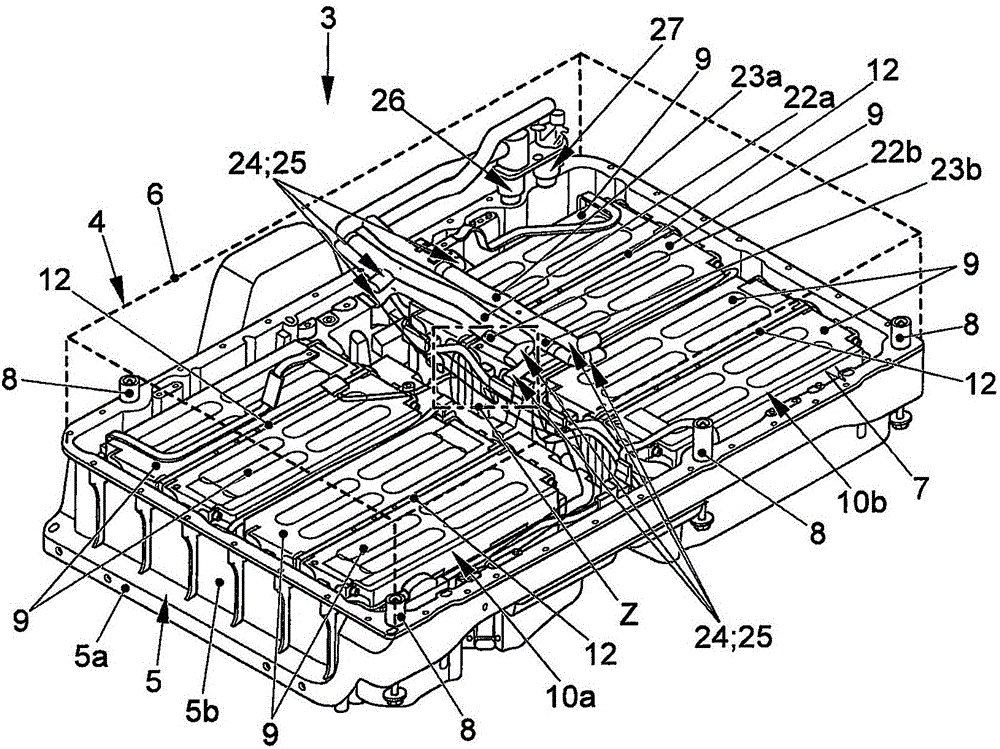

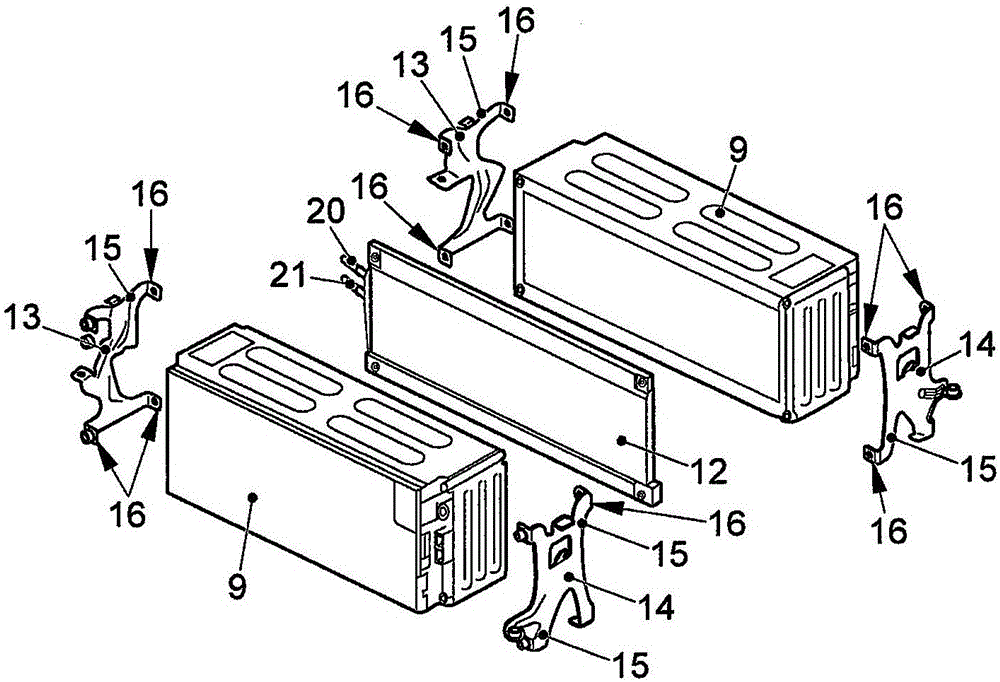

Battery pack assembly and vehicle having same

ActiveCN106410316ASave manufacturing timeSave materialSecondary cellsCell component detailsEngineeringElectrical and Electronics engineering

The invention particularly provides a battery pack assembly (3) having a battery pack housing (4), a battery pack support (5) forming a bottom, and two or more battery modules (9) fastened to the battery pack support (5) and electrically connected. At least one heat exchanger (12) is arranged between two adjacent battery modules (9). The heat exchanger by means of at least one joint short pipe of an inlet section and at least one joint short pipe (20, 21) of a backflow section is fluidly connected or capable of being connected to the inside of the battery case (4) and the dispensing receiving element (24, 25) of the fluid circulating fluid line, wherein the joint short pipe (20, 21) together with the receiving element (24, 25) can construct a quick connector which can be released.

Owner:VOLKSWAGEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com