Machining method for large high-strength stamping part with inner hole

A processing method and high-strength technology, which is applied in the processing of large-scale high-strength steel plate stamping and forming parts, and the processing of large-scale high-strength stamping parts. Problems, to achieve the effect of saving mold making time and mold testing and modification time, which is beneficial to the improvement of leveling efficiency and saving mold making costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

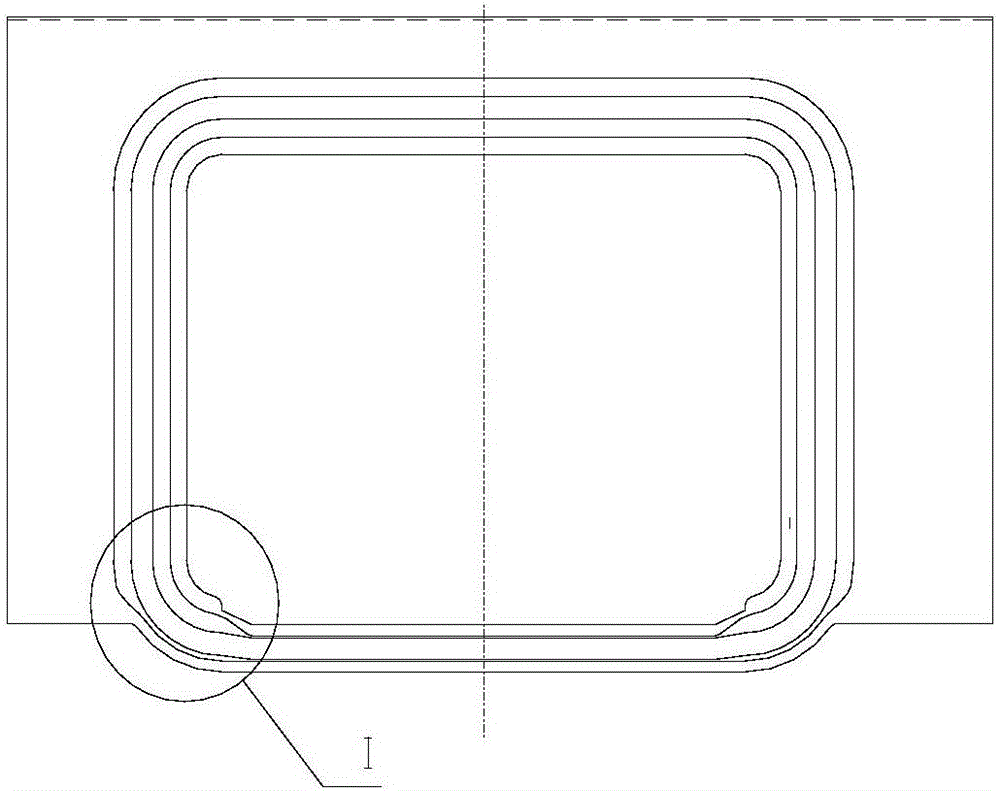

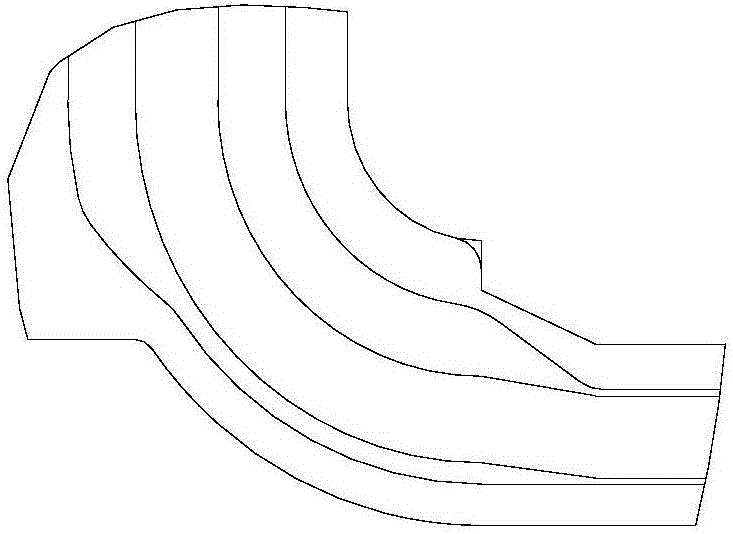

[0041] As shown in Figure 1, according to the material properties, plate thickness, part shape, size and related technical requirements of large high-strength stamping parts with inner holes, proceed in sequence: lofting and unfolding, determining the size of the blank, cutting the blank, stamping, cutting Internal hole, cut outer straight edge, cut outer curved edge, leveling.

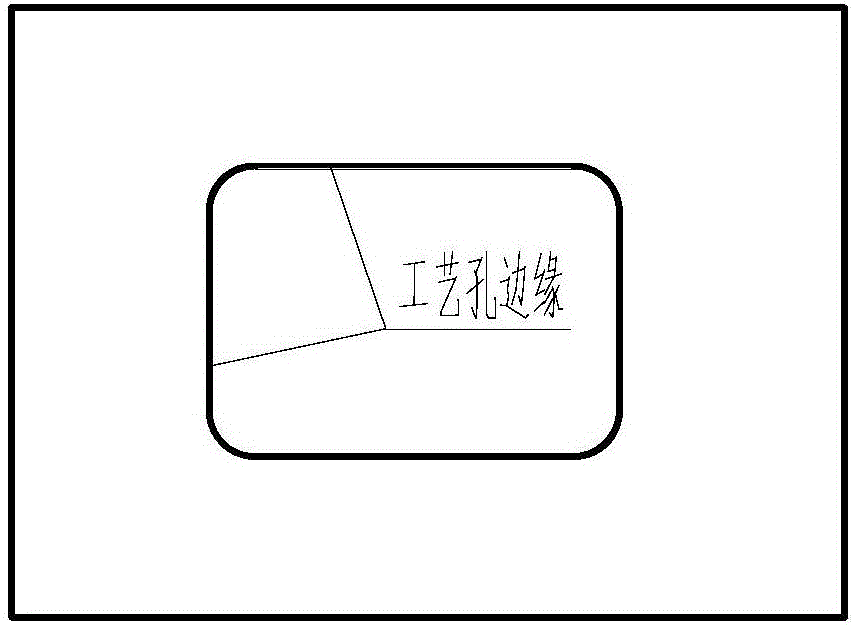

[0042] When determining the size of the blank, it is necessary to reserve a certain amount of profiling allowance according to the expanded size. In order to ensure that the raw material has good fluidity during stamping, an appropriate process hole should be reserved for the blank. In order to ensure that there is no or less cracking of the raw materials at the corners of the convex ribs during pressing, the pressing rough parts need to be cut with equipment with high processing section quality; when making stamping dies, it is necessary to reserve a certain amount of anti-deformation , to offset pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com