Inkjet printing OLED display panel and preparation method thereof

An inkjet printing and display panel technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as the degradation of thin-film transistor devices, achieve the suppression of threshold voltage drift, save photomasks, and save preparation time and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention provides a kind of preparation method of the OLED display panel of inkjet printing, and this preparation method comprises the following steps:

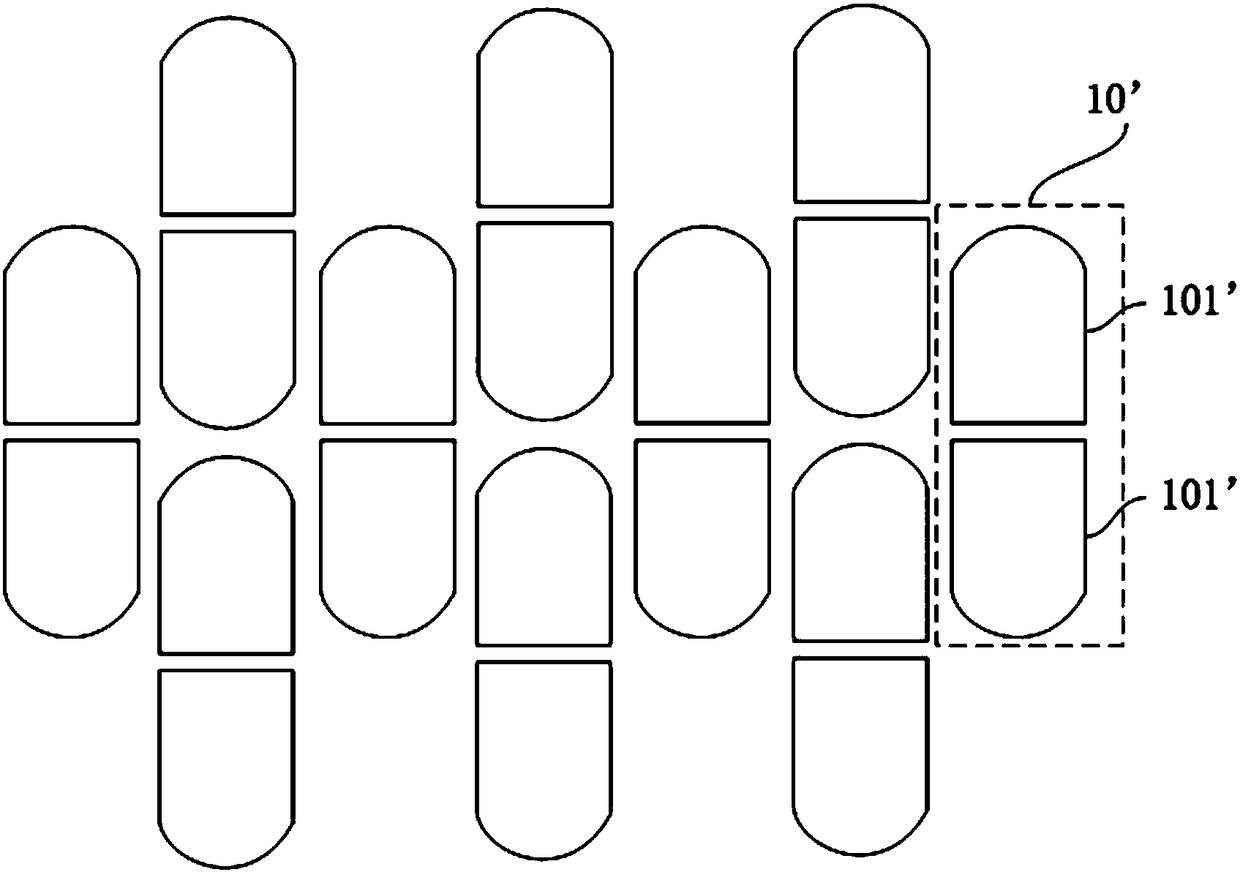

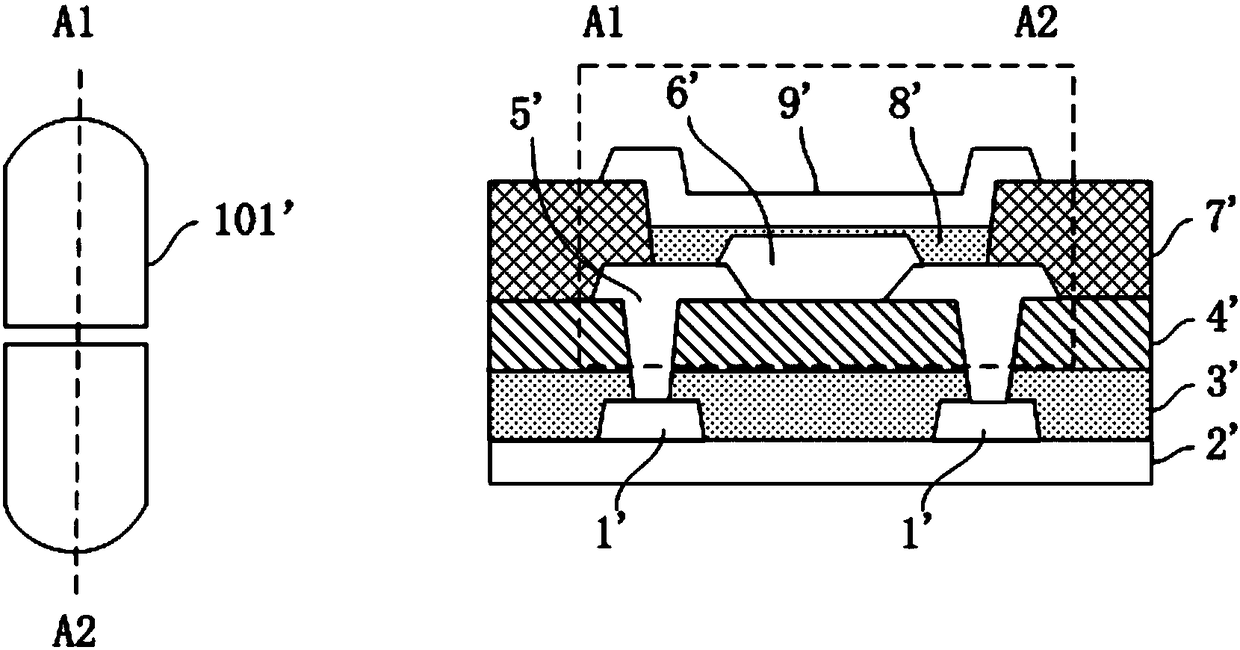

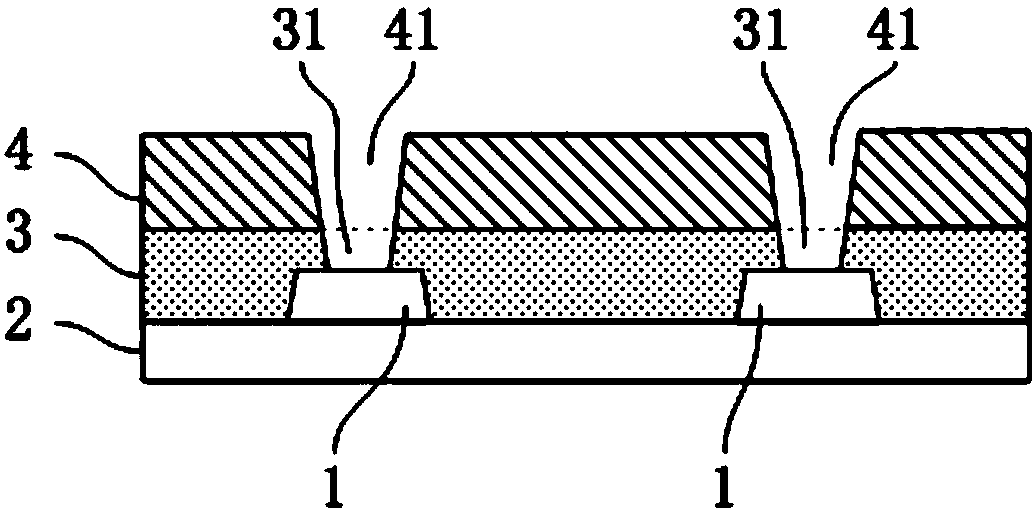

[0041] Such as image 3 As shown, at least one pair of thin film transistors 1 are prepared on a glass substrate 2;

[0042] Depositing a passivation layer 3 on the glass substrate 2, the passivation layer 3 covers at least one pair of thin film transistors 1;

[0043] depositing a planarization layer 4 on the passivation layer 3;

[0044] At least one pair of via holes are formed on the passivation layer 3 and the planar layer 4, and the via holes 31 on the passivation layer 3 are opposite to the via holes 41 on the planar layer 4 and the via holes 31 on the passivation layer 3 are opposite to the via holes 41 on the planar layer 4. The via holes 41 on the planar layer 4 are located above at least one pair of thin film transistors 1;

[0045] Such as Figure 4 As shown, at least one pair of anodes 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com